Abstract

Studies on the separation of calcium and neodymium ions by using ethylenediaminetetraacetic acid (H4EDTA) as a complexing agent were performed. This research was undertaken due to the possibility of H4EDTA applying to isolate rare earth elements from the solution after acidic leaching of phosphogypsum, and because of the similarity of coordination properties of calcium and lanthanides ions. The experiment was carried out in model systems containing Ca2+ and Nd3+ ions in hydrochloric or sulphuric acid. The content of calcium and neodymium metals, phase composition and thermal behaviour of the obtained products were determined by ICP-OES, FTIR, XRD and TG/DTA techniques. During the separation process, the precipitates of a light pink colour were obtained. The obtained results show that the neodymium ethylenediaminetetraacetate has been successfully formed and that the isolation of neodymium ions was more efficient in chloride medium. The precipitate included 72.2 and 3.9% of the starting amount of neodymium and calcium used in the experiment, respectively. However, in sulphates medium, these amounts were equal to 73.8 and 53.5%, respectively. Moreover, the obtained powder was polluted with sulphates. The addition of the EDTA in an excess (15%) contributed only to an increase in calcium content in the complex.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rare earth elements (RE) constitute a group of great importance for technology. There has been a considerable increase in applications of RE due to their desirable chemical, catalytic, electrical, magnetic and optical properties. These applications widely range from polishing agents [1, 2] through lasers [3, 4] and magnets [5, 6] or batteries [7] to modern technologies such as those of solar panels [8, 9], high–temperature superconductors [10] and plasma display panels [11, 12].

The RE, in contrast to the designation, in fact, are not uncommon—for instance, the cerium content in the Earth’s crust is similar to that of copper and nickel [13]. However, the problem appears with their large dispersion which makes the mining and separation be difficult and inefficient. These elements occur in nature mostly in the form of phosphates and silicates in so-called rare earth minerals (e.g. monazite, rhabdophane, xenotime). Currently, most exploited deposits of the elements are those in China. However, the China export used to be limited to 40% in 2012. This may cause serious problems for technologies outside of China, hence alternative RE sources, are being searched for [14–18]. One of the possible sources can be phosphogypsum which is a by-product (End-of-Life material) in the process of phosphoric acid production from phosphate rocks, phosphorites and apatites, by the wet method. Phosphogypsum contains RE metals in an amount dependent on the origin of rocks used in the process, usually, there is ~ 0.5–1% [19]. The largest content is observed for lanthanum, cerium and neodymium [19–21]. Attempts to obtain RE from the waste materials of phosphate fertilisers production were made in the past [22–25]. Those ways chiefly consist in the leaching of phosphogypsum with an inorganic acid to be followed by precipitation of the RE salts from the obtained solution. Usually rare earth elements are recovered by precipitation as RE oxalates or sodium-RE double sulphates, separated by hydrofluoric acid and then converted into desired commercial rare earth salts. Unfortunately, the precipitates contain not only lanthanides but large amounts of calcium the primary component of phosphogypsum. Due to a similar chemical reactivity and coordination properties of Ca and RE, separation of those elements is difficult.

Therefore, in the present investigations, we described the first step leading to separation of calcium and neodymium ions by using H4EDTA as the strongly chelating agent and the difference in the stability of Ca(II) and Nd(III) with ethylenediaminetetraacetic acid complexes. Citric acid and amino acids similar to EDTA were found to separate some REE but could not separate as many as EDTA [26, 27]. Ethylenediaminetetraacetic acid (EDTA) may be an improvement over the use of other chelating agents. The experiment was performed in model systems which consisted of calcium and neodymium in sulphates or chlorides medium. The task was undertaken in view of the possibility to apply H4EDTA to the selective separation of RE from the solution after leaching process of phosphogypsum as well as for the known similar coordination properties of calcium and neodymium ions. Chemical effect of Nd ions in examined model systems should be typical of whole RE group elements owing to their electron configuration (n–1) d1ns2. The choice of the salts was made for the possibility of using sulphuric(VI) or hydrochloric acids as the phosphogypsum leaching agent. The studied Nd and Ca separation process is considered to be applied in the future for the recycling technology of RE elements from the waste phosphogypsum in Poland.

Materials and methods

Chemical synthesis

The following reagents, commercially available, were used without any additional purification: calcium chloride hexahydrate (analytically pure), ammonium sulphate (analytically pure), ethylenediaminetetraacetic acid (H4EDTA; ≥ 99.0%), neodymium(III) oxide (99 +), sulphuric(VI) acid (96%), hydrochloric acid (35-38%). Dihydrate calcium sulphate(VI) was obtained via reaction of calcium chloride hexahydrate with ammonium sulphate and its purity was confirmed by XRD.

In the first stage of the study, the calcium and neodymium complexes with H4EDTA were obtained by treating the relevant sulphates or chlorides with ethylenediaminetetraacetic acid.

Test S1: CaSO4·2H2O water suspension (pHS1 = 5.7) was mixed with H4EDTA in the molar ratio 1:1 with a small amount of water. Then the mixture was heated and refluxed for 2 h. The precipitate was filtered, washed with distilled water and dried in the air at room temperature.

Test C1 was carried out in a similar way, with a solution of CaCl2·6H2O and at pHC1 = 5.2.

In the S2 and C2 test, neodymium oxide was dissolved in the stoichiometric amount of 1 M H2SO4 (pHS2 = 6.5) and 1 M HCl (pHC2 = 2.5), respectively. Then the H4EDTA acid was added ensuring the molar ratio Nd3+:H4EDTA to amount 1:1. The mixtures were refluxed for 2 h. The precipitates were filtered, washed and dried.

The next stage was an attempt to separate calcium and neodymium ions through chelating of sulphates (test S3) and chlorides (test C3). Neodymium oxide was dissolved in a similar way as in the case of tests S2 and C2. The obtained solutions were treated with the appropriate calcium salt (pHS3 = 6.5; pHC3 = 2.3) and H4EDTA. The molar ratio Nd3+:Ca2+:H4EDTA was 2:1:2 and 1:1:1 in tests S3 and C3, respectively.

Experimental methods

The content of C, H, N, S and Cl was determined by atomic absorption spectrometry (AAS) using the analyser CHNS Vario EL III (Elementar). Ca and Nd analysis was performed by the inductively coupled plasma-optical emission spectrometry (ICP-OES) using the apparatus ARL3410 ICP with argon plasma excitation. Moreover, the obtained products were characterised by Fourier transform infrared (FTIR) spectroscopy, powder X-ray diffraction (XRD), and thermal analysis (TGA/DTA). The FTIR spectra were measured with a Perkin-Elmer System 2000 FTIR spectrophotometer in the medium IR range (4000–400 cm−1) at room temperature. The samples were prepared in the form of KBr pellets. The XRD measurements were performed with a SIEMENS D5000 diffractometer (copper X-ray tube) in the range 2θ of 5–50° with a 0.04° step and at least 2 s per step. The TGA/DTA analyses were carried out using a derivatograph 3427 (MOM, Hungary) in a temperature range of 20–1000°C (heating rate 7.5°C/min, platinum crucible, air atmosphere).

Results and discussion

To obtain RE from the leaching solution, chelating agents can be used. One of the widely applied agents is ethylenediaminetetraacetic acid (H4EDTA). This agent is capable of complexing the ions of most metals; it is applied, in the form of sodium salts, in quantitative chemical analysis owing to a simple stoichiometry of the reaction with metals. The capability of H4EDTA agent to chelate metal ions depends on the pH value of the solution, which affects the protonation of H4EDTA acid as well as the equilibrium of complexes formation. In a neutral or slightly alkaline medium, an HEDTA3− ion will be the prevalent form of the acid. Complexing will proceed according to equation:

The formation reaction of metal complexes with H4EDTA at the pH in the range from 3.5 to 5.5 can be described as:

At lower pH, the H4EDTA occurs in the form of H3EDTA− ions as well as the non-dissociate H4EDTA (with a pH less than 2), which is manifested as metal complexing reactions:

and/or

According to the above reactions, lowering of pH shifts an equilibrium to the left and reduces the stability of the metal–EDTA complexes. The stability of metal–EDTA complexes is characterised by the value of stability constant β which lowers with decreasing of the solution pH. The higher β value of complex then the lower pH of a solution can be for complex creation. The difference in the β values of Ca–EDTA (logβ = 10.65) and Nd–EDTA (logβ = 16.51) complexes can be used for separation of these coordination compounds because the calcium complex is stable at pH above 8 and dissociates in a neutral or acidic medium. In the case of solutions containing Ca and Nd ions, carrying out the complexing in an acidic medium should ensure an efficient separation of these elements. Formation and satisfying stability of the Nd–EDTA complex in an acidic medium are confirmed by the results of Refs. [28, 29].

From the above reasons, it was decided to use the complexing agent in the acid form—H4EDTA which forms with neodymium ions stable and insoluble in water coordination compound. The use of sodium ethylenediaminetetraacetate Na4EDTA is pointless because it forms with both calcium and neodymium stable and water soluble complex. In this case, both ions would be coordinated and the separation will not occur.

In the case of metal complexes with ethylenediaminetetraacetic acid, the most typical band of an IR spectrum is that corresponding to the asymmetric stretching vibration of carboxyl groups ν asCOO. When the carboxyl groups are non-ionised and non-coordinated, this signal appears at 1750–1700 cm−1. As a result of metals coordination, the band is shifted towards low frequencies to the 1650–1590 cm−1 range. In the range from 1630 to 1575 cm−1, bands of free and ionised carboxyl groups occur [30].

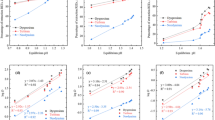

An FTIR spectrum of a precipitate obtained in the C1 test is shown in Fig. 1a. In the figure, a band of stretching vibration at the wave number 1697 cm−1 is visible. This means that the carboxyl groups of H4EDTA were non-coordinated to the metal. In fact, Fig. 1a shows an FTIR spectrum of the free ligand—ethylenediaminetetraacetic acid [31]. The result of the S1 test (Fig. 1b) was similar; any calcium complex with H4EDTA was not obtained. Two absorption bands are observed in the FTIR spectrum in the range 1600–1700 cm−1. One of them, at 1687 cm−1, is originated from the ν asCOO vibration and indicates the presence of non-coordinated protonated carboxyl groups of the ligand. Bending vibration of δO–H in hydration molecules in CaSO4·2H2O combined with sulphate ions via hydrogen bond [32] are responsible for the occurrence of absorption at 1622 cm−1. The presence of sulphate ions is confirmed by a broad band in the range 1225–1030 cm−1 and two bands at 667 and 602 cm−1 originated from the stretching vibration of SO 2−4 ions [30]. The FTIR spectrum showed on Fig. 1b indicates that the S1 attempt did not result in coordinating the metal to a ligand.

Hence, no calcium complexes with H4EDTA were obtained in the course of C1 and S1 tests. The unreacted H4EDTA and CaSO4·2H2O (in test C2) are present in the obtained precipitates. Calcium chloride used in the C1 test as a water soluble compound remains in the solution and is not observed in the FTIR spectrum. These conclusions were also confirmed by XRD analysis of the C1 precipitate. The XRD pattern showed only H4EDTA to be present in the powder. This is in accordance with the literature data on the conditions for calcium complexes formation with H4EDTA [29].

A different situation is observed for the C2 and S2 tests which aimed at obtaining neodymium complexes with H4EDTA. In both cases, the precipitate was a light pink colour typical of neodymium compounds. Analysis of the 1750–1575 cm−1 range in the FTIR spectra (Fig. 2) leads to the following conclusions. For both cases, an absorption band occurs at the same frequency corresponding to 1670 cm−1. This band does not appear in the case of anhydrous complexes, according to the data of Ref. [33] whose authors have studied different forms of hydrated europium complexes with H4EDTA. Hence, the observed band should be connected with the presence of hydration water and the deformation vibration δO–H. Other absorption bands are those at frequencies of 1598 cm−1 (C2, Fig. 2a) and 1599 cm−1 (S2, Fig. 2b). Their origin can be ascribed to the asymmetric valence vibrations of metal-coordinated carboxyl groups. Because those bands are located at the lower limit of a theoretical range of 1650–1590 cm−1, quite likely is the occurrence of hydrogen bonds in the crystal lattice of the compound and/or ionic character of the metal–ligand bonding rather than a covalent one. The bands overlap the succeeding ones of absorption at 1580 cm−1 (C2) and 1581 cm−1 (S2). The presence of the latter one absorption indicates that one or more carboxyl groups do not form a bond with the metal. Consequently, the free, ionised groups COO− are present in a molecule of the complex. Based on the analysis of the region 1350–1450 cm−1, it can be noted that the products of C2 and S2 experiments were single hydrates because, in the case of the hydrated and anhydrous complexes, respectively, three and two bands were observed in the range under discussion [34]. In view of the high coordination number of neodymium (9 [35] or 10 [36]), it can be assumed that water molecule will coordinate the metal in addition to H4EDTA. However, a further X-ray study on monocrystals is needed to acquire detailed information on the coordination environment of the central ion. The lack of absorption bands in the range 1225–1030 cm−1 for the S2 test indicates the absence of sulphate ions, whereas the 1102 cm−1 band should be ascribed to the valence vibration of the νCN ligand skeleton.

The results described above are satisfactory from the viewpoint of the question how to separate neodymium from calcium ions by using EDTA. Carrying out separation process in the sulphuric or hydrochloric acid medium, one may expect that the complex will be formed by neodymium ions, while calcium ions remain non-coordinated.

Tests C3 and S3 also resulted in a precipitate that was a light pink colour which indicated the presence of Nd3+ compounds. As shown in Fig. 3 FTIR spectra indicate that a neodymium complex with EDTA was formed in both cases. Both precipitates exhibit bands at a frequency of 1600 cm−1 which originate in the νasCOO vibrations of carboxyl groups. In contrast with the S2 product, the S3 product shows contamination with sulphate(VI) ions, which is indicated by a broad band at 1225–1030 cm−1 and two distinct signals at 666 cm−1 and 601 cm−1 connected with bending vibration of sulphate(VI) ions derived from calcium sulphate(VI). The presence of H[Nd(EDTA)]·H2O complex and unreacted EDTA in the C3 and S3 samples as well as of calcium sulphate(VI) in the S3 precipitate, is confirmed by the result of XRD (Fig. 4) and ICP-OES (Table 1) analysis.

The ICP-OES results show that the complex included 72.2% of the neodymium relative to that contained in the substrates used to carry out experiment C3. Moreover, the C3 product contained 3.9% of the starting amount of calcium used in the experiment. For the S3 sample, 73.8% of neodymium was chelated, although the product contained 53.5% of the calcium initial amount. The increased content of C, N, and H in the C3 product could be a result of the presence of unreacted EDTA. The accompanying lower content of neodymium is also meaningful.

The C3 and S3 precipitates were subjected to the thermal analysis by TGA/DTA (Fig. 5a, b). A multistep decomposition of the C3 sample (Fig. 5a) started at 210°C. In contrast to the results of Ref. [37, 38], an endothermic effect appears on the DTA curve at the onset temperature of 210°C. Consequently, complex dehydration process starts at this temperature, which is accompanied by a mass loss of about 10% visible on TG curve. The high dehydration temperature may be explained by coordination of metal ions with a water molecule. A multistage exothermic decomposition of organic residues of the obtained complex and non-chelated EDTA starts at a temperature of approximately 290 °C. The related thermal effects are observed on the DTA curve at onset temperatures of 290, 340 and 400°C, with the summary mass loss about 57%.

Decomposition of the precipitate in the test S3 runs in a similar way (Fig. 5b). Two endothermic effects occur on the DTA curve at onset temperatures of 100 and 190°C, respectively. The accompanying mass loss amounts to about 5%. As it was shown above (Table 1; Fig. 4), the sample S3 was contaminated with CaSO4·2 H2O. Since the two-step dehydration of gypsum to anhydrous CaSO4 proceeds in the 100–200°C temperature range [39], the changes of the DTA curve fragment in question can be attributed to the gypsum dehydration process. It can be assumed that dehydration of the complex acquired in test S3 will proceed at a higher temperature (190°C) due to coordination water molecule to the metal ion. The DTA curve in Fig. 5b shows exothermic effects at onset temperatures of 260, 355 and 480°C, which are ascribed to the decomposition process of an organic ligand. These effects were accompanied by a considerable mass loss of about 45% (see TG curve).

In the case of the C3 and S3 samples, a slight endothermic effect was also observed at onset temperature of about 610°C, which was not accompanied by a clear mass loss. This is just the polymorphic transition temperature for neodymium oxide A-Nd2O3 → C-Nd2O3 [40]. The sample’s mass became stable at a temperature of approximately 650°C.

The products acquired in tests C3 and S3 were heated in air at 800°C for 6 h. The compounds changed their colour into blue during sintering. The XRD analysis of C3 powder (Fig. 6a) showed the presence of neodymium oxide crystallized in the trigonal system (A–Nd2O3) and also revealed the presence of cubic neodymium oxide as well. The sample annealed at 1000°C was a monophase cubic form.

For the S3 product, after heating at 800°C, the following phases were found: anhydrous calcium sulphate(VI) (as an insoluble anhydrite, Anhydrite II), and two modifications of neodymium oxide, trigonal A–Nd2O3 and cubic C-Nd2O3 (Fig. 6b). The presence of anhydrite in the sample after sintering at 800 °C was independently confirmed by the FTIR technique (spectrum not shown). Heating of S3 sample at 1000°C caused the disappearance of reflections typical for cubic neodymium oxide.

In order to gain a higher efficacy of calcium and neodymium ion separation, the C3 experiment was repeated with a small excess (15%) of EDTA. As a result, the neodymium chelating efficiency somewhat increased (from 72.2 to 73.7%), which was not accompanied by a noticeable enhancement in separation of neodymium and calcium ions. The ICP-OES analysis showed the lowering of neodymium content in the sample to 25.15% and also a nearly twofold increase of calcium concentration (0.74%). Thereby the final product contained 7.8% of the original calcium amount.

Conclusions

The results of this study indicate that the separation of neodymium and calcium ions from the hydrochloric acid solution in the presence of complexing agent like ethylenediaminetetraacetic acid, i.e.: EDTA is possible, even with a good efficiency. A small amount of contamination in the form of non-coordinated EDTA is of no importance from the viewpoint of the issue of lanthanides recovery from phosphogypsum. In order to receive rare earth metals in the desired form of oxides, the complex Me–EDTA should be treated with high temperatures (> 800°C), at which its organic component will undergo a complete decomposition into gaseous products. The use of an excess of complexing agent contributes to deterioration of selectivity of the separation process and, consequently, makes the calcium concentration be increased in the final product. The further research on effect of the other ions present in the actual leach solution during the separation of metals ions from such system is needed.

References

Lebedeva MI, Dzidziguri EL, Sidorova EN. Study of dispersion characteristics of polishing nanopowder based on fluorinated solid solution of rare earth metals. Nanotechnol Russia. 2012;7:262–7.

Tsai MS. Powder synthesis of nano grade cerium oxide via homogenous precipitation and its polishing performance. Mater Sci Eng B. 2004;110:132–4.

Sheetal, Taxak VB, Mandeep, Khatkar SP. Synthesis, characterization and luminescent properties of Eu/Tb-doped LaSrAl3O7 nanophosphors. J Alloy Compd. 2013;549:135–40.

Liu W, Zhang D, Li J, Pan Y, Bo Y, Li C, Wang B, Peng Q, Cui D, Xu Z. High power single wavelength ceramic Nd:YAG laser at 1116 nm. Opt Laser Technol. 2013;46:139–41.

Coey JMD. Permanent magnet applications. J Magn Magn Mater. 2002;248:441–56.

Goll D, Kronmüller H. High-performance permanent magnets. Naturwissenschaften. 2000;87:423–38.

Yao J, Wei S, Zhang P, Shen C, Aguey-Zinsou KF, Wang L. Synthesis and properties of Li3V2−xCex(PO4)3/C cathode materials for Li-ion batteries. J Alloy Compd. 2012;532:49–54.

Chen D, Wang Y, Hong M. Lanthanide nanomaterials with photon management characteristics for photovoltaic application. Nano Energy. 2012;1:73–90.

De Wild J, Meijerink A, Rath JK, Van Sark WGJHM, Schropp REI. Upconverter solar cells: materials and applications. Energy Environ Sci. 2011;4:4835–48.

Ivanovskii AL. New high-temperature superconductors based on rare-earth and transition metal oxyarsenides and related phases: synthesis, properties and simulations. Phys-Usp. 2008;51:1229–60.

Song WS, Kim YS, Yang H. Hydrothermal synthesis of self-emitting Y(V, P)O4 nanophosphors for fabrication of transparent blue-emitting display device. J Lumin. 2012;132:1278–84.

Choi S, Park BY, Seo JH, Yun YJ, Jung HK. Plasma-driven transparent display panel using (Y, Gd)BO3:Eu3 + nanophosphors prepared by solvothermal reaction. ECS Trans. 2012;45:207–11.

Haxel GB, Hedrick JB, Orris GJ. Rare earth elements—critical resources for high technology. USGS Fact Sheet 087-02. 2002. http://pubs.usgs.gov/fs/2002/fs087-02/. Accessed 23 Apr 2015.

Johnson BE, Santschi PH, Chuang CY, Otosaka S, Addleman RS, Douglas M, Rutledge RD, Chouyyok W, Davidson JD, Fryxell GE, Schwantes JM. Collection of lanthanides and actinides from natural waters with conventional and nanoporous sorbents. Environ Sci Technol. 2012;46:11251–8.

Aly MM, Mohammed NA. Recovery of lanthanides from Abu Tartur phosphate rock, Egypt. Hydrometallurgy. 1999;52:199–206.

Moldoveanu GA, Papangelakis VG. Recovery of rare earth elements adsorbed on clay minerals: II. Leaching with ammonium sulphate. Hydrometallurgy. 2013;131:158–66.

Seredin VV, Dai S. Coal deposits as potential alternative sources for lanthanides yttrium. Int J Coal Geol. 2012;94:67–93.

Binnemans K, Jones PT, Blanpain B, Van Gerven T, Yang Y, Walton A, Buchert M. Recycling of rare earths: a critical review. J Clean Prod. 2013;51:1–22.

Arocena JM, Rutherford PM, Dudas MJ. Heterogeneous distribution of trace elements and fluorine in phosphogypsum by-product. Sci Total Environ. 1995;162:149–60.

Szczygieł I, Jagoda Z. Phosphogypsum. The possibilities of the use. Przem Chem. 2013;92:970–4.

de Oliveira SMB, da Silva PSC, Mazzilli BP, Favaro DIT, Saueia CH. Rare earth elements as tracers of sediment contamination by phosphogypsum in the Santos estuary, southern Brazil. Appl Geochem. 2007;22:837–50.

Wang L, Long Z, Huang X, Yu Y, Cui D, Zhang G. Recovery of rare earths from wet-process phosphoric acid. Hydrometallurgy. 2010;101:41–7.

Jarosiński A, Kowalczyk J, Mazanek C. Development of the Polish wasteless technology of apatite phosphogypsum utilization with recovery of rare earths. J Alloy Compd. 1993;200:147–50.

Preston JS, Cole PM, Craig WM, Feather AM. The recovery of rare earth oxides from a phosphoric acid by-product. Part 1: leaching of rare earth values and recovery of a mixed rare earth oxide by solvent extraction. Hydrometallurgy. 1996;41:1–19.

Ibrahim TM, El-Husaini OM. Production of anhydrite-gypsum and recovery of rare earths as a by-product. Hydrometallurgy. 2007;87:11–7.

Powell JE. Separation chemistry. In: Gschneider Jr KA, Eyring L, editors. Handbook on the physics and chemistry of the rare earths. Amsterdam: North-Holland; 1979. p. 81–109.

Moore BW, Froisland LJ, Petersen AE. Rapid separation of heavy rare-earth elements. report of investigations 9564, ISSN 1066-5552. United States Department of the Interior; 1995. pp. 1–23.

Bukietyńska K, Mondry A. Spectroscopy and structure of neodymium complexes with EDTA. Inorg Chim Acta. 1985;110:1–5.

Harris DC. Quantitative chemical analysis. 8th ed. New York: W.H. Freeman and Company; 2010.

Nakamoto K. Infrared and Raman spectra of inorganic and coordination compounds part A. Theory and applications in inorganic chemistry. 6th ed. New York: Wiley; 2009.

Langer HG. Infrared spectra of ethylenediaminetetraacetic acid (EDTA). Inorg Chem. 1963;2:1080–2.

Hass M, Sutherland GBBM. The infra-red spectrum and crystal structure of gypsum. Proc R Soc Lond A. 1956;236:427–45.

Mackey JL, Goodney DE, Cast JR. Different hydrated forms of the ethylenediaminetetraacetato complexes of the light rare earths. J Inorg Nucl Chem. 1971;33:3699–706.

Kolat RS, Powell JE. The solid rare earth chelates of ethylenediaminetetraacetic acid. Inorg Chem. 1962;1:485–90.

Shavaleev NM, Scopelliti R, Gumy F, Bunzil JC. Near-infrared luminescence of nine-coordinate neodymium complexes with benzimidazole-substituted 8-hydroxyquinolines. Inorg Chem. 2008;47:9055–68.

Mondry A, Starynowicz P. Ten-coordinate neodymium(III) complexes with triethylenetetraaminehexaacetic acid. Eur J Inorg Chem. 2006;9:1859–67.

Gigante AC, Caires FJ, Gomes DJC, Lima LS, Treu-Filho O, Pivatto M, Ionashiro M. Spectroscopic study and thermal behavior of trivalent lanthanides and yttrium(III) chelates of EDTA using TG-DSC, FTIR, and TG-DSC coupled to FTIR. J Therm Anal Calorim. 2014;115:127–35.

Mercadante A, Ionashiro M, de Oliveira LCS, Ribeiro CA, Moscardini D’Assuncao L. Preparation and thermal decomposition of solid-state lanthanide (III) and yttrium (III) chelates of ethylenediaminetetraacetic acid. Thermochim Acta. 1993;216:267–77.

Paulik F, Paulik J, Arnold M. Thermal decomposition of gypsum. Termochim Acta. 1992;200:195–204.

Fedorov PP, Nazarkin MV, Zakalyukin RM. On polymorphism and morphotropism of rare earth sesquioxides. Crystallogr Rep. 2002;47:281–6.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Jagoda, Z., Pelczarska, A. & Szczygieł, I. Model studies on the separation of Ca2+ and Nd3+ ions using ethylenediaminetetraacetic acid. J Therm Anal Calorim 133, 391–397 (2018). https://doi.org/10.1007/s10973-017-6822-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6822-2