Abstract

The following compounds have been synthesized: (a) hydantoins 5,5-dimethylimidazolidine-2,4-dione (1), 1′,3′-dihydrospiro[imidazolidine-4,2′-indene]-2,5-dione (2), 3′,4′-dihydro-1′H-spiro[imidazolidine-4,2′-naphthalene]-2,5-dione (3); (b) monomers: 5,5-dimethyl-3-(4-vinylbenzyl)imidazolidine-2,4-dione (4), 1-(4-vinylbenzyl)-1′,3′-dihydrospiro[imidazolidine-4,2′-indene]-2,5-dione (5), 1-(4-vinylbenzyl)-3′,4′-dihydro-1′H-spiro[imidazolidine-4,2′-naphthalene]-2,5-dione (6), (two of them are unknown: 5 and 6); (c) macromolecular compounds: poly(chloromethyl-p-styrene) (7), used as reference, and three polymers (two of them are novel) obtained by substitution of hydantoins 1–3 to poly(methyl-p-styrene) (8–10). Their thermal properties have been studied by thermogravimetry. It was found that the chemical structure, tautomerization, and intermolecular interaction influence the thermal stability of substrates. The presence of phenyl rings causes the increase of resistance of studied hydantoins. The obtained polymers are characterized by significantly improved thermal stability comparing to poly (chloromethyl-p-styrene). The mechanism of thermal degradation of investigated polymers and explanation of their thermal resistance has been proposed. The relatively high temperatures of glass transition of polymers have been determined by DSC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polystyrene (PS) is the thermoplastic material applied in numerous industrial branches and its properties are well-known since many years. PS thermal stability had been intensively studied because of few reasons. First of them is understanding its behavior at elevated temperature during processing and using of PS articles. The important is also to know what will happen in the case of fire and if the thermal recycling or incineration during utilization of PS waste is possible and safe [1–5].

PS is often modified for manufacturing the modern plastics with completely different properties than origin polymer. For instance, PS derivatives containing coumarine groups has liquid crystalline properties [6]; p-substitution of the π-conjugated oligothiophenes leads to electro-active polymer [7]; synthesis of living PS with 60-fullerene allows to obtain the dumbbell-like structure characterized by high solubility in many common organic solvent [8].

Other example of PS modification is the synthesis with oligofluorene pendants via Friedel–Crafts reaction, leading to non-conjugated fluorescent polymer for photoelectric devices [9] or manufacturing the stereoregular diblock copolymer of PS and polylactide, which forms the self-assembled nanostructures [10].

Recently PS found the application as the raw material for preparation of novel polymers, which can have the unusual biological properties. Anticoagulant biomaterials were made from PS beads bearing the functional groups of heparin [11]. Insoluble PS substituted with arginine groups exhibited specific interactions with viruses [12]. Other PS derivatives were characterized by the selective surface adhesion of the toxic microalga [13].

In the previous study, we described the synthesis of new biocidal materials based on poly (chloromehtyl-p-styrene), in which the active organic compounds—hydantoin derivatives—were introduced instead of chlorine atoms in macro chains [14]. The preparation of biocidal polymers comprises three steps: the synthesis of hydantoins, synthesis of monomers, and modification of reactive polymer (chloromethylated PS,7). The properties of polymers have been characterized by 13C NMR and FTIR spectroscopy and compared to the properties of poly (chloromethyl-p-styrene).

Obviously, the modification of macromolecular compounds by substitution reaction leads to the changes of theirs thermal stability. Thus, the aim of our study was to examine the thermal resistance of all obtained substrates (initial compounds for synthesis of biocidal monomers: hydantoins of different chemical structure), styrene derivatives (monomers), and polymers with expected biological activity. Besides the thermogravimetry also DSC has been applied for determination of the glass transition of obtained polymers.

Experimental part

Materials

Reagents

Ketones (acetone, 2-indanone, 2-tetralone), potassium cyanide, ammonium carbonate, potassium carbonate anhydrous, AiBN, and all solvents used in this research were purchases from Sigma Aldrich (Saint Louis, MO). All reagents were of high purity and were used without further purification.

Hydantoins

Three different hydantoins (Fig. 1):

-

(1) 5,5-dimethylimidazolidine-2,4-dione

-

(2) 1′,3′-dihydrospiro[imidazolidine-4,2′-indene]-2,5-dione

-

(3) 3′,4′-dihydro-1′H-spiro[imidazolidine-4,2′-naphthalene]-2,5-dione

were synthesized by the Bucherer method [15]. An appropriate amount of ketone, potassium cyanide, and ammonium carbonate in 50% ethanol solution were heated at 60 °C for 6 h in autoclave. The crude derivative was removed by filtration and recrystallized from ethanol or ethyl acetate.

Monomers

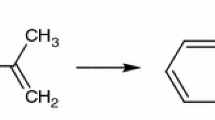

The monomers have been prepared by N-alkylation reaction of listed above hydantoins (1–3) with 4-vinylbenzyl chloride in DMF at the room temperature overnight [16]. The following monomers have been obtained (Fig. 2):

-

(4) 5,5-dimethyl-3-(4-vinylbenzyl)imidazolidine-2,4-dione

-

(5) 1-(4-vinylbenzyl)-1′,3′-dihydrospiro[imidazolidine-4,2′-indene]-2,5-dione

-

(6) 1-(4-vinylbenzyl)-3′,4′-dihydro-1′H-spiro[imidazolidine-4,2′-naphthalene]-2,5-dione

Polymers

The poly (chloromethyl-p-styrene) has been obtained by radical polymerization in bulk at 70 °C in nitrogen atmosphere by 2 h, using azobisisobutyronitrile (AiBN) as initiator. The details of polymerization and characterization of structure of synthesized monomers and polymers (determined by 1H and 13C NMR and FTIR) were described elsewhere [14]. The structures and names of obtained polymers are shown below (Fig. 3):

-

(7) poly(1-(chloromethyl)-4-vinylbenzene)

-

(8) poly(5,5-dimethyl-3-(4-vinylbenzyl)imidazolidine-2,4-dione)

-

(9) poly(1-(4-vinylbenzyl)-1′,3′-dihydrospiro[imidazolidine-4,2′-indene]-2,5-dione)

-

(10) poly(1-(4-vinylbenzyl)-3′,4′-dihydro-1′H-spiro[imidazolidine-4,2′-naphthalene]-2,5-dione).

Methods

Thermogravimetry

All studied hydantoins, obtained monomers and polymers were subjected to thermal analysis, which was carried out using SDT 2920 Simultaneous TG-DTA.

The TG, DTG, and DTA curves were recorded at nitrogen atmosphere from room temperature to 600 °C. The sample mass was about 5 mg and the heating rate was 5°/min.

On-set temperature (T o), temperature of maximum process rate (T max), temperature at the end of decomposition (T end), and weight loss (Δm) were determined from recorded TG and DTG curves.

Melting point

Melting temperature (T m, uncorrected) of dry, homogeneous substrates (hydantoins and monomers) in powdered form has been determined by capillary method using DigiMelt MPA161 melting point apparatus (Standford Research Systems, USA). The temperature at liquefaction point (clear point in which the last crystals were melted) has been chosen as T m.

The compounds have been beforehand accurately purified by recrystallization from ethanol or ethyl acetate.

Differential scanning calorimetry

DSC measurements were carried out in the temperature range of 20–250 °C using Diamond DSC power compensation type (Perkin-Elmer). The indium was used for calibration. The following conditions were applied: helium atmosphere, flow rate—20 mL/min, heating rate of 50 °C/min, sample weight—ca. 5 mg. The samples after 1st run heating has been hold for 3 min at 250 °C, then cooled from 250 to 20 °C at 50 °C/min and again heated with the same rate (2nd run). The glass transition temperature (T g) was obtained from the second heating run as the midpoint of the change in a heat flow versus temperature curve.

Results and discussion

The thermogravimetry of substrates has been conducted for checking if the stability of imidazolidines is dependent on the neighboring groups and if the coupled aromatic-alicyclic rings (tetralin or indan) substituted to poly (p-methylstyrene) influence its thermal resistance.

Thermal analysis of hydantoins

TG, DTG, and DTA curves of substrates (1–3) applied later for the monomer synthesis are presented in Fig. 4. All three hydantoins exhibit the one-step degradation in which almost complete decay is observed (weight loss is about 95–99% at the end of process, i.e., at 600 °C).

Thermal decomposition in compound 1 starts at about 120 °C, while in compounds 2 and 3—at significantly higher temperature (188 and 197 °C, respectively).

The main thermal parameters calculated from TG and DTG curves are listed in Table 1. All parameters confirm the above observation: two hydantoins (2 and 3) are characterized by the higher thermal stability comparing to compound 1. One can conclude that the covalent binding of imidazolidine to five- or six-membered alicyclic ring cumulated with aromatic moiety improves the thermal resistance of monomers. Thus, aromatic rings are mainly responsible for stabilization effect.

Simultaneously, the recorded DTA curves allow to compare the endothermal effect, which is similar in all studied hydantoins.

From these curves, the melting temperature (T m) can be also determined from the first endothermic sharp peak. The obtained T mDTA temperatures of hydantoins are in good agreement with results obtained by classic capillary method (T mcap) and literature values (T mlit, Table 2) [17–19].

The detailed analysis of TG curves leads to the conclusion that thermal decomposition (gradual weight loss) of compounds 1–3 starts already before melting temperature (Fig. 4; Table 2).

Thermal analysis of monomers

The results of thermogravimetry of monomers (4–6) are shown in Fig. 5 and Table 3. The compounds 4 and 5 exhibit the high thermal resistance, their degradation starts above 300 °C and temperature of maximum rate of decomposition in both cases is higher than 400 °C.

The compound 4 decomposes almost completely during heating to 500 °C—the final carbonaceous residue is lower than 1%. TG curve indicates that small amount (~3%) of this sample decomposes already at 190 °C (Fig. 5a), which can indicate the presence of impurities.

The compound 5 shows one degradation step, however, its decay at 500 °C is not completed (~13% residue was found). The lack of any peak at lower temperatures proves the high purity of this specimen (Fig. 5b).

The compound 6 behaves dissimilar than both previous monomers upon heating. As can be seen from Fig. 5c, two separated peaks appear: first of them at relatively low temperature (maximum at about 273 °C). Accompanying weight loss in this step is equal to 28%. The second step with maximum rate at 427 °C is connected to weight loss of about 64%, thus, the final polymer residue at 500 °C is 8%. The monomer 6 is characterized by much lower thermal resistance than 5. This result can be explained by the difference in the chemical structure of compound 5 and 6. Although the six-membered structure is rather stable because of no ring strain, it seems that the rupture of bond between two methyl groups (CH2–CH2) in compound 6 is privileged comparing to CH2–C x split in five-membered ring in compound 5 (where C x is carbon atom in imidazolidine or in phenyl ring).

The main thermal decomposition in studied monomers is endothermic process (DTA down peak). However, the other narrow endothermic peaks appear at lower temperatures, due to the melting point. In the case of compounds 4 and 5, these values (T mDTA) are in good accordance to the melting temperatures (T mcap) determined by classic method (Table 2).

The melting temperatures of monomers increase in the following order:

The larger substituents (indan, tetralin) in pendant groups in macro chains increase the melting temperature in compound 5 and 6 comparing to T m of 4.

The thermal analysis of 4-vinylbenzyl chloride has not been done because it is liquid with high boiling temperature (229 °C) but relatively low flash point (105 °C) [20].

Thermal analysis of polymers

An important property determining the practical application of novel materials is their resistance to heat. The Fig. 6 presents the TG, DTG, and DTA curves for obtained new PS derivatives (8–10). The parameters characterizing the thermal decomposition of polymers are listed in Table 4. Because in the case of partially overlapped degradation steps it is difficult to read the temperature of maximum rate of decomposition from the inflection point on TG, this value was obtained from the differential curve (i.e., DTG). DTA of all polymers do not show any melting peak, which indicates their amorphous character.

Poly (chloromethyl-p-styrene) (chlorometylated PS): compound 7

Thermal degradation of chloromethylated PS (7), used as reference, occurs in two stages, which is in accordance to other data published by Zhao et al. [21]. These authors found also two steps of thermal decomposition for this polymer; moreover, they proved that its thermal stability decreased with increasing content of chloromethyl groups. In this polymer, beside the monomer also hydrogen chloride was the second abundant degradation product [22].

In our study, the degradation steps of polymer 7 start at ~250 and 400 °C, respectively. In the first stage, about 38% of polymer decomposes but in the second step, the weight loss is smaller (about 25%). Moreover, the first step is characterized by the higher rate than the second one. Careful analysis of DTG curve leads to the conclusion that at the end of the second stage, small peak at about 500 °C and corresponding ~10% weight loss appear. It can be assigned to the decomposition of the more stable products formed at both previous stages. The carbonaceous residue at 600 °C is rather big—approximately 30%.

Hydantoin-containing polymers: compounds 8–10

Two studied polymers (8, 9) are characterized by much better thermal stability than chloromethylated PS (7)—their onset temperature of decomposition was raised significantly (Fig. 6; Table 4). However, only small improvement of thermal resistance is observed in the case of polymer 10 (T o and T max of the first step increases about 26 and 18 °C, respectively).

In all these samples, the small (8–11%) weight loss is observed before the main decomposition, just at temperatures about 150 °C, which is probably due to the presence of impurities from polymerization. Similar but smaller peak (and at lower temperature) was found in DTG of chloromethylated PS (7). It indicates the presence of solvent residue, which was difficult to remove although the samples were accurately purified and dried.

Thermal degradation of two polymers (8 and 9) proceeds in one main step, while the compound 10 decomposes in two overlapping stages. These endothermic processes are very fast at about 415 °C but they are not completed even at 600 °C (the char residue is about 20–30%). Only sample 10 differs from both other polymers (8, 9), before the main degradation stage, the new significant peak appears at the range of 300–400 °C. It means that this polymer contains two parts in its structure with completely different thermal resistance.

Taking into account the T o and T max of the main degradation stage (Table 4), it can be stated that thermal stability of polymers 8 and 9 is similar and better than for 10. All new polymers (8–10) are more resistant than polymer 7.

The trend in thermal stability of polymers is the same as observed in monomers. Such results clearly indicate the various thermal resistances of chemical bonds in six- and five-membered ring introduced between imidazolidine and phenyl group.

Glass temperature of polymers (8–10)

DSC analysis of obtained polymers supplied the information on the glass transition temperature (T g). The relatively high rate of heating (50°/min) has to be applied in this experiment because at lower rates the signal was too weak for T g detection.

All DSC curves exhibit the single inflection point which means that homopolymer with uniform structure was obtained during polymerization. The following T g values have been obtained:

-

8—175 °C

-

9—179 °C

-

10—181 °C

The differences in glass temperatures of studied polymers are insignificant. Only polymer 8 shows somewhat lower T g than polymers 9 and 10, which is caused by the lack of cyclic substituents in imidazolidine ring. It should be added that studied polymers 8–10 are characterized by much higher T g than PS (93–110 °C) or chloromethylated PS (7) (76–77 °C) [31, 32].

One can conclude that introduction of imidazolidine and their derivative (containing hydrocarbon conjugated rings) into poly (methyl-p-styrene) significantly increases the chain rigidity. Such high stiffness of macromolecules can be caused by strong interactions between pendant side groups.

It should be added that no relaxation peaks was found on DSC curves indicating the lack of molecular mobility in studied polymers.

Discussion of mechanism of thermal degradation of new poly (methyl-p-styrene) derivatives containing hydantoins

The obtained novel polymers are derivatives of PS, thus, we should remind the main thermal processes occurring in PS.

The mechanism of PS thermal degradation is based on a random main chain scission and depolymerization initiated at unsaturated chain ends. The homolytic breaking of chemical bonds causes the formation of free radicals (main of them are: primary and secondary benzyl macro radicals and allyl benzene radicals stabilized by resonance), which can propagate or terminate [1–3]. In the propagation step, also the tertiary alkyl macro radicals can be created resulting of hydrogen abstraction from the next macromolecule by any neighboring radical.

The other important reactions (dependent on the atmosphere and conditions) are intramolecular abstraction (hydrogen atom or phenyl substituent), crosslinking (via macro radical recombination), oxidation (in the presence of air), and isomerization, addition to unsaturated bonds, rearrangement, and chromophore formation.

The mixture of degradation products of PS is reach in aromatic compounds such as: styrene monomer, dimer, tirmer, and benzene as well as other saturated or unsaturated aliphatic hydrocarbons containing aromatic rings (α-methylstyrene, toluene, ethylbenzene 1,3-diphenylpropane) [3, 5].

The mechanism and rate of thermal degradation can change significantly in the case of modified PS. For example, poly-α-methylstyrene is almost qualitatively depolymerized during heating in the absence of air [1].

It was found that in the case of other para-substituted polystyrenes also monomer is usually the main degradation product, however, the composition of other minor formed compounds is very complex [21–25]. The course of thermal degradation is dependent on the kind and amount of substituents. Alkyne-containing PSs showed the strong tendency to crosslinking, thus, monomer was recovered in very low amount in thermal degradation [24]. The thermostability of PS-derivatives depends on the electronic nature of substituent (electron-donating, electron-attracting) and their possibility to stabilize the macro radicals [23].

The great thermal stability of polymers containing hydantoins in main chain, similarly as other heterocyclic rings, is known [1, 26]. Our studies proved that also hydantoin pendant groups improve the PS thermal resistance.

Obtained results clearly indicate that chemical bonds between methylene side group and nitrogen atom from imidazolidine ring (CH2–N) in PS derivatives (8–9) are much stronger than CH2–Cl in chloromethylated PS (7). It can be explained by the higher energy of dissociation of C–N (179 kcal/mol) comparing to C–Cl bond (93 kcal/mol) [27].

The mechanism of thermal degradation of poly (p-methylstyrene) containing hydantoin substituents can be proposed per analogy to other PS derivatives. It seems obvious that in the case of one step degradation (8, 9), the random main chain scission can overlap side group elimination. The degradation started at rather high temperature indicates that the pendant groups are strongly bound to PS backbone and no low molecular product are evolved before this main stage. Also depolymerization from unsaturated chain ends can occur (the presence of double terminal bonds in our polymers had been confirmed by NMR spectroscopy [14]).

The interesting differences have been found in thermal degradation of polymer 9 and 10. It can be concluded that the energy supplied before main decomposition in compound 8 and 9 is rapidly dissipated among all molecules and bonds. This is typical behavior in condensed systems. In the case of phenyl and imidazolidine rings, the stabilization via resonance is possible. In simple imodazolidone ring five tautomeric forms exist (Fig. 7) [28] while in monomers only three tautomeric structures can be proposed because one nitrogen atom participates in covalent bond (Fig. 8). However, the stability via resonance does not explain the significant differences in the thermal stability of compound 5 and 6 as well as between polymer 9 and 10.

The lower thermal stability of monomer 6 (comparing to 4 and 5) and polymer 10 (comparing to 8 and 9) indicates that additional methylene group in ring probably hampers the energy dissipation. Therefore, the bond CH2–CH2 in side substituent undergoes rupture at lower temperature. One can additionally mention that the heat of combustion calculated per single CH2 group is somewhat lower in cyclohexane (658.6 kJ/mol) than in cyclopentane (664.0 kJ/mol) [29]. Of course, the simple application of these data to our results cannot be done because we studied the thermal decomposition in nitrogen atmosphere, whereas the mentioned above values concern the oxidative conditions.

The other factor influencing the thermal stability in indene substituent (monomer 5 and polymer 9) is resonance stabilization (resulting of electron delocalization owing to only one CH2 group similar to well known resonance in other homoaromatic compounds) that reinforces the structure, thus the bond breaking in ring is more difficult. In this case only the degradation at higher temperatures leads to the decomposition of hydantoin ring, while at lower temperatures its abstraction from polymeric chain is favored. In compound 6 and polymer 10, the presence of one additional methylene group in the acyclic tetralin ring (comparing to indene ring) decreases the structure stiffness, which facilitates the C–C bond breaking with formation of stable benzyl compound.

We can also suppose that enhancement of polymer structure and improvement of its thermal stability is caused by dipol–dipol interactions as well as by hydrogen bonds between pendant groups from vicinal units. Per analogy to substituted hydantoins [30], some examples of such interactions in studied polymers are proposed in Fig. 9. Particularly, amine groups are able to interact with carbonyls, and it can explain the difference between compound 9 and 10. It seems very probable that larger six-membered ring makes the interactions difficult between neighboring side groups. Contrary, the distance between adjacent five-membered rings are short enough for efficient interactions in strengthening the macromolecules (Fig. 9). Such hypothesis can be supported by the comparison of molar volumes (understood as the space occupied by particular groups, which is impenetrable to other fragments of molecule). The molar volume of cyclopentane and cyclohexane group is equal to 46.5 × 10−3 and 56.8 × 10−3L/mol, respectively [31].

The general mechanism of thermal degradation of studied polymers is proposed in Fig. 10 (the most probable breakage points are indicated by dashed lines). The degradation starts when the sufficient energy that exceeds the dissociation energy is absorbed by macromolecules. The main reactions: random chain scission, depolymerization, side group abstraction, and recombination leading to crosslinking or cyclization are expected in all studied polymers (8–10). In the case of substituent elimination, full side groups (Ph-R) or groups without phenyl ring from styrene unit (R) can be abstracted because the C–C bond is weaker than C–N [27]. Low molecular weight degradation products including monomers and eliminated substituents are decomposed at the same range temperature as polymers, which were proved by the thermogravimetry of substrates.

The final step is termination of thermal decomposition, which occurs by recombination of different radicals as well as by disproportionation. Intermolecular recombination causes crosslinking, whereas such reaction in the same macromolecule leads to cyclization.

Figure 11 illustrates the ring opening reaction expected in polymer 10 at relatively low temperatures. As can be seen, o-xylene can be released in this reaction. The opening of rings in imidazolidine (in 4–5, 8–10) or indan (in 5, 9) during heating is not excluded but thermogravimetry indicates that it needs higher temperatures (probably it occurs simultaneously with random chain scission).

Summary and conclusions

The thermal stability (TS) of studied compounds can be summarized as following:

-

Hydantoins: TS(1) < TS(2) ≈ TS(3)

-

Monomers: TS(4) ≈ TS(5) > TS(6)

-

Polymers: TS(8) ≈ TS(9) > TS(10) > TS(7)

Thermal properties of hydantoins and monomers depend on the type of substituents, the possibility of tautomerization as well as hydrogen bond formation. Introduction of tetralin or indan structure to hydantoin improves its thermal resistance.

The obtained methylstyrene-based polymers containing the hydantoin derivatives in para-position are more thermally stable than chloromethylated PS (7). All studied polymers are stable up to around 350 °C and particular good resistance to high temperature exhibit compounds 8 and 9. Only polymer 10 decomposed into 2 stages and its decomposition starts at lower temperature (T o ~270 °C) comparing to 8 and 9. It was explained by higher sensitivity of chemical bond CH2–C x to thermal rupture. Such difference has been also found in obtained monomers. The main reason of observed differences can be the stabilization by hydrogen bonds between side groups which is possible in 4, 5, 8, and 9 but difficult in 6 and 10. The strong interactions in substituents are also the reason of high glass temperatures (175–181 °C).

The enhancement of thermal stability of obtained polymers comparing to other PS derivatives is an advantage from practical point of view. In the case of practical application of these polymers, their high thermal resistance allows for the processing, recycling, and safe usage even at high temperatures.

The broad application of such polymers is predicted due to their potential biocidal activity, which is intensively studied and discussed recently ([33] and references cited herein).

References

Schnabel W. Polymer degradation. Principles and practical applications. Berlin: Akademie-Verlag; 1981.

Cameron GG, Meyer JM, Walter ITM. Thermal degradation of polystyrene. 3. A Reappraisal. Macromolecules. 1978;11:696–700.

Faravelli T, Pinciroli M, Pisano F, Bozzano G, Dente M, Ranzi E. Thermal degradation of polystyrene. J Anal Appl Pyrolysis. 2001;60:103–21.

Yagmur S, Durusoy T. Kinetics combustion of oil shale with polystyrene. Therm J Anal Calorim. 2009;96:189–94.

Miskolczi N, Bartha L, Deak G. Thermal degradation of polyethylene and polystyrene from the packaging industry over different catalysts into fuel-like feed stocks. Polym Degrad Stab. 2006;91:517–26.

Kang H, Kang D, Lee JCh. Liquid crystal alignment properties of polystyrene derivatives containing coumarin side group. Liq Cryst. 2008;35:1005–13.

Hu Z, Reichmanis E. Synthesis of electoactive polystyrene derivatives para-substitued with pi-conjugated oligothiophene via postgrafting functionalization. J Polym Sci Part A Polym Chem. 2011;49:1155–62.

Zheng J, Shen JZ, Pan J, Cai R. Preparation and characterization of novel dumbbell-like [60] fullerene polystyrene derivatives. Synth Metals. 2002;125:375–7.

Hu XD, Wang SH, Hou ZX. Synthesis and photophysical properties of novel polystyrene derivatives containing oligofluorene pendants. Mater Sci Forum, Optoelectronic Mater. 2010;663–665:308–11.

Hsiao TJ, Lee JY, Mao YC, Chen YC, Tsai JC, Lin SC, Ho RM. Stereoregular diblock copolymers of syndiotactic polystyrene derivatives and polyactide: syntheses and self-assembled nanostructures. Macromolecules. 2011;44:286–98.

Dulos E, Dufoureq J, Fougnot C, Jozefowicz M. Adsorption of plasma proteins onto anticoagulant polystyrene derivatives: a fluorescence study. Biomaterials. 1988;9:405–12.

Imbert-Laurenceau E, Crepinior J, Crance JM, Jouan A, Migonney V. Polystyrene derivatives substituted with arginine interact with Babanki (Togaviridae) and Kedougou (Flaviviridae) viruses. J Med Virol. 2003;69:503–9.

La Barre S, Hamadouche N, El Khadali Z, Gottini Y, Muller D, ERard-Le Denn E, Jozefowicz M. Selective surface adhesion of the toxic microalga Alexandrium minutum induced by contact with substituted polystyrene derivatives. J Biotechnol. 2002;93:59–71.

Ziegler-Borowska M, Chylińska M, Kaczmarek H, Eur Polym J. Submitted.

Day AR, Kelly CF. The chemistry of the hydantoins. J Org Chem. 1939;4:101.

Ziegler-Borowska. M, Chylińska M, Kaczmarek H. Patent no P.395.035. submitted May 27. 2011.

Wagner EC, Baizer M. 5,5-dimethylhydantoin. Org Synth. 1955;3:323–24.

Pesquet A, Daich A, Van Hiffte L. General and versatile entry to 4,5-fused polycyclic imidazolones systems. Use of the tandem transposition/п-cyclization of N-acyliminium species. J Org Chem. 2006;71:5303–11.

Sun Y, Sun G. Durable and refreshable polymeric N-halamine biocides containing 3-(4′-vinylbenzyl)-5,5-dimethylhydantoin. J Polym Sci: Part A: Polym Chem. 2001;39:3348–55.

Catalog online—http://www.chemblink.com/products/1592-20-7.htm.

Zhao H, Guo J, Li J, Gao L, Bian C. Synthesis and thermal property of linear chloromethylated polystyrene. Adv Mater Res, Adv Compos. 2010;150–151:1504–7.

Boinon B, Ainad-Tabet D, Montheard JP. Kinetics and mechanism of the thermal degradation of poly-p-chloromethylstyrene. Thermogravimetric and gas chromatography-mass spectrometry studies. J Anal Appl Pyrolysis. 1988;13:171–81.

Zuev VV, Bertini F, Audisio G. Thermal degradation of para-substituted polystyrenes. Polym Degrad Stab. 2001;71:213–21.

Bertini F, Audisio G, Kiji J, Fujita M. Thermal degradation of alkylene-containing polystyrenes. J Anal Appl Pyrolysis. 2003;68–69:61–81.

Al Ani KE, Barghouthi MA, Buzor MA. Solvent effect on thermal degradation of plasticized para-substituted polystyrenes. Polym Degrad Stab. 2006;91:3252–8.

Salle RH, Sillion BJ, de Gaudemaris GP. A new class of heterocyclic polymers: polyhydantoins. J Polym Sci: Part A-1. 1966;14:2903–6.

Lide DR, Haynes WM. CRC handbook of chemistry and physics: a ready-reference book of chemical and physical data. Boca Raton: CRC Press; 2009.

Safi Z S, Abu-Awwad FM. Tautomerism of 5-methyl imidazolidine thio derivatives in the gas phase: a density functional study. E-J Chem. 2008;5:884–93.

Solomons TWG. Organic chemistry. 6th ed. New York: Wiley; 1996. p. 148.

Kleinepeter E, Heydenreich M, Kalder L, Koch A, Henning D, Kempter G, Benassi R, Taddei F. NMR spectroscopic and theoretical structural analysis of 5,5-disubstituted hydantoins in solution. J Mol Struct. 1997;403:111–22.

Van Krevelen DW. Properties of polymers. 3rd ed. Amsterdam: Elsevier; 1990.

Traiphol R. Influence of chain heterogenity on instability of polymeric thin films: dewetting of polystyrenes, polychloromethylstyrenes and its copolymers. J Colloid Interface Sci. 2007;310:217–28.

Chylińska M, Kaczmarek H. Polymeric biocides based on N-halamines: current state-of-the art. Polimery. 2012; 57, no 1 (in print, in Polish) and references therein.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Kaczmarek, H., Chylińska, M. & Ziegler-Borowska, M. Thermal properties of novel polymers based on poly(hydantoin-methyl-p-styrene) and their substrates. J Therm Anal Calorim 110, 1315–1326 (2012). https://doi.org/10.1007/s10973-011-2076-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-2076-6