Abstract

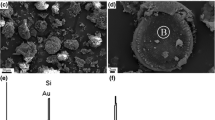

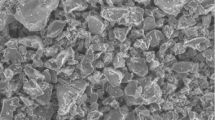

Silicon nitride (Si3N4) wires have been prepared by means of carbothermal reduction followed by the nitridation (CTRN) of silica gel containing ultrafine decomposed saccharose. The influence of temperature of reaction and mass ratio of carbon to silicon \( \left( \frac{C}{Si} \right) \) on the synthesis of Si3N4 wires were studied. The presence of nitrogen gas in the pores of gel at high temperature starts the CTRN reaction leading to the formation of Si3N4 wires. The results show that the Si3N4 was fully formed with two kinds of morphologies including globular and wire with a width of 100–500 nm and length of several microns at sintering temperature of 1,400 °C by employing the mass ratio of \( \frac{C}{Si} \; = \;0.5 \). The infrared adsorption of the wires exhibits absorption bands related to the absorption peaks of Si–N bond of Si3N4. The thermal analysis results reveal that carbothermal nitridation reaction was completed at temperature of 1,400 °C.

Similar content being viewed by others

References

Ljiljana SC, Slobodan K, Bahloul-Hourlier D (2002) Surface properties of silicon nitride powders. Physicochem Eng Aspects 197:147–156

Riley FL (2000) Silicon nitride and related materials. J Am Ceram Soc 83:245–265

Jinhui D, Jianbao L, Yongjun Ch (2003) Effect of the residual phases in β-Si3N4 seed on the mechanical properties of self-reinforced Si3N4 ceramics. J Eur Ceram Soc 23:1543–1547

Aleksandra V, Snez B, Branko M, Milan V, Vladimir K (2006) Effect of β-Si3N4 seeds on densification and fracture toughness of silicon nitride. Ceram Int 32:303–307

Mahua Gh, Rajib D, Manoj M, Siddhartha M (2008) A novel method for synthesis of α–Si3N4 nanowires by sol–gel route. Sci Technol Adv Mater 9:2–6

Pez-Sua reza A, Fandin J, Monroy BM, Santana G, Alonso JC (2008) Study of the influence of NH3 flow rates on the structure and photoluminescence of silicon-nitride films with silicon nanoparticles. Physical 40:3141–3146

Feng W, Xiaofan Q, Guoqiang J, Xiangyun G (2010) Temperature-controlled synthesis of Si3N4 nanomaterials via direct nitridation of Si powders. Physica 42:2033–2035

Ortega A, Alcala MD, Real C (2008) Carbothermal synthesis of silicon nitride (Si3N4): kinetics and diffusion mechanism. J Mater Process Technol 195:224–231

Cengiz B, Halil A (2010) Investigation of direct pressureless sinterability of Si3N4 produced from brown sepiolite and its characterization. Sci Res Essays 5:309–321

Jian F, Shao-Yun Sh, Gerold S, Tatsuki O, Shuzo K (2005) Synthesis of fibrous β-Si3N4 structured porous ceramics using carbothermal nitridation of silica. Acta Mater 53:2981–2990

Martin H, Stefan K, Bohumil D, Jana M, Pavol S (2003) Synthesis of high purity Si3N4 and SiC powders by CVD method. Ceramics—Silikáty 47:88–93

Weiqiang H, Shoushan F, Qunqing L, Binglin G (1997) Synthesis of silicon nitride nanorods using carbon nanotube as a template. J Appl Phys 71:16–20

MinKee K, JongKu P, Hae-Weon L, Shinhoo K (2005) A cyclic process for the nitridation of Si powder. Mater Sci Eng A 408:85–91

Priya S, Larry L (2003) Mesoporous calcium silicate glasses. I. Synthesis. J Non-Cryst Solids 318:1–13

Halil A (2003) Synthesis of Si3N4 by the carbo-thermal reduction and nitridation of diatomite. J Eur Ceram Soc 23:2005–2014

Ortega A, Alcala MD, Real C (2008) Carbothermal synthesis of silicon nitride (Si3N4): kinetics and diffusion mechanism. J Mater Process Technol 195:224–231

Mashkoor A, Jiong Z, Caofeng P, Jing Z (2009) Ordered arrays of high-quality single-crystalline Si3N4 nanowires: synthesis, properties and applications. J Cryst Growth 311:4486–4490

Feng W, Guo-Qiang J, Xiang-Yun G (2006) Sol–gel synthesis of Si3N4 nanowires and nanotubes. Mater Lett 60:330–333

Lia XK, Liua L, Zhangb YX, Shenb ShD, Geb Sh, Linga LCh (2001) Synthesis of nano metric silicon carbide whiskers from binary carbonaceous silica aerogels. Carbon 39:159–165

Hwa Y, Jeunghee P, Hyunik Y (2003) Synthesis of silicon nitride nanowires directly from the silicon substrates. Chem Phys Lett 372:269–274

Nuray K, Osman A, Zkan Toplan H (2009) Synthesizing high α-phase Si3N4 powders containing sintering additives. Ceram Int 35:2381–2385

Silva PC, Figueiredo JL (2001) Production of SiC and Si3N4 whiskers in C + SiO2 solid mixtures. Mater Chem Phys 72:326–331

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omidi, Z., Ghasemi, A. & Bakhshi, S.R. The influence of processing parameters on the fabrication of Si3N4 wires. J Sol-Gel Sci Technol 64, 245–250 (2012). https://doi.org/10.1007/s10971-012-2853-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-012-2853-0