Abstract

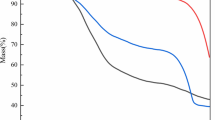

In this paper, calcium carbonate was chemically treated with two kinds of dicarboxylic acids before compounding with polypropylene in the presence of dicumyl peroxide (DCP). It was observed that the mixture of dicarboxylic acids could improve the crystallization and impact strength properties of calcium carbonate/polypropylene composite. With further addition of DCP, more PP-g-MA was produced in the blend, resulting in PP composites with larger β-phase content and improved mechanical properties. In the experiments, the maximum K β value of 52.0 % was obtained. The elongation at break of composite increased from 252 % for PP composite with untreated calcium carbonate to 444 % for PP composite with chemically treated calcium carbonate.

Similar content being viewed by others

References

Zhidan L, et al. Preparation, structures and properties of shell/polypropylene biocomposites. Thermochim Acta. 2013;551:149–54.

Enescu D, Frache A, Gualtieri G. Combustion behavior of polypropylene-based composites used in industrial plasticollar. Abingdon: Taylor and Francis Ltd; 2013.

Gahleitner M, Grein C, Bernreitner K. Synergistic mechanical effects of calcite micro- and nanoparticles and -nucleation in polypropylene copolymers. Eur Polymer J. 2012;48(1):49–59.

Nevalainen K, et al. Characterization of melt-compounded and masterbatch-diluted polypropylene composites filled with several fillers. Polym Compos. 2013;34(4):554–69.

Zhang Z, et al. Synergistic effects of toughening of nano-CaCO3 and toughness of -polypropylene. Compos A. 2012;43(1):189–97.

Zixian G, Zhidan L, Kancheng M. Monetaria moneta as a novel β-nucleating agent for isotactic polypropylene. Compos Sci Technol. 2013;87:58–63.

Castillo LA, Barbosa SE, Capiati NJ. Influence of talc morphology on the mechanical properties of talc filled polypropylene. J Polym Res. 2013;. doi:10.1007/s10965-013-0152-2.

Pollanen M, et al. Morphological, mechanical, tribological, and thermal expansion properties of organoclay reinforced polyethylene composites. Polym Eng Sci. 2013;53(6):1279–86.

Nevalainen K, et al. Characterization of twin-screw-extruder-compounded polycarbonate nanoclay composites. Polym Eng Sci. 2009;49(4):631–40.

Toro P, et al. Influence of grafted polypropylene on the mechanical properties of mineral-filled polypropylene composites. J Appl Polym Sci. 2007;103(4):2343–50.

Zhidan L, et al. Crystallization and melting behavior of polypropylene in β-PP/polyamide 6 blends containing PP-g-MA. J Ind Eng Chem. 2013;19(2):692–7.

Miyauchi K, Yuasa M. A study of adhesive improvement of a Cr–Ni alloy layer on a polyimide surface by low pressure gas plasma modification. Prog Org Coat. 2013;76(11):1536–42.

Chen MH, et al. Microstructure changes of polyimide/MMT-AlN composite hybrid films under corona aging. Appl Surf Sci. 2012;263:302–6.

Fernandez M, Alba MD, Torres RM. Sanchez, Effects of thermal and mechanical treatments on montmorillonite homoionized with mono- and polyvalent cations: insight into the surface and structural changes. Colloids Surf A. 2013;423:1–10.

Kamal M, et al. Calcium carbonate (CaCO3) nanoparticle filled polypropylene: effect of particle surface treatment on mechanical, thermal, and morphological performance of composites. J Appl Polym Sci. 2012;124(4):2649–56.

Borysiak S. Supermolecular structure of wood/polypropylene composites: i. the influence of processing parameters and chemical treatment of the filler. Polym Bull. 2010;64(3):275–90.

Diaz MF, Barbosa SE, Capiati NJ. Improvement of mechanical properties for PP/PS blends by in situ compatibilization. Polymer. 2005;46(16):6096–101.

Kock C, et al. Polypropylene/polyethylene blends as models for high-impact propylene-ethylene copolymers, part 2: relation between composition and mechanical performance. J Appl Polym Sci. 2013;130(1):287–96.

Mishra S, Chatterjee A. Effect of nano-polystyrene (nPS) on thermal, rheological, and mechanical properties of polypropylene (PP). Polym Adv Technol. 2011;22(12):1547–54.

Meng M-R, Dou Q. Effect of filler treatment on crystallization, morphology and mechanical properties of polypropylene/calcium carbonate composites. J Macromol Sci Part B. 2009;48(2):213–25.

Li L, Dou Q. Effect of malonic acid treatment on crystal structure, melting behavior, morphology, and mechanical properties of isotactic polypropylene/nano-CaCO3 composites. J Macromol Sci Part B Phys. 2011;50(5):831–45.

Nava DP, et al. Induction of phase nucleated polypropylene using a CaCO3 micrometer in industrial conditions. In: 19th International Materials Research Congress 2010, 15 Aug 2010–19 Aug 2010. Cancun: Materials Research Society; 2010.

Varga J, Mudra I, Ehrenstein GW. Highly active thermally stable beta-nucleating agents for isotactic polypropylene. J Appl Polym Sci. 1999;74(10):2357–68.

Varga J, Mudra I, Ehrenstein GW. Crystallization and melting of beta-nucleated isotactic polypropylene. J Therm Anal Calorim. 1999;56(3):1047–57.

Turner-Jones A, Aizlewood J, Beckett D. Crystalline forms of isotactic polypropylene. Macromol Chem Phys. 1964;75:134–58.

Karger-Kocsis J, et al. Instrumented tensile and falling mass impact response of injection-molded α- and β-phase polypropylene homopolymers with various melt flow indices. J Appl Polym Sci. 1999;73(7):1205–14.

Karger-Kocsis J, Varga J. Effects of β‐α transformation on the static and dynamic tensile behavior of isotactic polypropylene. J Appl Polym Sci. 1996;62(2):291–300.

Karger-Kocsis J, Varga J, Ehrenstein GW. Comparison of the fracture and failure behavior of injection-molded α- and β-polypropylene in high-speed three-point bending tests. J Appl Polym Sci. 1997;64(11):2057–66.

Tjong SC, Shen JS, Li RKY. Impact fracture toughness of β-form polypropylene. Scr Metall Mater. 1995;33(3):503.

Tjong SC, Shen JS, Li RKY. Morphological behaviour and instrumented dart impact properties of β-crystalline-phase polypropylene. Polymer. 1996;37(12):2309–16.

Acknowledgements

The Project was supported by Natural Science Foundation of China and Project of Science (Grant No. 21101076).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, Z., Cao, L., Guan, Z. et al. Grafting polypropylene and treatment of calcium carbonate to improve structure and properties of polypropylene composites. J Therm Anal Calorim 117, 765–772 (2014). https://doi.org/10.1007/s10973-014-3824-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-3824-1