Abstract

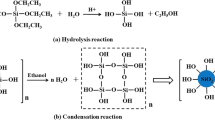

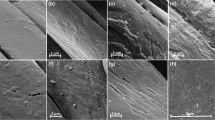

Titanate xerogels have attracted increasing attention due to their extraordinary properties such as thermal conductivity, fire resistance, hydrophobicity and low density. This work focuses on the development of a new multifunctional textile, based on xerogel as filler for cotton fabric for applications in technical textiles. The microstructure was determined in each material using SEM observations, detection of different chemical bonds using FT-IR and XDR techniques. Thermal properties were evaluated by TGA, DSC and thermal conductivity measurements. The results show that the treated fabrics are hydrophobic with contact angles greater than 90°, the final contact angle varies with the drying temperature of the treated fabrics and reaches a maximum value of 127.50 ± 5°. The thermal results showed all the developed samples present an excellent insulation performance with conductivity coefficients between 0.035 and 0.04 W/m.K. which values are highly acceptable for applications in technical textiles. It is interesting to note that the treated fabrics present an average post-flame time compared to the raw fabric and significantly lower compared to the PA coating. The mass loss ranged from 40.8 to 51.1%, showing the effectiveness of xerogel as a filler for polyacrylate resin contributing to the flame-retardant synergy. Consequently, the deposition of a titanate xerogel coating creates a multifunctional textile with great promise for smart clothing and personal heating applications.

Graphical Abstract

Titanate xerogels have attracted increasing attention due to their extraordinary properties such as thermal conductivity, fire resistance, hydrophobicity and low density. This work focuses on the development of a new multifunctional textile, based on xerogel as filler for cotton fabric for applications in technical textiles. The microstructure was determined in each material using SEM observations, detection of different chemical bonds using FT-IR and XDR techniques. Thermal properties were evaluated by TGA, DSC and thermal conductivity measurements. The results show that the treated fabrics are hydrophobic with contact angles greater than 90°, the final contact angle varies with the drying temperature of the treated fabrics and reaches a maximum value of 127.50 ± 5°. The thermal results showed all the developed samples present an excellent insulation performance with conductivity coefficients between 0.035 and 0.04 W/m.K. which values are highly acceptable for applications in technical textiles. It is interesting to note that the treated fabrics present an average post-flame time compared to the raw fabric and significantly lower compared to the PA coating. The mass loss ranged from 40.8 to 51.1%, showing the effectiveness of xerogel as a filler for polyacrylate resin contributing to the flame-retardant synergy. Consequently, the deposition of a titanate xerogel coating creates a multifunctional textile with great promise for smart clothing and personal heating applications.

Highlights

-

The optimization of the synthesis conditions of xerogel leads to an improved xerogel-coated textile performance.

-

The synthesized xerogel’s porosity is relatively homogeneous, with a visible pore size between 3 and 30 μm.

-

Xerogel-coated textiles exhibit enhanced hydrophobicity, resulting in a higher surface energy.

-

The thermal stability of xerogel-treated fabrics was improved, as indicated by a thermal conductivity coefficient ranging from 0.041 to 0.035 W.m−1.k−1.

Similar content being viewed by others

References

Al-Homoud MS (2005) Performance characteristics and practical applications of common building thermal insulation materials. Build Environ 40:353–366. https://doi.org/10.1016/j.buildenv.2004.05.013

Cetiner I, Shea AD (2018) Wood waste as an alternative thermal insulation for buildings. Energy Build 168:374–384. https://doi.org/10.1016/j.enbuild.2018.03.019

Yu Z-L, Yang N, Apostolopoulou-Kalkavoura V, Qin B, Ma Z-Y, Xing W-Y, Qiao C, Bergström L, Antonietti M, Yu S-H (2018) Fire-Retardant and Thermally Insulating Phenolic-Silica Aerogels. Angew Chem Int Ed 57:4538–4542. https://doi.org/10.1002/anie.201711717

Jia G, Li Z, Liu P, Jing Q (2018) Preparation and characterization of aerogel/expanded perlite composite as building thermal insulation material. J Non-Cryst Solids 482:192–202. https://doi.org/10.1016/j.jnoncrysol.2017.12.047

Berardi U (2018) Aerogel-enhanced systems for building energy retrofits: Insights from a case study. Energy Build 159:370–381. https://doi.org/10.1016/j.enbuild.2017.10.092

Liu S, Zhu K, Cui S, Shen X, Tan G (2018) A novel building material with low thermal conductivity: Rapid synthesis of foam concrete reinforced silica aerogel and energy performance simulation. Energy Build 177:385–393. https://doi.org/10.1016/j.enbuild.2018.08.014

Nocentini K, Biwole P, Achard P, Silica Aerogel Blankets as Superinsulating Material for Developing Energy Efficient Buildings, in: Sustain. Energy-Effic. Build., CRC Press, 2018

Aegerter MA, Leventis N, Koebel M, SAS III, eds., Springer Handbook of Aerogels, 1st ed. 2023 edition, Springer, 2022

Ibrahim M, Improving the buildings envelopes energy performance using aerogel-based insulating mineral rendering, (n.d.) 255

Kistler SS (1932) Coherent expanded-aerogels. J Phys Chem 36:52–64. https://doi.org/10.1021/j150331a003

Berardi U (2017) A cross-country comparison of the building energy consumptions and their trends. Resour Conserv Recycl 123:230–241. https://doi.org/10.1016/j.resconrec.2016.03.014

Baetens R, Jelle BP, Gustavsen A (2011) Aerogel insulation for building applications: A state-of-the-art review. Energy Build 43:761–769. https://doi.org/10.1016/j.enbuild.2010.12.012

Vareda J, Lamy-Mendes A, Durães L (2017) A reconsideration on the definition of the term aerogel based on current drying trends. Microporous Mesoporous Mater 258:211–216. https://doi.org/10.1016/j.micromeso.2017.09.016

Thapliyal PC, Singh K (2014) Aerogels as promising thermal insulating materials: an overview. J Mater 2014:1–10. https://doi.org/10.1155/2014/127049

Bozoglu D, Deligoz H, Ulutas K, Yakut S, Deger D (2019) Structural and dielectrical characterization of low-k polyurethane composite films with silica aerogel. J Phys Chem Solids 130:46–57. https://doi.org/10.1016/j.jpcs.2019.02.013

Timusk M, Kangur T, Locs J, Šutka A, Järvekülg M (2021) Aerogel-like silica powders by combustion of sol-gel derived alcogels. Microporous Mesoporous Mater 315:110895. https://doi.org/10.1016/j.micromeso.2021.110895

Liu P, Gao H, Chen X, Chen D, Lv J, Han M, Cheng P, Wang G (2020) In situ one-step construction of monolithic silica aerogel-based composite phase change materials for thermal protection. Compos Part B Eng 195:108072

Casini M (2014) Smart materials and nanotechnology for energy retrofit of historic buildings. Int J F Civ Struct Eng IJCSE 2372-3971:1

El Wazna M, El Fatihi M, El Bouari A, Cherkaoui O (2017) Thermo physical characterization of sustainable insulation materials made from textile waste. J Build Eng 12:196–201. https://doi.org/10.1016/j.jobe.2017.06.008

Wazna ME, Ouhaibi S, Gounni A, Belouaggadia N, Cherkaoui O, Alami ME, Bouari AE (2020) Experimental and numerical study on the thermal performance of alternative insulation materials based on textile waste: A finite-difference approach. J Ind Text 49:1281–1303

Chrysicopoulou P, Davazoglou D, Trapalis C, Kordas G (1998) Optical properties of very thin (<100 nm) Sol–Gel TiO2 Films. Thin Solid Films 323:188–193. https://doi.org/10.1016/S0040-6090(97)01018-3

Pohl ER, Osterholtz FD, Kinetics and mechanism of aqueous hydrolysis and condensation of alkyltrialkoxysilanes, in: H. Ishida, G. Kumar (Eds.), Mol. Charact. Compos. Interfaces, Springer US, Boston, MA, 1985: pp. 157–170. https://doi.org/10.1007/978-1-4899-2251-9_10

Artemyev MV, Woggon U, Wannemacher R, Jaschinski H, Langbein W (2001) Light trapped in a photonic dot: microspheres act as a cavity for quantum dot emission. Nano Lett 1:309–314. https://doi.org/10.1021/nl015545l

LB Nyai, SW Koch, Semiconductor Quantum Dots, World Scientific, 1993.

Hay JN, Porter D, Raval HM (2000) A versatile route to organically-modified silicas and porous silicas via the non-hydrolytic sol–gel process. J Mater Chem 10:1811–1818. https://doi.org/10.1039/A908900D

Xu L, Chen K, Zhu J, Chen H, Huang H, Xu J, Huang X (2001) Core-shell structure and quantum effect of CdSe/HgSe/CdSe quantum dot quantum well. Superlattices Microstruct 29:67–72. https://doi.org/10.1006/spmi.2000.0922

Lukic I, Pajnik J, Tadic V, Milovanovic S (2022) Supercritical CO2-assisted processes for development of added-value materials: Optimization of starch aerogels preparation and hemp seed extracts impregnation. J CO2 Util 61:102036. https://doi.org/10.1016/j.jcou.2022.102036

Manzocco L, Mikkonen KS, García-González CA (2021) Aerogels as porous structures for food applications: Smart ingredients and novel packaging materials. Food Struct 28:100188. https://doi.org/10.1016/j.foostr.2021.100188

Dr. IR François Collignon, Le Sol-Gel: la chimie douce au service de l innovation, (n.d.). https://docplayer.fr/39661116-Le-sol-gel-la-chimie-douce-au-service-de-l-innovation.html (accessed October 7, 2022).

Pierre AC, Pajonk GM, Chemistry of aerogels and their applications, ACS Publ. (2002). https://doi.org/10.1021/cr0101306.

Jean Phalippou, Laurent Kocon, Méthodes d’obtention des aérogels, Tech. Ing. (n.d.). https://www.techniques-ingenieur.fr/base-documentaire/procedes-chimie-bio-agro-th2/cosmetiques-procedes-de-formulation-42634210/elaboration-des-gels-et-des-aerogels-j2230/methodes-d-obtention-des-aerogels-j2230niv10004.html (accessed October 7, 2022).

Yosry A. Attia, Sol-Gel processing and applications, n.d. https://link.springer.com/book/10.1007/978-1-4615-2570-7 (accessed October 7, 2022).

Kim S, Seo J, Cha J, Kim S (2013) Chemical retreating for gel-typed aerogel and insulation performance of cement containing aerogel. Constr Build Mater 40:501–505. https://doi.org/10.1016/j.conbuildmat.2012.11.046

Gao T, Jelle BP, Gustavsen A (2016) Building integration of aerogel glazings. Procedia Eng 145:723–728. https://doi.org/10.1016/j.proeng.2016.04.090

Ng S, Jelle BP, Sandberg LIC, Gao T, Wallevik ÓH, Experimental investigations of aerogel-incorporated ultra-high performance concrete, Constr. Build. Mater. Complete (2015) 307–316. https://doi.org/10.1016/j.conbuildmat.2014.12.064

Wind O, Gindele F, Woggon U, Excited state luminescence and fine structure in CdSe quantum dots, J. Lumin. 72–74 (1997) 300–301. https://doi.org/10.1016/S0022-2313(97)00005-7.

Aelion R, Loebel A, Eirich F, Hydrolysis of Ethyl Silicate*, ACS Publ. (2002). https://doi.org/10.1021/ja01168a090.

Livage J, Sanchez C (1992) Sol-gel chemistry. J Non-Cryst Solids 145:11–19. https://doi.org/10.1016/S0022-3093(05)80422-3

Gallagher D, Ring TA, Sol-Gel Processing of Ceramic Films, (n.d.) 10.

Zha J, Roggendorf H, Sol–gel science, the physics and chemistry of sol–gel processing, Ed. by C. J. Brinker and G. W. Scherer, Academic Press, Boston 1990, xiv, 908 pp., bound—ISBN 0-12-134970-5, Adv. Mater. 3 (1991) 522–522. https://doi.org/10.1002/adma.19910031025.

Guzel Kaya G, Deveci H (2020) Modified silica xerogel derived from groundnut hull ash by alkyl-ammonium salt for epoxy nanocomposites: Synergistic effects on thermal stability and flame retardancy. Thermochim Acta 689:178637. https://doi.org/10.1016/j.tca.2020.178637

Bakhshi H, Sarraf-Mamoory R, Yourdkhani A, AbdelNabi AA, Mozharivskyj Y (2020) Sol-gel synthesis, spark plasma sintering, structural characterization, and thermal conductivity measurement of heavily Nb-doped SrTiO3/TiO2 nanocomposites. Ceram Int 46:3224–3235. https://doi.org/10.1016/j.ceramint.2019.10.027

Uz M, Yasar Mahlicli F, Seker E, Alsoy Altinkaya S (2020) Development of AgCl-TiO2 xerogels entrapped antibacterial polyacrylonitrile membranes: The effect of high salinity water on silver release, antibiofouling and antibacterial efficacies. Desalination 492:114496. https://doi.org/10.1016/j.desal.2020.114496

ISO 6940:2004(en), Textile fabrics — Burning behaviour—Determination of ease of ignition of vertically oriented specimens, (n.d.). https://www.iso.org/obp/ui/es/#iso:std:iso:6940:ed-2:v1:en (accessed October 7, 2022).

NF ISO 105-D02, Afnor Ed. (n.d.). https://www.boutique.afnor.org/fr-fr/norme/nf-iso-105d02/textiles-essais-de-solidite-des-teintures-partie-d02-solidite-des-teintures/fa006670/64451 (accessed December 29, 2022).

Li P, Qiao Z, Qian Z, Zhu C, Yu Z, Fu W, Zhao N, Xu J (2020) Facile synthesis of robust hybrid xerogels by an emulsion assistant method. Chem Eng J 401:125937. https://doi.org/10.1016/j.cej.2020.125937

Lee DH, Jo MJ, Han SW, Yu S, Park H (2020) Polyimide aerogel with controlled porosity: Solvent-induced synergistic pore development during solvent exchange process. Polymer 205:122879. https://doi.org/10.1016/j.polymer.2020.122879

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Assal, M., El Wazna, M., Oumghar, K. et al. Multifunctional textile based on titanium xerogel: performance optimization through composition and microstructure. J Sol-Gel Sci Technol 106, 672–683 (2023). https://doi.org/10.1007/s10971-023-06102-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06102-0