Abstract

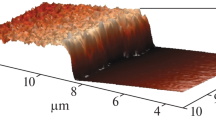

Carbonaceous films containing Pd nanocrystals can be applied as active layers in gas sensor applications. In this article we show results of studies of C-Pd films, obtained with two different methods: (1) physical and (2) physical + chemical deposition. First type of film prepared by physical vapor deposition (PVD) process was composed of fullerenes, amorphous carbon, and palladium nanograins. In the second method PVD film was modified in chemical vapor deposition (CVD) process forming a foam-like structure. Both types of films were studied by SEM, TEM, TGA, and electrical characterization (measurement of resistivity versus composition of gaseous hydrocarbons mixture).

Similar content being viewed by others

References

Sinha N, Ma J, Yeow JTW. Carbon nanotube based sensor. J Nanosci Nanotechnol. 2006;6(3):573–90.

Kong J, Franklin NR, Zhou C, Chapline MG, Peng S, et al. Nanotube molecular wires as chemical sensors. Science. 2000;287:622–5.

Zhao J, Buldum A, Han J, Lu JP. Gas molecule adsorption in carbon nanotubes and nanotube bundles. Nanotechnology. 2002;13:195–200.

Penza M, Antolini F, Vittori MA. Carbon nanotubes as SAW chemical sensors materials. J Sens Actuators B. 2004;100:47–59.

Li J, Lu Y, Ye Q, Cinke M, Han J, Meyyappan M. Carbon nanotube sensors for gas and organic vapor detection. Nano Letters. 2003;3(7):929–33.

Lu Y, Li J, Han J, Ng H-T, Binder C, Partridge C, Meyyappan M. Room temperature methane detection using palladium loaded singlewalled carbon nanotube sensors. Chem Phys Lett. 2004;391:344–8.

Young P, Lu Y, Terrill R, Li J. High sensitivity NO2 detection with carbon nanotubes - gold nanoparticle composite films. J Nanosci Nanotechnol. 2005;5(9):1509–12.

Rode AV, Hyde ST, Gamaly EG, et al. Structural analysis of a carbon foam formed by a high pulse-rate laser ablation. Appl Phys A. 1999;69:S755–9.

Chen Ch, Kennel EB, Stiller AH, et al. Carbon foam derived from various precursors. Carbon. 2006;44:1535–43.

Ford WD: US Patent 3121050. 1964.

Googin J, Napier J, Scrivner M: US Patent 3345440. 1967.

Inagaki M, Morishita T, Kuno A, et al. Carbon foams prepared from polyimide using urethane foam template. Carbon. 2004;42:497–502.

Ying JY, Garcia-Martinez J, Lancaster TM: US Patent Pub. No. WO/2005/102964. 2005.

Rode AV, Elliman RG, Gamaly EG, et al. Electronic and magnetic properties of carbon nanofoam produced by high-repetitionrate laser ablation. Appl Surf Sci. 2002;197–198:644–9.

Gjurova K, Troev K, Bechev Chr, Borisov G. Thermal behavior of rigid polyurethane foams. J Therm Anal. 1986;31:853–9.

Gjurova K, Troev K, Bechev Chr, Borisov G. A study of rigid polyurethane foam containing reactive antypirenes. J Therm Anal. 1987;32:97–105.

Hakateyama H, Kosugi R, Hatakeyama T. Thermal properties of lignin-and molasses-based polyurethane foams. J Therm Anal Cal. 2008;92:419–24.

Czerwosz E, Kowalska E, Wronka H, Radomska J: Patent notification nr P384 591. 2008.

Czerwosz E, Diduszko R, Dłużewski P, et al. Properties of Pd nanocrystals prepared by PVD method. Vacuum. 2008;82:372–6.

Gallagher PK, Gross ME. The thermal decomposition of palladium acetate, J Therm Anal. 1986;31:1231–41.

Fang PH. Diffusion mechanism of fullerene extraction from soot. Materials Research Innovations. 2000;4:1:60–3.

Hydrogen Sensor, Fast, Sensitive, Reliable and Inexpensive to Produce, 2006 Argonne National Laboratory, http://www.anl.gov/techtransfer/pdf/Profile_HydrogenSensor9_06.pdf.

Luongo K, Sine A, Bhansali S. Development of a highly sensitive porous Si based hydrogen sensor using Pd nano-structures. Sens Actuators B. 2005;111–112:125–9.

Acknowledgements

This research was co-financed by the European Regional Development Fund within the Innovative Economy Operational Programme 2007-2013 (“Development of technology for a new generation of the hydrogen and hydrogen compounds sensor for applications in above normative conditions”, No UDA-POIG.01.03.01-14-071/08-00) No UDA-POIG.01.03.01-14-071/08-00).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kowalska, E., Czerwosz, E., Kozłowski, M. et al. Structural, thermal, and electrical properties of carbonaceous films containing palladium nanocrystals. J Therm Anal Calorim 101, 737–742 (2010). https://doi.org/10.1007/s10973-010-0869-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-0869-7