Abstract

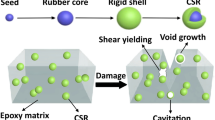

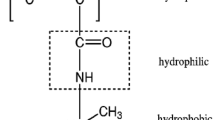

In this work, the effect of a new filler on cross-linking of ethylene–propylene rubber (EPM) was investigated. A filler with a core–shell structure ZnO/SiO2 (precipitated silica modified with zinc oxide) was introduced into rubber compounds. It was proved using of those substance to cross-link EPM caused the formation of labile ionic clusters in elastomer network. These non-covalent cross-links were generated due to interactions occurring between metal ions and functional groups of rubber (namely carboxyl groups) introduced via rubber functionalization with maleic and itaconic acids derivatives. The optimal curing time of rubber compounds was investigated. The cross-link density of the vulcanizates obtained was studied by equilibrium swelling in solvents (e.g., toluene). Additionally, the results confirmed that vulcanizates received using modified silica contained specific cross-links disintegrating under ammonia vapors. Physical relaxation at ambient temperature confirmed the influence of non-covalent cross-links on stress dissipation in the vulcanizate. The static and dynamic mechanical properties of vulcanizates obtained were also determined.

Similar content being viewed by others

References

Brostow W, Datashvili T, Hackenberg KP. Effect of different types of peroxides on properties of vulcanized EPDM + PP blends. Polym Compos. 2010. doi:10.1002/pc.20958.

van Duin M, Orza R, Chechik V. Mechanism of peroxide cross-linking of EPDM rubber. Macromol Symp. 2010. doi:10.1002/masy.201050508.

Głuszewski W, Zagórski ZP, Rajkiewicz M. Radiation physics and chemistry. Rad Phys Chem. 2014. doi:10.1016/j.radphyschem.2013.07.019.

Lenko D, Schlogl S, Temel A, Schaller R, Holzner A, Kern W. Dual crosslinking of carboxylated nitrile butadiene rubber latex employing the thiol-ene photoreaction. J Appl Polym Sci. 2013. doi:10.1002/app.38983.

Manaila E, Stelescu MD, Craciun G, Surdu L. Effects of benzoyl peroxide on some properties of composites based on hemp and natural rubber. Polym Bull. 2014. doi:10.1007/S00289-014-1168-4.

Maciejewska M, Zaborski M, Krzywania-Kaliszewska A. Mineral oxides and layered minerals in combination with itaconic acid as coagents for peroxide crosslinking of hydrogenated acrylonitrile-butadiene elastomer. C R Chimie. 2012;15:414. doi:10.1016/j.crci.2012.01.001.

Vallat MF, Ruch F, David MO. A structural study of EPDM networks—the influence of the crosslinking mode on their microscopic structure. Eur. Polym. J. 2004. doi:10.1016/j.eurpolymj.2004.01.026.

López-Manchado MA, Valentin JL, Carretero J, Barroso F, Arroyo M. Rubber network in elastomer nanocomposites. Eur Polym J. 2007. doi:10.1016/j.eurpolymj.2007.07.023.

Ohbi DS, Purewal TS, Shah T, Siores E. Crosslinking reaction mechanism of diisopropyl xanthogen polysulfide accelerator in bromobutyl elastomer for medical device applications. J Appl Polym Sci. 2008. doi:10.1002/app.27618.

Alam N, Mandal SK, Debnath SC. Bis(N-benzyl piperazino) thiuram disulfide and dibenzothiazyl disulfide as synergistic safe accelerators in the vulcanization of natural rubber. J Appl Polym Sci. 2012. doi:10.1002/app.36874.

Przybyszewska M, Zaborski M, Jakubowski B, Zawadiak J. Zinc chelates as new activators for sulphur vulcanization of acrylonitrile-butadiene elastomer. Express Polym Lett. 2009. doi:10.3144/expresspolymlett.2009.32.

Rybiński P, Janowska G. Effect of the spatial network structure and cross-link density of diene rubbers on their thermal stability and fire hazard. J Therm Anal Calorim. 2014. doi:10.1007/s10973-014-3673-y.

Boochathum P, Prajudtake W. Vulcanization of cis- and trans- polyisoprene and their blends: cure characteristics and crosslink distribution. Eur Polym J. 2001. doi:10.1016/S0014-3057(00)00137-3.

Bhowmick AK, Stephens HL. Handbook of elastomers. New York: Marcel Dekker Inc.; 2001. p. 565–7.

Ibarra L, Alzorriz M. Ionic elastomers based on carboxylated nitrile rubber and magnesium oxide. J Appl Polym Sci. 2007. doi:10.1002/app.25411.

Ibarra L, Rodrigues A, Mora I. Ionic nanocomposites based on XNBR-OMg filled with layered nanoclays. Eur Polym J. 2007. doi:10.1016/j.eurpolymj.2006.12.007.

Ibarra L, Rodrigues A, Mora-Barrantes I. Crosslinking of carboxylated nitrile rubber (XNBR) induced by coordination with anhydrous copper sulfate. Polym Int. 2009. doi:10.1002/pi.2519.

Ibarra L, Rodrigues A, Mora-Barrantes I. Crosslinking of unfilled carboxylated nitrile rubber with different systems: influence on properties. J Appl Polym Sci. 2008. doi:10.1002/app.27893.

Tobolski AV, Lyons PF, Hata N. Ionic clusters in high-strength carboxylic rubbers. Macromolecules. 1968. doi:10.1021/ma60006a012.

Eisenberg A. Clustering of ions in organic polymers. A theoretical approach. Macromolecules. 1970. doi:10.1021/ma60014aoo6.

Mora-Barantes I, Malmierca MA, Valentin JL, Rodriguez A, Ibarra L. Effect of covalent cross-links on the network structure of thermo-reversible ionic elastomers. Soft Matter. 2012. doi:10.1039/c2sm06975j.

de Luca MA, Jacobi MM, Orlandini LF. Synthesis and characterisation of elastomeric composites prepared from epoxidised styrene butadiene rubber, 3-aminopropyltriethoxysilane and tetraethoxysilane. J Sol Gel Sci Technol. 2009. doi:10.1007/s10971-008-1851-8.

Chokanandsombad Y, Sirisinha C. MgO and ZnO as reinforcing fillers in cured polychloroprene rubber. J Appl Polym Sci. 2013. doi:10.1002/app.38579.

Przybyszewska M, Zaborski M. The effect of zinc oxide nanoparticle morphology on activity in crosslinking of carboxylated nitrile elastomer. Express Polym Lett. 2009. doi:10.3144/expresspolymlett.2009.68.

Gaca M, Zaborski M. The properties of elastomers obtained with the use of carboxylated acrylonitrile-butadiene rubber and new crosslinking substances. Polimery. 2016. doi:10.14314/polimery.2016.031.

Tachino H, Hara H, Hirasawa E, Kutsumizu S, Tadano K, Yano S. Dynamic mechanical relaxations of ethylene ionomers. Macromolecules. 1993. doi:10.1021/ma00056a029.

Mandal UK. Ionic elastomer based on carboxylated nitrile rubber: infrared spectral analysis. Polym Int. 2000. doi:10.1002/1097-0126(200012)49:12%3C1653:AID-PI586%3E3.0.CO;2-U.

Ibarra L, Marcos-Fernandez A, Alzorriz M. Mechanistic approach to the curing of carboxylated nitrile rubber (XNBR) by zinc peroxide/zinc oxide. Polymer. 2002. doi:10.1016/S0032-3861(01),00734-0.

Chatterjee K, Naskar K. Development of thermoplastic elastomers based on maleated ethylene propylene rubber (m-EPM) and polypropylene (PP) by dynamic vulcanization. Express Polym. Lett. 2007. doi:10.3144/expresspolymlett.2007.75.

Li Q, Zhao S, Pan Y. Structure, morphology, and properties of HNBR filled with N550, SiO2, ZDMA, and two of three kinds of fillers. J Appl Polym Sci. 2010. doi:10.1002/app.31744.

Wei Z, Lu Y, Yan S, Meng Y, Zhang L. Dramatic Influence of curing temperature on micro-nano structure transform of HNBR filled with zinc dimethacrylate. J Appl Polym Sci. 2012. doi:10.1002/app.34615.

Burlett DJ. Thermal techniques to study complex elastomer/filler systems. J Therm Anan Calorim. 2004. doi:10.1023/B:JTAN.0000027143.59565.5f.

Janowska G, Kucharska A. The influence of the method of butadiene rubbers crosslinking on their thermal properties. J Therm Anan Calor. 2009. doi:10.1007/s10973-008-9395-2.

Likozar B, Kranjc M. Influence of morphology on the dynamic mechanical properties of hydrogenated acrylonitrile butadiene elastomer/coagent nanodispersion. J Appl Polym Sci. 2008. doi:10.1002/app.28525.

Owczarek M, Zaborski M, Paryjczak T, Boiteux G, Gain O. New type of inorganic filler with a core-shell structure. Macromol Symp. 2003. doi:10.1002/masy200390098.

Owczarek M, Zaborski M. Chlorosulfonated polyethylene elastomers containing zinc oxide incorporated on SiO2. Kautsch Gummi Kunstst. 2004;57:218.

Owczarek M, Zaborski M. Chlorosulfonated polyethylene cross-linked with aminosilanes. Kautsch Gummi Kunstst. 2005;58:432.

Chen Y, Xu C. Crosslink network evolution of nature rubber/zinc dimethacrylate composite during peroxide vulcanization. Polym Compos. 2011. doi:10.1002/pc.21179.

Chen Y, Xu C. Stress-strain behaviors and crosslinked networks studies of natural rubber-zinc dimethacrylate composites. J Macromol Sci Part B. 2012. doi:10.1080/00222348.2011.629904.

Xu C, Chen Y, Zeng X. A study on the crosslink network evolution of magnesium dimethacrylate/natural rubber composite. J Appl Polym Sci. 2012. doi:10.1002/app.36346.

Henning S.K. The use of coagents in the radical cure of elastomers. Rubber World 2008, Aug., 35.

Ansarifar A, Wang L, Ellis RJ, Haile-Meskel Y. Using a silanized silica nanofiller to reduce excessive amount of rubber curatives in styrene-butadiene rubber. J Appl Polym Sci. 2011. doi:10.1002/app32772.

Magg H. Crosslinking of carboxylated nitrile rubber with resol resins. Gummi Fasern Kunstst. 2013;6:368.

Fuchs E, Reinartz KS. Improvement of the crosslinking of polychloroprene. Kautsch Gummi Kunstst. 2000;53:419.

Zaborski M, Owczarek M, Paryjczak T, Każmierczak A. Właściwości karboksylowanego kauczuku butadienowo-akrylonitrylowego usieciowanego za pomocą układu ZnO/SiO2. Polimery. 2002;47:339.

Mahaling RN, Kumar S, Rath T, Das CK. Effects of rubber filler interaction on the developments of physical, mechanical, and interfacial properties of vamac silica nano-composites. J Elastomers Plast. 2007. doi:10.1177/0095244307076495.

Zaborski M, Paryjczak T, Kaźmierczak A, Albińska J. Charakterystyka fizykochemicznych właściwości nieorganicznych składników mieszanin polimerowych o budowie “jądro-powłoka”. Polimery. 2002;47:95.

Flory PJ. Statistical mechanics of swelling of network structures. J Chem Phys. 1950. doi:10.1063/1.1747424.

Shinichi Y, Kenji T, Nobuaki N, Shoichi K, Hitoshi T, Eisaku H. Dielectric relaxation studies on water absorption of ethylene ionomers. Macromolecules. 1992. doi:10.1021/ma00052a015.

Mandal UK, Tripathy DK, De SK. Effect of silica filler on dynamic mechanical properties of ionic elastomer based on carboxylated nitrile rubber. J Appl Polym Sci. 1995. doi:10.1002/app.1995.070550805.

Vondracek P, Pouchaleon A. Ammonia-induced tensile set and swelling in silica-filled silicone rubber. Rubb Chem Technol. 1990. doi:10.5254/1.3538251.

Holliday L. Ionic polymers. London: Applied Science Pubilshers Ltd; 1975. p. 54.

Ponnamma D, Sadasivuni KK, Strankowski M, Guo Q, Thomas S. Synergistic effect of multi walled carbon nanotubes and reduced graphene oxides in natural rubber for sensing application. Soft Matter. 2011. doi:10.1039/c3sm51978c.

Crawford DM, Bass RG, Haas TW. Strain effects on thermal transitions and mechanical properties of thermoplastic polyurethane elastomers. Thermochim Acta. 1998. doi:10.1016/S0040-6031(98),00541-3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaca, M., Zaborski, M. The properties of ethylene–propylene elastomers obtained with the use of a new cross-linking substance. J Therm Anal Calorim 125, 1105–1113 (2016). https://doi.org/10.1007/s10973-016-5404-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5404-z