Abstract

In this study, polycardanol, which was synthesized by enzymatic oxidative polymerization of thermally treated cashew nut shell liquid (CNSL) using fungal peroxidase, was partially or fully cured using methyl ethyl ketone peroxide (MEKP) as initiator and cobalt naphthenate (Co-Naph) as accelerator. The curing behavior of polycardanol was extensively investigated in terms of curing temperature, curing time, concentration of initiator and accelerator, and the monomer-to-polymer conversion of polycardanol by means of differential scanning calorimetry (DSC). The curing behavior significantly depends on the thermal condition given and it was monitored with the change of the exotherms as a function of temperature. The optimal conditions for fully curing polycardanol are 1 wt% MEKP, 0.2 wt% Co-Naph, curing time 120 min, and curing temperature 200 °C. This study suggests that a polycardanol with high monomer-to-polymer conversion would be useful for processing a polycardanol matrix composite under the optimal conditions of curing.

Similar content being viewed by others

References

Ikeda R, Tanaka H, Uyama H, Kobayashi S. A new crosslinkable polyphenol from a renewable resource. Macromol Rapid Commun. 2000;21:496–9.

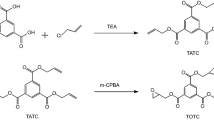

Kim YH, An ES, Park SY, Song BK. Enzymatic epoxidation and polymerization of cardanol obtained from a renewable resource and curing of epoxide-containing polycardanol. J Mol Catal B. 2007;45:39–44.

Park SY, Kim YH, Song BK. Polymer synthesis by enzyme catalysis. Polym Sci Technol. 2005;16:342–53.

Kim YH, Won K, Kwon JM, Jeong HS, Park SY, An ES, et al. Synthesis of polycardanol from a renewable resource using a fungal peroxidase from Coprinus cinereus. J Mol Catal B. 2005;34:33–8.

Won K, Kim YH, An ES, Lee YS, Song BK. Horseradish peroxidase-catalyzed polymerization of cardanol in the presence of redox mediators. Biomacromolecules. 2004;5:1–4.

Sharma P, Choudhary V, Narula AK. Curing and thermal behaviour of epoxy resin in the presence of a mixture of imide-amines. J Therm Anal Calorim. 2008;94:805–15.

Jovičić MC, Radičević RŽ, Budinski-Simendić JK. Curing of alkyds based on semi-drying oils with melamine resin. J Therm Anal Calorim. 2008;94:143–50.

Ikeda R, Tanaka H, Uyama H, Kobayashi S. Synthesis and curing behaviors of a crosslinkable polymer from cashew nut shell liquid. Polymer. 2002;43:3475–81.

Tawfik SY, Asaad JN, Sabaa MW. Effect of polyester backbone structure on the cured products properties. Polym Test. 2003;22:747–59.

Nazareth da Silva AL, Teixeira SCS, Widal ACC, Coutinho FMB. Mechanical properties of polymer composites based on commercial epoxy vinyl ester resin and glass fiber. Polym Test. 2001;20:895–9.

Kim H-S, Choi S-W, Lee B-H, Kim S, Kim H-J, Cho CW, et al. Thermal properties of bio-flour-filled polypropylene bio-composites with different pozzolan contents. J Therm Anal Calorim. 2007;89:821–7.

Lee HS, Cho D, Han SO. Effect of natural fiber surface treatments on the interfacial and mechanical properties of henequen/polypropylene biocomposites. Macromol Res. 2008;16:411–7.

Kim H-S, Kim H-J, Cho D. Thermal analysis of hydrolysis and degradation of biodegradable polymer and bio-composites. J Therm Anal Calorim. 2009;96:211–8.

Mwaikambo LY, Ansell MP. Hemp fibre reinforced cashew nut shell liquid composites. Compos Sci Technol. 2003;63:1297–305.

Aziz SH, Ansell MP. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: part 2-cashew nut shell liquid matrix. Compos Sci Technol. 2004;64:1231–8.

Maffezzoli A, Calo E, Zurlo S. Cardanol based matrix biocomposites reinforced with natural fibres. Compos Sci Technol. 2004;64:839–45.

Zhou Q. Studies on cure behavior of polycardanol and various natural fiber/polycardanol biocomposites. Master Thesis, Kumoh National Institute of Technology, Gumi, Korea; 2008.

Pryde CA. IR studies of polyimides. I. Effects of chemical and physical changes during cure. J Polym Sci A. 1989;27:711–24.

Cho D, Drzal LT. Characterization, properties, and processing of LaRC PETI-5 as a high-temperature sizing material. II. Thermal characterization. J Appl Polym Sci. 2000;75:1278–87.

Acknowledgment

This work was financially supported by the Korea National Cleaner Production R&D Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Q., Cho, D., Song, B.K. et al. Curing behavior of polycardanol by MEKP and cobalt naphthenate using differential scanning calorimetry. J Therm Anal Calorim 99, 277–284 (2010). https://doi.org/10.1007/s10973-009-0171-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0171-8