Abstract

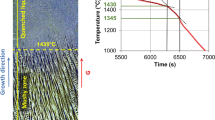

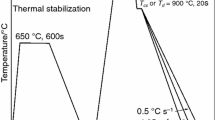

Sigma phase precipitation occurring during the exposure of duplex stainless steels in the temperature range from 800 to 900 °C deeply affects the material toughness and corrosion resistance. σ-Phase precipitation process is strongly influenced by many physical parameters, such as the specific chemical composition, the ferrite amount and its average grain size, and the entity of plastic deformation due to the previous technological process. The strong dependencies of σ-phase precipitation on all these factors justify the continuous study of the process kinetics. This paper focuses on the σ-phase precipitation kinetics in F55 steel grade. The investigation has been performed by an innovative experimental method, such as the anisothermal dilatometric technique. The application of the Kissinger’s method has been used for deriving the process activation energy and kinetics. The results have been compared with the ones obtained by metallographic analysis and hardness tests performed on isothermally aged samples, heat-treated in a laboratory furnace at 850 °C.

Similar content being viewed by others

References

Nilsson JO. Overview: super duplex stainless steels. Mater Sci Eng. 1992;8:685–700.

Topolska S, Labanowsky J. Effect of microstructure on impact toughness of duplex and superduplex stainless steels. J Achiev Mater Manuf Eng. 2009;36:142–9.

Dominguez-Aguilar MA, Newman RC. Detection of deleterious phases in duplex stainless steels by weak galvanostatic polarization in alkaline solution. Corros Sci. 2006;48:2560–76.

Berecz T, Fazakas E, Mészáros I, Sajó I. Decomposition kinetics of ferrite in isothermally aged SAF 2507-type duplex stainless steel. J Mater Eng Perform. 2015. https://doi.org/10.1007/s11665-015-1793-6.

Rivolta B, Pinasco MR. Study of the age-hardening in an Au–Cu–Ag dental alloy with Pt and Pd additions with dilatometry, hardness measurements and microstructural analysis. Int J Microstruct Mater Prop. 2009;4:487–506.

Rivolta B, Gerosa R, Pinasco MR, Pellati G. Dilatometric analysis for investigating age hardening in a commercial precious metal dental alloy. J ASTM Int. 2009;6:1–12.

Gerosa R, Rivolta B, Derudi U. Dilatometric analysis to study aging of aluminum alloys. In: Canale LF, Narazaki M, editors. Quenching and cooling, residual stress and distortion control. ASTM Edition. p. 1055–65. ISBN: 978-0-8031-7509-9.

Gerosa R, Rivolta B, Sala A. Optimization of the heat treatment of a 17-4 PH stainless steel by dilatometric technique. In: Canale LF, Narazaki M, editors. Quenching and Cooling, Residual Stress and Distortion Control. ASTM Edition. p. 1066–76. ISBN: 978-0-8031-7509-9.

Rivolta B, Gerosa R. On the non-isothermal precipitation of copper-rich phase in 17-4 PH stainless steel using dilatometric techniques. J Therm Anal Calorim. 2010. https://doi.org/10.1007/s10973-010-0882-x.

Smith GW. Precipitation kinetics in an air-cooled aluminium alloy: a comparison of scanning and isothermal calorimetry measurements methods. Termochimica Acta. 1998;313:27–36.

Smith GW. Precipitation kinetics in solutionized aluminium alloy 2124: II. Effect of prior Guinier–Preston zone formation. Termochimica Acta. 1998;323:123–30.

Smith GW. Precipitation kinetics in solutionized aluminium alloy 2124: determination by scanning and isothermal calorimetry. Termochimica Acta. 1998;317:7–23.

Gojić M, Sućeska M, Rajić M. Thermal analysis of low alloy Cr–Mo steel. J Therm Anal Calorim. 2004;75:947–56.

Wielgosz E, Kargul T. Differential scanning calorimetry study of peritectic steel grades. J Therm Anal Calorim. 2015;119:1547–53. https://doi.org/10.1007/s10973-014-4302-5.

Standard specification for forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service, A182/A182M, ASTM International; 2016.

Hardin RA, Beckermann C. Simulations of the effect of section size and cooling on sigma phase formation in duplex stainless steel. In: Proceedings of the 66th SFSA technical and operating conference, Steel Founders’ Society of America; 2012.

Standard practice for microetching metals and alloys, E407, ASTM International; 2007.

Metallic materials—Vickers hardness test, UNI EN ISO 6507, UNI Standard; 2005.

Mittemeijer EJ, Cheng L, van der Schaaf PJ, Brakman CM, Korevaar BM. Analysis of nonisothermal transformation kinetics; tempering of iron-carbon and iron-nitrogen martensites. Met Trans. 1988;19A:925–32. https://doi.org/10.1007/BF02628377.

Magnabosco R. Kinetics of sigma phase formation in a duplex stainless steel. Mater Res. 2009. https://doi.org/10.1590/S1516-14392009000300012.

Blachoswski A, Dubiel SM, Zukrowski J. On the activation energy of the σ-phase formation in a pure and Ti-doped Fe-Cr alloy. Intermetallics. 2001;9:493–8.

Ferro P. A dissolution kinetics model and its application to duplex stainless steels. Acta Mater. 2013;61:3141–7.

Costa BFO, Cieslak J, Dubiel SM. Kinetics of σ-phase formation in equiatomic cold-rolled Fe–V alloys. Mater Chem Phys. 2013;143:19–25.

Bowen W, Leak GM. Diffusion in BCC iron base alloys. Metall Trans. 1970;1:2767–73.

Bowen W, Leak GM. Solute diffusion in alpha- and gamma-iron. Metall Trans. 1970;1:1695–700.

Lee KM, Cho HS, Choi DC. Effect of isothermal treatment of SAF 2205 duplex stainless steel on migration of δ/γ interface boundary and growth of austenite. J Alloys Compd. 1999;285:156–61.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rivolta, B., Gerosa, R. & Tavasci, F. The dilatometric technique for studying sigma phase precipitation kinetics in F55 steel grade. J Therm Anal Calorim 132, 869–877 (2018). https://doi.org/10.1007/s10973-017-6940-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6940-x