Abstract

A new dichromium(III) cobalt(II) diphosphate(V) of the formula CoCr2(P2O7)2 was detected in the Co3Cr4(PO4)6–Cr(PO3)3 system. The new compound was obtained as a result of high-temperature solid-state reactions between CoCO3, Cr2O3 and (NH4)2HPO4 as well as between Cr(PO3)3 and Co3Cr4(PO4)6. CoCr2(P2O7)2 was characterized using XRD, DTA and IR methods. Results demonstrated that CoCr2(P2O7)2 crystallizes in the triclinic system and its unit cell parameters were calculated. Its infrared spectrum was presented. CoCr2(P2O7)2 melts incongruently at 1270±10 °C with a formation of solid α-CrPO4. The compound Co3Cr4(PO4)6, component of the system under study, was obtained for the first time as a pure phase. Its thermal stability was also investigated. Co3Cr4(PO4)6 is stable in air up to 1410 ± 20 °C.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The phosphates(V) of di- and trivalent metals are the objects of extensive studies as they have many possibilities of application. Some of such phosphates exhibit anticorrosion properties [1], and the other can be used as ceramic pigments [2, 3], as an anode material for lithium-ion batteries [4] or as efficient catalysts [5, 6]. Research work aimed at synthesis and characterization of new phosphates(V) is very important for designing of new materials which can be applied in different areas of contemporary technology. Such new phosphates can be formed inter alia in the ternary oxide system CoO–P2O5–Cr2O3. Cobalt(II) phosphates(V) and chromium(III) phosphates(V), forming in the lateral systems of the mentioned ternary oxide system, are known and widely investigated [1, 2, 4–9], but only one article [10] was found referring to a phase, which is formed with an involvement of all three oxides, i.e. Co3Cr4(PO4)6. The compound was synthesized by heating the mixture of Co3O4, Cr2O3 and NH4H2PO4 at a molar ratio 1:2:6 up to 1000 °C for 300 h [10]. The authors [10], however, could not obtain Co3Cr4(PO4)6 as a pure phase. However, they assumed that this compound is isostructural with the compounds from the family M3 2+M4 3+(PO4)6, and on this basis, the structure of Co3Cr4(PO4)6 was solved [10]. The compound crystallizes in the triclinic system, and its unit cell parameters are the following: a = 7.8561 Å, b = 9.2350 Å, c = 6.2785 Å, α = 108.173°, β = 101.808°, γ = 105.329° [10]. To the best of our knowledge, there is no literature information on thermal stability of Co3Cr4(PO4)6.

Therefore, it follows from literature survey that, till now, there were no systematic investigations on phase formation in the CoO–P2O5–Cr2O3 system. The main aim of the presented work was to check whether in one of the cross sections of the CoO–P2O5–Cr2O3 system, i.e. in the system Co3Cr4(PO4)6–Cr(PO3)3, any new phosphate(V) is formed and if so—the second point of the study was to determine some of its physicochemical properties. Additionally, necessary investigations, verifying and supplementing literature data relating to Co3Cr4(PO4)6, were conducted.

Experimental

As the initial reagents were used: Cr2O3 (p.a., Aldrich, Germany), CoCO3 (p.a., Fluka, Switzerland), (NH4)2HPO4 (p.a., POCh, Poland).

Reactions were conducted by the conventional method of calcining samples [9–14]. Appropriate portions of reacting substances were homogenized by grinding, pressed into pellets and heated in air atmosphere in several stages, until an equilibrium state was attained. The first heating stage (at 350 °C) of samples containing in initial mixtures precursors of CoO and P2O5 was applied mainly to remove NH3, H2O and CO2, so they were pressed into pellets only from the second heating stage. Next, the heating temperature was gradually increased, because it follows from our earlier studies that heating immediately at higher temperatures leads to obtaining the samples in glass form. After each heating stage, samples were gradually cooled down in the furnace to room temperature and next the pellets were ground and examined by XRD method or by DTA, too. Generally, to avoid the melting of the samples the maximum temperature of their heating was several dozen of °C lower than their melting temperatures, which were read from their DTA curves.

The XRD method was used to determine the type of the phases occurring in particular samples [13, 14]. The powder diffraction patterns of samples were recorded with the aid of the Empyrean II diffractometer (PANalytical, Netherlands) using CuKα radiation with graphite monochromator. The identification of phases, present in the samples, was conducted based on their XRD characteristics contained in the PDF cards. The powder diffraction pattern of the new compound was indexed by means of the POWDER programme [15]. The internal standard was α-Al2O3. The parameters of the unit cell were refined by the refinement programme of DHN/PDS package.

Thermal stability of some obtained samples was investigated using the F.Paulik–J.Paulik–L.Erdey-type derivatograph Q – 1500 D (MOM, Hungary), in the temperature range 20–1400 °C, at a heating rate of 7.5 °C min−1 and sample mass 500 mg. The investigations were conducted also in temperature range 20–1500 °C using an optical pyrometer (Raytek, model RAYMM1MHSF2V, Germany).

The density of the new compound was determined with the help of an Ultrapyc 1200e ultrapycnometer (Quantachrome Instruments, USA) using argon (5 N purity) as a pycnometric gas. The measurements were taken in five repetitions using ~2 g of each sample for the test.

The IR spectroscopic measurement (the Specord M 80 spectrometer, Carl Zeiss, Germany) was conducted applying the technique of pressing pastilles of the sample with KBr [13, 16, 17] at the ratio 1:300 by weight.

Results and discussion

Synthesis and thermal stability of Co3Cr4(PO4)6

Preliminary stage of the study was devoted to verification and supplementation of the information needed for realization of the main aim of the work and concerning one of the components of Co3Cr4(PO4)6–Cr(PO3)3 system, i.e. Co3Cr4(PO4)6.

The authors [10] have synthesized a compound of the composition corresponding to the formula Co3Cr4(PO4)6. Despite the prolonged heating time of the reactants mixture (300 h) in the temperature range of 800–1000 °C, they have not obtained a monophase sample. Therefore, the aim of the first stage of the study was to obtain pure Co3Cr4(PO4)6 compound and to determine its thermal stability in air atmosphere. The stoichiometric mixture of CoCO3, Cr2O3 and (NH4)2HPO4 was heated in the following stages: 350 °C(12 h) + 500 °C(12 h) + 650 °C(12 h) + 700 °C(12 h) + 950 °C(12 h) + 1050 °C(12 h) × 2 + 1100 °C(12 h) × 2 + 1200 °C(12 h). XRD phase analysis of the sample obtained after its last heating stage has proved that it is monophase, because its diffractogram contains only a set of lines characteristic for Co3Cr4(PO4)6 (PDF 49-0499). These results testify that shorter heating stages, but at higher temperatures (in comparison with those given in the literature [10]) allowed to obtain pure Co3Cr4(PO4)6 compound, according to the complete stoichiometric reaction:

As thermal stability of Co3Cr4(PO4)6 has not been known, it was subjected to DTA measurements in air in the temperature range 20–1400 °C. In this range on DTA curve, no thermal effects were recorded. This result means that Co3Cr4(PO4)6 undergoes decomposition or melting at temperature higher than 1400 °C. In order to assess its thermal stability, the sample containing Co3Cr4(PO4)6 was heated in air in a horizontal tube furnace equipped with an optical pyrometer. Based on the result of the study, it was found that the resulting compound is stable in air up to 1410 ± 20 °C.

It is known from the literature that the second compound, constituting the system under study, i.e. Cr(PO3)3, decomposes to Cr2P4O13 and P2O5 at 1325 °C [9].

Reactions in the Co3Cr4(PO4)6 –Cr(PO3)3 system

In order to determine the kind of phases forming in the system Co3Cr4(PO4)6 –Cr(PO3)3 11 mixtures of CoCO3, Cr2O3 and (NH4)2HPO4 were prepared. The composition of initial mixtures, in terms of the components of the system Co3Cr4(PO4)6 –Cr(PO3)3 as well as of the system CoO–P2O5 –Cr2O3, is given in Table 1. All the samples were heated in the following stages: 350 °C(12 h) + 500 °C(12 h) + 650 °C(12 h) + 700 °C(12 h) + 950 °C(12 h) + 1050 °C(12 h) × 2, while samples 5–11 were additionally heated at 1100 °C (12 h) twice. Table 1 presents XRD analysis results for the samples after their last heating stage. In the diffractograms of all the investigated samples, a set of unidentified lines denoted by X was detected. However, only as a result of heating a mixture initially containing 33.33 mol% Co3Cr4(PO4)6 and 66.67 mol% Cr(PO3)3 [in terms of the components of the system Co3Cr4(PO4)6 –Cr(PO3)3] a monophase sample was obtained whose diffractogram consisted only of a set of unidentified lines X. These lines were not assigned to any initial reactants as well as to any previously known phases that belong to the lateral binary systems constituting the ternary oxide system CoO–P2O5–Cr2O3. It has been concluded that the recorded set of lines X is an XRD characteristic of a new compound of the formula CoCr2(P2O7)2 that is formed according to the complete stoichiometric reaction:

In the component concentration range up to 33.33 mol% of Co3Cr4(PO4)6 (in terms of the components of the Co3Cr4(PO4)6 –Cr(PO3)3 system), in the cross section under study, Cr(PO3)3 also occurs. In the remaining component concentration range, i.e. above 33.33 mol% of Co3Cr4(PO4)6, apart from CoCr2(P2O7)2, Co3Cr4(PO4)6 is formed.

The new compound has been also obtained by reaction occurring by heating the stoichiometric mixture of Cr(PO3)3 and Co3Cr4(PO4)6 in the following stages: 700 °C(12 h) + 950 °C(12 h) + 1050 °C(12 h) ×2 + 1100 °C(12 h) ×2:

In the next stage of the study, two mixtures (Table 1, samples 12 and 13) were prepared with their compositions being very close to that which corresponds to the formula CoCr2(P2O7)2 but not representing the system under study (Fig. 1). Heating conditions for sample 13 were the same as for samples 1–4, while sample 12 was additionally heated at 1100 °C (12 h) twice (as samples 5–11). After the last heating stage, besides of CoCr2(P2O7)2, the other compounds were also identified in sample 12 and 13 (Table 1). The obtained results additionally prove that the composition of the new phase corresponds to the formula CoCr2(P2O7)2.

Figure 1 shows the positions of: the Co3Cr4(PO4)6 –Cr(PO3)3 cross section studied, samples 12 and 13 as well as the new obtained compound in the component concentration triangle of the ternary oxide system.

Some properties of the new compound CoCr2(P2O7)2

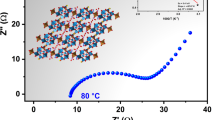

In a further part of the work, some physicochemical properties of the new compound were investigated. CoCr2(P2O7)2 has a patina colour; its density amounts to d obs = 3.63(5) g cm−3. Figure 2 shows a powder diffraction pattern of the new compound, whereas Table 2 presents the results of its indexing. CoCr2(P2O7)2 crystallizes in the triclinic system. The parameters of its primitive unit cell are as follows: a = 6.684(3) Å, b = 10.295(5) Å, c = 20.136(9) Å, α = 121.41(8)°, β = 94.25(4)°, γ = 86.04(4)°. The unit cell volume V = 1178.5 Å3; the number of stoichiometric formula units in the unit cell Z = 5; the XRD calculated density d calc = 3.60 g cm−3.

It is known from the literature that there exist compounds of the formulae CuFe2(P2O7)2 [18] and CuIn2(P2O7)2 [19], i.e. with a composition analogous to the composition of the obtained new compound. However, some considerable differences between the powder diffraction patterns of CoCr2(P2O7)2 and CuM2(P2O7)2 (M = Fe, In) indicate that these compounds are not isostructural.

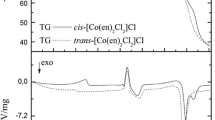

In the DTA curve of CoCr2(P2O7)2, two endothermic effects were recorded (Fig. 3), with onset temperatures 1270 and 1350 °C, respectively. In order to determine the type of the transformation that the first effect is due to, a sample of CoCr2(P2O7)2 was heated for 2 h at 1285 °C, i.e. at the temperature of the maximum of this effect, and next it was rapidly cooled to room temperature and subjected to XRD analysis. The obtained results indicate that the first endothermic effect is due to incongruent melting of CoCr2(P2O7)2 with a formation of solid α-CrPO4.

The IR spectrum of CoCr2(P2O7)2 is shown in Fig. 4. Univocal attribution of the recorded absorption bands to the specific vibrations is not possible, because the full structure of the new compound is unknown. However, probable attribution can be made in the light of literature data [20–25]. IR spectrum of CoCr2(P2O7)2 is complex, but in general, four characteristic groups of bands are observed in the range 1500–300 cm−1. The broadening character observed in the region 1270–1190 cm−1 corresponds to asymmetric stretching vibration of O–P–O groups, while the next broad band in the region 1120–1000 cm−1 is related to the symmetric stretching vibration of those linkages, e.g. O–P–O [20–22]. The absorption bands at 970, 945, 925 are assigned to the asymmetric stretching vibration of P–O–P linkages, while the relatively weak band around 725 cm−1 is due to the symmetric stretching vibration of those linkages: P–O–P [20–23]. A weak band registered at 745 cm−1 occurring in the IR spectrum of CoCr2(P2O7)2 is probably due to symmetric stretching vibration of the P–O bonds with an internal oxygen atom [23, 24]. The shoulder at about 625 cm−1 can be assigned to asymmetric bending vibrations of the O–P–O groups [20, 21] and to stretching vibrations of the Cr–O bonds [20, 23, 25]. The absorption bands at 570, 540, 510 and 460 cm−1 may be assigned either to the harmonics of P–O–P bending vibration or to the characteristic frequency of the P2O7 2− group [21, 22, 25]. Stretching vibration of Co–O bonds appears in the spectra below 400 cm−1 [22, 25].

Studies on the other properties of the new obtained compound CoCr2(P2O7)2, especially from the point of view of its application as ceramic pigment, are in progress.

Conclusions

The results obtained in this study showed that in the ternary oxide system CoO–P2O5–Cr2O3, besides Co3Cr4(PO4)6, a new compound of the stoichiometric formula CoCr2(P2O7)2 is also formed in air atmosphere. The new compound, forming in the cross section Co3Cr4(PO4)6–Cr(PO3)3, was obtained as a result of reaction between CoCO3, Cr2O3 and (NH4)2HPO4, mixed at a molar ratio 1:1:4 as well as in the reaction of mixture of Cr(PO3)3 and Co3Cr4(PO4)6 (2:1). CoCr2(P2O7)2 has a patina colour and crystallizes in the triclinic system with the primitive unit cell parameters: a = 6.684(3) Å, b = 10.295(5) Å, c = 20.136(9) Å, α = 121.41(8)°, β = 94.25(4)°, γ = 86.04(4)°. The volume of such selected unit cell is V = 1178.5 Å3, and the number of stoichiometric formula units in the unit cell Z = 5 and the density, calculated from the unit cell parameters, is 3.60 g cm−3. CoCr2(P2O7)2 melts incongruently at 1270±10 °C with a formation of solid α-CrPO4. Co3Cr4(PO4)6 compound, one of the components of the system studied, was obtained for the first time as a pure phase. It is stable in air up to 1410 ± 20 °C.

References

Jašková V, Kalendová A. Anticorrosive coatings containing modified phosphates. Prog Org Coat. 2012;75:328–34.

Meseguer S, Tena MA, Gargori C, Badenes JA, Llusar M, Monrós G. Structure and colour of cobalt ceramic pigments from phosphates. Ceram Int. 2007;33:843–9.

Llusar M, García A, Gargori C, Galindo R, Badenes JA, Monrós G. Synthesis of dophosphate Mn2−xMgxP2O7 solid solutions woth thortveitite structure: new pink ceramic dyes for the colouration of ceramic glazes. J Eur Ceram Soc. 2012;32:765–76.

Choi C, Seo S-D, Shim H-W, Dar MA, Cho IS, Kim D-W. Facile synthesis and electroactivity of 3-D hierarchically superstructured cobalt orthophosphate for lithium-ion batteries. J Alloy Compd. 2015;652:100–5.

Xu S, Yan X, Bu Q, Xia H. Highly efficient conversion of carbohydrates into 5-hydroxymethylfurfural using the bi-functional CrPO4 catalyst. RSC Adv. 2016;6:8048–52.

Di T, Zhu B, Zhang J, Cheng B, Yu J. Enhanced photocatalytic H2 production on CdS nanorod using cobalt-phosphate as oxidation cocatalyst. Appl Surf Sci. 2016;389:775–82.

Sarver JF. Compound formation and phase-equilibrium relationships in the systems CoO–P2O5 and NiO–P2O5. Trans Br Ceram Soc. 1966;65:191–8.

De Guire MR, Prasanna TRS, Kalonji G, O’Handley RC. Phase equilibria in the iron oxide–cobalt oxide–phosphorus oxide system. J Am Ceram Soc. 1987;70:831–7.

Bosacka M, Jakubus P, Rychłowska-Himmel I. Obtaining of chromium(III) phosphates(V) in the solid-state and their thermal stability. J Therm Anal Calorim. 2007;88:133–7.

Belik AA, Pokholok KV, Malakho AP, Khasanov SS, Lazoryak BI. Synthesis and structure of phosphates M3R4(PO4)6 (M = Cu, Co; R = Fe, Cr, Ga, In) and their interaction with hydrogen. Zh Neorg Khim. 2000;45:1633–48.

Blonska-Tabero A, Bosacka M, Dabrowska G, Filipek E, Piz M, Rychlowska-Himmel I, Tabero P, Tomaszewicz E. The synthesis and properties of the phases obtained by solid-solid reactions. J Min Metall. 2008;44B:19–26.

Tĕšitelová K, Šulcová P. Synthesis and study of Bi2Ce2O7 as inorganic pigment. J Therm Anal Calorim. 2016;125:1047–52.

Bosacka M, Filipek E, Paczesna A. Unknown phase equilibria in the ternary oxide V2O5–CuO–In2O3 system in subsolidus area. J Therm Anal Calorim. 2016;125:1161–70.

Souza MT, Cesconeto FR, Arcaro S, Teixeira AHB, Raupp-Pereira F, Montedo ORK, Novaes de Oliveira AP. Synthesis and characterization of Li2TiSiO5 obtained by melting and solid-state reaction. J Therm Anal Calorim. 2017;127:463–7.

Taupin D. A powder-diagram automatic-indexing routine. J Appl Crystallogr. 1973;6:380–5.

Świderski G, Kalinowska M, Rusinek I, Samsonowicz M, Rzączyńska Z, Lewandowski W. Spectroscopic (IR, Raman) and thermogravimetric studies of 3d-metal cinchomeronates and dinicotinates. J Therm Anal Calorim. 2016;126:1521–32.

Tabero P, Frackowiak A. Synthesis of Fe8V10W16O85 by a solution method. J Therm Anal Calorim. 2016;125:1445–51.

Weimann I, Jahn T, Feller J, Zak Z. Synthesis, crystal structure and characterization of the copper iron phosphate Cu8Fe2O5(PO4)4. Z Anorg Allg Chem. 2014;640:219–23.

Hanzelmann C, Weimann I, Feller J, Žak Z. Synthesis and characterization of the new copper indium phosphate Cu8In8P4O30. Z Anorg Allg Chem. 2014;640:213–8.

Abo-Naf SM, El-Amiry MS, Abdel-Khalek AA. FT-IR and UV-Vis optical absorption spectra of γ-irradiated calcium phosphate glasses doped with Cr2O3, V2O5 and Fe2O3. Opt Mater. 2008;30:900–9.

Lezama L, Rojo JM, Mesa JL, Rojo T. Synthesis and magnetic and electrical properties of the molybdenum and tungsten pyrophosphates MP2O7 (M = Mo, W). J Solid State Chem. 1995;115:146–51.

Etcheverry SB, Baran EJ. Diphosphate as a bidentate ligand. Spectroscopic study of the bis(ethylenediamine)diphosphatocobaltate(III) anion. Z Anorg Allg Chem. 1979;457:197–202.

Fuks H, Kaczmarek SM, Bosacka M. EPR and IR investigations of some chromium(III) phosphate(V) compounds. Rev Adv Mater Sci. 2010;23:14–34.

Tarte P, Rulmont A, Sbai K, Simonot-Grange MH. Vibrational spectrum of KMIIP3O9 tricyclophosphates with the benitoite structure. Spectrochim Acta. 1987;43A:337–43.

Voitenko LV, Zhilyak ID, Kopilevich VA. Double hydrated cobalt(II) copper(II) and nikel(II) copper(II) ammine diphosphates. Zh Prikl Khim. 2005;78:369–72.

Acknowledgements

This work was partly supported by Ministry of Science and Higher Education (Poland) and funded from science resources: UPB-DZS 518-10-020-3101-01/18 (Faculty of Chemical Technology and Engineering, West Pomeranian University of Technology, Szczecin).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bosacka, M., Błońska-Tabero, A., Filipek, E. et al. High-temperature reactions in the Co3Cr4(PO4)6–Cr(PO3)3 system. J Therm Anal Calorim 130, 95–101 (2017). https://doi.org/10.1007/s10973-017-6390-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6390-5