Abstract

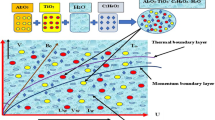

A new promising HTPB pasty propellant was designed and prepared using PEO-PPO-PEO block copolymer and ultra SiO2 as gelators. Then the gelling mechanism and rheological behaviors of this slurry were respectively studied through molecular simulation and rheological tests, further, an improved constitutive model for the slurry was proposed. Results show that the gels in slurries are formed by the hydrogen bondings between gelators and binder, and micellization of the block copolymer. The characteristics of shear thinning and creep-recovery were found in slurries in the rheological tests, viscosity of the slurry containing more block copolymer is insensitive to shear rate (\(\dot \gamma\)), moreover, this slurry has higher deformation in the creep process and greater elastic recovery during unloading. The improved structural dynamic model was built by introducing the structural coefficient (λ) related yield stress (τy) and plastic viscosity (μp) into the structural equation, it can describe the relaxation and thixotropic behaviors of slurry well.

Graphical Abstract

We designed and prepared a new promising HTPB pasty propellant using the PEO-PPO-PEO block copolymer and ultra SiO2 as gelators. Moreover, the gelling mechanism and rheological behaviors of these pasty slurries were explored through theoretical and experimental techniques. Remarkably, we established a dynamic model considering the variation of micro structures for this fuel.

Similar content being viewed by others

References

Austin B, Heister S, Dambach E, Wernimont E, Meyer S. Variable thrust, multiple start hybrid motor solutions for missile and space applications, 46th AIAA/ASME/SAE/ASEE Jt. Propulsion Conf. Exhibit. July 25–28, 2010, Nashville TN, USA, 7121. https://doi.org/10.2514/6.2010-7121

Carlson RW (2013) Method and system for controlling solid propellant thrust. US Pat 8584443:B1

Glushkov DO, Kuznetsov GV, Nigay AG, Yashutina OS (2019) Heat and mass transfer induced by the ignition of single gel propellant droplets. J Energy Inst 92:1944–1955. https://doi.org/10.1016/j.joei.2018.10.017

Natan B, Rahimi S (2002) The status of gel propellants in year 2000. Int J Energ Mater Ch 5:1–6. https://doi.org/10.1615/IntJEnergeticMaterialsChemProp.v5.i1-6.200

Ivanchenko AM, Bondarenko SG, Protsan YV, Wilson SA (2012) Deep regulation and reusable rocket propulsion using premixed slurry propellant. J Propul Power 28:869–875. https://doi.org/10.2514/1.B34280

Guo L, Zhang JB, Bai JQ, Li PY, Liu K, Cheng D. Simulation study on flow rate regulation of pasty propellant in lateral extrusion pipe, J. Phys.: Conf. Ser. Nov. 19–21, 2021, Beijing, China, 2174, 012070. https://doi.org/10.1088/1742-6596/2174/1/012070

Nusca MJ, McQuaid MJ. Combustion chamber fluid dynamics and hypergolic gel propellant chemistry simulations for selectable thrust rocket engines, 2004 Users Group Conference (DOD_UGC'04), Jun. 7–11, 2004, Williamsburg, VA, USA, 180–189. https://doi.org/10.1109/DOD_UGC.2004.8

Mueller DC, Turns SR (1996) Theoretical effects of aluminum gel propellant secondary atomization on rocket engine performance. J Propul Power 12:591–597. https://doi.org/10.2514/3.24074

Javed I, Baek SW, Waheed K. Autoignition and combustion characteristics of kerosene droplets with dilute concentrations of aluminum nanoparticles at elevated temperatures, Combust Flame. 162, 774–787. https://doi.org/10.1016/j.combustflame.2014.08.018

Liu CH, Feng F, Cao QL (2018) Study on starts of pasty propellant gas generator. J Propul Technol 39:374–379. https://doi.org/10.13675/j.cnki.tjjs.2018.02.016

Surovtsev AB, Paios HG, Dyachenko MP, Mandzyuk IA (2019) The effect of pre-encapsulating dispersed filler on the rheological properties of highly filled paste-like compositions based on oligomeric rubbe. Vopr Khimii i Khimicheskoi Tekhnologii 5:143–152. https://doi.org/10.32434/0321-4095-2019-126-5-143-152

Zhang, JX, Ju YT, Zhou SQ, Zhou C. Air-pasty propellant pressure drop and heat transfer through round pipe, 2008 Asia Simulation Conference-7th Intl. Conf. on Sys. Simulation and Scientific Computing, Oct. 10–12, 2008, Beijing, China, 1282–1285. https://doi.org/10.1109/ASC-ICSC.2008.4675568

Zhang JX, Zheng Y, Ju YT (2009) Modeling and simulation of pasty propellant flow in hot pipe. J Nanjing Univ Sci Technol 33:312–314. https://doi.org/10.3969/j.issn.1005-9830.2009.03.008

Teipel U, Foerter-Barth U (2004) Mechanical properties of gel propellants with nanoparticles. J Energ Mater 22:69–82. https://doi.org/10.1080/07370650490492824

Yoon C, Heister S, Xia G, Merkle C. Numerical simulations of gel propellant flow through orifices. 46th AIAA/ASME/SAE/ASEE Jt. Propulsion Conf Exhibit Aug. 2–5, 2009, Denver, Colorado, USA, 5045. https://doi.org/10.2514/6.2009-5045.

Rahimi S, Peretz A, Natan B (2007) On shear rheology of gel propellants. Propell Explos Pyrot 32:165–174. https://doi.org/10.1002/prep.200700018

Rahimi S, Peretz A, Natan B (2010) Rheological matchi ng of gel propellants. J Propul Power 26:376–378. https://doi.org/10.2514/1.42904

Sun H, Jiang J, Zhang L, Yuan C, Jiang Y, Liu P (2022) Rheological and atomization behavior of glycyrrhizic acid based supramolecular gel propellant stimulant. Colloid Surf A 640:128460. https://doi.org/10.1016/j.colsurfa.2022.128460

Jyoti BV, Baek SW (2015) Formulation and comparative study of rheological properties of loaded and unloaded ethanol-based gel propellants. J Energ Mater 33:125–139. https://doi.org/10.1080/07370652.2014.939311

Jyoti BV, Baek SW. Formulation and rheological characterization of eco-friendly ethanol gel propellant, 21th Int. Symp. Air Breathing Engines, Sept. 8–14, 2013, Busan, Republic of Korea, 1504

Botchu VSJ, Baek SW (2015) Flow and dynamic rheological characterization of ethanolamine gel propellant with hybrid gelling agent. Sci Technol Energ Mater 76:62–67

Acceryls Inc (2013) Material Studio 7.0. Acceryls Inc, San Diego

Ma S, Li Y, Li Y, Luo Y (2016) Research on structures, mechanical properties, and mechanical responses of TKX-50 and TKX-50 based PBX with molecular dynamics. J Mol Model 22:1–11. https://doi.org/10.1007/s00894-016-2913-4

Bunte SW, Sun H (2000) Molecular modeling of energetic materials: the parameterization and validation of nitrate esters in the COMPASS force field. J Phys Chem B 104:2477–2489. https://doi.org/10.1021/jp991786u

Zhang C (2010) Understanding the desensitizing mechanism of olefin in explosives versus external mechanical stimuli. J Phys Chem C 114:5068–5072. https://doi.org/10.1021/jp910883x

Mo KC, Gubbins KE, Jacucci G, McDonald IR (1974) The radial distribution function in fluid mixtures: conformal solution theory and molecular dynamics results. Mol Phys 27:1173–1183. https://doi.org/10.1080/00268977400101041

Lan Y, Zhai J, Li D, Yang R. Multiscale simulation on the influence of dimethyl hydantoin on mechanical properties of GAP/RDX propellants, Propell Explos Pyrot. 39, 18–23. https://doi.org/10.1002/prep.201200210

Lu S, Shao Z, Zhang Z, Wang H, Wang W (2012) Studies on rheological properties of gelled propellant based on new energetic cellulose. Acta Chim Sin 70:200–206. https://doi.org/10.6023/A1109253

Macosko CW. Rheology, principles, measurements and applications. New York, Wiley-VCH, 1994, 103–107. https://doi.org/10.1002/aic.690411025

Toorman EA (1997) Modelling the thixotropic behaviour of dense cohesive sediment suspensions. Rheol Acta 36:56–65. https://doi.org/10.1007/BF00366724

Cheng DCH (1973) A differential form of constitutive relation for thixotropy. Rheol Acta 12:228–233. https://doi.org/10.1007/BF01635109

Worrall WE, Tuliani S (1964) Viscosity changes during the ageing of clay-water suspensions. Trans Brit Ceram Soc 63:167–185

Funding

This research was funded by National Natural Science Foundation of China, Grant no. 11902247.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, S., Shi, X., Huang, H. et al. Rheological behaviors and structural dynamics of HTPB pasty propellant gelled by PEO-PPO-PEO block copolymer/ultra SiO2. J Sol-Gel Sci Technol 105, 721–733 (2023). https://doi.org/10.1007/s10971-023-06059-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06059-0