Abstract

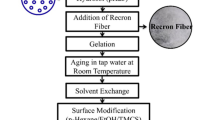

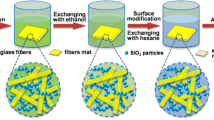

Silica aerogel composites reinforced with reclaimed cotton fibers obtained from textile industry wastes are here presented. These fibers were obtained from fabric leftovers of textile clothing industry, using only mechanical processes for reverting wasted fabric scraps to elementary fibers. The syntheses were carried out following environmentally friendly solutions. The post-gelation silylation/washing steps were performed applying ethyl acetate, recognized as a non-hazardous solvent. The tetraethyl orthosilicate-based aerogel composites were developed with a co-precursor having a non-hydrolysable bulky branch, isobutyltriethoxysilane, aiming to reduce brittleness and increase hydrophobicity. The aerogel matrix composition used here, reinforcement conception and modification solvent are being presented for the first time in the literature. The composites, manufactured in small cylindrical-shape (diameter ~3 cm) and disk-shape (diameter ~9 cm and ~14 cm) were silylated with hexamethyldisilazane and ambient pressure dried. Thermal conductivities were assessed by non-stationary and steady-state methods, the later yielding values 25–37% lower, achieving a value as low as 21 ± 3 mW m–1 K–1. The composites exhibit a high degree of flexibility conferred by the embedded cotton fibers, that imparted as well good acoustic insulation, since at frequencies near 1300 Hz, the sound absorption coefficient is 0.8. Cotton fibers are well known by their moisture buffering. By taking advantage of that water adsorption/desorption, the thermal regulation ability of the aerogels is studied here as a novel application for these materials. At 85% of relative humidity, silica aerogel composites with ~15 wt% of cotton fibers adsorbed 2.6 wt% of moisture and the process reversibility was confirmed.

Silica aerogel composites reinforced with textile waste cotton fibers and processed with ethyl acetate, able to perform moisture buffering while acting as thermal and acoustic barrier.

Highlights

-

Cotton-silica aerogel composites reinforced with waste fibers obtained from fabric scraps.

-

Reclaimed industrial cotton fibers mechanically processed, without detrimental chemicals.

-

A non-hazardous solvent, ethyl acetate, used for the first time for aerogel manufacturing.

-

Multifunctional silica-aerogel composite: moisture regulator and thermal/acoustic barrier.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author.

Code availability

No codes were developed in this work, but the following licensed software was used: Microsoft® Excel for Mac (Version 16.44), Microsoft® PowerPoint for Mac (Version 16.44).

References

Deshpande R, Smith DM, Brinker CJ (1996) Preparation of high porosity xerogels by chemical surface modification.

Pierre AC, Rigacci A (2011) SiO2 Aerogels. In: Aegerter MA, Leventis N, Koebel MM (eds) Aerogels Handbook. Springer Science+Business Media, New York, pp 21–45

Oh JK, Perez K, Kohli N et al. (2015) Hydrophobically-modified silica aerogels: Novel food-contact surfaces with bacterial anti-adhesion properties. Food Control 52:132–141. https://doi.org/10.1016/j.foodcont.2014.12.029

Zhang W, Liu Y, Yu H, Dong X (2019) Eu and Tb co-doped porous SiO2 aerogel composite and its luminescent properties. J Photochem Photobio A Chem 379:47–53. https://doi.org/10.1016/j.jphotochem.2019.04.040

Madyan OA, Fan M, Feo L, Hui D (2016) Enhancing mechanical properties of clay aerogel composites: An overview. Compos Part B Eng 98:314–329. https://doi.org/10.1016/j.compositesb.2016.04.059

Wang L, Cui L, Sánchez-Soto M et al. (2018) Highly flame retardant melamine-formaldehyde cross-linked cellulose Nanofibrils/Sodium Montmorillonite Aerogels with Improved Mechanical Properties. Macromol Mater Eng 303:1–9. https://doi.org/10.1002/mame.201800379

Sachithanadam M, Joshi SC (2016) Silica Aerogel Composites Novel Fabrication Methods. Springer, Singapore

Innocenzi P (2016) The Sol to Gel Transition. Springer, Cham-Switzerland

He S, Chen X (2017) Flexible silica aerogel based on methyltrimethoxysilane with improved mechanical property. J Non Cryst Solids 463:6–11. https://doi.org/10.1016/j.jnoncrysol.2017.02.014

Fu J, Wang S, He C et al. (2016) Facilitated fabrication of high strength silica aerogels using cellulose nanofibrils as scaffold. Carbohydr Polym 147:89–96. https://doi.org/10.1016/j.carbpol.2016.03.048

Markevicius G, Ladj R, Niemeyer P et al. (2016) Ambient-dried thermal superinsulating monolithic silica-based aerogels with short cellulosic fibers. J Mater Sci 52:2210–2221. https://doi.org/10.1007/s10853-016-0514-3

Linhares T, Amorim MTP, Durães L (2019) Silica aerogel composites with embedded fibres: a review on their preparation, properties and applications. J Mater Chem A 7:22768–22802. https://doi.org/10.1039/c9ta04811a

Rao AV, Pajonk GM, Bangi UKH, et al. (2011) Sodium Silicate Based Aerogels via Ambient Pressure Drying. In: Aegerter MA, Leventis N, Koebel MM (eds) Aerogels Handbook. Springer Science+Business Media, New York, pp 103–124

Stojanovic A, Koebel MM (2015) Low Cost Silica Aerogel Production. In: Scartezzini J-L (ed) Proceedings of CISBAT 2015 International Conference on Future Buildings and Districts - Sustainability from Nano to Urban Scale - Vol. I. EPFL Solar Energy and Building Physics Laboratory, Lausanne, pp 27–32

Hasan MA, Sangashetty R, Esther ACM et al. (2017) Prospect of Thermal Insulation by Silica Aerogel: A Brief Review. J Inst Eng Ser D 98:297–304. https://doi.org/10.1007/s40033-017-0136-1

Coffman B, Fesmire J, White S, et al. (2010) Aerogel Blanket Insulation Materials for Cryogenic Applications. In: Weisend J, Barclay J, Breon S, et al. (eds) Advances in Cryogenic Engineering, Vols 55A and 55B. American Institute of Physics, Melville, New York, pp 913–920

Fomitchev DV, Trifu R, Gould G (2004) Fiber Reinforced Silica Aerogel Composites: Thermal Insulation for High-Temperature Applications. In: Malia RB, Maji A (eds) Engineering Construction and Operations in Challenging Environments Earth and Space 2004: Proceedings of the Ninth Biennial ASCE Aerospace Division International Conference. ASCE, Texas, pp 968–975

Shao Z, He X, Niu Z et al. (2015) Ambient pressure dried shape-controllable sodium silicate based composite silica aerogel monoliths. Mater Chem Phys 162:346–353. https://doi.org/10.1016/j.matchemphys.2015.05.077

Ban G, Song S, Lee HW, Kim HT (2019) Effect of Acidity Levels and Feed Rate on the Porosity of Aerogel Extracted from Rice Husk under Ambient Pressure. Nanomaterials 9:300. https://doi.org/10.3390/nano9020300

Kumar RS, Vinjamur M, Mukhopadhyay M (2013) A Simple Process to Prepare Silica Aerogel Microparticles from Rice Husk Ash. Int J Chem Eng Appl 4:321–325. https://doi.org/10.7763/ijcea.2013.v4.318

Voinescu AE, Kellermeier M, Carnerup AM et al. (2007) Co-precipitation of silica and alkaline-earth carbonates using TEOS as silica source. J Cryst Growth 306:152–158. https://doi.org/10.1016/j.jcrysgro.2007.03.060

Koebel MM, Rigacci A, Achard P (2011) Aerogels for Superinsulation: A Synoptic View. In: Aegerter MA, Leventis N, Koebel MM (eds) Aerogels Handbook. Springer Science+Business Media, New York, pp 607–633

Wu X, Shao G, Liu S et al. (2017) A new rapid and economical one-step method for preparing SiO2 aerogels using supercritical extraction. Powder Technol 312:1–10. https://doi.org/10.1016/j.powtec.2017.01.067

Toth AJ (2019) Comprehensive evaluation and comparison of advanced separation methods on the separation of ethyl acetate-ethanol-water highly non-ideal mixture. Sep Purif Technol 224:490–508. https://doi.org/10.1016/j.seppur.2019.05.051

Global Market Insights Inc. (2019) Ethyl Acetate Market size, Industry Analysis Report, Regional Outlook, Application Development Potential, Price Trends, Competitive Market Share & Forecast, 2019 – 2025

EPA (2006) Action Memorandum: Inert Reassessment – Ethyl Acetate (CAS Reg. No. 141-78-6) and Amyl Acetate (CAS Reg. No 628-63-7.). Washington, D.C

Ng F, Mure T, Jiang M, et al. (2005) Avada—a New Green Process for the Production of Ethyl Acetate. In: Sowa Jr. JR (ed) Catalysis of Organic Reactions. Taylor & Francis Group, Boca Raton, pp 251–260

Prat D, Hayler J, Wells A (2014) A survey of solvent selection guides. Green Chem 16:4546–4551. https://doi.org/10.1039/c4gc01149j

Samanta KK, Basak S, Chattopadhyay SK (2015) Recycled fibrous and nonfibrous biomass for value-added textile and nontextile applications. In: Muthu SSK (ed) Environmental Implications of Recycling and Recycled Products. Springer Science+Business Media, Singapore, pp 167–212

Textile Exchange (2021) Preferred Fiber & Materials Market Report 2021

Smith B (2003) Wastes From Textile Processing. In: Andrady AL (ed) Plastics and the Environment. John Wiley & Sons Inc., New Jersey, pp 243–309

Karahan M, Masood Z, Nawab Y, Karahan N (2018) Development and Characterization of Hybrid Green Composites from Textile Waste. In: Trzcielinski S (ed) Advances in Ergonomics of Manufacturing: Managing the Enterprise of the Future. Springer International Publishing, Los Angeles, pp 37–49

Blount DH (1990) US4954327: Production of silica aerogels

Chen H, Wang X, Li J, Wang X (2015) Cotton derived carbonaceous aerogels for the efficient removal of organic pollutants and heavy metal ions. J Mater Chem A 3:6073–6081. https://doi.org/10.1039/c5ta00299k

Bi H, Yin Z, Cao X et al. (2013) Carbon fiber aerogel made from raw cotton: A novel, efficient and recyclable sorbent for oils and organic solvents. Adv Mater 25:5916–5921. https://doi.org/10.1002/adma.201302435

Cheng H, Gu B, Pennefather MP et al. (2017) Cotton aerogels and cotton-cellulose aerogels from environmental waste for oil spillage cleanup. Mater Des 130:452–458. https://doi.org/10.1016/j.matdes.2017.05.082

Motahari S, Javadi H, Motahari A (2015) Silica-Aerogel Cotton Composites as Sound Absorber. J Mater Civ Eng 27:1–6. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001208

Dochia M, Sirghie C, Kozłowski RM, Roskwitalski Z (2012) Cotton fibres. In: Kozłowski RM (ed) Handbook of Natural Fibres: Types, Properties and Factors Affecting Breeding and Cultivation, Volume 1. Woodhead Publishing, Cambridge, pp 11–23

Gulich B (2006) Development of products made of reclaimed fibres. In: Wang Y (ed) Recycling in Textiles. Woodhead Publishing, Cambridge, pp 117–136

Chapagain AK, Hoekstra AY, Savenije HHG, Gautam R (2005) The water footprint of cotton consumption, UNESCO-IHE, Value of Water Research Report Series No. 18. Delft

Muthu SS (2020) Assessing the Environmental Impact of Textiles and the Clothing Supply Chain, 2nd ed. Woohead Publishing, Kidlington

Tan B, Rankin SE (2006) Effects of progressive changes in organoalkoxysilane structure on the gelation and pore structure of templated and non-templated sol-gel materials. J Non Cryst Solids 352:5453–5462. https://doi.org/10.1016/j.jnoncrysol.2006.09.026

Wei G, Liu Y, Zhang X et al. (2011) Thermal conductivities study on silica aerogel and its composite insulation materials. Int J Heat Mass Transf 54:2355–2366. https://doi.org/10.1016/j.ijheatmasstransfer.2011.02.026

Anderson AM, Carroll MK (2011) Hydrophobic Silica Aerogels: Review of Synthesis, Properties and Applications. In: Aegerter MA, Leventis N, Koebel MM (eds) Aerogels Handbook. Springer Science+Business Media, New York, pp 47–74

Meador MAB (2011) Improving Elastic Properties of Polymer-Reinforced Aerogels. In: Aegerter MA, Leventis N, Koebel MM (eds) Aerogels Handbook. Springer Science+Business Media, New York, pp 315–334

Purcar V, Cinteza O, Ghiurea M et al. (2014) Influence of hydrophobic characteristic of organo-modified precursor on wettability of silica film. Bull Mater Sci 37:107–115. https://doi.org/10.1007/s12034-014-0628-7

Kanamori K, Aizawa M, Nakanishi K, Hanada T (2007) New transparent methylsilsesquioxane aerogels and xerogels with improved mechanical properties. Adv Mater 19:1589–1593. https://doi.org/10.1002/adma.200602457

Kanamori K, Nakanishi K (2011) Controlled pore formation in organotrialkoxysilane-derived hybrids: From aerogels to hierarchically porous monoliths. Chem Soc Rev 40:754–770. https://doi.org/10.1039/c0cs00068j

Hearle JWS (2007) Physical structure and properties of cotton. In: Gordon S, Hsieh Y-L (eds) Cotton: Science and technology. Woodhead Publishing, Boca Raton, p 35–67

ISO (2008) ISO 22007-2 Plastics — Determination of thermal conductivity and thermal diffusivity — Part 2: Transient plane heat source (hot disc) method

ASTM International (2017) ASTM C518- Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. West Conshohocken, PA

ASTM International (2004) C 1498-04a Standard Test Method for Hygroscopic Sorption Isotherms of Building Materials. West Conshohocken, PA

Baktash MY, Bagheri H (2017) A superhydrophobic silica aerogel with high surface area for needle trap microextraction of chlorobenzenes. Microchim Acta 184:2151–2156. https://doi.org/10.1007/s00604-017-2212-5

Eckert M, Fleischmann G, Jira R, et al. (2007) Acetaldehyde. In: Ullmann’s Encyclopedia of Industrial Chemistry. VCHVerlagGmbH&Co.KGaA, Weinheim

Kohlpaintner C, Schulte M, Falbe J, et al. (2005) Aldehydes, Aliphatic and Araliphatic. In: Ullmann’s Encyclopedia of Industrial Chemistry. Wiley-VCHVerlagGmbH&Co.KGaA, Weinheim

Strittmatter H, Hildbrand S, Pollak P (2007) Malonic Acid and Derivatives. In: Ullmann’s Encyclopedia of Industrial Chemistry. Wiley-VCHVerlagGmbH&Co.KGaA, Weinheim

Varshney VK, Naithani S (2011) Chemical Functionalization of Cellulose Derived from Nonconventional Sources. In: Kalia S, Kaith BS, Kaur I (eds) Cellulose Fibers: Bio- and Nano-Polymer Composites: Green Chemistry and Technology. Springer-Verlag, Berlin, pp 43–60

Abbas A, Zhao Y, Zhou J et al. (2013) Improving thermal conductivity of cotton fabrics using composite coatings containing graphene, multiwall carbon nanotube or boron nitride fine particles. Fibers Polym 14:1642–1649

Hearle JWS, Morton WE (2008) Physical properties of textile fibres. Woodhead Publishing Limited, Cambridge

Jaxel J, Markevicius G, Rigacci A, Budtova T (2017) Thermal superinsulating silica aerogels reinforced with short man-made cellulose fibers. Compos Part A Appl Sci Manuf 103:113–121. https://doi.org/10.1016/j.compositesa.2017.09.018

Basit A, Latif W, Ashraf M et al. (2019) Comparison of mechanical and thermal comfort properties of tencel blended with regenerated fibers and cotton woven fabrics. Autex Res J 19:80–85. https://doi.org/10.1515/aut-2018-0035

Frydrych I, Dziworska G, Bilska J (2002) Comparative analysis of the thermal insulation properties of fabrics made of natural and man-made cellulose fibres. Fibres Text East Eur 10:40–44

Stana-Kleinschek K, Ehmann HMA, Spirk S, et al. (2012) Cellulose and other polysaccharides surface properties and their characterisation. In: Navard P (ed) The European Polysaccharide Network of Excellence (EPNOE). Springer-Verlag, Wien, pp 215–251

Wagh PB, Begag R, Pajonk GM et al. (1999) Comparison of some physical properties of silica aerogel monoliths synthesized by different precursors. Mater Chem Phys 57:214–218. https://doi.org/10.1016/S0254-0584(98)00217-X

Al-Oweini R, El-Rassy H (2009) Synthesis and characterization by FTIR spectroscopy of silica aerogels prepared using several Si(OR)4 and R′′Si(OR′)3 precursors. J Mol Struct 919:140–145. https://doi.org/10.1016/j.molstruc.2008.08.025

Torres RB, Vareda JP, Lamy-Mendes A, Durães L (2019) Effect of different silylation agents on the properties of ambient pressure dried and supercritically dried vinyl-modified silica aerogels. J Supercrit Fluids 147:81–89. https://doi.org/10.1016/j.supflu.2019.02.010

Smith BC (1999) Infrared Spectral Interpretation- A Systematic Approach. CRC Press, Boca Raton

Júlio MDF, Ilharco LM (2017) Ambient Pressure Hybrid Silica Monoliths with Hexamethyldisilazane: From Vitreous Hydrophilic Xerogels to Superhydrophobic Aerogels. ACS Omega 2:5060–5070. https://doi.org/10.1021/acsomega.7b00893

Deng Q, Mauritz KA, Moore RB (1995) (Perfluorosulfonate Ionomer)–(Inorganic Oxide) Nanocomposites: Organic Modification of Surfaces of Silicon Oxide Nanoparticles Grown in Situ. In: Mark JE, Lee CY-C, Bianconi PA (eds) ACS Symposium Series, Vol. 585 Hybrid Organic-Inorganic Composites. American Chemical Society, San Diego, pp 66–84

Innocenzi P (2003) Infrared spectroscopy of sol–gel derived silica-based films: a spectra-microstructure overview. J Non Cryst Solids 316:309–319

Kondo T (1997) The assignment of IR absorption bands due to free hydroxyl groups in cellulose. Cellulose 4:281–292

Garside P, Wyeth P (2004) Identification of Cellulosic Fibres by FTIR Spectroscopy: Thread and Single Fibre Analysis by Attenuated Total Reflectance. Stud Conserv 48:269–275. https://doi.org/10.1179/sic.2003.48.4.269

Yan Y (2016) Developments in fibers for technical nonwovens. In: Kellie G (ed) Advances in Technical Nonwovens. Elsevier Ltd., Kidlington, pp 19–96

Shi M, Tang C, Yang X et al. (2017) Superhydrophobic silica aerogels reinforced with polyacrylonitrile fibers for adsorbing oil from water and oil mixtures. RSC Adv 7:4039–4045. https://doi.org/10.1039/C6RA26831E

Chakraborty S, Pisal AA, Kothari VK, Rao AV (2016) Synthesis and characterization of fibre reinforced silica aerogel blankets for thermal protection. Adv Mater Sci Eng 2016:1–8

Li Z, Cheng X, He S et al. (2016) Aramid fibers reinforced silica aerogel composites with low thermal conductivity and improved mechanical performance. Compos Part A 84:316–325. https://doi.org/10.1016/j.compositesa.2016.02.014

Ghica ME, Almeida CMR, Fonseca M et al. (2020) Optimization of polyamide pulp-reinforced silica aerogel composites for thermal protection systems. Polym (Basel) 12:1–5. https://doi.org/10.3390/POLYM12061278

Woignier T, Primera J, Alaoui A et al. (2020) Techniques for characterizing the mechanical properties of aerogels. J Sol-Gel Sci Technol 93:6–27. https://doi.org/10.1007/s10971-019-05173-2

Venkateswara Rao A, Kalesh RR, Amalnerkar DP, Seth T (2003) Synthesis and characterization of hydrophobic TMES/TEOS based silica aerogels. J Porous Mater 10:23–29. https://doi.org/10.1023/A:1024074231777

Iler RK (1979) The Chemistry of Silica —Solubility, Polymerization, Colloid and Surface Properties, and Biochemistry. John Wiley & Sons,Inc., Hoboken

Chen J, Greenlief CM (1997) Reactions of diethylgermane, triethylgermane, and ethyl groups on Ge(100). J Vac Sci Technol A Vacuum. Surf, Film 15:1140–1145. https://doi.org/10.1116/1.580444

Zhuravlev LT (2005) The surface chemistry of silica. Zhuravlev model. Colloid Silica Fundam Appl 173:261–266

Woignier T, Fernandez-Lorenzo C, Sauvajol JL et al. (1995) Raman study of structural defects in SiO2 aerogels. J Sol-Gel Sci Technol 5:167–172. https://doi.org/10.1007/BF00487013

Vareda JP, Matias T, Durães L (2018) Facile preparation of ambient pressure dried aerogel-like monoliths with reduced shrinkage based on vinyl-modified silica networks. Ceram Int 44:17453–17458. https://doi.org/10.1016/j.ceramint.2018.06.213

Edler KJ (2018) Formation of Ordered Mesoporous Thin Films Through Templating. In: Klein L, Aparicio M, Jitianu A (eds) Handbook of Sol-Gel Science and Technology - Processing, Characterization and Applications, 2nd ed. Springer International Publishing AG, Cham-Switzerland, pp 917–983

Abu-Jdayil B, Mourad A-H, Hittini W et al. (2019) Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr Build Mater 214:709–735. https://doi.org/10.1016/j.conbuildmat.2019.04.102

Sekar V, Noum SYE, Sivanesan S et al. (2021) Effect of thickness and infill density on acoustic performance of 3D printed panels made of natural fiber reinforced composites. J Nat Fibers 18:1–9. https://doi.org/10.1080/15440478.2021.1944426

Jones D (2008) Acoustical Treatment for Indoor Areas. In: Ballou GM (ed) Handbook for Sound Engineers, 4th ed. Elsevier Inc., Oxford, pp 65–94

European Commission DG Environment News Alert Service (2011) Science for Environment Policy. Bristol

Feng J, Le D, Nguyen ST et al. (2016) Silica–cellulose hybrid aerogels for thermal and acoustic insulation applications. Colloids Surf A Physicochem Eng Asp 506:298–305. https://doi.org/10.1016/j.colsurfa.2016.06.052

Wakelyn PJ, Bertoniere NR, French AD, et al. (2007) Cotton Fiber Chemistry and Technology. CRC Press, Boca Raton

Raabe J, Fonseca ADS, Bufalino L et al. (2014) Evaluation of reaction factors for deposition of silica (SiO2) nanoparticles on cellulose fibers. Carbohydr Polym 114:424–431. https://doi.org/10.1016/j.carbpol.2014.08.042

Li Y, Wong ASW (2006) Physiology of thermal comfort. In: Li Y, Wong ASW (eds) Clothing biosensory engineering. Woodhead Publishing, Boca Raton, pp 60–73

Wahba M (1948) Moisture relationships of cellulose. I. The heat of wetting in water and in certain organic liquids. J Phys Colloid Chem 52:1197–1208. https://doi.org/10.1021/j150463a012

Varga K, Schädel U, Nilsson H et al. (2007) Measuring the heat of wetting of textile fibres by reaction calorimetry. Fibres Text East Eur 15:59–63

Acknowledgements

The authors are very grateful to SASIA - Reciclagem de Fibras Têxteis, S.A. for kindly providing cotton fibers used in this work. Teresa Linhares and Beatriz Merillas also gratefully acknowledge, respectively, Fundação para a Ciência e a Tecnologia, FCT, I.P., and the Spanish Ministry of Science, Innovation and Universities for their attributed Doctoral Grants.

Funding

Teresa Linhares acknowledges the PhD grant Ref. SFRH/BD/131819/2017, attributed by Fundação para a Ciência e Tecnologia, I.P. (FCT, Portugal), funded by national funds from MCTES (Ministério da Ciência, Tecnologia e Ensino Superior) and, when appropriate, co-funded by the European Commission through the European Social Fund. Consumables for the syntheses and characterizations performed at CIEPQPF and 2C2T research units were funded by the European Regional Development Fund (ERDF), through COMPETE 2020-Operational Programme for Competitiveness and Internationalization, combined with Portuguese National Funds, through FCT, I.P. under the projects POCI-01-0145-FEDER-006910 and POCI-01-0145-FEDER-007136 (FCT Refs. UIDB/EQU/00102/2020 and UID/CTM/00264/2020, respectively). Beatriz Merillas work was supported by the PhD grant Ref. FPU17/03299, funded by the Spanish Ministry of Science, Innovation and Universities (RTI2018-098749-B-I00).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Consent to participate

All authors agreed to participate in this manuscript and were informed about their inclusion.

Consent for publication

The publication of this manuscript was approved by all authors and tacitly or explicitly by the responsible authorities where the work was carried out.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

About this article

Cite this article

Linhares, T., Carneiro, V.H., Merillas, B. et al. Textile waste-reinforced cotton-silica aerogel composites for moisture regulation and thermal/acoustic barrier. J Sol-Gel Sci Technol 102, 574–588 (2022). https://doi.org/10.1007/s10971-022-05808-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-022-05808-x