Abstract

Films of poly (methyl methacrylate) (PMMA) were prepared by the addition of photoinitiator to the polymer. The influence of five organic photoinitiators on thermal stability of poly(methyl methacrylate) was studied by thermogravimetric analysis. Next, the PMMA films doped with these photoinitiators were UV irradiated and investigated in terms of changes in their thermal stability. It was found that the photoinitiators had accelerated thermal degradation of non-irradiated PMMA films due to the action of free radicals coming from the additives’ thermolysis. For UV-irradiated specimens, the effect of photoinitiator on PMMA thermal stability depended on the chemical structure of organic compound modifying the polymer. In general, thermal stability of irradiated samples was higher in the presence of additives. Thermal destruction of modified PMMA can be explained by the formation of resonance structures in aromatic photoinitiators and consumption of energy in dissipation processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, production, processing, and modification of polymers are important branches of the plastic industry in Europe. The areas of polymer application are huge as they are used in electronics, medicine, transport, construction, aviation, in production of wraps, glue, tapes, paints, etc.

Poly(methyl methacrylate) (PMMA) is a well-known, inexpensive, broadly used thermoplastic material. The application of this polymer is still increasing because of its profitable physical and chemical properties, e.g., excellent transparency, high resistance to heat and light, good surface properties, biological stability, facility for processing, and product formation as well as easy modification.

Thermal stability of PMMA depends on the polymer microstructure: internal defects and type of chain end groups. It has been reported that vinylidine-terminated PMMA is considerably less stable than PMMA containing saturated chain ends. Head-to-head linkages also facilitate the thermal degradation of PMMA [1].

The recent works devoted to PMMA concern the effect of atmosphere and particle size [2], tacticity [3], new antioxidants [4], flame retardants [5], inorganic nanoparticles [6], bioadditives [7], chemical modification [8], and polymerization conditions [9] on polymer thermal degradation.

Addition of different types of modifiers to polymer matrix is a simple method of alteration of its properties; however, it is necessary to take into account that the beneficial change of one feature can induce the negative change of other traits. The prediction of final behavior of polymeric material doped with photosensitive compound is difficult; hence, the detailed investigation of various properties determining the product usefulness should be conducted. Modern thermo-analytical techniques are often used for investigations of polymers like PMMA [10, 11].

The aim of our work was to study the influence of a few selected organic compounds, which played a role of activators (called further “photoinitiators”), on PMMA thermal stability. These activators induced PMMA photodegradability [12, 13], but changed the nanomechanical and surface properties of such modified polymer insignificantly [14, 15].

Experimental

Materials

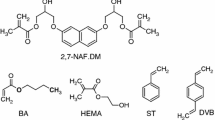

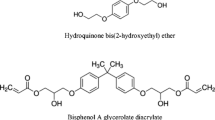

PMMA (Sigma-Aldrich), with an average molecular mass of 120,000, and five photoinitiators (Ciba, Basel, Switzerland; Sigma-Aldrich) were used as supplied. The chemical structure of photointiators, theirs abbreviations (in round brackets), molecular masses, and main physical parameters—density (d), melting (T

m), or boiling temperature (T

b) (under given pressure)—are given below:

Two compounds (Irg. 651 and BP) are solids, while tBPB, DtBP, and 2,5-tBPDMH are viscous liquids at room temperature.

Polymeric films preparation

2 % solutions of PMMA or photoinitiators in tetrahydrofurane were prepared. Both solutions were mixed in a proper ratio for the purpose of incorporating 5 mass% of initiator with respect to the polymer mass. Polymer solutions (PMMA, PMMA+photoinitiator) were cast onto leveled smooth glass plates. After solvent evaporation, thin polymeric films were obtained. Next, the samples were dried in a vacuum at 30 °C to remove the solvent residue, which was checked by UV–Vis spectroscopy. The average film thickness, measured by the Sylvac 229 type digital indicator (Switzerland), was about 20 μm.

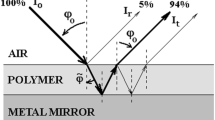

Irradiation conditions

Films of pure PMMA and PMMA+5 % of photoinitiator were UV irradiated up to 8 h in air atmosphere at room temperature. The irradiation source was a low-pressure mercury vapor lamp (TUV30W; Philips) emitting radiation of 254 nm wavelength. The distance between the light source and the sample was 5 cm. The intensity of the incident light, measured by HD 9021 radiometer, was 32.2 W m−2. After each hour of exposure, thermogravimetric analysis was done for all samples.

To compare the influence of the photoinitiators on thermal behavior of PMMA, two irradiation times were chosen: 1 and 4 h. In some cases, there was a difference between shorter (1 and 2 h) and longer irradiation time (above 4 h).

Thermogravimetric analysis

The polymer degradation characteristics were determined by thermogravimetry (TG) using a Thermal Analysis SDT2960 Simultaneous DSC-TGA (USA) instrument. Measurements were carried out under nitrogen atmosphere, in the temperature range from 25 to 600 °C, at a heating rate of 20 °C min−1. TG, DTG, and DTA curves were recorded simultaneously. The onset temperature of decomposition (T 0), the temperature at 10 % of mass loss (T 10), the temperature at maximum process rate (T max), and mass loss (Δm) were determined by TA Instruments Universal Analysis 2000 software.

The gases evolved from heated samples were analyzed by TG coupled with a Fourier transform infrared spectroscope—Excalibur BIO-RAD—in the 25–500 °C temperature range, in nitrogen atmosphere at a heating rate of 6° min−1. The flow rate of N2 into the IR cell was 100 mL min−1. The gas transport line and IR cell were maintained at 230 °C. 32 scans for each IR spectrum were recorded. The spectra resolution was 4 cm−1.

Results

Effect of photoinitiators on unirradiated PMMA films

TG and DTG curves of two solid photoinitiators (Irg. 651 and BP) are shown in Fig. 1. Thermal decomposition of Irg. 651 occurred in one stage with a maximum decomposition rate at 260 °C. It was completed below 300 °C (i.e., mass loss was 100 %). In the case of BP, the two-stage decomposition with a maximum rate at 112 and 307 °C was observed. In the first stage, about 20 % of the initiator decomposed, while ~80 % disappeared at about 400 °C in the second stage. The thermogravimetric analysis of liquid initiators was impossible to conduct because of instrumental problems.

Figures 2 and 3 show TG and DTG curves of unirradiated polymer films (pure PMMA and PMMA with 5 mass% of photoinitiators). There are three main stages of PMMA degradation. These stages are not completely separated (the second and the third stages partially overlap). Moreover, the first stage is complex for all samples with the exception of pure PMMA. The complexity of this stage may be a result of overlapping decomposition of PMMA and photoinitiator. It is seen that TG and DTG curves of PMMA without additives were different from curves of PMMA with additives, which suggested that these photoinitiators influenced PMMA decomposition.

The main parameters characterizing the thermal behavior of studied samples are listed in Table 1. As it can be seen, T 0 decreased negligibly for all modified PMMA compared to PMMA without additive. For this reason, we analyzed T 10 parameter which decreased substantially for polymer in the presence of liquid photoinitiators (PMMA with tBPB, DtBP, and 2,5-tBPDMH). The drop in this parameter (T 10) may be a result of both accelerating action of the additives on PMMA decomposition and partial evaporation of these additives. The slow evaporation takes place for DtBP having the boiling temperature (T b) of about 110 °C. But, decomposition below the boiling temperature under atmospheric pressure occurs in the case of tBPB and 2,5-tBPDMH (their T b under reduced pressure is about 75 and ~55 °C, respectively). Furthermore, T max in the first stage was lower for PMMA films with additives than that for pure PMMA. However, PMMA with Irg.651 was the exception to the rule for which T max in this stage increased slightly. T max in the second stage was marginally lower for modified polymer than that for pure PMMA. T max in the third stage was practically the same for all specimens compared to pure PMMA. These results suggest that studied photoinitiators accelerate thermal degradation of PMMA and their influence is especially seen in the first stage of decomposition.

Different shapes of thermogravimetric curves (TG, DTG) of studied samples can indicate the effect of the chemical structure of photoinitiator on the course of PMMA thermal degradation. In the case of PMMA films with the addition of Irg. 651 or BP, two sub-stages can be distinguished in the first stage of decomposition. The maximum at lower temperature in DTG curve comes from decomposition of photoinitiator, but the maximum at higher temperature can be related to the polymer decomposition. For the specimens containing other additives (tBPB, DtBP, and 2,5-tBPDMH), photoinitiator decomposition may overlap with polymer decomposition in the first stage of PMMA thermal degradation.

Greater mass loss in the Ist stage of decomposition for PMMA with tBPB, DtBP, and 2,5-tBPDMH than that for pure PMMA confirmed that polymer stability was diminished in the presence of these photoinitiators (Table 1), which may indicate that polymer was involved in this stage of decomposition. We should also take into account the possibility of gradual evaporation of the liquid additives. However, their amount, randomly distributed in a polymer matrix, was only 5 %. The differences in Δm for PMMA and PMMA with photoinitiators were less noticeable in the second stage of decomposition. The substantial changes in Δm (48–64 %) appeared in the third stage of decomposition (in the range of 320–490 °C) for all samples. The mass loss in the third stage was smaller (but in the first stage, it was greater) in the case of PMMA modified with DtBP, tBPB, or 2,5-tBPDMH compared to that for pure PMMA and PMMA with Irg. 651 or BP, which might suggest that liquid photoinitiators influenced PMMA decomposition especially in the first and the third stage.

It was worth noticing that sample decomposition was completed at 500 °C in the case of polymeric films with Irg. 651 and 2,5-tBPDMH (Figs. 2, 3). However, carbon residue was present even at 600 °C in the case of the other samples.

The combined TG/FTIR analysis indicated that the volatile products of thermal degradation were the same for pure and doped PMMA. It is understandable because the content of photoinitiator in polymer matrix was low and thus only the products of polymer decomposition were detected. An example of infrared spectra of gases acquired at different temperatures is shown in Fig. 4. The recorded spectra are very similar to those published recently by Saladino et al. [16]. These spectra can be assigned to monomer (MMA), which is the major product of PMMA thermal degradation. On the other hand, the carbonyl band is composed of two maxima (at about 1735 and 1745 cm−1), which suggests that another volatile product of PMMA degradation was evolved besides monomer [17]. It was probably the ethyl formate (HCOOCH3) formed as a result of abstraction of side groups from polymer backbone. On the basis of our recorded FTIR spectra, the presence of CO, CO2, anhydride, and methanol was excluded.

Effect of UV-irradiation on modified PMMA

The changes in thermogravimetric curves (TG and DTG) of chosen samples exposed to UV light are presented in Figs. 5 and 6. Tables 2, 3, and 4 contain the thermal parameters obtained from thermogravimetric curves recorded for all studied samples.

It is seen that the course of thermal degradation of UV-irradiated PMMA films with and without photoinitiators was different.

As it was mentioned above, DTG curve of unirradiated pure PMMA consisted of three peaks, but the second peak disappeared after exposure to UV light (Figs. 5, 6). This peak became less distinct after 1 h of irradiation, but it was completely invisible after longer UV action. Disappearance of the second stage of thermal decomposition was found for all samples. Table 2 contains data of thermal parameters for exposed PMMA. The slight decrease in T 0 and a significant drop in T max in the Ist and IIIrd stage for UV-irradiated PMMA were observed. However, a substantial rise in T 10 after UV treatment was noticed, which may indicate that thermal stability of UV-irradiated PMMA was higher. On the other hand, the mass loss (Δm) in the Ist stage decreased gradually for UV-irradiated PMMA probably owing to the formation of non-volatile products which came from recombination of free radical generated in polymer under UV.

In all the cases, the photoinitiator did not influence the onset temperature (T 0) of PMMA decomposition after UV-irradiation (Tables 3, 4). However, T 10 parameter increased considerably for all UV-irradiated samples. The changes in this parameter were much bigger in the case of PMMA+Irg. 651 and PMMA+tBPB, but smaller for PMMA+DtBP and PMMA+2,5-tBPDMH than those in unmodified PMMA exposed to UV. The rise in T 10 parameter might indicate that the UV light enhanced thermal stability of these samples.

The effect of photoinitiator on T max depends on its chemical structure. The significant decrease in T max in the Ist stage after 1 h of UV-irradiation was observed in pure PMMA and PMMA+Irg.651 (Tables 2, 3; Fig. 6), but after longer irradiation, a gradual increase in T max was noticed only in PMMA. In the case of PMMA+BP and PMMA+2,5-tBPDMH, irradiation caused a rise in T max in the first stage (Tables 3, 4). Rather negligible changes in this parameter appeared in PMMA+tBPB (Table 4). The PMMA sample containing DtBP was characterized by the increase in T max, and then by marked decrease in this parameter after 4 h (Table 4).

The mass loss in the first stage of decomposition was lower for all UV-irradiated PMMA films (without and with photoinitiators) compared to unirradiated samples, which suggests that the efficiency of this process was reduced after irradiation. However, an increase in the mass loss in the IIIrd stage after irradiation was observed simultaneously and in this stage almost the whole sample gets decomposed.

The spectra of volatile products of exposed films were similar to the spectra of unexposed ones, which may indicate that there was a subtle difference in mechanism of thermal degradation of PMMA before and after UV-irradiation.

Discussion

The results obtained from TG curves for pure PMMA are similar to the results published previously by other authors. Three stages of mass loss in thermal degradation of PMMA were mostly observed [16, 18]. In general, the first stage was related to the depolymerization beginning from head-to-head linkages; the second stage—to depolymerization starting from unsaturated vinyl ends; and the third stage—to random chain scissions. Manring proposed somewhat different explanations for thermal degradation of PMMA [19–21]. He found that the presence of head-to-head structures made the temperature of degradation lower; however, decomposition of these structures took place rather at the second stage. He showed that unsaturated ends of chains were responsible for two stages of degradations, at about 180 and 270 °C, which covered the process of breaking head-to-head structures. Manring also suggested that the last stage of degradation (at 350–400 °C) was caused rather by scission of a methoxycarbonyl side group than by random scission of main chain as it was suggested earlier [18]. Studies performed by Holland and Hay [22] proved that PMMA degradation occurred in four stages: the complex stage (at 350–400 °C) was divided into two other stages due to simultaneous scissions of end groups and random breaking of chains. Research performed by Ferriol et al. [23] confirmed findings on the four-stage decomposition of PMMA.

In our case, three main stages of PMMA degradation were considered; however, their complexity was clearly seen on curves.

The decrease in PMMA thermal stability in the presence of photoinitiators can be explained by their thermolysis at the beginning of heating and by reaction of formed free radicals with polymer. Small radicals coming from decomposed photoinitiator are mobile and can initiate formation of radicals in macromolecules. When free radical chain process starts, it can continue until termination. Higher temperature enhances chain mobility and radical diffusion, and thus the probability of reactions increases. Weak peroxide bonds present in four studied initiators (BP, tBPB, DtBP, and 2,5-tBPDMH) can be easily destroyed. Such bonds do not exist in Irgacure 651, but this compound can undergo the Norrish type I reaction, which leads to the formation of benzoyl and α,α-dimethoxybenzyl radicals accelerating PMMA thermal degradation.

In all UV-irradiated samples, an increase in T 10 was observed, which might indicate that thermal stability of UV-irradiated samples was higher. Initiators obviously undergo photolysis, but probably not all radicals react with polymer during exposure to UV light. Some of them are stable and thus they can still exist in irradiated PMMA films. Such trapped radicals can react with macroradicals (appearing as a result of primary degradation process) after heating, and polymer decomposition can be retarded. It also seems possible that some intermediate products which formed during recombination of polymeric radicals with initiator radicals are more stable than regular PMMA structures. In the case of the presence of aromatic rings (benzoyl or phenyl groups) in macrochains, the resonance structures can be formed, which stabilizes polymer. As a consequence, the resonance energy can be partially used in non-harmful processes or can be dissipated, which retards PMMA thermal degradation.

Conclusions

Thermogravimetric analysis proved that small amount (5 mass%) of photosensitive modifiers introduced into PMMA reduced its thermal stability significantly, which was seen especially when DtBP, tBPB, or 2,5-tBPDMH was added to PMMA. As a result of thermolysis of weak bonds in photoinitiators, the free radicals were formed and they initiated polymer degradation at lower temperature compared to unmodified PMMA.

The presence of photoinitiators in UV-irradiated PMMA films caused polymer thermal stability enhancement. But, the efficiency and mechanism of PMMA decomposition depended on the chemical structure of applied modifier. The stabilizing effect of additives containing aromatic rings in their structure on thermal stability of PMMA was observed. Also, aliphatic peroxides (tBPB or 2,5-tBPDMH) improved thermal stability of PMMA in such conditions, but in a smaller degree.

The volatile products of PMMA thermal degradation may be considered the same in the case of pure and modified PMMA. The composition of gases evolved did not change after UV irradiation of the samples, which suggests that the mechanism of degradation of unirradiated and irradiated PMMA films was almost the same.

References

Srinivasan SA, Hedrick JL, McKean DR, Miller RD, Hilbom JG. Preparation of thermally labile PMMA particles by combined non-aqueous dispersion polymerization and polymer chain transfer. Polymer. 1998;39:1497–501.

Dakka SM. TG/DTA/MS of poly(methyl methacrylate). J Therm Anal Calorim. 2003;74:729–34.

Zhang B, Blum FD. Thermogravimetric study of ultrathin PMMA films on silica: effect of tacticity. Thermochim Acta. 2003;396:211–7.

Lomonaco D, Cangane FY, Mazzetto SE. Thiosphate esters of cashew nutshell liquid derivatives as new antioxidants for poly(methyl methacrylate). J Therm Anal Calorim. 2011;104:1177–83.

Wang X, Wu L, Li J. Synergistic flame retarded poly(metyl methacrylate) by nano-ZrO2 and triphenylphosphate. J Therm Anal Calorim. 2011;103:741–6.

Pal MK, Singh B, Guatam J. Thermal stability and UV-shielding of polymethyl methacrylate and polystyrene modified with calcium carbonate nanoparticles. J Therm Anal Calorim. 2012;107:85–96.

Lomonaco D, Maia FJN, Mazzetto SE. Thermal evaluation of cashew nutshell liquid as new bioadditives for poly(metyl methacrylate). J Therm Anal Calorim. 2013;111:619–26.

Cervantes-Uc JM, Cauich-Rodriguez JV, Herera-Kao WA, Vazquez-Torres H, Marcos-Fernandez A. Thermal degradation behavior of polymethacrylates containing side groups. Polym Degrad Stab. 2008;93:1891–900.

Holland BJ, Hay JN. The effect of polymerization conditions on the kinetics and mechanisms of thermal degradation of PMMA. Polym Degrad Stab. 2002;77:435–9.

Pratap A, Sharma K. Applications of some thermo-analytical techniques to glasses and polymers. J Therm Anal Calorim. 2012;107:171–82.

Sakatsuji W, Konishi T, Miyamoto Y. Effects of thermal history on enthalpy relaxation. J Therm Anal Calorim. 2013;113:1129–34.

Kaczmarek H, Gałka P. Effect of Irgacure 651 initiator on poly(methyl methacrylate) studied by UV–Vis spectroscopy. Open Process Chem J. 2008;1:8–11.

Kaczmarek H, Gałka P. Influence of a photoinitiator on the photochemical stability of poly(methyl methacrylate) studied with fourier transform infrared spectroscopy. J Appl Polym Sci. 2010;115:1598–607.

Kaczmarek H, Gałka P. Nano-mechanical properties of modified poly(methyl methacrylate) films studied by atomic force microscopy. Tribol Lett. 2011;41:541–54.

Kaczmarek H, Gałka P, Szalla A. Atomic force microscopy studies of poly(methyl methacrylate) doped with photoinitiators. J Appl Polym Sci. 2012;123:2458–66.

Saladino MI, Motaung TE, Luyt AS, Spinella A, Nasillo G, Caponetti E. The effect of silica nanoparticles on the morphology, mechanical properties and thermal degradation kinetics of PMMA. Polym Degrad Stab. 2012;97:452–9.

Wilkie CA. TGA/FTIR: an extremely useful technique for studying polymer degradation. Polym Degrad Stab. 1999;66:301–6.

Kashiwagi T, Inaba A, Brown JE, Hatada K, Kitayama T, Masuda E. Effect of weak linkages on the thermal degradation of poly(metyl methacrylate). Macromolecules. 1986;19:2160–8.

Manring LE. Thermal degradation of poly(methyl methacrylate). 2. Vinyl-terminated polymer. Macromolecules. 1989;22:2673–7.

Manring LE, Sogath DY, Cohen GM. Thermal degradation of poly(methyl methacrylate). 3. Polymer with head-to-head linkages. Macromolecules. 1989;22:4562–654.

Manring LE. Thermal degradation of poly(methyl methacrylate). 4. Random side-group scission. Macromolecules. 1991;24:3304–9.

Holland BJ, Hay JN. The kinetics and mechanisms of the thermal degradation of poly(methyl methacrylate) studied by thermal analysis-Fourier transform infrared spectroscopy. Polymer. 2001;42:4825–35.

Ferriol M, Gentilhomme A, Cochez M, Oget N, Mieloszynski JL. Thermal degradation of poly(methyl methacrylate) (PMMA) modeling of DTG and TG curves. Polym Degrad Stab. 2003;79:271.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Gałka, P., Kowalonek, J. & Kaczmarek, H. Thermogravimetric analysis of thermal stability of poly(methyl methacrylate) films modified with photoinitiators. J Therm Anal Calorim 115, 1387–1394 (2014). https://doi.org/10.1007/s10973-013-3446-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3446-z