Abstract

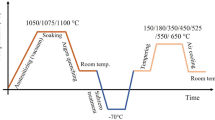

A Maraging M300 steel was produced by ball milling of elemental powders and Spark Plasma Sintering (SPS) consolidation at two different temperatures (950 and 1050 °C). Two types of nanostructured steels have been obtained. Thermal behaviors of these steels were investigated by means of Differential Scanning Calorimetry (DSC) and Dilatometry. Data provided by the two different techniques were seen to be in good agreement. A difference between the behaviors of the steel sintered at 950 °C and that sintered at 1050 °C was observed, due to the material sintered at lower temperature being more reactive to the intermetallics precipitation and austenite reversion on heating. On cooling, it shows a single martensite start temperature (Ms), whereas the steel sintered at 1050 °C shows a double peak for Ms.

Similar content being viewed by others

References

ASM handbook, vol. 1. ASM International, Materials Park, OHIO, USA, 2005. pp. 1225–1237.

Decker RF, Floreen S. Maraging steels-the first 30 years. In: Wilson RK, editors. Maraging steels: recent developments and applications. The Minerals, Metals & Materials Society, Warrendale, Pennsylvania; 1988. p. 1.

Servant C, Lacombe P. Structural transformations produced during tempering of Fe–Ni–Co–Mo alloys. J Mater Sci. 1977;12:1807–26.

Sha W, Cerezo A, Smith GDW. Phase chemistry and precipitation reactions in maraging steels: part I. Introduction and study of co-containing C-300 steel. Metall Trans A. 1993;24:1221–32.

Tewari R, Mazumder S, Batra IS, Dey GK, Banerjee S. Precipitation in 18 wt% Ni maraging steel of grade 350. Acta Mater. 2000;48:1187–200.

Pardal JM, Tavares SSM, Terra VF, Da Silva MR, Dos Santos DR. Modeling of precipitation hardening during the aging and overaging of 18Ni–Co–Mo–Ti maraging 300 steel. J Alloy Comp. 2005;393:109–13.

Peters DT. A study of austenite reversion during aging of maraging steels. Trans ASM. 1968;61:62.

Menapace C, Libardi S, D’Incau M, Molinari A. Advances in powder metallurgy & particulate materials. In Proceedings of PM2008, international conference on powder metallurgy and particulate materials, vol. 9, Washington 8–12 June 2008, MPIF, Princeton, New Jersey; 2008. pp. 402–406.

Wilson EA. Quantification of early stages of age hardening in Fe–12Ni–6Mn maraging type alloy. Mater Sci Tech. 1998;14:277–82.

He Yi, Yang Ke, Guo Zhanli, Liu Kai. Age hardening and mechanical properties of a 2400 MPa grade cobalt-free maraging steel. Metall Mater Trans A. 2006;37:1107–16.

Pektas I, Atala H. The effects of various heat treating parameters on the hardness and microstructures of the experimental 18% Nickel maraging steels. J Therm Anal Calorim. 1998;54:803–14.

Kapoor R, Kumar L, Batra IS. A dilatometric study of the continuous heating transformations in 18wt.% Ni maraging steel of grade 350. Mater Sci Eng A. 2003;352:318–24.

Wilson EA. Quantification of age hardening in an Fe–12Ni–6Mn alloy. Scripta Mater. 1997;36(10):1179–85.

Kladaric I, Krumer D, Markovic R. The influence of multiple-solution annealing on kinetics of structural transformation of maraging steels. Mater Manuf Process. 2006;21:783–5.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Menapace, C., Lonardelli, I. & Molinari, A. Phase transformation in a nanostructured M300 maraging steel obtained by SPS of mechanically alloyed powders. J Therm Anal Calorim 101, 815–821 (2010). https://doi.org/10.1007/s10973-010-0745-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-0745-5