Abstract

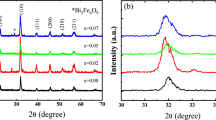

A series of Yb and X co-doped BiFeO3 (X = Nb, Mn, Mo) and undoped BiFeO3 polycrystalline ceramics were prepared by sol-gel method. The X-ray diffraction pattern confirmed the rhombohedral perovskite structure for all the ceramics. Reitveld refinement results bring out the impact of doping on the structural distortion. The Transmission Electron Micrograph observation reveals the nanostructure of the doped samples. Well saturated ferromagnetic hysteresis curves were obtained for the doped samples in contrary to undoped BiFeO3 and this is attributed to the distortion of spin spiral structure. The doped ceramics exhibited improved ferroelectric parameters and very low leakage current density of the order of 10−9 to 10−7 A/cm2, which is remarkably lower than that of undoped BFO. Remarkable dielectric properties were exhibited for the doped samples. An abrupt noticeable enhancement of magetoelectric coupling for the doped samples in comparison with the undoped BiFeO3 has been demonstrated in our work.

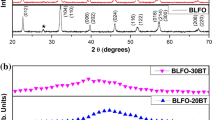

The left figure depicts the ferromagnetic character and the right figure depicts the ferroelectric behavior of (Yb, Nb), (Yb, Mn) and (Yb, Mo) doped BiFeO3 multiferroic

Highlights

-

Novel (Yb, X) doped BFO (X = Nb, Mn, Mo) multiferroic materials were synthesized.

-

All the doped samples exhibit significantly enhanced magnetic, ferroelectric and dielectric properties.

-

Leakage current of the doped BFO is very low compared to that of undoped BFO.

-

Remarkably improved magnetoelectric coupling is shown by the doped samples.

Similar content being viewed by others

References

Kimura T, Goto T, Shintani H, Ishizaka K, Arima T, Tokura Y (2003) Nat Lond 426:55

Hur N, Park S, Sharma PA, Ahn JS, Guha S, Cheong SW (2004) Nat Lond 429:392

Spaldin NA, Feibig M (2005) Science 309:391

Erenstein W, Mathur ND, Scott JF (2006) Nat Lond 442:759

Feibig M, Lottermoser Th, Frohlich D, Goltsev AV, Pisarev RV (2002) Nat Lond 419:818

Kubel F, Schmid H (1990) Acta Crystallogr B 46:698

Fischer P, Polomska M, Sosnowska I, Szymanski M (1931) J Phys C 13:1980

Jiang Y-P, Tang X-G, Liu Q-X, Chen D-G, Ma C-B (2014) J Mater Sci Mater Electron 25:495–499

Yuan GL, Or SW, Liu JM, Liu ZG (2006) Appl Phys Lett 89:052905

Li Y, Fan Y, Zhang H, Teng H, Dong X, Liu H, Ge X, Li X, Chen W, Li X, Ge Z (2014) J Supercond Nov Magn 27:1239

Zhang ST, Zhang Y, Lu MH, Du CL, Chen YF, Liu ZG, Zhu YY, Ming NB, Pan XQ (2006) Appl Phys Lett 88:162901

Ye W, Tan G, Dong G, Ren H, Xia A (2015) Ceram Int 41:4668

Ablat A, Wu R, Mamat M, Li J, Muhemmed E, Si C, Wu R, Wang J, Qian H, Ibrahim K (2014) Ceram Int 40:14083

Quan C, Ma Y, Han Y, Tang X, Lu M, Mao W, Zhang J, Yang J, Li X, Huang W (2015) J Alloy Compd 635:272–277

Hu Z, Li M, Yu Y, Liu J, Pei L, Wang J, Liu X, Yu B, Zhao X (2010) Solid State Commun 150:1088–1091

Yan X, Tan G, Liu W, Ren H, Xia A (2015) Ceram Int 41:3202–3207

Tang P, Kuang D, Yang S, Zhang Y (2016) J Alloy Compd 656:912–919

Beniwal A, Bangruwa JS, Walia R, Verma V (2016) Ceram Int 42:10373–10379

Wang D, Wang M, Liu F, Cui Y, Zhao Q, Sun H, Jin H, Cao M (2015) Ceram Int 41:8768–8772

Hernandez N, Gonzalez-Gonzalez VA, Dzul-Bautista IB, Gutierrez J, Barandiaran JM, Ruiz de Larramendi I, Cienfuegos-Pelaes RF, Ortiz- Mendez U (2015) J Alloy Compd 638:282–288

Arora M, Chauhan S, Sati PC, Kumar M, Chhoker S (2014) Ceram Int 40:13347–13356

Wang T, Song SH, Wang XL et al. (2018) J Sol-Gel Sci Technol 85:356

Priya S, Banu IBS, Anwar MS, Hussain S (2016) J Sol-Gel Sci Technol 80:579

Priya S, Banu IBS, Anwar MS (2016) J Magn Magn Mater 401:333–338

Zheng Y, Tan G, Xia A, Ren H (2016) J Alloy Compd 684:438–444

Ahmed MA, Mansour SF, Ei-Dek SI, Karamany MM (2016) J Rare Earths 34:495–506

Vanga PR, Mangalaraja RV, Giridharan NV, Ashok M (2016) J Alloy Compd 684:55–61

Chen L, He Y, Zhang J, Mao Z, Zhao Y-J, Chen X (2014) J Alloy Compd 604:327–330

Xu J, Wang G, Wang H, Ding D, He Y (2009) Mater Lett 63:855

Ederer C, Spaldin NA (2005) Phys Rev B 71:224103

Rojac T, Bencan A, Malic B, Tutuncu G, Jones JL, Daniels JE, Damjonovic D (2014) J Am Ceram Soc 97:1993

Wang Y, Zheng RY, Sim CH, Wang J (2009) J Appl Phys 105:016106

Palkar VR, Kundaliya DC, Malik SK, Bhattacharya S (2004) Phys Rev B 69:212102

Kumar A, Yadav KL (2013) J Alloy Compd 554:138

Kim WS, Jun YK, Kim KH, Hong SH (2009) J Magn Magn Mater 321:3262

Dutta DP, Mandal BP, Mukadam MD, Yusuf SM, Tyagi AK (2014) Dalton Trans 43:7838

Priya S, Banu IBS, Mohammed Z (2017) J Mater Sci Mater Electron 28:8467

Acknowledgements

The authors acknowledge the sophisticated analytical instrumentation facilities at the Indian Institute of Technology Madras for providing the facility of vibrating sample magnetometer. They also thank the sophisticated test and instrumentation centre, Cochin, for extending the TEM and HRTEM characterization. The authors thank Dr. M. S. Ramachander Rao, Department of Physics, Indian Institute of Technology Madras, for helping to characterize the electrical studies using Radiant Technology Pvt Ltd. The authors are extremely thankful to the Department of Science and Technology, India, for providing the financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lakshmi, S.D., Banu, I.B.S. Multiferroism and magnetoelectric coupling in single-phase Yb and X (X = Nb, Mn, Mo) co-doped BiFeO3 ceramics. J Sol-Gel Sci Technol 89, 713–721 (2019). https://doi.org/10.1007/s10971-018-4901-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4901-x