Abstract

This research uses two different dosimetry techniques (films and gels) to evaluate how γ-rays affect anthocyanin, AC, a naturally occurring pigment found in carrots. The first method relies on combining AC with poly (vinyl alcohol) to create a thin film dosimeter, while the second uses AC with gelatin to create a gel dosimeter that is more sensitive to γ-rays. The produced film or gel changes visually from red to colorless when exposed to γ-rays. The usable dose range of films was up to 35 kGy, and for gels, it was between 10 and 150 Gy. All dosimetric characteristics were studied.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A wide variety of natural sources, including plants, animals, minerals, and microorganisms, are used to create natural dyes and pigments [1, 2]. Natural pigments found in plants' leaves, roots, fruits, flowers, and some grains of corn are antioxidants, such as anthocyanin. Anthocyanin, derived from red carrots, is the most common category of water-soluble flavonoids, deeply colored substances that provide red, purple, and blue coloration [3]. These substances are also used as food coloring agents, and consumers are increasingly interested in creating natural colorants for food use instead of synthetic ones [4, 5].

Radiation treatment has been thoroughly studied, with a focus on food irradiation and medical sterilization in particular. It was primarily started as the ultimate minimum processing approach [6]. When subjected to gamma radiation, a material, equipment, or system known as a radiation dosimeter changes and may be measured by any instrumental analytical technique, including a UV-spectrophotometer, electron spin resonance, infrared, and electrical conductivity. Long-term stability is one of the many benefits [7,8,9]. These days, dosimeters are vital for determining how much ionizing radiation a subject has been exposed to in one, two, or three dimensions. The principal objectives of a dosimeter are to ensure its long-term stability, simplicity, cost-effectiveness, and the ability to demonstrate a permanent color change or bleaching under ionizing radiation either gamma or X-ray doses [9,10,11]. A plastic film that relies on the mixing of pigments or dyes with a polymer such as poly (vinyl alcohol), PVA is used in radiation dosimetry [9]. Polymers are readily available, flexible, and clear, making them suitable for manufacturing dosimetric films. Recent advancements in radiation dosimetry have resulted in the development of a new thin plastic film dosimeter using dyes, pigments and PVA. This film can be easily prepared in a lab and is considered a promising radiation dosimeter [12]. PVA is widely used to produce polymeric films due to its good chemical and physical qualities, its ability to form films well, and its hydrophilicity, which makes it a highly porous substance. It is a substance that dissolves in water and has a considerable number of hydroxyl groups. It may be combined with dye to create optical materials [7, 10]. Numerous types of dosimeter are utilized for high-dose dosimetry applications, including film dosimeters [7,8,9,10,11,12,13,14] and liquid dosimeters [15,16,17,18,19]; low-dose dosimetry applications typically involve the use of sensitive dosimeters. The gel dosimeter is considered the most sensitive type, as it combines an organic dye with a substance that is highly sensitive to gelation, such as gelatin. This sensitive dosimetry system, falling under the category of low-dose dosimetry applications such as medical radiation dosimetry, was the subject of various techniques at this stage [7, 20,21,22,23,24,25].

Using the extracted red carrot anthocyanin as the basis, the current study compared two dosimetry systems; gel dosimeters and thin plastic films. These dosimeters were used for low- and high-dose gamma radiation examinations to assess the potential applications of these samples as novel dosimeters for monitoring ionizing absorbed radiation in radiotherapy, seed production, water treatment, medical sterilization and food irradiation processing. Several dosimetric characteristics were examined.

Materials and methods

Preparation of AC/PVA film dosimeters

To investigate colored polymeric films, 5 g of PVA powder (average M.W. 19,000 fully hydrolyzed, 99–100% purity J.T. Baker Chemical Co., USA) were dissolved in 125 ml of double-distilled water at a temperature of about 60 °C. After approximately twenty-four hours of vigorous stirring at that temperature, the solution was allowed to cool. Additionally, each 14 ml of PVA solution contained 0.61, 1.21, and 2.5 phr of AC stock solution (phr* = parts per hundred parts of resin), which was then mixed for approximately three hours at room temperature to create a uniformly colored solution. Following a final stirring, the colored PVA solutions were cast onto a 10 × 10 cm vertical glass sheet and allowed to dry for about 72 h at room temperature. The film thickness was measured to be 0.043 ± 0.03 mm (1σ).

Preparation of AC/gelatin gel dosimeters

After dissolving the gelatin derived from porcine skin (300 blooms, G2500, Sigma-Aldrich) in distilled water, AC pigment was added from a stock solution. The mixture was stirred regularly in a water bath at 70 ± 5 °C for four hours to facilitate rapid color transfer. In a previous study using the same materials and method [2], three different dye concentrations (3.4 × 10−3, 6.8 × 10−3, and 1.4 × 10−2 mol L−1) and a gelatin concentration of 20% w/w of gelatin (mass of gelatin relative to the mass of the final gel) were dripped from a pipette into a 1 cm-thick glass test tube. The test tubes were then immediately placed in a refrigerator at approximately 4 °C for four hours. Scheme 1 shows the structure of Anthocyanin.

Instrumental analysis and irradiation

An UV4-visible spectrophotometer (KONTRON Co. Ltd., Switzerland) was used to evaluate the absorption spectra of both irradiated and unirradiated films and gel samples in the 200–800 nm wavelength range. Moreover, the gamma-irradiation process was carried out using a Co-60 Gamma Cell GC-220 Excel (manufactured by MDS Nordion, Canada) with an absorbed dose rate of 1.2 kGy h−1. The film thickness was measured using a Digitrix-Mark II thickness gauge (precision ± 1 µm, 1σ).

Results and discussion

Absorption spectra

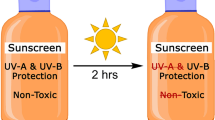

To apply a thin plastic film and a gel dosimeter, two different dosimetry approaches that rely on the same pigment anthocyanin will be discussed. Previous research has shown that films tend to be used at high gamma-ray-absorbed doses, whereas gel dosimeters are suitable for low-dose applications [6,7,8,9]. In addition, Figs. 1 and 2 may be used to explain why various absorbed dosages of materials (films or gels) cause varied color changes when evaluated spectrophotometrically throughout the wavelength range of 300–800 nm [2].

Based on the absorption spectra of the AC/PVA films and gels (2.5 phr and 1.4 × 10−2 mol L−1, respectively), it can be inferred that the visible region of the absorption spectra of both irradiated and unirradiated films shows a central absorption sharp peak with a red color that peaks at 540 nm for dyed films and a slightly broad peak for gels, respectively. Meanwhile, as the absorbed dosage of γ-rays increases, the peak's magnitude gradually declines. According to this study, the spectra of the films and gels exposed to radiation revealed that this pigment bleached [25,26,27].

Radiation response curves

Anthocyanin's have the potential to be highly reactive and easily broken down into colorless compounds [2]. For the dose measurements [2, 7, 8], optical density was read at 540 nm for anthocyanin films and gels. The prepared samples, AC/PVA and AC/Gelatin, have response curves in Figs. 3 and 4 that illustrate the variation in absorption coefficient, ΔA, at 540 nm against the absorbed dose, D, where (ΔA = Ao − Ai) and Ao and Ai are values of the absorption coefficient for the unirradiated and irradiated films or gels, respectively. Moreover, the pigment concentrations in the films are 0.61, 1.21, and 2.5 phr, and for the gel samples, the pigment concentrations are 3.4 × 10−3, 6.8 × 10−3, and 1.4 × 10−2 mol L−1. The response curve indicates evidence that the film dosimetry system's usable dosage ranges up to 35 kGy, depending on the pigmnt concentrations, and for the gel dosimetry system, up to 150 Gy.

By examining the data from the two response curves, 3 and 4, we observe that the influence of gamma radiation on water has been previously studied [2]. Furthermore, it is also known that two dosimetry systems, the polymer PVA and the gelatin were dissolved in water and that many radiolytic species from the water were affected by gamma rays, which were considered to be free radicals, oxidizing, and reducing agents that made the process of bleaching the pigment easier [16].

The PVA polymer in films, on the other hand, has a structure that is dependent on free hydrogen and hydroxyl atoms. When the film is dissolved in water following radiation, a large number of reactive species participate in the reaction that leads to pigment degradation or color bleaching; however, the rigidity of the film reduces the reaction, which explains why film dosimeters have a wide dose range [9,10,11,12].

In contrast, gel dosimetry systems exhibit high sensitivity to gamma radiation due to the composition of the medium, which involves gelatin dissolved in water and combined with pigment. Additionally, all of these materials are exposed to gamma radiation since gelatin is a naturally occurring, nontoxic biopolymer composed of polypeptides with an internal structure that links various amino acids through peptide bonds, such as (–NH–CO–), which is similar to a hydrogen bond [22]. Furthermore, radioactive species with easy, medium-free mobility in the gel accelerate the reaction rate. For these and other reasons, gel dosimeters are the most sensitive dosimetry systems among all the systems that have been prepared [2]. Finally, these prepared dosimeters can be applied in many fields such as food irradiation processing, medical sterilization, seed production, blood irradiation, and water treatment.

Radiation chemical yield (G-value)

The number of moles of dye destroyed by the absorption of 1 J of energy is known as the radiation-chemical yield (G-value) (unit: mol/J). The general relation is used to determine the G-value [28].

where ΔA is the change in absorbance at λmax, b is the optical path length (1 cm), ε is the molar extinction coefficient at λmax (L mol−1 cm−1), ρ is the density of the solid AC/PVA films and AC/Gelatin gels dosimeters (g cm−3), D is the absorbed dose (Gy). Using the dye concentration in mol/L and the average value of A0/b, the molar extinction coefficient of these concentrations had been found to be 1211.3 L mol−1 cm−1 for Anthocyanin incorporating with gelatin and 32,402 L mol−1 cm−1 for Anthocyanin incorporating with the polymer PVA. The computed G-value for these gels or films and the concentration of the dye inside the gels or films matrix were listed in Tables 1 and 2, using the densities of gelatin and PVA to calculate the G-value in terms of µmol/J. It is clear from the tables, Figs. 5 and 6 that, in both cases, the G-value increases as the dye concentration increase. This might be a result of the number of PVA and gelatin radiolysis products. However, the data from the two tables revealed that, compared to the equivalent pigment in PVA, the radiolysis and bleaching of the pigment in the gelatin composite increased. This is because gelatin has a polypeptide bond structure. [19, 21] However, after being exposed to radiation, PVA includes free hydrogen atoms and hydroxyl groups, but in a solid, thin plastic film where the free mobility of radiolytic species is lower than that of ions, free radicals, oxidizing and reducing agents, and free radicals in the gel mixture [2, 17]. As a result, the gel samples' G-values are greater than the film samples', indicating that gel dosimeters are more sensitive to gamma radiation and its range of applications than film dosimeters.

Humidity rates during irradiation affect the performance of AC/PVA films

By irradiating [AC/PVA] = 2.5 phr at a 10 kGy dose of radiation at various relative humidities (0, 11, 33, 54, 76, and 92%), the influence of RH during irradiation on the dose–response functions of these films is examined [9]. With the exception of the 0% RH film, which was created using films suspended over dried silica gel, all of the films were irradiated while they were suspended over different saturated-salt solutions in an enclosed jar. In order to achieve equilibrium moisture content in the dosimeter during irradiation, films were held for three days prior to irradiation under circumstances of the same relative humidity.

Figure 7 displays, against the RH% of the films following γ-ray exposure, the relative response (Ai/Ao) change at 540 nm, normalized with the value observed at RH 33%. The film's response is not significantly affected by an increase in RH during irradiation in the range of 0–54%. Nevertheless, the highest RH levels have a major influence on the response and cause the RH values to drop significantly. It is thus strongly recommended to package and seal the dosimeter films tightly within the RH range of 0–54% in order to minimize the errors caused by RH effects during irradiation. The films must be calibrated using actual processing conditions if that is not possible.

Sensitivity and comparative study between media

Film dosimeters may be used up to 35 kGy, which is considered a high-dose dosimetry application based on prior research [6, 9,10,11,12]. However, these films are less sensitive to gamma-radiation based on data estimates of G-values. In contrast, the manufactured gel dosimeter, which uses the same pigment, has an extended dosage range of up to 150 Gy. This can be classified distinguished as a low-dose dosimetry application but has the advantage of greater sensitivity to gamma radiation [19].

Assessment of uncertainties

The reproducibility of the Unicam UV-4vis Spectrophotometer was determined by reading the absorbance value (at 540 nm) of irradiated films several times. From the data obtained, it was found that the coefficient of variation (1σ) is ± 0.25%, reflecting the precision of the spectrophotometer. The reproducibility of the thickness gauge was determined by reading the thickness value for AC/PVA films several times. Furthermore, it was found that the coefficient of variation (1σ) is ± 0.44%. The reproducibility of the measurements of several films (20 times for each film) was found to be 0.55% (1σ).

On the other hand, the type A uncertainties (at one standard deviation, i.e. 1σ) arising during calibration over the useful response range were found to be ± 2.6% (ISO/ASTM, 2004) [29]. Combining all the components in quadrature at one standard deviation 1σ is explained as follows:

The expanded uncertainty (at two standard deviations, i.e. 2σ, approximately equal to a 95% confidence level) is found by multiplying Uc (at 1σ) by two. Hence, the combined uncertainty using TP/PVA film is 5.4%.

Pre-irradiation stability

The absorbance of the produced AC/PVA/Gelatin was measured at a wavelength of 540 nm at regular intervals during the two-month pre-irradiation storage period. Figure 8 illustrates that these films demonstrate good stability under both dark and light storage conditions at room temperature. Figure 9 indicates that the produced gel samples, exhibit acceptable stability before irradiation throughout the storage period.

Post-irradiation stability

After being exposed to 10 kGy of radiation, the AC/PVA films exhibited post-irradiation stability at a concentration of 2.5 phr. As demonstrated in Fig. 10, the samples showed strong stability after irradiation under light and dark conditions at room temperature, except for the first 4 days for samples exposed to light and dark. Both stabilities after irradiation of these films were very good for about two months. However, Fig. 11, which evaluated the stability of these irradiated samples exposed to 20 Gy, showed appropriate results under various storage conditions for approximately one month. The gel samples were kept in the dark, at room temperature, and in daylight.

Conclusion

The dosimetric characteristics of thin plastic films and gel samples containing various concentrations of the natural color anthocyanin were studied. Both the gel and thin plastic film samples showed a noticeable radiation-induced UV-spectrophotometer peak, which decreased as the radiation-absorbed doses increased. The gel and film samples were able to absorb up to 35 kGy and 150 Gy of gamma-ray radiation; respectively. However, the radiation chemical yield (G-value) calculations indicated that the gel dosimeters were more sensitive than the films. Additionally, it was found that the relative humidity in the range of 0–54% at the time of irradiation did not affect the AC/PVA film dosimeter. Moreover, pre- and post-irradiation stability over 30 days, while these film dosimeters respond with exceptional pre- and post-irradiation stability during 60-day storage and their due date. Eventually, the constructed dosimeters indicate that they can be effectively used for dosimetry applications, including both low and high doses.

References

Lizamoni C, Smita B, Ava RP (2021) Natural dyes: extraction and applications. Int J Curr Microbiol Appl Sci 10(1):1669–1677

Abd-El-Kader NM, Gafar SM (2022) Effect of gamma radiation on a natural pigment and its possible use as a label dosimeter. J Radioanal Nucl Chem 331(1):461–467

Lourembam MD, Amit BD, Laxmikant SB (2023) Effect of gelatin and acacia gum on anthocyanin coacervated microcapsules using double emulsion and its characterization. Biolog Macromolecul 235:123896

Rezvan S, Javad H, Sodeif AD, Hamed H, Bahram FA (2018) Double emulsion followed by complex coacervation as a promising method for protection of black raspberry anthocyanins. Food Hydrocollo 77:803–816

Hock EK, Azrina A, Sou TT, See ML (2017) Anthocyanidins and anthocyanins: colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr Res 61(1):136–142

Gafar SM, Abdel-Kader NM (2020) Dosimetric characteristics and applications of cross-linking and degradation of a natural biopolymer gum acacia. Radiochim Acta 108(3):223–229

Gafar SM, El-Kelany M (2017) Development of two dosimeters for industrial use with low doses. Nucl Tech Radiat Prot 32:148–154

El-Kelany M, Gafar SM (2016) Preparation of radiation monitoring labels to γ ray. Optik 127:6746–6753

Gafar SM, El-Ahdal MA (2015) A new developed radiochromic film for high-dose dosimetry applications. Dye Pigm 114:273–277

Rabaeh KA, Basfar AA, Hammoudeh IME (2023) Novel polyvinyl alcohol film dosimeter containing 3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide dye for high dose application. Nucl EngTech 55:3383–3387

Chand B, Priyamvda KM, Sangeeta P, Mukesh K (2022) Feasibility study of a chlorophyll dosimeter for high energy X-ray beam used in radiotherapy. J Radioanal Nucl Chem 331:1881–1887. https://doi.org/10.1007/s10967-021-08106-y

Gafar SM, El-Ahdal MA (2014) Dosimetric characteristics of 2,6 di-nitro phenol for high dose dosimetry. Dye Pigment 109:67–71

Kattan M, Kassiri H, Daher Y (2011) Using polyvinyl chloride dyed with bromocresol purple in radiation dosimetry. Appl Radiat Isot 69(2):377–380

Rabaeh KA, Basfar AA (2020) A polystyrene film dosimeter containing dithizone dye for high dose applications of gamma-ray source. Radiat Phys Chem 170:108646

Gafar SM, Abd El-Kader NM, Mohamed TM (2020) Radiation induced Bismuth nanoparticles and its possible use as radiation dosimeter. Radiat Effect Defect Solids 175(5–6):529–539

Gafar SM, Abdel-Kader NM (2020) Radiation induced degradation of murexide dye in two media for possible use in dosimetric applications. Pigment Resin Technol 48(6):540–546

Chairunisa W, Imawan C (2020) the radiochromic indicator using methyl red dye solution as a high-dose gamma-ray dosimeter application. IOP Conf Ser Mater Sci Eng 763:1–5

Abdel-Kader NM, Gafar SM (2019) Development of two dosimetry systems based on basic violet dye for possible use as radiation dosimeters. Pigment Resin Technol 51(2):204–211

Sobhy A, Faheem E, Gafar SM (2019) Dosimetric studies and chemical kinetics of resazurin dye and its possible use as radiation dosimeter. J Radioanal Nucl Chem 45:1–7

Gafar SM, El-Ahdal MA (2016) Radiochromic fuchsine gel and its possible use for low dosimetry applications. Adv Polym Technol 35(2):146–151

Moftah B, Basfar AA, Almousa AA, Al Kafi AM, Rabaeh KA (2020) Novel 3D polymer gel dosimeters based on N-(3-Methoxypropyl)acrylamide (NMPAGAT) for quality assurance in radiation oncology. Radiat Measurm 135:106372

Gafar SM, El-Shawadfy SR, El-Kelany MA (2022) Effect of gamma rays on sensitive prepared dyed gels as radiation dosimeters. J Radioanal Nucl Chem 331:4425–4435

Lotfy S, Basfar AA, Moftah B, Al-Moussa AA (2017) Comparative study of nuclear magnetic resonance and UV–visible spectroscopy dose-response of polymer gel based on N-(Isobutoxymethyl) acrylamide. Nucl Instrum Method Phys Res B 413:42–50

Rabaeh KA, Eyadeh MM, Hailat TF, Aldweri FM, Alheet SM, Eid RM (2018) Characterization of ferrous-methylthymol bluepolyvinyl alcohol geldosimeters using nuclear magnetic resonance and optical techniques. Radiat Phys Chem 148:25–32

Butson MJ, Peter KNY, Tsang C, Peter M (2003) Radiochromic film for medical radiation dosimetry. Mater Sci Eng R Rep 41(3–5):61–120. https://doi.org/10.1016/S0927-796X(03)00034-2

Ramirez-Niño J, Mendoza D, Castaño VM (1998) A comparative study on the effect of gamma and UV irradiation on the optical properties of chlorophyll and carotene. Radiat Meas 29:195–202. https://doi.org/10.1016/S1350-4487(97)00248-5

Foldvary CM, Wojnarovits L (2009) Role of reactive intermediates in the radiolytic degradation of acid red1 in aqueous solution. Radiat Phys Chem 78:13–18

McLaughlin WL, Desrosiers MF (1995) Dosimetry systems for radiation processing. Radiat Phys and Chem 46(4–6):163–174

ISO/ASTM 51707 (2004) Standard Guide for Estimating Uncertainties in Dosimetry for Radiation Processing. In: Annual Book of ASTM Standards. ASTM International, West Conshohocken, PA

Acknowledgements

The National Center for Radiation Research and Technology (NCRRT) of the Egyptian Atomic Energy Authority (EAEA), located in Nasr City, Cairo, Egypt, provided financial assistance for this research in the field of fundamental radiation technology applications.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). This work was supported by The National Center for Radiation Research and Technology (NCRRT) of the Egyptian Atomic Energy Authority (EAEA).

Author information

Authors and Affiliations

Contributions

The study's idea and design involve all of the writers. Moreover, material preparation, data collection, and analysis were done by H. H. El-Tokhy and S. M. Gafar. They wrote a draft of the text. Comments were made on all manuscript revisions regarding software, visualization, computations, peer review, and editing. All authors have read and approved the final draft.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Ethical approval

This article does not contain any studies involving human participants or animals performed by any of the authors.

Consent for publication

All authors mutually agree the submission of the manuscript to Journal of Radioanalytical and Nuclear chemistry.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gafar, S.M., El-Tokhy, H.H. The effective role of a natural pigment extracted from carrots and its applications in dosimetry. J Radioanal Nucl Chem (2024). https://doi.org/10.1007/s10967-024-09560-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10967-024-09560-0