Abstract

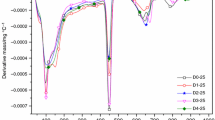

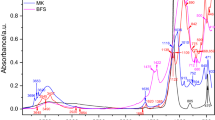

The effect of curing temperatures on the hydration of two binary systems comprising of Portland cement (PC) blended by metakaolin (MK) and blast-furnace slag (BFS) in two relative mass ratios (6/4, 5/5) was studied by means of isothermal calorimetry and combined TG/DSC technique in the temperature range of 30–60 °C. Higher curing temperatures accelerated the initial hydration reactions, especially in the case of more reactive MK-blended samples. However, except the lower replacement level of PC by BFS, all other samples displayed slowdown of hydration at later stages. The use of MK together with curing at 50 and 60 °C even resulted in the lower ultimate hydration degree after 48 h when compared with corresponding samples cured at 30 °C. Deceleration effect of higher curing temperatures was demonstrated mainly by decreasing amount of CSH phases. Pozzolanic activity of supplemental materials was affected by curing temperatures less than primary hydration reactions.

Similar content being viewed by others

References

Li Z, Ding Z. Property improvement of Portland cement by incorporating with metakaolin and slag. Cement Concrete Res. 2003;33:579–84.

Poona CS, Lama L, Koua SC, Wonga YL, Wong R. Rate of pozzolanic reaction of metakaolin in high-performance cement pastes. Cement Concrete Res. 2001;31:1301–6.

Curcio F, Deangelis BA, Pagliolico S. Metakaolin as a pozzolanic microfiller for high-performance mortars. Cement Concrete Res. 1998;28(6):803–9.

Fattuhi NI. The setting of mortar mixes subjected to different temperatures. Cement Concrete Res. 1988;18(5):669–73.

Kjellsen KO, Detwiler RJ. Reaction kinetics of Portland cement mortars hydrated at different temperatures. Cement Concrete Res. 1992;2:112–20.

Escalante-García JI, Sharp JH. Effect of temperature on the hydration of the main clinker phases in Portland cements: Part I, neat cements. Cement Concrete Res. 1998;28(9):1245–57.

Escalante-García JI, Sharp JH. The microstructure and mechanical properties of blended cements hydrated at various temperatures. Cement Concrete Res. 2001;31(5):695–702.

Verbeck GJ, Helmuth RH. In: Proceedings of the International Conference on Cement Microscopy, Tokyo, pp. 1–32; 1968.

Elkhadiri I, Palacios M, Puertas F. Effect of curing temperature on cement hydration. Ceram-Silikáty. 2009;53(2):65–75.

Khan SU, Nuruddin MF, Ayub T, Shafiq N. Effects of different mineral admixtures on the properties of fresh concrete. Hindawi Publishing Corporation. Sci World J. 2014;. doi:10.1155/2014/986567.

Wang Q, Li M, Jiang G. The difference among the effects of high-temperature curing on the early hydration properties of different cementitious systems. J Therm Anal Calorim. 2014;118:51–8.

Krajči Ľ, Mojumdar SC, Janotka I, Puertas F, Palacios M, Kuliffayová M. Performance of composites with metakaolin-blended cements. J Therm Anal Calorim. 2015;119:851–63.

Silva PS, Glasser FP. Phase relation in the system CaO–Al2O3–SiO2–H2O relevant to metakaolin–calcium hydroxide hydration. Cement Concrete Res. 1993;23:627–39.

Frías Rojas M, Sánchez de Rojas MI. The effect of high curing temperature on the reaction kinetics in MK/lime and MK-blended cement matrices at 60 °C. Cement Concrete Res. 2003;33:643–9.

Frías Rojas M, Sánchez de Rojas MI. Influence of metastable hydrated phases on the pore size distribution and degree of hydration of MK-blended cements cured at 60 °C. Cement Concrete Res. 2005;35:1292–8.

Escalante-García JI, Sharp JH. Effect of temperature on the early hydration of Portland cement and blended cements. Adv Cem Res. 2000;12(3):121–30.

Pane I, Hansen W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cement Concrete Res. 2005;35:1155–64.

Nasir NAM, Abd Aziz FNA, Safiee NA. Hydration of the combinations of ground granulated blast furnace slag cements. Aust J Basic Appl Sci. 2014;8(1):392–6.

Moser RD, Jayapalan AR, Garas VY, Kurtis KE. Assessment of binary and ternary blends of metakaolin and Class C fly ash for alkali-silica reaction mitigation in concrete. Cement Concrete Res. 2010;40:1664–72.

Shekarchi M, Bonakdar A, Bakhshi M, Mirdamadi A, Mobasher B. Transport properties in metakaolin blended concrete. Cement Concrete Res. 2010;24:2217–23.

Justice JM, Kurtis KE. Influence of metakaolin surface area on properties of cement-based materials. ASCE J Mater Civil Eng. 2007;19(9):762–71.

Lagier F, Kurtis KE. Influence of Portland cement composition on early age reactions with metakaolin. Cement Concrete Res. 2007;37:1411–7.

Deboucha W, Nadjib Oudjit M, Bouzid A, Belagraa L. Effect of incorporating blast furnace slag and natural pozzolana on compressive strength and capillary water absorption of concrete. Proc Eng. 2015;108:254–61.

Taylor HFW. Cement chemistry. 2nd ed. London: Thomas Telford Publishing; 1998.

Ylmén R, Wadsö L, Panas I. Insights into early hydration of Portland limestone cement from infrared spectroscopy and isothermal calorimetry. Cement Concrete Res. 2010;40:1541–6.

Hesse C, Goetz-Neunhoeffer F, Neubauer J. A new approach in quantitative in situ XRD of cement pastes: Correlation of heat flow curves with early hydration reactions. Cement Concrete Res. 2011;41:123–8.

Han F, Zhang Z, Wang D, Yan P. Hydration kinetics of composite binder containing slag at different temperatures. J Therm Anal Calorim. 2015;121:815–27.

Klemczak B, Batog M. Heat of hydration of low-clinker cements part I. Semi-adiabatic and isothermal tests at different temperature. J Therm Anal Calorim. 2016;123:1351–60.

Liu S, Wang L, Gao Y, Yu B, Bai Y. Comparing study on hydration properties of various cementitious systems. J Therm Anal Calorim. 2014;118:1483–92.

Lin F, Meyer C. Hydration kinetics modeling of Portland cement considering the effects of curing temperature and applied pressure. Cement Concrete Res. 2009;39:255–65.

Angulski da Luz C, Hooton RD. Influence of curing temperature on the process of hydration of supersulfated cements at early age. Cement Concrete Res. 2015;77:69–75.

Xiong X, van Breugel K. Isothermal calorimetry study of blended cements and its application in numerical simulations. HERON. 2001;46(3):151–9.

Barnett SJ, Soutsos MN, Millard SG, Bungey JH. Strength development of mortars containing ground granulated blast-furnace slag: Effect of curing temperature and determination of apparent activation energies. Cement Concrete Res. 2006;36:434–40.

Escalante JI, Gómez LY, Johal KK, Mendoza G, Mancha H, Méndez J. Reactivity of blast-furnace slag in portland cement blends hydrated under different conditions. Cement Concrete Res. 2001;31:1403–9.

Fares H, Remond S, Noumowe A, Cousture A. High temperature behavior of self-consolidating concrete microstructure and physicochemical properties. Cement Concrete Res. 2010;40:488–96.

Ibrahim IA, ElSersy HH, Abadir MF. The use of thermal analysis in the approximate determination of the cement content in concrete. J Therm Anal Calorim. 2004;76:713–8.

Paulik F, Paulik J, Arnold M. Thermal decomposition of gypsum. Thermochim Acta. 1992;200:195–204.

Silva de Souzab LM, Fairbairn EMR, Filho RDT, Cordeiro GC. Influence of initial CaO/SiO2 ratio on the hydration of rice husk ash-Ca(OH)2 and sugar cane bagasse ash-Ca(OH)2 pastes. Quim Nova. 2014;37(10):1600–5.

Moropoulou A, Bakolas A, Aggelakopoulou E. Evaluation of pozzolanic activity of natural and artificial pozzolans by thermal analysis. Thermochim Acta. 2004;420:135–40.

Cabrera J, Rojas MF. Mechanism of hydration of the metakaolin–lime–water system. Cement Concrete Res. 2001;31:177–82.

Bažant ZP, Kaplan MF. Concrete at high temperatures. London: Longman Addison-Wesley; 1996.

Matsushita F, Aono Y, Shibata S. Carbonation degree of autoclaved aerated concrete. Cement Concrete Res. 2000;30:1741–5.

Villain G, Thiery M, Platret G. Measurement methods of carbonation profiles in concrete: Thermogravimetry, chemical analysis and gammadensimetry. Cement Concrete Res. 2007;37:1182–92.

Sauman Z. Carbonization of porous concrete and its main binding components. Cement Concrete Res. 1971;1:645–62.

Amin MS, Abo-El-Enein SA, Abdel Rahman A, Alfalous Khaled A. Artificial pozzolanic cement pastes containing burnt clay with and without silica fume. J Therm Anal Calorim. 2012;107:1105–15.

Amer AA. Thermal analysis of hydrated fly ash-lime pastes. J Therm Anal Calorim. 1998;54:837–43.

Palou MT, Šoukal F, Boháč M, Šiler P, Ifka T, Živica V. Performance of G-Oil Well cement exposed to elevated hydrothermal curing conditions. J Therm Anal Calorim. 2014;118:865–74.

Habert G, Choupay N, Montel JM, Guillaume D, Escadeillas G. Effects of the secondary minerals of the pozzolans on their Pozzolanic activity. Cement Concrete Res. 2008;7:963–75.

Kuliffayová M, Krajči Ľ, Janotka I, Šmatko V. Thermal behaviour and characterization of cement composites with burnt kaolin sand. J Therm Anal Calorim. 2012;108:425–32.

Shaw S, Henderson CMB, Komanschek BU. Dehydration/recrystallization mechanisms, energetics, and kinetics of hydrated calcium silicate minerals: An in situ TGA/DSC and synchrotron radiation SAXS/WAXS study. Chem Geol. 2000;167:141–59.

Acknowledgements

This work was supported by courtesy of the Slovak Grant Agency VEGA No. 2/0082/14 and by Project Centres for Materials Research at FCH BUT, Reg. No. CZ.1.05/2.1.00/01.0012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palou, M.T., Kuzielová, E., Žemlička, M. et al. The effect of curing temperature on the hydration of binary Portland cement. J Therm Anal Calorim 125, 1301–1310 (2016). https://doi.org/10.1007/s10973-016-5395-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5395-9