Abstract

Sorption properties of porous copolymers 1-vinyl-2-pyrrolidone-divinylbenzene (VP-DVB) were investigated by thermogravimetry. Water, n-butanol and n-heptane were used as sorptives. The current studies were performed for VP-DVB copolymers which were synthesized under different condition and vary in terms of porous structure. Additionally, VP-DVB 5 sample has more polar character comparing with other samples. It was demonstrated that porous structure of the adsorbent has the fundamental impact on the adsorption process but not only the value of specific surface area but also the pore diameter plays important role. Sorption of water is enhanced by the presence of micropores and polar character of the adsorbent.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sorption properties of porous materials are the subject of many studies [1–9]. Among different techniques that can be applied for the determination of sorption properties of porous materials an interesting approach is thermogravimetric analysis (TG). This method is based on the measurement of the mass change as a function of temperature and is a simple and effective method that can be used in the characterisation of the sorption properties of the porous material [10–12]. However, high thermal resistance of the polymeric adsorbent is indispensable. The studied copolymers of 1-vinyl-2-pyrrolidone-divinylbenzene (VP-DVB) are characterised by a high degree of cross-linking and consequently high temperature resistance [13]. This feature enables them to be used in high-resolution thermogravimetric analysis. In our recent paper [14] we demonstrate that porous copolymers exhibit specific sorption properties when exposed to vapour of various substances and TG can be successfully applied in the investigation of their sorption properties. It was found out that the sorption properties are the outcome of polarity and porosity of the copolymers under study. In order to separate the contribution of these components we synthesised a series of VP-DVB copolymers. They have analogous chemical structure, but differ in terms of porous structure. Porous copolymers with different pore structure can be controllably prepared via varying synthesis parameters. The key variables are composition of the pore-forming solvent mixture, content of cross-linking agent, temperature, the kind and amount of initiator and polymerisation technique [15–21]. These parameters allow the tuning of average pore size within a broad range spanning 2 orders of magnitude. In this study we used different diluent compositions to create various porous structures. The question, therefore, arose how these morphological differences might affect the binding properties of otherwise chemically identical copolymers. To determine the structure–property relationship thermodesorption behaviour of water, n-butanol and n-heptane from porous copolymers of 1-vinyl-2-pyrrolidone (VP) with divinylbenzene was studied. In this study the copolymers were obtained in the form of porous microspheres. The saturated samples of these materials were studied using thermogravimetry (TG-DTG).

Experimental

Preparation of porous copolymers

Chemicals

Divinylbenzene (DVB), Merck (Darmstadt, Germany); trimethylpropane trimethacrylate (TRIM), Fluka (Buchs, Switzerland); VP, Fluka (Buchs, Switzerland) were washed with 5 % aqueous sodium hydroxide in order to remove inhibitors. Poly(vinyl alcohol) and α,α′-azoisobisbutyronitrile from Fluka (Buchs, Switzerland) were used without purification. Toluene, n-dodecane, acetone and methanol (reagent grade) were from POCh (Gliwice, Poland).

Preparation of porous copolymers

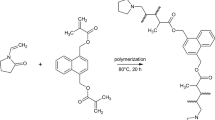

VP-DVB copolymer was prepared via free radical cross-linking copolymerisation similar to as described elsewhere [13, 22]. Toluene and dodecane were applied as pore-forming diluents. Poly(vinylalcohol) (PVP), calcium chloride (CaCl2) and bis(2-ethylhexyl)sulfosuccinate sodium salt (AOT) were used as stabilisers. The molar ratio of VP to DVB was maintained 1:1 for samples 1–4 whereas for sample 5 it was 3:1. The detailed experimental parameters are listed in Table 1. Copolymerisation was performed for 20 h at 80 °C. The porous beads formed in this process were filtered, washed with hot water and extracted in a Soxhlet apparatus with acetone, toluene and methanol. The purified beads were separated into fractions by sieving. For further experiments microspheres of diameters in the range of 0.08–0.12 mm were chosen. They were dried in vacuum at 80 °C for 24 h. Then the samples were exposed at 20 °C to the vapour of n-butanol, water and n-heptane in a desiccator for 24 h. Before the sorption experiment the air was evacuated from the desiccator. Thus, one can assume that at equilibrium practically saturated (p/p 0 ≈ 0.99) vapours of the adsorptive were present over the sample.

Thermogravimetry

TG of the saturated samples was performed using the STA449, F1 Jupiter analyser from Netzsch (Günzbung, Germany). The procedure was as follows: about 10 mg of the sample was placed in the TG pan and heated in helium atmosphere at the rate of 10 °C min−1 up to 200 °C. The mass change of the blank sample with respect to temperature was also measured to correct its influence on the thermodesorption date of water, n-butanol and n-heptane.

Relative thermodesorption plot

The total amount desorbed was calculated with respect to the mass residue at 200 °C. This amount was used to calculate the relative desorption, which is defined as the ratio of the amount desorbed at a given temperature T to the total amount desorbed. Then, the relative desorption for each sample was plotted versus temperature.

Characterisation of the porous structure

The textural characterisation of the copolymers was carried out by the low-temperature nitrogen adsorption–desorption method. Nitrogen adsorption–desorption measurements were made at 77 K using a volumetric adsorption analyser ASAP 2405 (Micrometrics Inc., USA). The measurements of the surface properties of the copolymers were preceded by outgassing the samples at 140 °C for 2 h. The specific surface areas of the investigated copolymers were calculated by the Brunauer–Emmet–Teller (BET) method for the adsorption data in the range of the relative pressure of p/p o 0.05–0.25. The total pore volume was estimated from a single point adsorption at a relative pressure of 0.985. The pore size distributions (PSD) were obtained from the desorption branch of the isotherm using the Barrett–Joyner–Halenda (BJH) procedure.

The maximum of PSD was defined as pore diameter in contrast to the average pore diameter calculated as D p = 4V p/S BET (on assumption of a cylindrical shape of pores).

The beads were imaged using a LEO 1430 VP numerical scanning electron microscope (Germany) with a countershaft and an energy-dispersive X-ray detector.

The surface of the obtained beads was also examined using an atomic force microscope (AFM), AFM Nanoscope III (Digital Instruments, USA) operating in contact mode.

IGC experiments

Chromatographic measurements were carried out on a Dani GC 1000 gas chromatograph (Dani, Italy) equipped with a packed injector, a thermal conductivity detector (TCD), using stainless-steel columns (100 cm × 1.6 mm I.D.), and helium as carrier gas at the flow rate of 50 mL min−1. The samples were manually injected using of 1-μL syringe (SGE, North Melbourne, Australia).

Chromatographic columns were packed with obtained porous polymers in the form of spherical beads. The diameter of the sorbent beads was always 0.08–0.12 mm. Before measurements all the columns were conditioned in a stream of helium. The columns were conditioned with temperature programming from 60 to 130 °C at 4 °C min−1 and then overnight isothermally at the final temperature.

Polarity

The polarity of the studied copolymers was determined according to the procedure described in detail in our earlier papers [23]. The measurements were carried out at 140 °C. The sum of McReynolds constant (the difference between Kovats’ indices on the examined copolymers and graphitised thermally carbon black) for benzene, n-butanol and pentan-2-one was used to define the overall polarity.

Results and discussion

In the synthesis of porous microspheres a broad variety of functional monomers and crosslinkers can be used. In most cases they have non-polar character. However, in many applications the significant polarity of adsorbent is desirable. For this reason synthesis of porous copolymers of a more polar character remains the subject of comprehensive studies. In our study we used VP as a functional monomer. It contains a highly polar amide group conferring hydrophilic and polar—attracting properties and also apolar methylene groups in the backbone and the ring, conferring hydrophobic properties. It also possesses several practically valuable properties such as non-toxicity, biocompatibility and good complexing properties for an ionic or π-electron system. As a consequence porous pyrrolidone copolymers can be used in liquid chromatography with the advantage of being adsorbents for both non-polar and polar solutes and eluents.

Crosslinked porous copolymers used in this study were obtained in the form of regular microspheres (Fig. 1). DVB served as a cross-linking agent. Independent parameters of the synthesis were changed during the polymerisation process in order to create copolymers of different porous structures (Table 1). As can be seen in Table 1, toluene and dodecane were applied as pore-forming diluents. The solvating power of these solvents is quite different. Solubility parameters amount to 18.2 (MPa)0.5 for toluene (solvating solvent) and 16.2 (MPa)0.5 for dodecane (non-solvating solvent). Consequently, by changing the composition of the pore-forming solvent mixtures, different porosities can be generated and controlled (Table 2). The highest value of a specific surface area was obtained for copolymer synthesized with the presence of pure toluene (VP-DVB 4) and is equal 695 m2 g−1. Addition of non-solvating solvent results in decrease of the value of a specific surface area (VP-DVB 1: 643 m2 g−1); however, the volume of pores increases and the maximum of pore size distribution is shifted towards a larger pore size. This effect could be explained by the fact that phase separation occurs earlier in this system. Therefore, the nuclei of polymers in formation could capture preferably monomers from the local solution, and consequently increase their size and the sizes of pores formed between them. Further addition of non-solvating solvent (VP-DVB 4) results in higher local concentration of monomers in the swollen nuclei than in the surrounding solution. The polymerisation reaction proceeds principally in the swollen nuclei rather than in the surrounding solution. As a result both large microglobules and large pores are formed. Consequently, the value of specific surface area of the VP-DVB 4 copolymer poses the lowest value between all the copolymers under study (190 m2 g−1).

Apart from the composition of the pore-forming solvent mixture the content of cross-linking agent also influences the porous structure. Copolymers VP-DVB 1 and VP-DVB 5 were obtained in the presence of exactly the same solvent mixture but the ratio of functional monomer to crosslinker was maintained 1:1 for VP-DVB 1 whereas for copolymer VP-DVB 5 it was changed to 3:1. As a result, a copolymer of lower cross-linking degree was synthesised. Diminution of the content of crosslinker resulted in less developed porous structure. The value of specific surface is equal to 390 m2 g−1 and the pore volume is equal to 0.490 cm3 g−1. It is also worth noticing that stabilisers that are prerequisite during the synthesis of polymeric microspheres have an impact on the porous structure of the obtained copolymers. Addition of calcium chloride that restricts the solubility of VP into polymerisation medium also induces an earlier onset of phase separation. The precipitated microglobules can attract the polymer chains in formation and coalescence with them. This process leads to an increase in their size and consequently diminish the value of specific surface area.

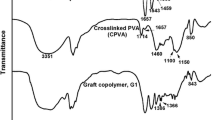

Sorption properties of the synthesised copolymers were investigated using n-butanol, water and n-heptane. For all the investigated samples and adsorbates considerable adsorption was noticed. Table 3 summarises the desorbed amount of n-butanol, water and n-heptane from the copolymers under study. Figures 2, 3 and 4 are the graphical representation of the desorption process. It can be seen that the sample of the lowest surface area (VP-DVB 3) exhibits relatively week interactions towards molecules of n-butanol, water and n-heptane. Along with the increase of the value of the surface area the growth of the amount of adsorbed molecules can be observed. In the case of copolymers with well-developed internal structures not only the value of the surface area but also the diameters of pores play an important role. Copolymers VP-DVB 1 and VP-DVB 4 possess highly developed porous structure but the maximum of pore size distribution is quite different (Fig. 5). VP-DVB 4 is microporous. This phenomenon also has an impact on the value of pore volume. Despite the higher specific surface area of VP-DVB 4 its pore volume is lower than in the VP-DVB 1 copolymer. The question, therefore, arose how these morphological differences affected the binding properties of otherwise chemically identical copolymers. Micropores present in the internal structure of the VP-DVB 4 copolymer facilitate the adsorption of n-butanol and water. In the case of n-heptane higher adsorption is observed for 1. The impact of micropores is especially visible when comparing the amount of water desorbed from copolymers VP-DVB 1 and VP-DVB 2. Despite the much higher value of the surface area the amount of water is almost twice as small as in the case of copolymer VP-DVB 2. The differences are also visible on the curves of water mass loss from the discussed copolymers (Fig. 6).

It was also of interest to investigate the influence of polarity of the studied copolymers on their sorption properties. Copolymers VP-DVB 2 and VP-DVB 5 are quite similar in terms of the value of the specific surface area, pore volume and pore size distribution. However, copolymer VP-DVB 5 indicates much polar character. The polarity of polymers can be generated and controlled by the amount of polar monomers used in the synthesis. In the case of VP-DVB 5 sample the molar ratio of VP to the crosslinker was maintained at 3:1. Consequently, its polarity is 426 compared to 243 of VP-DVB 2 (Table 4). As a result, the amount of polar molecule of water is much higher. It is 14.9 mmol g−1 whereas in the case of VP-DVB 2 this parameter is 7.16 mmol g−1. It is worth noticing that the observed 14.9 mmol g−1 is the highest value among all the adsorptives and adsorbents under study. The polar character of copolymer VP-DVB 5 along with its microporous structure is responsible for this phenomenon. In the case of the molecule of n-heptane the polarity of the adsorbent has an imperceptible impact on the adsorption process. The amount of adsorbed n-heptane is almost the same in the case of copolymers VP-DVB 2 and VP-DVB 5 (Fig. 3). The same observation was made for the n-butanol (Fig. 4).

More information to complete the study can be derived from the relative desorption plots. Figure 7 presents the relative desorption curves of water with respect to temperature for two copolymers that have a similar specific surface area but differ considerably in terms of pore diameter (VP-DVB 1 and VP-DVB 4). Thermodesorption of water continues until about 200 °C for the macroporous VP-DVB 1, whereas in the case of the microporous VB-DVB 4 copolymer this process runs only until about 120 °C. An analogical observation was made for porous carbon black [12]. For macroporous materials it is taken for granted that water molecules are first adsorbed on the primary active sites, which act as the secondary sites for further adsorption and formation of hydrogen-bonded clusters [24].

The relative desorption curves for n-heptane and n-butanol are shown in Figs. 8 and 9. It can be seen that the porous copolymers VP-DVB exhibit relatively weak interactions towards molecules of n-butanol and n-heptane compared to a water molecule. Thermodesorption of the molecules of n-butanol continues only to about 100 °C. In the case of n-heptane the temperature is slightly lower.

Conclusions

The results presented show that porous copolymers of VP-DVB exhibit specific sorption properties when exposed to vapour of various substances. Along with the increase of the value of specific surface area the amount of adsorbed molecules also increases. In the case of adsorbents of well-developed internal structure not only the value of specific surface area but also the pore diameter plays an important role. The presence of pores facilitates adsorption of water. Water is also preferably adsorbed into copolymers of more polar character. The polarity of the adsorbent has no impact on the adsorption process of molecules of non-polar character.

References

Sobiesiak M, Gawdzik B, Puziy A, Poddubnaya O. Polymer-based carbon adsorbents obtained from copolymer of 4,4′-bis(maleimidodiphenyl)methane and divinylbenzene for use in SPE. Chromatography. 2006;64:175–81.

Maciejewska M, Gawdzik J. Preparation and characterization of sorption properties of porous microspheres of 1-vinyl-2-pyrrolidone-divinylbenzene. J Liq Chromatogr Relat Technol. 2008;31:950–61.

Bielicka-Daszkiewicz K, Voelkel A, Szejner M, Osypiuk J. Extraction properties of new polymeric sorbents in SPE/GC analysis of phenol and hydroquinone from water samples. Chemosphere. 2006;62(6):890–8.

Trochimczuk AW, Streat M, Kolarz N. Highly polar polymeric sorbents characterization and sorptive properties towards phenol and its derivatives. React Funct Polym. 2001;46:259–71.

Trochimczuk AW, Kolarz N. Synthesis and chelating properties of resins with methylthiourea, guanylthiourea and dithiocarbamate groups. J Chem Soc. 2000;36:2359–63.

Deryło-Marczewska A, Goworek J, Kusak R, Zgrajka W. Sorption properties of porous melamine—formaldehyde resins. App Surf Sci. 2002;195:117–25.

Drechny D, Trochimczuk AW. Synthesis and some sorptive properties of highly crosslinked cyanomethyl styrene/divinylbenzene copolymers. React Funct Polym. 2006;66:323–33.

Marczewski AW, Derylo-Marczewska A, Skrzypek I, Pikus S, Kozak M. Study of structure properties of organized silica sorbents synthesized on polymeric templates. Adsorption. 2009;15:300–5.

Azanova V, Hradil J. Sorption properties of macroporous and hypercrossslinked copolymers. React Funct Polym. 1999;41:163–75.

Araujo A, Jaroniec M. Determination of the surface area and mesopore volume for lanthanide-incorporated MCM materials by using high resolution thermogravimetry. Thermochim Acta. 2000;345:173–7.

Goworek J, Kierys A, Iwan M, Stefaniak W. Sorption on as-synthesized MCM-41. J Therm Anal Calorim. 2007;87:165–9.

Li Z, Jaroniec M. Comparative studies of carbon blacks by thermogravimetry and nitrogen adsorption. J Colloid Interface Sci. 1999;210:200–6.

Maciejewska M. Characterization of macroporous 1-vinyl-2-pyrrolidone copolymers obtained by suspension polymerization. J Appl Polym Sci. 2012;124:568–75.

Maciejewska M, Osypiuk-Tomasik J. Studies of sorption properties of porous copolymers of 1-vinyl-2-pyrrolidone. J Therm Anal Calorim. 2013;111:1595–601.

Okay O. Macroporous copolymer network. Prog Polym Sci. 2000;25:711–79.

Gokmen MT, Du Prez FE. Porous polymer particles—a comprehensive guide to synthesis, characterization, functionalization and applications. Prog Polym Sci. 2012;37:365–405.

Gawdzik B, Maciejewska M, Pikus S. Comparison of the porous structure of polymeric beads obtained by the modified suspension and multi-step swelling polymerizations. Adsorpt Sci Technol. 2006;24:701–11.

Grochowicz M, Gawdzik B. Preparation and characterization of porous crosslinked microspheres of new aromatic methacrylates. J Porous Mater. 2013;20:339–49.

Podkościelna B. The highly crosslinked dimethacrylic/divinylbenzene copolymers. J Therm Anal Calorim. 2011;104:725–30.

Svec F, Frechet JMJ. Temperature, a simple and efficient tool for the control of pore size distribution in macroporous polymers. Macromolecules. 1995;28:7580–2.

Grochowicz M, Gawdzik B, Jaćkowska M, Buszewsk B. Investigation of the thermal behavior of new silica-polymer anion exchangers. J Therm Anal Calorim. 2012. doi: 10.1007/s10973-012-2635-5.

Zaleski R, Stefaniak W, Maciejewska M, Goworek J. Porosity of polymer materials by various techniques. J Porous Mater. 2009;6(6):691–8.

Maciejewska M, Szajnecki Ł, Gawdzik B. Investigation of the surface area and polarity of porous copolymers of maleic anhydride and divinylbenzene. J Appl Polym Sci. 2012;125:300–7.

Gregg SJ, Sing KSW. Adsorption, surface area and porosity. London: Academic Press; 1982.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Maciejewska, M., Osypiuk-Tomasik, J. Sorption on porous copolymers of 1-vinyl-2-pyrrolidone-divinylbenzene. J Therm Anal Calorim 114, 749–755 (2013). https://doi.org/10.1007/s10973-013-3107-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3107-2