Abstract

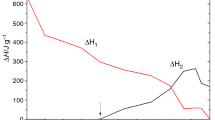

Vinyl ester-unsaturated polyester resin (VER) with adipic acid presented the lowest shrinkage and highest flexural strength among VER with CaCO3, polymer vinyl acetate (PVAc), or adipic acid after curing. The Gibbs free energy change of adipic acid/VER specimen was the highest among pure VER, CaCO3/VER, PVAc/VER, and adipic acid/VER, indicating the lowest polymerization spontaneity of adipic acid/VER. Semiquantitative Fourier transform infrared proved that adipic acid did not consume during the curing process. With the presence of adipic acid, traditional two-step curing process of VER glue changed to a one-step curing process with a slower reaction rate constant via the analysis of the curing kinetics. 1H nuclear magnetic resonance and dynamic differential scanning calorimetry (DSC) show the existence of hydrogen bonding between VER and adipic acid. The network structure formed by hydrogen bonding of VER and adipic acid inhibited the cross-linking between unsaturated polyester and styrene, leading to the decrease of curing degree of adipic acid/VER. Thermogravimetric was applied to demonstrate the thermal decomposition behavior of adipic acid for VER, identifying the inefficient curing of adipic acid/VER characterized by DSC.

Similar content being viewed by others

References

Huang YJ, Liang CM. Volume shrinkage characteristics in the cure of low-shrink unsaturated polyester resins. Polymer. 1996;37:401–12.

Xia C, Lee LJ. Control of shrinkage and final conversion of vinyl ester resins cured in low-temperature molding processes. J Appl Polym Sci. 2003;90:1486–96.

Li W, Lee LJ. Shrinkage control of low-profile unsaturated polyester resins cured at low temperature. Polymer. 1998;39:5677–87.

Li W, Lee LJ. Low temperature cure of unsaturated polyester resins with thermoplastic additives. II. Structure formation and shrinkage control mechanism. Polymer. 2000;41:685–96.

Xu L, Lee LJ. Effect of nanoclay on shrinkage control of low profile unsaturated polyester (UP) resin cured at room temperature. Polymer. 2004;45:7325–34.

Dong JP, Chiu SG, Hsu MW. Effects of reactive low-profile additives on the volume shrinkage and internal pigmentability for low-temperature cure of unsaturated polyester. J Appl Polym Sci. 2006;100:967–79.

Wang K, Wang JH, Zhu YD. The effect of low profile additives on unsaturated polyester resins during curing at low/medium temperature: shrinkage behavior study. Key Eng Mater. 2003;249:351–4.

Zhang Z, Zhu S. Microvoids in unsaturated polyester resins containing poly(vinyl acetate) and composites with calcium carbonate and glass fibers. Polymer. 2000;41:3861–70.

Yan Y, Wang H, Wang XJ. Effect of 2,2-dimethyl malonate on the volume shrinkage control of the CaCO3/unsaturated polyester resin composites. J Appl Polym Sci. 2012;124:4606–11.

Hong CM, Wang XJ, Kong P. Effect of succinic acid on the shrinkage of unsaturated polyester resin. J Appl Polym Sci. 2015;132:651–9.

Hong CM, Wang XJ, Pan ZG. Curing thermodynamics and kinetics of unsaturated polyester resin with different chain length of saturated aliphatic binary carboxylic acid. J Therm Anal Calorim. 2015;122:1–10.

Yf Xue, Patel A, Sant V. Semiquantitative FTIR analysis of the crosslinking density of poly(ester amide)-based thermoset elastomers. Macromol Mater Eng. 2015;301:296–305.

Esmizadeh E, Naderi G, Yousefi AA. Investigation of curing kinetics of epoxy resin/novel nanoclay–carbon nanotube hybrids by non-isothermal differential scanning calorimetry. J Therm Anal Calorim. 2016;126:771–84.

Mustata F, Tudorachi N. Thermal behavior of epoxy resin cured with aromatic dicarboxylic acids. J Therm Anal Calorim. 2016;125:97–110.

Lu C, Yan X, Zou L. Effect of CaCO3 fillers on volume shrinkage of unsaturated polyester and their mechanism. Acta Mater Compos Sin. 2008;25:33–8.

Schubel PJ, Johnson MS, Warrior NA. Characterisation of thermoset laminates for cosmetic automotive applications: part III—shrinkage control via nanoscale reinforcement. Compos A. 2006;37:1757–72.

Li W, Lee LJ. Shrinkage control of low-profile unsaturated polyester resins cured at low temperature. Polymer. 1998;39:5677–87.

Hayaty M, Beheshty MH. Shrinkage, cure characterization and processing of unsaturated polyester resin containing PVAc low-profile additive. Iran Polym J. 2004;13:389–96.

Pan ZR. Polymer chemistry. 5th ed. Beijing: Chemical Industry Press; 2011.

Avella M, Martuscelli E, Mazzola M. Kinetic study of the cure reaction of unsaturated polyester resins. J Therm Anal Calorim. 1985;30:1359–66.

Pucić I, Ranogajec F. Phase separation during radiation crosslinking of unsaturated polyester resin. Radiat Phys Chem. 2003;67:415–9.

Scott TF, Cook WD, Forsythe JS. Kinetics and network structure of thermally cured vinyl ester resins. Eur Polym J. 2002;38:705–16.

Jost N, Karger KJ. On the curing of a vinylester–urethane hybrid resin. Polymer. 2002;43:1383–9.

Ochiai B, Tomita I, Endo T. Thermal crosslinking of acetylene-containing polymers obtained by radical polymerization of aromatic enynes. Polymer. 2001;42:8581–6.

Zhang GZ, Zheng HC, Xiang X. Thermal decomposition and kinetics studies on the 2,2-dinitropropyl acrylate–styrene copolymer and 2,2-dinitropropyl acrylate–vinyl acetate copolymer. J Therm Anal Calorim. 2013;111:1039–44.

Cheng J, Li J, Yang W. Curing behavior and thermal properties of trifunctional epoxy resin cured by 4,4′-diaminodiphenylmethane. J Appl Polym Sci. 2009;114:1976–83.

Xiong X, Chen P, Zhang J. Cure kinetics and thermal properties of novel bismaleimide containing phthalide cardo structure. Thermochim Acta. 2011;514:44–50.

Sun LF, Negulescu II, Pang SS. Characterization of epoxy prepreg curing process. J Adhes. 2006;82:161–79.

Acknowledgements

The authors would like to thank Jinling Aliancys Resins Co. Ltd., for supplying materials, the foundation of the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD 2011-6), and the Open Experimental Foundation of Nanjing Tech University (2017DC086).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sheng, H., Wang, X., Pan, Z. et al. Thermodynamics and kinetics of one-step curing process for vinyl ester-unsaturated polyester resin in low shrinkage. J Therm Anal Calorim 130, 823–833 (2017). https://doi.org/10.1007/s10973-017-6403-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6403-4