Abstract

Ethoxysilanes were hydrolyzed, and the resulting hydrolyzates were dimethylsilylated to produce Si–H terminated oligosiloxanes (CLs). These CLs were characterized using gel permeation chromatography, nuclear magnetic resonance, and Fourier-transform infrared spectroscopy. The results indicated the formation of highly condensed cyclic siloxanes, four-membered cyclic siloxanes, and linearly condensed cyclic siloxanes when derived from tetraethoxysilane, hexaethoxydisiloxane, and octaethoxytrisiloxane, respectively. The CLs were subsequently reacted with vinyl-terminated polydimethylsiloxane in the presence of the Karstedt catalyst to yield PDMS elastomers, which are comprised of di- and quadra-functional silicones. Tests for transmittance, thermal properties, tensile strength, and swelling in toluene were conducted to assess the impact of the molecular weight and microstructure of the CLs on the final products. As the number of silicon atoms in the ethoxysilanes increased, there was a rise in the secant modulus and a reduction in the degree of swelling. These findings suggest that the structure of PDMS elastomers can be tailored by varying the structure of the ethoxysilanes used as a cross-linking agent.

Graphical Abstract

Highlights

-

Si–H terminated oligosiloxanes were synthesized from hydrolyzates of tetraethoxysilane, hexaethoxydisiloxane, or octaethoxytrisiloxane and chloro(dimethyl)silane.

-

PDMS elastomers were synthesized via the hydrosilylation of the Si–H terminated oligosiloxanes with vinyl-terminated polydimethylsiloxane.

-

Secant modulus increased, while the degree of swelling decreased, with an increase in the number of silicon atoms in ethoxysilanes.

-

Mechanical testing and the swelling test in toluene demonstrated that the structure of PDMS elastomers can be influenced by the structure of ethoxysilanes used as a cross-linking agent.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Organic–inorganic hybrid materials are composed of organic and inorganic components, offering the potential for novel functions and applications by combining the advantages of each component [1, 2]. Sanchez et al. proposed a classification for organic–inorganic hybrid materials based on the hybridization of organic and inorganic components, ranging from a few Ångstroms to several nanometers in length [3, 4]. Class I hybrid materials are characterized by weak interactions, such as van der Waals forces, hydrogen bonding, coordination bonding, electrostatic forces, among others, between the organic and inorganic segments. Conversely, Class II hybrid materials are formed through stronger interactions, like covalent and ionic bonds.

Our research has also delved into organic–inorganic hybrid materials. Examples include triethoxysilyl modified C60, polyhedral oligomeric silsesquioxane, and titanium phosphonate clusters as inorganic segments, combined with hydroxy-terminated polydimethylsiloxane (PDMS) as the organic segment, resulting in Class II hybrid materials [5,6,7]. Notably, the siloxane/epoxy hybrid within Class II displayed enhanced physical properties, exhibiting high mechanical strength when the organic and inorganic polymers were joined through covalent bonds [8].

Recently, we discussed the hydrolysis-condensation reaction of ethoxysilanes, known to form during the early stages of the sol–gel reaction of tetraethoxysilane (TEOS) [9]. Our findings indicate that TEOS, hexaethoxydisiloxane (HEDS), and octaethoxytrisiloxane (OETS) produce polymers with distinct characteristics: network-type polymers containing cyclic siloxanes, polymers containing cyclic siloxanes with four silicon atoms, and polymers containing various cyclic siloxanes, respectively. These results shed light on the structural and chemical variations in the starting materials. This type of findings suggests the potential application of hydrolyzates derived from ethoxysilanes as inorganic components in organic–inorganic hybrid materials. Moreover, to fine-tune the properties of PDMS-based hybrid materials, the structure of the inorganic segment is considered pivotal [10].

In this study, we investigated difference in cross-linking capability and physical properties depending on oligosiloxane cross-linker in PDMS silicone elastomers. The PDMS silicone elastomers were prepared by the follows: Si–H terminated oligosiloxanes (CLs) were synthesized by hydrolysis–condensation of ethoxysiloxanes (TEOS, HEDS, OETS) followed by silylation with Me2HSiCl, and then PDMS silicone elastomers (PDMS–CLs) were prepared by hydrosilylation between vinyl-terminated PDMS (PDMS–Vi) and CLs (Scheme 1). The structures of CLs were determined by nuclear magnetic resonance. The properties of PDMS–CLs were evaluated by thermal stabilities, swelling behavior in toluene, and tensile strength tests, and differences in CLs were compared.

2 Experimental sections

2.1 Measurements

Nuclear magnetic resonance (NMR) spectra were recorded using a JNM-ECZ 400 spectrometer (JEOL, Japan; 1H: 399.00 MHz, 29Si{1H}: 79.00 MHz). The chemical shifts were reported in ppm relative to residual chloroform in deuterated chloroform (CDCl3) (for 1H: 7.26 ppm) or residual tetrahydrofuran (THF) in THF-d8 (for 1H: 1.72 ppm) and tetramethylsilane (for 29Si{1H}: 0.00 ppm) as the internal standards. For 29Si{1H} NMR spectra, chromium(III) acetylacetonate was added to the sample as a paramagnetic relaxation agent. Fourier–transform infrared (FTIR) spectra were recorded on a FT/IR-6100 spectrophotometer (JASCO, Japan) via the neat method, in which the sample is sandwiched between two KBr crystal disks, or via attenuated total reflectance (ATR) method using a JASCO ATR PRO 0450-S (ZnSe prism). Thermal gravimetric analysis (TGA) was performed using a TG-DTA analyzer 2000SE (Netzsch Japan, Japan) at a heating rate of 10 °C min−1 up to 1000 °C under nitrogen or air flow. Ultraviolet-visible (UV–Vis) transmittance spectra were recorded using a V-670 UV–VIS/NIR spectrophotometer (JASCO, Japan) with an integrating sphere (ISN-470 type). High-resolution electrospray ionization time-of-flight mass spectrometry (HR-ESI-TOF MS) was performed using a JMS-T100CS AccuTOF CS (JEOL, Japan). Gel permeation chromatography (GPC) was performed using a LC-20AD HPLC prominence liquid chromatograph (Shimadzu, Japan) attached to a Plgel 5-μm Mixed-D column. THF was used as an eluent (1 mL min−1), and a RID-20A was used as the detector at 40 °C. The number-average molecular weight (Mn), weight–average molecular weight (Mw), and polydispersity (Mw/Mn) were calculated based on the standard polystyrene. Scanning electron microscopy (SEM) was performed using a JCM-6000 (JEOL, Japan) instrument with an accelerating voltage of 15 kV. The tensile strength test of samples, which were cut to a size of 30 mm × 5 mm, was evaluated using a MCT-2150 (A&D, Japan) at a tensile speed of 10 mm/min at approximately 23 °C. A swelling test was evaluated by solvent uptake of samples immersed in toluene for 3 days. The degrees of swelling (DS) for the samples were calculated using the following equation: DS (%) = 100 × (Wa − Wb)/Wbwhere Wa and Wb denote the weight after and before sample immersion, respectively.

2.2 Materials

Ethanol (EtOH), THF, toluene, and diethylether were purified via standard processes and stored over activated molecular sieves. Tetraisocyanatosilane was provided by Matsumoto Fine Chemical Co., Ltd (Japan). Octamethylcyclotetrasiloxane (D4) was purchased from Shin–Etsu Chemical (Japan). Ammonium carbonate ((NH4)2CO3) and potassium hydroxide (KOH) were purchased from Kanto Chemical Co., Inc. (Japan). N,N-Dimethylformamide (DMF) and 6 M hydrochloric acid (HCl aq.) were purchased from FUJIFILM Wako Pure Chemical Corporation (Japan). TEOS, thionyl chloride (SOCl2), chlorodimethylsilane, and chlorodimethylvinylsilane were purchased from Tokyo Chemical Industry Co. Ltd (Japan). PDMS–OH (45–85 cSt) and Karstedt catalyst (0.1 M in xylene solution) were purchased from Sigma-Aldrich (Tokyo, Japan). TEOS and tetraisocyanatosilane were purified by distillation. Hexaethoxydisiloxane (HEDS) and octaethoxytrisiloxane (OETS) were synthesized according to previous report [10]. KOH powder was prepared as follows: KOH pellets were dissolved in EtOH and reprecipitated with THF followed via drying under vacuum at 90 °C for 3 h [11]. Dimethylvinylsiloxy terminated polydimethylsiloxane (PDMS–Vi) was prepared by the ring–opening polymerization of D4 with KOH powder followed by silylation using chlorodimethylvinylsilane, and Mw and Mw/Mn of PDMS–Vi were 49,000 Da and 3.3, respectively. Low-molecular dimethylvinylsiloxy terminated polydimethylsiloxane (Low-PDMS–Vi) was prepared by the reaction of PDMS–OH with chlorodimethylvinylsilane. The preparation methods and characterization are provided in Supporting Information.

2.3 Synthesis of Si–H terminated oligosiloxane cross–linkers (CLTEOS, CLHEDS, CLOETS)

HCl aq. was slowly added to EtOH solution of ethoxysilane monomer (TEOS, HEDS, OETS). These molar ratios were HCl/Si = 0.1 (HCl/TEOS = 0.1, HCl/HEDS = 0.2, HCl/OETS = 0.3), H2O/Si–OEt=0.5 (H2O/TEOS = 2, H2O/HEDS = 3, H2O/OETS = 4), and EtOH/Si=10 (EtOH/TEOS = 10, EtOH/HEDS = 20, EtOH/OETS = 30). The mixture was stirred in an ice bath for 10 min. Then, the mixture was stirred for 3 h at room temperature (approximately 23 °C). Chlorodimethylsilane (equimolar ratio of added H2O) was added with stirring in an ice bath for 10 min. The mixture was poured into a mixed solvent of THF/hexane (1/2 v/v) followed by washing with water for twice and brine for twice. The organic layer was dried over anhydrous sodium sulfate, filtered, and then evaporated. The resulting Si–H terminated oligosiloxane cross-linkers were obtained as a colorless liquid.

2.4 Model reaction of low-PDMS–Vi and CLTEOS with Karstedt catalyst

Low-PDMS–Vi (0.06 g) and CLTEOS (0.04 g) were dissolved in THF-d8 (0.75 ml) followed by addition of 1 μl of Karstedt catalyst (0.1 M in xylene solution). The progress of hydrosilylation was monitored by measuring 1H NMR spectra at specific time intervals.

2.5 Preparation of PDMS-CLs

A 1-g mixture, containing PDMS–Vi and Si–H terminated oligosiloxane cross-linkers (at concentrations of 10 wt%, 20 wt%, and 40 wt% relative to PDMS–Vi), was dissolved in 4 g of THF. To this solution, 10 μl of Karstedt catalyst (0.1 M in xylene solution) was added and the mixture was stirred for 30 min. Subsequently, the mixture was poured into a 50-mm ϕ Teflon Petri dish. It was then cured at 50 °C for one day, followed by heating at 150 °C for an additional day. The resulting PDMS–CLs were obtained as elastomers.

3 Results and discussion

3.1 Characterization of Si–H terminated oligosiloxane cross-linkers (CLs)

The 29Si{1H} NMR spectra of the hydrolysis condensates of TEOS, HEDS, and OETS, before and after silylation, are presented in Fig. 1. Before silylation, all hydrolysis condensates primarily displayed signals corresponding to the 4-membered cyclic Q2(OEt)(OH) (−92.7 ppm) and 4-membered cyclic Q2(OEt)2 (−95.1 ppm). Minor signals associated with Q1(OEt)2(OH) (around −86 ppm), cyclic Q2(OH)2 (−90.6 ppm), Q3–OH (−99.6 to −101 ppm), and Q3–OEt (−101.5 to −103 ppm) were also observed [10, 12,13,14]. Small signals due to 5- or 6-membered cyclic Q2(OEt)2 (−95.4 ppm) were observed in the hydrolysis condensates of TEOS and OETS before silylation [11, 15]. Following silylation, complex signals attributed to the dimethylsiloxyl group emerged between −1 to −5 ppm [12]. All the silylated hydrolyzates (CLTEOS, CLHEDS, and CLOETS) included end-group Q1(OEt)3 (−89.0 ppm), 4-membered cyclic Q2(OEt)2 (−95.3 ppm), and linear Q2(OEt)2 (−96.5 ppm). The Q3 and Q4 units were evident between −99 to −105 ppm and −105 to −110 ppm, respectively, but their detailed structures remained unidentified. Table 1 provides GPC results, OEt/Si–H ratios, siloxane unit ratios, and the degree of crosslinking (DC). The OEt/Si–H ratios of the CLs showed no discernible differences.

FTIR spectra of CLs are shown in Supplementary Fig. S1. The adsorption bands due to υSi–H (2139 cm−1), δCH3 (approximately 1255 cm−1), δSi–Me (approximately 1155 cm−1), υCC (970 cm−1), and ρSi–Me (903 cm−1) were observed, indicating the completion of the silylation process [12, 16]. The absorption bands due to υasCH3 (approximately 2977 cm−1), υsCH2 (approximately 2930 cm−1), υsCH3 (approximately 2897 cm−1), υCO (approximately 1100 cm−1), υasSi–O–Si (approximately 1080 cm−1), ρCH3 in Si–CH3 (860 cm−1), υsSi–O–Si (795 cm−1), and δCCO and δSiOSi (approximately 455 cm−1) were also observed [11, 12, 17, 18].

Supplementary Fig. S2 presents the mass spectra of the CLs. These spectra indicate the presence of a variety of chemical species, spanning from trisiloxane to octasiloxane. However, precise interpretations of the CLs’ mass spectra are challenging due to the existence of structures with overlapping molecular weights.

Figure 2 provides schematics of the anticipated structures of the CLs. Specifically, CLTEOS primarily consists of cyclic siloxane derivatives, which were converted from mainly Q1 and Q2 to Q4 due to silylation. CLHEDS is largely made up of 4-membered cyclic siloxane derivatives, transitioning chiefly from Q2 to Q4 due to silylation. Meanwhile, CLOETS primarily consists of cyclic siloxane derivatives, converting mainly from Q2 to both Q3 and Q4 as a result of the silylation process.

3.2 Properties of PDMS cross- linked with Si–H terminated TEOS, HEDS, and OETS oligomers (PDMS–CLs)

To confirm progression of hydrosilylation between PDMS–Vi and CLs, hydrosilylation reaction between Low-PDMS–Vi and CLTEOS in THF-d8 as a model reaction was monitored by 1H NMR (Fig. 3). Signals due to vinyl and hydrosilyl groups were appeared at 5.7–6.2 and 4.8 ppm, respectively, and these integral ratios decreased with increasing time (Fig. 4). The signals attributed to methylene (SiCH2) moieties were confirmed at 0.55 ppm [19, 20], and this integral ratio increased with increasing time (Fig. 4). This suggests that β-addition reaction proceeded [20]. 2 h after the start of the reaction, vinyl group was detection limit on 1H NMR. These results suggested that hydrosilylation between PDMS-Vi and CLs and β-addition reaction mainly proceeds.

Supplementary Fig. S3 presents the FT-IR spectra of PDMS–CLs and PDMS–Vi acquired using the ATR method. Absorption bands of PDMS chain attributed to υasCH3 (2962 cm−1), υsCH2 (2903 cm−1), δCH3 in Si–CH3 (1258 cm−1), ρCH3 in Si–CH3 (860 cm−1), both υSi–C (785 cm−1), and υSi–C (700 cm−1) were observed [11, 12, 17, 18]. Strong bands associated with υasSi–O–Si (1060 cm−1), υO–Si–O (1010 cm−1), δSiCH3 and υSiO4 (780 cm−1), and υSi–O (750 cm−1) emerged, with the υO–Si–O (1010 cm−1) and υSi–O (750 cm−1) being bands derived from the PDMS chain [17, 18, 21]. No absorption band attributed to υSi–H (2139 cm−1) was detected, supporting the progress of the hydrosilylation reaction [12, 16]. Fig. 4b. [12, 19]. The absorption bands of the ethoxy group were discerned at ρCH3 (1160 cm−1), υC–O (1070 cm−1), υC–C (970 cm−1), and ρCH2 (848 cm−1) [12, 21, 22].

The surface morphology of PDMS–CLs with 40 wt% was observed using scanning electron microscopy (SEM). Some spherical accumulation domains (1–2 μm) were observed in the surface, which may be attributed to aggregation of CLs (Fig. 5). Although the aggregation phenomenon was appeared PDMS–MQ elastomer prepared by condensation reaction of PDMS–OH with MQ polymer [23].

The physical attributes of PDMS–CLs were assessed based on their transmittance, temperatures corresponding to 5% weight loss (Td5), their swelling behavior in toluene, and tensile strength tests. Although PDMS–CLs displayed good transparency (≥80% at 500 nm), their appearance was tinted due to the inclusion of the Pt catalyst (as seen in Supplementary Fig. S4) [24]. Elastomer without Karstedt catalyst was investigated as a control experiment; however, brittle and weakness elastomer was obtained (Supplementary Fig. S4).

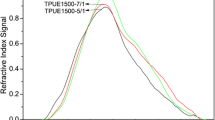

Thermal properties were investigated using TGA in a nitrogen atmosphere. The TGA profiles of PDMS–Vi and PDMS–CLs are depicted in Fig. 6. Td5 value of PDMS–Vi was 364 °C, and the residual mass at 1000 °C was 5.5. This is due to formation and elimination of cyclic siloxanes such as D3 and D4 through a depolymerization process by the thermal degradation of PDMS under a nitrogen flow [25]. Td5 values for PDMS–CLs increased to 420–480 °C. Increased crosslinking can inhibit random polymer main chain degradation [26,27,28,29] because PDMS primarily depolymerizes from its chain ends and then random main chain degradation at elevated temperatures in an inert environment [26]. Hence, improvement of Td5 values attributed to the increased crosslink density. However, there was a tendency to decrease Td5 values with increasing addition amounts of CLs. Since ethoxy groups undergo decomposition between 250–350 °C [30, 31], decomposition of ethoxy group caused the decrease in Td5 values. The residual masses for PDMS–CLHEDS and PDMS–CLOETS increased in the order 20 wt% > 40 wt% > 10%, but general view is that the higher crosslink density, the higher the residual mass [32]. We proposed that the inhibit of cyclization of PDMS through thermal degradation and the small amount of decomposition of ethoxy groups in CLs may affect the residual mass; hence, PDMS–CL 40 wt% has lower residual mass than PDMS–CL 20 wt% due to the large amount of ethoxy groups. However, it is postulated that the thermal attributes of PDMS materials might be more influenced by the PDMS chain length than by the degree of crosslinking [11, 33,34,35,36]; therefore, this thermal degradation behavior of PDMS–CLs is expected to vary with PDMS chain length. A similar trend was noticed under aerobic conditions, with Td5 results detailed in Supplementary Table S1.

To explore the mechanical reinforcement effects when incorporated with CLs, the tensile properties of PDMS–CLs were evaluated. The outcomes of the tensile strength tests are presented in Supplementary Fig. S5. The secant modulus value was determined from the tensile strength and strain values at the breaking point. The PDMS–CLs displayed low secant modulus and tensile strengths, ranging from 0.67 MPa (with 10 wt% of CLTEOS) to 1.4 MPa (with 40 wt% of CLOETS) and from 0.06 MPa (with 10 wt% of CLTEOS) to 0.96 MPa (with 40 wt% of CLOETS), respectively. The behavior of the secant modulus for PDMS–CLs is depicted in Fig. 7. As the content of CLs increased, the secant modulus values for PDMS–CLs also increased. Mackenzie et al. highlighted that the mechanical properties of PDMS–SiO2 are influenced by the composition ratio between PDMS and silicates [37]. Furthermore, the secant modulus and tensile strength of PDMS materials are contingent upon the crosslinked network [33, 38]. Consequently, it is inferred that CLHEDS and CLOETS exhibit superior crosslinking efficiency compared to CLTEOS, consistent with earlier findings.

Swelling tests for PDMS–CLs were conducted by measuring solvent uptake while stored in toluene at approximately 23 °C for 3 days. The outcomes of these tests are presented in Fig. 8. No soluble fraction was detected in the swelling test, which validates that all PDMS–CLs underwent reaction and cross-linking. The degree of swelling is inversely proportional to the extent of cross-linking; as the cross-linking degree increases, the swelling degree diminishes [11, 39,40,41]. As the content of CL increased, there was a corresponding decrease in the swelling degree. This trend suggests an escalation in the degree of cross-linking with increasing CL content. The solvent uptake for CLs decreased in the sequence: CLTEOS < CLHEDS ≤ CLOETS. Both CLHEDS and CLOETS are posited to exhibit superior cross-linking efficiency compared to CLTEOS. This hypothesis stems from the presumed relation to the content of 4-membered cyclic siloxane derivatives and silylation on Q3 silicon [10, 41]. However, when the percentage of CLs reaches 40 wt%, the swelling degree did not show a significant difference. Because PDMS–CLs 40 wt% were observed aggregates on SEM as seen above and the interface between PDMS chain and CLs was bigger, it is thought that structural characteristic of CLs became weak.

4 Conclusion

The Si–H terminated ethoxyoligosiloxanes (CLs) were employed as cross-linkers for DQ silicone elastomers. All CLs exhibited a similar Mw (around 1400 Da), Mw/Mn (1.1), and OEt/Si–H ratio (4). However, their structures varied: CLTEOS was primarily composed of cyclic siloxane derivatives silylated on Q4 silicon; CLHEDS mainly consisted of 4-membered cyclic siloxane derivatives silylated on Q4 silicon; and CLOETS predominantly comprised cyclic siloxane derivatives silylated on both Q3 and Q4 silicon. The properties of PDMS–CLs are summarized in Table 2. The effects of these distinct cross-linker structures were assessed in terms of transmittance, thermal stability, tensile strength, and swelling in toluene. Based on these evaluations, CLHEDS and CLOETS appear to offer superior cross-linking efficiency compared to CLTEOS. These differences are believed to arise from the content of 4-membered cyclic siloxane derivatives and the silylation on Q3 silicon. Thus, it is inferred that the properties of the elastomers are significantly influenced by the structures of the cross-linkers.

References

Kuo SW (2022) Hydrogen bonding interactions in polymer/polyhedral oligomeric silsesquioxane nanomaterials. J Polym Res 29:69. https://doi.org/10.1007/s10965-021-02885-4

Gon M, Tanaka K, Chujo Y (2018) Recent progress in the development of advanced element-block materials. Polym J 50:109–126. https://doi.org/10.1038/pj.2017.56

Mammeri F, Bourhis EL, Rozes L, Sanchez C (2005) Mechanical properties of hybrid organic–inorganic materials. J Mater Chem 15:3787–3811. https://doi.org/10.1039/B507309J

Sanchez C, Julia´n B, Belleville P, Popall M (2005) Applications of hybrid organic–inorganic nanocomposites. J Mater Chem 15:3559–3592. https://doi.org/10.1039/B509097K

Gunji T, Sakai Y, Suyama Y, Arimitsu K, Abe Y, West R (2004) Preparation and properties of C60-polysiloxane hybrids. J Sol Gel Sci Technol 32:43–46. https://doi.org/10.1007/s10971-004-5762-z

Gunji T, Shioda T, Tsuchihara K, Seki H, Kajiwara T, Abe Y (2010) Preparation and properties of poly oligomeric silsesquioxane/polysiloxane copolymers. Appl Organo Chem Soc 24:545–550. https://doi.org/10.1002/aoc.1562

Hayami R, Wada K, Nishikawa I, Sagawa T, Yamamoto K, Tsukada S, Gunji T (2017) Preparation and properties of organic–inorganic hybrid materials using titanium phosphonate cluster. Polym J 49:665–669. https://doi.org/10.1038/pj.2017.34

Gunji T, Itagaki S, Kajiwara T, Abe Y, Hatakeyama T, Aoki R (2009) Preparation and properties of siloxane/epoxy organic-inorganic hybrid thin films, self-standing films, and bulk bodies. Polym J 41:541–546. https://doi.org/10.1295/polymj.PJ2008290

Sato Y, Sugimoto A, Iwashina T, Hayami R, Yamamoto K, Gunji T (2023) Hydrolysis and condensation behavior of tetraethoxysilane, hexaethoxydisiloxane, and octaethoxytrisiloxane. J. Sol–Gel Sci. Technol. 108:377–391. https://doi.org/10.1007/s10971-023-06159-x

Meshkov IB, Kalinina AA, Gorodov VV, Bakirov AV, Krasheninnikov SV, Chvalun SN, Muzafarov AM (2021) New principles of polymer composite preparation. MQ copolymers as an active molecular filler for polydimethylsiloxane rubbers. Polymers 13:2848. https://doi.org/10.3390/polym13172848

Hayami R, Nishikawa I, Hisa T, Nakashima H, Sato Y, Ideno Y, Sagawa T, Tsukada S, Yamamoto K, Gunji T (2018) Preparation and characterization of stable DQ silicone polymer sols. J Sol Gel Sci Technol 88:660–670. https://doi.org/10.1007/s10971-018-4839-z

Sato Y, Hayami R, Gunji T (2022) Characterization of NMR, IR, and Raman spectra for siloxanes and silsesquioxanes: a mini review. J Sol Gel Sci Technol 104:36–52. https://doi.org/10.1007/s10971-022-05920-y

Kelts LW, Armstrong NJ (1989) A silicon-29 NMR study of the structural intermediates in low pH sol-gel reactions. J Mater Res 4:423–433. https://doi.org/10.1557/JMR.1989.0423

Hook RJ (1996) A 29Si NMR study of the sol-gel polymerisation rates of substituted ethoxysilanes. J Non Cryst Solids 195:1–15. https://doi.org/10.1016/0022-3093(95)00508-0

Unger B, Jancke H, Hähnert M, Stade H (1994) The early stages of the sol-gel processing of TEOS. J Sol Gel Sci Technol 2:51–56. https://doi.org/10.1007/BF00486212

Gunji T, Igarashi T, Tsukada S, Abe Y (2017) Syntheses of cage octasilicate polymers. J Sol Gel Sci Technol 81:21–26. https://doi.org/10.1007/s10971-016-3998-z

Barthel H, Nikitina E (2002) INS and IR study of intermolecular interactions at the fumed silica-polydimethylsiloxane interphase, Part I. Polydimethylsiloxane models. Silicon Chem 1:239–247. https://doi.org/10.1023/B:SILC.0000018351.78847.f7

Barthel H, Nikitina E (2002) INS and IR study of intermolecular interactions at the fumed silica-polydimethylsiloxane interphase, Part 3. Sicica-siloxane adsorption complexes. Silicon Chem 1:261–279. https://doi.org/10.1023/B:SILC.0000018353.32350.c9

Ramli MR, Othman MBH, Arifin A, Ahmad Z (2011) Cross-link network of polydimethylsiloxane via addition and condensation (RTV) mechanisms. Part I: Synthesis and thermal properties. Polym Degrad Stab 96:2064–2070. https://doi.org/10.1016/j.polymdegradstab.2011.10.001

Si Q-F, Wang X, Fan X-D, Wang S-J (2005) Synthesis and characterization of ultraviolet-curable hyperbranched poly(siloxysilane)s. 43:1883–1894. https://doi.org/10.1002/pola.20675

Rubio F, Rubio J, Oteo JL (1998) A FT-IR study of the hydrolysis of tetraethoylorthosilicate (TEOS). Spectr Lett 31:199–219. https://doi.org/10.1080/00387019808006772

Richards RE, Thompson HW (1949) Infra-red spectra of compounds of high molecular weight. Part IV. Silicones and related compounds. J Chem Soc 1949:124–132. https://doi.org/10.1039/JR9490000124

Jianye J, Xin G, Xiaoyan P, Ruoling L, Shuyi W, Jiaqi S, Weijie L, Jianfang G (2019) Synthesis and characterization of room temperature vulcanized silicone rubber using methoxyl-capped MQ silicone resin as self-reinforced cross-linker. Polymers 11:1142. https://doi.org/10.3390/polym11071142

Ruslan YL, Aleksander VS, Aleksander DK, Alexey BD, Khasan RK, Oleg GS, Dmitry GY (2023) Synthesis, X-ray structure, and catalytic activity in the hydrosilylation process of platinum complexes bearing buchwald ligands. Organometallics 42:2447–2453. https://doi.org/10.1021/acs.organomet.2c00671

Camino G, Lomakin SM, Lazzari M (2001) Polydimethylsiloxane thermal degradation Part 1. Kinetic aspects. Polymer 42:2395–2402. https://doi.org/10.1016/S0032-3861(00)00652-2

Chen D, Yi S, Wu W, Zhong Y, Liao J, Huang C, Shi W (2010) Synthesis and characterization of novel room temperature vulcanized (RTV) silicone rubbers using vinyl-POSS derivatives as cross linking agents. Polymer 51:3867–3878. https://doi.org/10.1016/j.polymer.2010.06.028

Camino G, Lomakin SM, Lazzari M (2001) Thermal polydimethylsiloxane degradation. Part 2. The degradation mechanisms. Polymer 43:2011–2015. https://doi.org/10.1016/S0032-3861(01)00785-6

Tanaka K, Adachi S, Chujo Y (2009) Structure–property relationship of octa-substituted POSS in thermal and mechanical reinforcements of conventional polymers. J Polym Sci A Polym Chem 47:5690–5697. https://doi.org/10.1002/pola.23612

Sato Y, Hayami R, Miyase Y, Ideno Y, Yamamoto K, Gunji T (2020) Preparation and properties of methyl- and cyclohexylsilsesquioxane oligomers as organic–inorganic fillers. J Sol Gel Sci Technol 95:474–481. https://doi.org/10.1007/s10971-020-05291-2

Takamura N, Taguchi K, Gunji T, Abe Y (1999) Preparation of silicon oxycarbide ceramic films by pyrolysis of polymethyl- and polyvinylsilsesquioxanes. J Sol Gel Sci Technol 16:227–234. https://doi.org/10.1023/A:1008765103113

Abe Y, Kagayama K, Takamura N, Gunji T, Yoshihara T, Takahashi N (2000) Preparation and properties of polysilsesquioxanes. Function and characterization of coating agents and films. J Non Cryst Solids 261:39–51. https://doi.org/10.1016/S0022-3093(99)00614-6

Sabhani S, Bastani S, Gedde UW, Sari MG, Ramezanzadeh B (2017) Network formation and thermal stability enhancement in evolutionary crosslinked PDMS elastomers with sol-gel-formed silica nanoparticles: comparativeness between as-received and pre-hydrolyzed TEOS. Prog Org Coat 113:117–125. https://doi.org/10.1016/j.porgcoat.2017.08.012

Yamamoto K, Shimoda T, Sato Y, Nakaya T, Ohshita J, Gunji T (2022) Preparation and film properties of polysiloxanes consisting of di- and quadra-functional hybrid units. J Sol Gel Sci Technol 104:724–734. https://doi.org/10.1007/s10971-022-05806-z

Grassie N, MacFarlane J (1978) The thermal degradation of polysiloxanes—I. Poly (dimethylsiloxane). Eur Polym J 14:875–884. https://doi.org/10.1016/0014-3057(78)90084-8

Grassie N, MacFarlane J, Francey KF (1979) The thermal degradation of polysiloxanes—II. Poly (methylphenylsiloxane). Eur Polym J 15:415–422. https://doi.org/10.1016/0014-3057(79)90053-3

Han Y, Zhang J, Shi L, Qi S, Cheng J, Jin R (2008) Improvement of thermal resistance of polydimethylsiloxanes with polymethylmethoxysiloxane as crosslinker. Polym Degrad Stab 93:242–251. https://doi.org/10.1016/j.polymdegradstab.2007.09.010

Mackenzie JD, Huang Q, Iwamoto T (1996) Mechanical properties of ormosils. J Sol Gel Sci Technol 7:151–161. https://doi.org/10.1007/BF00401034

Seghir R, Arscott S (2015) Extended PDMS stiffness range for flexible systems. Sens Actuators A Phys 230:33–39. https://doi.org/10.1016/j.sna.2015.04.011

Sawvel AM, Chinn SC, Gee M, Loeb CK, Maiti A, Mason HE, Maxwell RS, Lewicki JP (2019) Nonideality in silicone network formation via solvent swelling and 1H double-quantum NMR. Macromolecules 52:410–419. https://doi.org/10.1021/acs.macromol.8b01939

Sawvel AM, Crowhurst JC, Mason HE, Oakdale JS, Ruelas S, Eshelman HV, Maxwell RS (2021) Spectroscopic signatures of MQ-resins in silicone elastomers. Macromolecules 54:4300–4312. https://doi.org/10.1021/acs.macromol.1c00086

Fan X, Cao X, Shang X, Zhang X, Huang C, Zhang J, Zheng K, Ma Y (2021) A transparent cyclo-linear polyphenylsiloxane elastomer integrating high refractive index, thermal stability and flexibility. Polym Chem 12:5149–5158. https://doi.org/10.1039/D1PY00688F

Acknowledgements

This study was supported by the Japan Science and Technology Agency (JST) for the establishment of university fellowships toward the creation of science technology innovation (grant number: JPMJFS2144) and JSPS KAKENHI grants (grant number: 23KJ1965).

Author contributions

YS: Investigation, conceptualization, visualization, methodology, writing–original draft. RH: Writing–review and editing, visualization. KY: Supervision. TG: Writing–review and editing, conceptualization, and supervision.

Funding

Open access funding provided by Tokyo University of Science.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sato, Y., Hayami, R., Yamamoto, K. et al. Preparation and properties of PDMS elastomer cross-linked with hydrolyzate of tetraethoxysilane, hexaethoxydisiloxane, and octaethoxytrisiloxane: influence of cross-linker structure. J Sol-Gel Sci Technol 109, 22–31 (2024). https://doi.org/10.1007/s10971-023-06247-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06247-y