Abstract

In this study, optimization of the synthesis process parameters of sol-gel method using orthogonal experiment was first applied for CuFe1.2Al0.8O4 catalysts in methanol steam reforming (MSR). OA9 (44) orthogonal experiments were applied to optimize the synthesis process parameters by sol-gel method, including precursor copper source complexing agent, calcination temperature, and calcination time. The MSR performance was selected as the objective function. Results show that copper source has the greatest impact among the four factors on the catalytic performance. The catalytic performance of the catalyst synthesized by using copper hydroxide as the precursor copper source was much better than the other copper sources. For the other three factors, the order of important factors is: calcination time > complexing agent > calcination temperature. According to the results of range analysis, the optimal synthesis process parameters for CuFe1.2Al0.8O4 with best MSR performance are as follows: the precursor copper source is copper hydroxide, the calcination time is 2 h, the complexing agent is ethanol and ethylene glycol, and the calcination temperature is 700 °C. The hydrogen production is 0.077 mol/min/goat, the methanol conversion rate can reach >95%, and the hydrogen selectivity can reach 99%. CuFe1.2Al0.8O4 spinel oxide catalyst which synthesized in this study has excellent catalytic performance for hydrogen production in MSR. Its low CO selectivity makes it a potential catalyst for producing high-purity hydrogen.

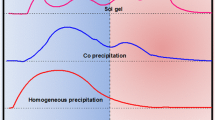

Graphical Abstract

Optimization of the synthesis process parameters of sol-gel method using orthogonal experiment was first applied for CuFe1.2Al0.8O4 catalysts in methanol steam reforming (MSR). Its low CO selectivity makes it a potential catalyst for producing high-purity hydrogen.

Highlights

-

Orthogonal experiments were applied to optimize the synthesis process parameters by sol-gel method.

-

Copper source has the greatest impact on the catalytic performance.

-

The synthesized spinel has high hydrogen selectivity and low CO selectivity.

Similar content being viewed by others

References

Xu YC, Song YX, Chen H et al. (2023) Influence of Ba on Co-Al-Ba composite oxide catalysts in auto-thermal reforming of acetic acid for hydrogen production. J Sol-Gel Sci Technol 105(1):202–211

Danwittayakul S, Dutta J (2014) Controlled growth of zinc oxide microrods by hydrothermal process on porous ceramic supports for catalytic application. J Alloy Compd 586:169–175

Gunter MM, Ressler T, Jentoft RE, Bems B (2001) Redox behavior of copper oxide/zinc oxide catalysts in the steam reforming of methanol studied by in situ X-ray diffraction and absorption spectroscopy. J Catal 203:133–149

Jiang X, Nie XW, Guo XW, Song CS, Chen JGG (2020) Recent advances in carbon dioxide hydrogenation to methanol via heterogeneous catalysis. Chem Rev 120(15):7984–8034

Uysal S, Kaya MF, Demir N, Huner B, Ozcan RU, Erdem ON, Yilmaz M (2021) Investigation of hydrogen production potential from different natural water sources in Turkey. Int J Hydrog Energ 46(61):31097–31107

Vaidya PD, Rodrigues AE (2009) Glycerol reforming for hydrogen production: a review. Chem Eng Technol 32(10):1463–1469

Kuc J, Neumann M, Armbrüster M, Yoon S, Zhang YC, Erni R, Weidenkaff A, Matam SK (2016) Methanol steam reforming catalysts derived by reduction of perovskite-type oxides LaCo1-x-y PdxZnyO3±δ. Catal Sci Technol 6(5):1455–1468

Li JJ, Mei XL, Zhang LJ, Yu ZJ, Liu Q, Wei T, Wu WB, Dong DH, Xu LL, Hu X (2020) A comparative study of catalytic behaviors of Mn, Fe, Co, Ni, Cu and Zn-Based catalysts in steam reforming of methanol, acetic acid and acetone. Int J Hydrog Energ 45(6):3815–3832

Kamyar N, Khani Y, Amini M, Bahadoran F, Safari N (2020) Copper-based catalysts over A520-MOF derived aluminum spinels for hydrogen production by methanol steam reforming: The role of spinal support on the performance. Int J Hydrog Energ 45(41):21341–21353

Yu W, Yan JL, Cui ZW, Yang N, Yuan SS (2022) Steam reforming of methanol over mesoporous Cu-Al spinel catalysts synthesized by mechanochemical method. J Indian Chem Soc 99(1):100286

Hou XN, Qing SJ, Liu YJ, Li LD, Gao ZX, Qin Y (2020) Enhancing effect of MgO modification of Cu-Al spinel oxide catalyst for methanol steam reforming. Int J Hydrog Energ 45(1):477–489

Shen Q, Cai Z, Zhang X et al. (2023) Novel spinel oxide catalysts CuFexAl2−xO4 with high H2 selectivity with low CO generation in methanol steam reforming. J Alloy Compd 951:169878

Tetsuya F, Naonori R, Nobuyuki I et al. (2009) Characterization of CuMn-spinel catalyst for methanol steam reforming. Catal Commun 10:1800–1803

Maiti S, Das D, Pal K et al. (2019) Methanol steam reforming behavior of sol-gel synthesized nanodimensional CuxFe1-xAl2O4 hercynites. Appl Catal A-Gen 570:73–83

Qin FJ, Liu YJ, Qing SJ et al. (2017) Cu-Al spinel as a sustained release catalyst for H2 production from methanol steam reforming: Effects of different copper sources. J Fuel Chem Technol 45(12):1481–1488

Shen QW, Cai ZW, Shao ZC et al. (2022) Improved performance of bimetallic oxides CuO-Y2O3 synthesized by sol-gel for methanol steam reforming. J Am Ceram Soc 105(11):6839–6850

Peppley BA, Amphlett JC, Kearns LM, Mann RF (1999) Methanol-steam reforming on Cu/ZnO/Al2O3. Part 1: the reaction network. Appl Catal A-Gen 179(1-2):21–29

Liu YJ, Qing SJ, Hou XN, Qin FJ, Wang X, Gao ZX, Xiang HG (2017) Temperature dependence of Cu-Al spinel formation and its catalytic performance in methanol steam reforming. Catal Sci Technol 7(21):5069–5078

Fukunaga T, Ryumon N, Ichikuni N, Shimazu S (2009) Characterization of Cu-Mn-spinel catalyst for methanol steam reforming. Catal Commun 10(14):1800–1803

Qiao WJ, Zhang L, Zhang KW et al. (2022) Low temperature synthesis of Cu1-xAl2.5 spinel solid solution as sustained release catalyst for methanol to hydrogen. Int J Hydrog Energ 47(75):32133–32144

Huang YH, Wang SF, Tsai AP, Kameoka S (2014) Reduction behaviors and catalytic properties for methanol steam reforming of Cu-based spinel compounds CuX2O4 (X= Fe, Mn, Al, La). Ceram Int 40(3):4541–4551

Marban G, Valdes-Solis T, Fuertes AB (2007) High surface area CuMn2O4 prepared by silica-aquagel confined co-precipitation. Characterization and testing in steam reforming of methanol (SRM). Catal Lett 118(1-2):8–14

Bagherzadeh SB, Haghighi M (2017) Plasma-enhanced comparative hydrothermal and coprecipitation preparation of CuO/ZnO/Al2O3 nanocatalyst used in hydrogen production via methanol steam reforming. Energ Convers Manag 142:452–465

Kameoka S, Tanabe T, Tsai AP (2005) Spinel CuFe2O4: a precursor for copper catalyst with high thermal stability and activity. Catal Lett 100(1-2):89–93

Author contributions

QS: Conceptualization, Methodology, Writing- Original draft preparation. ZC: Data curation, GC: Visualization, Investigation. XZ: Software, Validation. SL: Writing- Reviewing and Editing. GY: Supervision.

Funding

This work was supported by the China Postdoctoral Science Foundation (No.2019M651094), and Science and Technology Innovation Foundation of Dalian (2021JJ11CG004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, Q., Cai, Z., Chen, G. et al. Optimization of the sol gel synthesis process parameters by orthogonal experiment of novel spinel oxide catalyst CuFe1.2Al0.8O4 with improved performance for methanol steam reforming. J Sol-Gel Sci Technol 107, 490–502 (2023). https://doi.org/10.1007/s10971-023-06136-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06136-4