Abstract

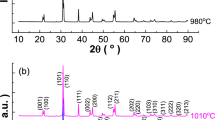

The influences of oxygen vacancies on the dielectric and electrical properties of Na1/2Bi1/2Cu3Ti4O12 ceramics prepared using a urea combustion method were investigated via an annealing treatment in an O2 atmosphere. Interestingly, a single Na1/2Bi1/2Cu3Ti4O12 phase was successfully prepared using a low calcination temperature of 800 °C. High dielectric permittivity (ε′) and dense ceramic microstructure were achieved by sintering compacted powders at a low temperature of 980 °C. ε′ and the loss tangent (tanδ) were decreased by annealing in an O2 atmosphere. This was associated with the oxygen vacancy concentration at grain boundaries (GBs). A decrease in low-frequency tanδ was caused by enhancement of GB resistance, which was due to filling oxygen vacancies at GBs. A slight decrease in ε′ was attributed to the reduction in GB capacitance. Through use of an annealing process, the conduction activation energy at GBs was increased, whereas the conduction activation energy inside the grains remained unchanged. These results clearly indicated the effect of oxygen vacancy concentration at the GBs on the giant dielectric response and correlated GB response.

Graphical Abstract

Similar content being viewed by others

References

Subramanian MA, Li D, Duan N, Reisner BA, Sleight AW (2000) J Solid State Chem 151:323

Krohns S, Lunkenheimer P, Meissner S, Reller A, Gleich B, Rathgeber A, Gaugler T, Buhl HU, Sinclair DC, Loidl A (2011) Nat Mater 10:899

Liu L, Fan H, Fang P, Chen X (2008) Mater Res Bull 43:1800

Liu L, Fan H, Fang P, Jin L (2007) Solid State Commun 142:573

Zhang JL, Zheng P, Wang CL, Zhao ML, Li JC, Wang JF (2005) Appl Phys Lett 87:142901

Shao SF, Zhang JL, Zheng P, Zhong WL, Wang CL (2006) J Appl Phys 99:084106

Krohns S, Lunkenheimer P, Ebbinghaus SG, Loidl A (2008) J Appl Phys 103:084107

Yang J, Shen M, Fang L (2005) Mater Lett 59:3990

Adams TB, Sinclair DC, West AR (2006) J Am Ceram Soc 89:3129

Marques VPB, Ries A, Simões AZ, Ramírez MA, Varela JA, Longo E (2007) Ceram Int 33:1187

Shao SF, Zhang JL, Zheng P, Wang CL (2007) Solid State Commun 142:281

Thomas P, Dwarakanath K, Varma KBR (2012) J Eur Ceram Soc 32:1681

Sun D-L, Wu A-Y, Yin S-T (2008) J Am Ceram Soc 91:169

Jha P, Arora P, Ganguli AK (2003) Mater Lett 57:2443

Hao W, Zhang J, Tan Y, Su W (2009) J Am Ceram Soc 92:2937

Shri Prakash B, Varma KBR (2006) J Mater Sci Mater Electron 17:899

Subramanian MA, Sleight AW (2002) Solid State Sci 4:347

Liang P, Yang Z, Chao X, Liu Z (2012) J Am Ceram Soc 95:2218

Qiu Y, Yuan S, Tian Z, Chen L, Wang C, Duan H, Guo K (2012) Appl Phys A 107:379

Liu Z, Chao X, Yang Z (2014) J Mater Sci Mater Electron 25:2096

Somphan W, Sangwong N, Yamwong T, Thongbai P (2012) J Mater Sci Mater Electron 23:1229

Tuichai W, Thongbai P, Amornkitbamrung V, Yamwong T, Maensiri S (2014) Microelectron Eng 126:118

Kum-onsa P, Thongbai P, Putasaeng B, Yamwong T, Maensiri S (2015) J Eur Ceram Soc 35:1441

Liang P, Li Y, Li F, Chao X, Yang Z (2014) Mater Res Bull 52:42

Yang Z, Liang P, Yang L, Shi P, Chao X, Yang Z (2015) J Mater Sci Mater Electron 26:1959

Ren H, Liang P, Yang Z (2010) Mater Res Bull 45:1608

Liu J, Duan C-G, Yin W-G, Mei W, Smith R, Hardy J (2004) Phys. Rev. B 70:144106

Liu J, Sui Y, Duan C-G, Mei W-N, Smith RW, Hardy JR (2006) Chem Mater 18:3878

Xu B, Zhang J, Tian Z, Yuan SL (2012) Mater Lett 75:87

Su Y, Song J, Liu R, Huang H (2013) J Electroceram 30:166

Liu Z, Jiao G, Chao X, Yang Z (2013) Mater Res Bull 48:4877

Rahaman MN (2003) Ceramic Processing and Sintering, 2nd edn. M. Dekker, New York

Mukherjee S, Gonal MR, Patel MK, Roy M, Patra A, Tyagi AK, Menon M (2012) J Am Ceram Soc 95:290

Wu J, Nan C-W, Lin Y, Deng Y (2002) Phys Rev Lett 89:217601

Meeporn K, Yamwong T, Pinitsoontorn S, Amornkitbamrung V, Thongbai P (2014) Ceram Int 40:15897

Liang P, Li Y, Chao X, Yang Z (2014) Mater Res Bull 60:212

Schmidt R, Stennett MC, Hyatt NC, Pokorny J, Prado-Gonjal J, Li M, Sinclair DC (2012) J Eur Ceram Soc 32:3313

Thongbai P, Putasaeng B, Yamwong T, Amornkitbamrung V, Maensiri S (2014) J Alloys Compd 582:747

Acknowledgments

This work was financially supported by the Higher Education Research Promotion and National Research University Project of Thailand, Office of the Higher Education Commission, through the Advanced Functional Materials Cluster of Khon Kaen University. This work was partially supported by the Integrated Nanotechnology Research Center (INRC), Khon Kaen University. W. Tuichai would like to thank the Thailand Graduate Institute of Science and Technology (TGIST) for his Master of Science Degree scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tuichai, W., Danwittayakul, S., Yamwong, T. et al. Synthesis, dielectric properties, and influences oxygen vacancies have on electrical properties of Na1/2Bi1/2Cu3Ti4O12 ceramics prepared by a urea combustion method. J Sol-Gel Sci Technol 76, 630–636 (2015). https://doi.org/10.1007/s10971-015-3814-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3814-1