Abstract

The metal retention behaviors of several simulated radiolysis products on zirconium metal were investigated, and it was found that acid phosphate radiolysis product HDEHP has the greatest effect. The effects of extraction nitric acid concentration, simulated radiolysis product concentration, metal concentration, and temperature on the zirconium metal retention behavior were also investigated. The results showed that zirconium metal forms complexes with HDEHP resulting in retention in the organic phase. Nitric acid concentration and metal concentration change the morphology of the metal thus affecting the extraction and metal retention behavior. The temperature has almost no effect on metal retention.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Plutonium Uranium Redox Extraction (PUREX) process is the most widely applied used nuclear fuel reprocessing process, utilizing an organic phase solvent system consisting of tributyl phosphate (TBP) mixed with a long-chain aliphatic hydrocarbon diluent for the recovery and separation of uranium–plutonium[1,2,3]. However, in the process, organic solvents are exposed to high levels of radioactivity and acidity, which makes them susceptible to radiation degradation. With the increased burnup of used nuclear fuel, the problem of radiolysis of PUREX solvents has become increasingly important and has been studied more and more extensively [4, 5]. The study found that the main radiolysis products of TBP/diluent systems are hydrogen, methane [6], acid phosphate esters (such as DBP and MBP) [7, 8], nitroalkanes [9], and other substances [10]. Due to the generation of radiolysis products, it is necessary to decontaminate the dirty solvent after several cycles of use. However, in the purification and regeneration of dirty solvents after irradiation decomposition, it was found that the radiolysis products can be divided into temporary radiolysis products and permanent radiolysis products, and the temporary radiolysis products (such as DBP and MBP) can be removed by alkali washing [11], while the permanent radiolysis products cannot be removed by alkali washing and will accumulate with solvent reuse [12]. Meanwhile, in the study of irradiation stability of the TBP/diluent system, it was found that in the presence of diluent, some strong metal complex agents that are difficult to be removed by alkali washing will appear [4]. These permanent radiolysis products, which are difficult to remove, are known to significantly impact the used nuclear fuel reprocessing process and may lead to problems such as difficult separation of two phases[13], generation of interfacial crud[14], and red oil accidents[15]. Furthermore, the strong metal complexing agent in the permanent radiolysis product will complex with the metal in the extraction process, making it difficult to enter the aqueous phase, resulting in the retention of uranium–plutonium elements or fission products during extraction, stripping, and solvent washing reuse. The issue of metal retention has occurred at the UP3 plant in France [16], the Tokai reprocessing plant in Japan [17], and the fast reactor reprocessing plant in India [18]. Since the metal retention problem directly impacts the trend of metals in the PUREX process and reduces the decontamination and recovery of uranium–plutonium metals, it is necessary to investigate the causes and mechanisms of the metal retention problem.

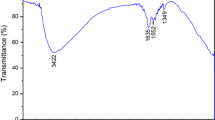

Previous scholars conducted a series of studies on metal retention and it was found that the irradiated TBP/diluent/nitric acid system appeared metal retention for actinide metals such as uranium and plutonium, and fission products such as ruthenium and zirconium [12, 19,20,21]. Furthermore, the metal retention values of plutonium, ruthenium, and zirconium increase continuously with increasing irradiation doses [12, 19, 22, 23]. In order to investigate which radiolysis product is responsible for the metal retention problem, The solvents causing metal retention after irradiation were separated using high vacuum distillation, and it was found that the heavy fraction had a strong retention effect on zirconium metal. The fraction was characterized by FTIR, GCMS, and NMR, and was found to contain ketones, acid phosphate esters [4], nitroalkanes [24], alcohols, and carboxylic acids [13]. Therefore, many hypotheses have been proposed by previous scholars for the permanent radiolysis products that cause metal retention. For example, the nitroalkane hypothesis, the hydroxamic acid hypothesis, the long-chain acid phosphate hypothesis, etc. [25]. However, there are many different opinions and it is difficult to conclude. Studies have shown that irradiation decomposition products of the TBP-diluent-nitrate system contain nitroalkane radiolysis products, and the secondary products of nitroalkanes, hydroxamic acids, and compounds produced by nitration of acidic phosphates with diluents are thought to be closely related to metal retention phenomena and have attracted extensive discussion. Hydroxamic acid is a powerful metal complexing agent and is thought to contribute to the metal retention phenomenon. And alkaline washing actually increases this hydroxamic acid concentration via the Nef reaction of the enol form of the nitroparaffin [26].

However, there has been considerable debate regarding the stability and role of radiolytically-produced hydroxamic acids and nitroparaffins in metal complexation [27]. It was noted that not enough hydroxamic acid was detected in the irradiated solvent to cause metal retention. The combination of higher molecular weight acidic phosphate produced by TBP irradiation with compounds produced by diluent nitration has been noted in the literature to cause difficulties in reverse extraction and poor separation factors [19]. However, studies on long-chain acidic phosphates indicate that some long-chain acidic phosphates have a strong retention effect on metals. In past studies, it was pointed out that TBP generates acid phosphate esters with long chains with carbon chain lengths of about 6 to 12 (hexyl to octyl) with diluents under irradiation, and the length of the side chain alkyl group of the long chain acid phosphate ester is related to the type of diluent [28, 29]. Dioctyl acid phosphate and butyl lauryl phosphate (HBLP) both exhibit properties similar to those of strongly complexed radiolysis products [30, 31]. Single long-chain alkyl acid phosphate esters had strong extraction and retention effects on zirconium metal while forming 2:1 type complexes [32]. As for the density functional study for the formation of complexes between acid phosphate and actinide metal elements, it was indicated that the bond lengths of coordination bonds formed between acid phosphate and Pu elements are shorter than those of TBP due to the influence of the steric hinder of the ligands, and have the higher coordination affinity [33]. Therefore, the acid phosphate hypothesis has gained more general agreement. There have been many studies on the retention of metals by HDBP and H2MBP [21, 34], however, the study of long-chain acid phosphate radiolysis products formed by the radiolysis of diluents together with TBP is not well defined [4]. Meanwhile, carboxylic acids and alcohols have been found to be important radiolysis products [10], however, their metal retention behavior has not been confirmed.

Bis(2-ethylhexyl) phosphate (HDEHP) is a homologue of dioctyl acid phosphate and a typical long-chain acid phosphate with branched chains, and it has been less studied before. Therefore, it was chosen to simulate the long-chain acidic phosphate ester radiolysis products, and 1-dodecanoic acid and 1-dodecanol were also chosen to investigate the retention of zirconium metal by carboxylic acid and alcohol radiolysis products. They were added to 30% TBP/n-DD to simulate the solvent after irradiation. Subsequently, extraction experiments were conducted to verify their effects on zirconium metal extraction. In the presence of HDEHP, the effects of nitric acid concentration, radiolysis product concentration, metal concentration, and temperature factors on metal retention values were investigated. In this work, whether HDEHP, dodecanoic acid and dodecanol retain metal zirconium was verified, and the substances that cause metal retention were further clarified, and experiments were conducted to investigate the effect of various influencing factors on the metal retention value, to investigate the mechanism of metal retention phenomenon, and to study the method of reducing the metal retention value by changing the parameters such as nitric acid concentration. The relationship between the concentration of radiolysis products and the metal retention value has been established, which contributes to the formulation of standards for the purification of dirty solvents, the determination of the concentration of radiolysis products that requires the purification of dirty solvents by distillation, and the increase of the number of cycles of extraction solvents.

Experimental

Materials

N-Dodecane (98%), Bis(2-ethylhexyl) phosphate (99%), Dodecanoic acid (99%), and 1-Dodecanol (98%) were purchased from Shanghai Macklin Biochemical Co., Ltd (Shanghai, China). The other chemicals were of analytical grade and purchased from Sino pharm Reagent Co., Ltd, and used without additional purification. The molecular structure of HDEHP is shown in Scheme 1.

Solvent Extraction experiment

Zirconium stock solution was prepared from zirconium nitrate pentahydrate. Zirconium nitrate pentahydrate was dissolved in different concentrations of the nitric acid solution by heating in a water bath, which generated aqueous zirconium nitrate solutions with different nitric acid concentrations, and then diluted to obtain aqueous zirconium nitrate solutions with different metal concentrations. The organic solution of 30/70 (v/v)% TBP/n-DD was obtained by dissolving TBP in the n-dodecane diluent. The simulated radiolysis products were added to the organic phase to obtain the simulated post-radiation solution. In the 1AF process in the PUREX process, a high acid feed is often used in order to improve the purification factor of the ruthenium, typically using a feed acidity of 3 mol L−1 to 4 mol L−1 for the nitric acid [35], and it was found in the study that the zirconium metal would hydrolyze into different forms when the acidity was too low [36], so a higher concentration of 4 mol L−1was selected as the experimental concentration in the concentration range; and the zirconium metal concentration in the process ranges from 8.8 mmol L−1 to 22 mmol L−1, and a relatively wider range has been chosen for experiments with zirconium metal in the literature [37], so the metal concentration was selected as the 10 mmol L−1 concentration value. Unless otherwise stated, the metal ion concentration and nitric acid concentration of the aqueous solution are 10 mmol L−1 Zr(IV) and 4 mol L−1 HNO3, respectively. it is known that the yield of irradiated decomposition products after irradiation is in the range of 0.12 g L−1–0.52 g L−1 [38], so a concentration of 10 mmol L−1 was chosen as the mixing ratio of TBP and simulated radiolysis products.

The extractant solution was taken in a 15 mL centrifuge tube and mixed with an equal volume of aqueous zirconium nitrate solution, and the extraction was carried out on a constant-temperature shaker for 30 min. It is demonstrated that 30 min is enough for the two phases to reach equilibrium. After a period of extraction, the phase was split by centrifugation in a centrifuge (LG16B high-speed centrifuge, Leiboer Medical Devices Co., Ltd., Beijing, China) at 2500 rpm for 10 min. An aliquot of the aqueous raffinate was taken into an individual tube containing 0.1 M HNO3 and the zirconium concentration was assayed by ICP-MS (X-II ICP-MS, Thermo Fisher Scientific, Waltham, MA, USA). The zirconium concentration in the organic phase after extraction was calculated using the subtraction method, and the ratio of zirconium concentration in the organic and aqueous phases was calculated. The distribution ratio, D, was derived from

where \(c_{o}\) is the metal concentration value in the organic phase after extraction and \(c_{w}\) is the metal concentration value in the aqueous raffinate. The error of the data obtained in the experiment is within 5%.

Zirconium retention

The zirconium metal retention values of the organic phase were measured using the fixed ratio method [19]. The organic phase solution after extraction and centrifugation was taken out and firstly stripped six times with an equal volume of 0.01 M nitric acid, then washed three times with an equal volume of 5% wt. Na2CO3, then washed three times with an equal volume of 0.1 M nitric acid and then washed with distilled water to neutralize. The aqueous phase after each washing was centrifuged, the metal concentration of the aqueous phase after washing was measured by ICP-MS, and the metal concentration of the organic phase after washing was calculated using the subtraction method. The ratio of the zirconium metal concentration in the organic phase after washing to the zirconium metal concentration in the organic phase after extraction was the retention value. The retention value, r, was derived from

where \(c_{1}\) is the metal concentration value in the organic phase after extraction and \(c_{2}\) is the metal concentration value in the organic phase after washing.

Results and discussion

Effects of several simulated radiolysis products on zirconium extraction

1-Dodecanoic acid, 1-dodecanol, and HDEHP were mixed with 30% TBP/n-DD solution, respectively, to obtain simulated radiolysis product solutions, and the literature showed that the concentration of radiolysis products and diluent degradation products (DDP) in the PUREX process ranged from 10–5 mol L–1 to 10–1 mol L–1[38]. Therefore the concentration of several simulated radiolysis products was determined to be 10−2 M. The solution of simulated radiolysis products was extracted with an aqueous solution of zirconium nitrate, and after extracting for different times, the phase was separated by centrifugation. The Zr concentration in the aqueous phase was measured by ICP-MS, and the Zr concentration in the organic phase was determined by subtraction, and the results are displayed in Fig. 1. As can be seen from Fig. 1, in the presence of 1-dodecanoic acid and 1-dodecanol, the extraction equilibrium time and extraction distribution ratio of the solution for zirconium metal were almost no different from that of pure 30% TBP/n-DD, while in the presence of HDEHP it was found that the extraction equilibrium time for zirconium metal became significantly faster and was completely equilibrated at 10 min, and the extraction distribution ratio became significantly larger, reaching 0.473. This work focuses on zirconium retention, so HDEHP, which has the greatest influence on the extraction and retention process of zirconium, was selected for the study.

The significant effect of HDEHP on zirconium extraction may be related to its ability to extract metal cations more strongly than TBP. Metal performed through ion exchange at low acidity while the solvation effect by sharing the electron pairs in the oxygen atoms from P = O dominated at high acidity [39, 40]. It is stated in the literature that the tetravalent cations of zirconium bind to HDEHP via cation-exchange and solvate mechanisms. Compounds M(NO3)nDEHP4-n are formed in a nitric acid medium, and the formation of M(NO3)2DEHP2∙2HDEHP is possible in mixtures of acids [39]. The equilibrium equation for the extraction of these two extractants is shown in Eq. (4–6).

The positively charged metal cation interacts with the negative dipole on the phosphoryl oxygen of TBP, resulting in the formation of a metal solvate [41]. The nonpolar butyl tails of TBP keep the resulting metal solvate dissolved in the aliphatic hydrocarbon diluent. And the hydrogen ions in HDEHP exchange with positively charged metal cations to form neutral metal complexes. In a study using alkyl phosphates for extraction of tetravalent metal cations, it was indicated that the \(\Delta {\text{G}}\) of the reaction for HDEHP extraction of tetravalent metal cations became smaller than that of TBP extraction, indicating that it reacts more easily with metals to form complexes[42].

Meanwhile, for the synergistic extraction system in which TBP and HDEHP coexist, a synergistic extraction effect of neutral extractant and acidic chelating extractant may be formed. It is indicated in the literature that when a mixture of HDEHP and TBP is used to extract metals, the former produces a neutral chelate with the metal cation, but the coordination number of the metal ion is not yet saturated, so it can further complex with TBP to form a stable extraction complex that is electrically neutral and saturated with coordination number, thus greatly increasing the extraction distribution ratio [43].

The following reaction was given to explain this phenomenon in a study on the synergistic extraction of metal cations by HDEHP and TBP [44]:

where L is the neutral extractant (TBP in this case) and HA is the acidic extractant (HDEHP in this case).

Effect of nitric acid concentration in the aqueous phase of extraction on the extraction and retention of zirconium

It was found that at high acidity, the zirconium distribution ratio varies significantly with the nitric acid concentration. Therefore, to investigate the effect of nitric acid concentration during extraction on the extraction and retention of zirconium metal, the extraction distribution ratios and retention values of zirconium for the HDEHP-TBP/n-DD system were determined at nitric acid concentrations in the range of 4 mol L–1 to 8 mol L–1 and the results are shown in Fig. 2. From Fig. 2-a, it can be seen that the extraction distribution ratio of zirconium metal increases slowly with the increase of the nitric acid concentration in the extraction aqueous phase at 4–6 mol L–1, while the extraction distribution ratio of zirconium metal increases significantly with the increase of the nitric acid concentration in the extraction aqueous phase at 6–8 mol L–1. It is assumed that the salting-out effect of N \({\mathrm{O}}_{3}^{-}\) resulted in an overall increasing trend of the distribution ratio. It is stated in the literature that in the extraction of zirconium metal by TBP, the extraction distribution ratio rises significantly as the nitric acid concentration rises when the nitric acid concentration is 2–8 M [45]. The reason for this is related to the following equations. It is stated in the literature that zirconium ions undergo hydrolysis in aqueous nitric acid solutions [36], and the chemical reaction equilibrium equation is given in Eq. (8).

Equation (8) states that in the aqueous nitric acid solution zirconium metal exists in the form of \({\text{Zr(OH)}}_{{\text{n}}}^{{\text{4 - n}}}\), which gradually transforms into extractable Zr4 + as the nitric acid concentration rises [36], therefore, as the concentration of nitric acid rises, all the reactants in Eq. (6) rise, leading to a significant increase in the extraction distribution ratio. And in the extraction of zirconium metal by HDEHP, at lower acidity it is shown that zirconium ions are extracted by ion exchange with hydrogen ions dissociated from HDEHP, and as the acidity rises, the dissociation of HDEHP is inhibited by hydrogen ions in nitric acid and extraction tends to occur more through the solvation effect, so the concentration of the HA substance in Eq. (5) and Eq. (7) rises, leading to an increase in the distribution ratio.

As can be seen from Fig. 2-b, the metal retention values in the washed organic phase gradually decreased with the increasing nitric acid concentration of the extracted aqueous phase in the experimental range. When the nitric acid concentration of the extracted aqueous phase increased to 7 mol L–1, the zirconium metal in the organic phase could be almost completely removed after stripping, alkaline washing, and acid washing, and it was assumed that the morphology of zirconium might have changed at the higher nitric acid concentration of the extracted aqueous phase.

Effect of the concentration of simulated radiolysis products in organic solvents on the extraction and retention of zirconium

To investigate the effect of the concentration of simulated radiolysis products in organic solvents on the extraction and retention of zirconium metal, the extraction distribution ratio, and retention values of zirconium for the HDEHP-TBP/n-DD system were determined for different HDEHP concentrations, and the results are shown in Fig. 3.

From Fig. 3-a, it can be seen that the distribution ratio increased gradually with the increase of HDEHP concentration in the experimental concentration range, and the distribution ratio increased slowly between \({1\times 10}^{-3}\) mol L–1 and \({1\times 10}^{-2}\) mol L–1, while it increased rapidly in the range of \({1\times 10}^{-2}\) mol L–1 to \({2\times 10}^{-2}\) mol L–1. The distribution ratio reached 80 or more. The reason may be that HDEHP has a stronger extraction capacity for zirconium than TBP, and they both form a synergistic extraction, which makes the extraction distribution ratio much higher.

It was stated in the study for HDEHP that because of the presence of P-OH and P = O bonds, HDEHP ligands tend to exist as dimers or polymers in non-polar diluents by forming intermolecular hydrogen bonds [46]. And suggested possible reactions, such as the equation[42]:

From Fig. 3-b, it can be seen that in the experimental concentration range, the metal retention value also increased gradually with the increase of HDEHP concentration. When the concentration of HDEHP reached \(1 \times 10^{ - 3}\) mol L–1, the metal retention value could reach more than 23% ± 2%, which had already seriously affected the solvent extraction separation and washing purification process. And at the HDEHP concentration of \(2 \times 10^{ - 2}\) mol L–1, the metal retention value reached more than 92% ± 3%, and it was almost impossible to remove zirconium metal from the organic phase by stripping and washing. In a study of organic solvent wastes at the nuclear fuel reprocessing plant in Karlsruhe, Germany, it was noted that at concentrations of \(5 \times 10^{ - 5}\) mol L–1 of long-chain acid phosphate esters, the solvent could no longer be used [47].

The cause of metal retention is unclear, and some studies have stated that it may be related to the aggregation of acid phosphate extractants in the extraction process with the formation of reversed micelles [48]. However, during the adsorption and elution experiments of zirconium using HDEHP sorbent, it was found that the structure of the residual HDEHP-zirconium complex was very similar to that of the third phase, while the aggregation of the extractant was not confirmed [49].

Effect of the temperature on the extraction and retention of zirconium

In order to investigate the effect of temperature during extraction and washing on the extraction and retention of zirconium metal, the extraction distribution ratio and retention values of zirconium for the HDEHP-TBP/n-DD system were determined at different temperatures, and the results are shown in Fig. 4. As can be seen from Fig. 4-a, the distribution ratio gradually increased with the increase of temperature over the range of the experiment. The extraction distribution ratio gradually increased from about 3.6 at 298 K to about 5.0 at 338 K. It is assumed that the extraction reaction of zirconium by the HDEHP-TBP/n-DD system is endothermic in nature, and the reaction equilibrium constant gradually increases with the increase of temperature, and the reaction moves positively, resulting in an increase of the distribution ratio.

According to the Vant' Hoff equation, the relationships between the Gibbs free energy change ∆G, the enthalpy change ∆H, the entropy change ∆S, the extraction equilibrium constant K, and the temperature T are given in Eq. (10):

From the relationship between the distribution ratio D and the equilibrium constant K of the extraction reaction, Eq. (11) can be obtained.

The enthalpy change ΔH can be calculated by plotting the slope of 1/T and lgD, and the result is shown in Fig. 5. From the calculation of the Fig. 5, \(\Delta_{{\text{r}}} {\text{H}}\) = 6.624 kJ mol–1, it can be seen that the extraction of zirconium by HDEHP-TBP/n-DD system is endothermic in nature, and increasing the temperature can promote the reaction in a positive direction.

Meanwhile, it can be seen from Fig. 4-b that the metal retention values did not change significantly with the increase of temperature in the range of the experiment, and it can be concluded that the effect of temperature on metal retention is not significant.

Effect of the concentration of Zr in the aqueous phase on the extraction and retention of zirconium

In the PUREX process, the concentration of metal ions varies in a certain range due to differences in the extraction process, fuel burnup, etc., and the literature states that the concentration range is generally 8.8 mmol L–1 to 22 mmol L–1 [37]; therefore, experiments were carried out to cover various process situations with Zr concentration in the range of 5 mmol L–1 to 50 mmol L–1. To investigate the effect of metal cation concentration on extraction and retention, the extraction distribution ratios and retention values of zirconium for the HDEHP-TBP/n-DD system were determined for different zirconium metal cation concentrations, and the results are shown in Fig. 6. As can be seen from Fig. 6-a, the distribution ratio decreases significantly as the metal concentration increases in the concentration range of the experiment. The extraction distribution ratio decreases rapidly from about 500 ± 5 at the metal concentration of 5 mmol L–1 to about 0.8 ± 2% at the metal concentration of 25 mmol L–1. The reason may be that under the condition of higher metal cation concentration, due to the limited content of extractant molecules, the metal cation is too much at this time to complex with the extractant molecules sufficiently, resulting in a decrease in the extraction distribution ratio.

Meanwhile, it was shown that with increasing zirconium metal concentration, the morphology of zirconium in solution gradually changes from extractable Zr4+ and ZrOH3+ to inextractable \({\text{Zr}}_{3}\text{(O}{\text{H)}}_{4}^{8+}\). The equilibrium equations for the extraction reactions of these forms and the reactions transformed between them are given in the following equations[37]:

From Fig. 6-b, it can be seen that the retention value of zirconium metal shows a trend of increasing and then decreasing with the increase of metal concentration in the experimental concentration range, and the maximum value occurs at the metal concentration of 15 mmol L–1. This phenomenon may be caused by a combination of two reasons: on the one hand, as the concentration of metal cations increases, the total amount of metal ions extracted into the organic phase gradually increases, which is difficult to be removed by alkaline washing, resulting in an increase in the metal retention value; on the other hand, as the concentration of metal cations increases, the extraction distribution ratio decreases, and the metal ions extracted into the organic phase gradually become saturated and are more easily removed by stripping, resulting in a decrease in metal retention values. Therefore, as the concentration of metal cations increases, the former effect dominates before the inflection point and the latter effect after the inflection point.

Conclusions

In this paper, three simulated radiolysis products, 1-dodecanoic acid, 1-dodecanol, and HDEHP, were investigated by adding them to 30% TBP/n-DD to simulate the solution after radiation. The effect of these simulated radiolysis products on the extraction and retention behavior of zirconium was evaluated by determining the extraction distribution ratio of zirconium. The results show that 1-dodecanoic acid and 1-dodecanol have almost no effect on the extraction of zirconium metal, however, when HDEHP is present, the extraction distribution ratio of the simulated radiation solution for zirconium metal increases considerably. It can be concluded that alcohols and carboxylic acids have no significant effect on the retention of zirconium metal, while the effect of acidic phosphate esters is significant.

The factors influencing the extraction and retention behavior of HDEHP-TBP/n-DD solutions for zirconium metal were subsequently investigated. The results indicated that (1) With the increase of nitric acid concentration, the distribution ratio of zirconium metal gradually increases while the retention value gradually decreases, which may be related to the salt-out effect and competition effect of nitric acid, and to the extraction of metal ions by HDEHP at high acidity through the solvation effect. (2) With the increase of HDEHP concentration, both the distribution ratio and retention value of zirconium metal increase, which indicates that the acid phosphate radiolysis products have a significant effect on the solution. (3) With the increase of temperature, the distribution ratio of zirconium metal gradually increases, while the change of retention value is not significant, which proved that the extraction of zirconium metal by the HDEHP-TBP/n-DD system is endothermic in nature. (4) With the increase of metal cation concentration, the extraction distribution ratio gradually decreases while the metal retention value first increases and then decreases, which may be related to the excess of metal ions.

However, the mechanism of metal retention caused by acidic phosphate esters is not well understood and needs to be further investigated.

References

Geist A, Adnet J-M, Bourg S, Ekberg C, Galán H, Guilbaud P, Miguirditchian M, Modolo G, Rhodes C, Taylor R (2020) An overview of solvent extraction processes developed in Europe for advanced nuclear fuel recycling, part 1 – heterogeneous recycling. Sep Sci Technol 56:1866–1881

Paulillo A, Dodds JM, Palethorpe SJ, Lettieri P (2021) Reprocessing vs direct disposal of used nuclear fuels: the environmental impacts of future scenarios for the UK. Sust. Mater. Technol 28:e00278. https://doi.org/10.1016/j.susmat.2021.e00278

Baker A, Fells A, Carrott MJ, Maher CJ, Hanson BC (2022) Process intensification of element extraction using centrifugal contactors in the nuclear fuel cycle. Chem Soc Rev 51:3964–3999

Mincher BJ, Modolo G, Mezyk SP (2009) Review Article: The Effects of Radiation Chemistry on Solvent Extraction: 1. Conditions in Acidic Solution and a Review of TBP Radiolysis. Solvent Extr Ion Exch 27:1–25

Wang F, Horne GP, Pernot P, Archirel P, Mostafavi M (2018) Picosecond pulse radiolysis study on the radiation-induced reactions in neat tributyl phosphate. J Phys Chem B 122(28):7134–7142. https://doi.org/10.1021/acs.jpcb.8b03715

Wang Y, Wan Y, Cai Y, Yuan L, Feng W, Liu N (2021) A review of the alpha radiolysis of extractants for actinide lanthanide separation in spent nuclear fuel reprocessing. Radiochim Acta 109:603–623

Serenko YuV, Belova EV, Ponomarev AV, Yudin NV (2022) The effect of radiolysis and thermally stimulated acid hydrolysis on tributyl phosphate and its solutions in ISOPAR-M. Rad Phys Chem 195:110080. https://doi.org/10.1016/j.radphyschem.2022.110080

Zilberman BY, Chistyakov VM (2016) α-Radiolysis of the tributyl phosphate–hydrocarbon diluent–nitric acid system. Radiochemistry 58:188–202

Dzhivanova Z, Kadyko M, Smirnov A, Belova E (2019) Study of the products of radiation and thermal destruction in the extraction system of 30 vol% TBP–Isopar-M–HNO3. J Radioanal Nucl Chem 321:439–447

Mishra S (2019) Characterization of gamma irradiated PUREX solvent – a systematic study. Sep Sci Technol 55:1485–1494

Velavendan P, Pandey NK (2021) Studies on the behavior of zirconium on the removal of DBP from degraded solvent by sodium carbonate wash. Bhabha Atomic Research Centre, India

Gao Y, Zheng W, Cao X, Chen S (2014) Influence of alpha and gamma radiolysis on Pu retention in the solvent TBP/kerosene. Nukleonika 59:123–128

Mishra S, Soda AK, Sridhar M, Mallika C, Pandey NK, Mudali UK (2018) Identification of diluent degradation products in radiolyzed PUREX solvent. Solvent Extr Ion Exch 36:54–65

Chen J (2004) Crud in the Solvent Extraction Process for Spent Fuel Reprocessing. At Energy Sci Technol 38:343–349

Li J, Li Z, Zhao H, Geng Y, Yang Z, Lan Z (2022) The investigation on thermal decomposition of TBP/n-dodecane-HNO3 mixtures. J Radioanal Nucl Chem 331:1559–1571

Delange M (1992) Advances in Technology and process in the spent fuel reprocessing operations in France. J Min Process Extr Metall Rev 9:83–90

Kawaguchi Y, Morimoto K, Kitao T, Ohyama K, Omori E (2009) Study of solvent degradation in reprocessing MOX spent fuelsolvent degradation and its effect on Pu purification cycle. Transact Atomic Energy Soc Japan 8:221–229

Natarajan R, Vijayakumar V, Subba Rao RV, Pandey NK (2015) Experiences of reprocessing of plutonium-rich mixed carbide fuels. J Radioanal Nucl Chem 304:401–407

Song FLYLJ, Zhe SU et al (2011) Retention of nitrato complexes of nitrosylruthenium by radiolyzed TBP-n-dodecane-HNO_3. J Nuclear Radiochem 33:148–155

Hidematsu I, Manabu T, Takehiko K (2005) Uranium (UO22+) retention property of degraded n-dodecane by acidic radiolysis in the purex process. Radioisotopes 54:35–40

Subramee Sarkar A, Suresh NS (2020) Alpha and gamma degradation behavior of tri-n-alkyl phosphates and tris(2-methylbutyl) phosphate: a comparative study. Rad Phys Chem 176:108923. https://doi.org/10.1016/j.radphyschem.2020.108923

Gao Y, Zheng W, Cao X, Chen S (2014) Studies on Pu238 induced alpha radiolysis of the solvent TBP. J Radioanal Nucl Chem 303:377–383

Sreenivasulu B, Suresh A, Rajeswari S, Ramanathan N, Antony MP, Sivaraman N, Joseph M (2017) Physicochemical properties and radiolytic degradation studies on tri-iso-amyl phosphate (TiAP). Radiochim Acta 105:249–261

Tripathi SC, Bindu P, Ramanujam A (2001) Studies on the identification of harmful radiolytic products of 30% TBP-n-dodecane-HNO3 by gas liquid chromatography. I. Formation of diluent degradation products and their role in Pu retention behavior. Sep Sci Technol 36:1463–1478

Gao Y, Zheng W (2010) Studies on the radiolysis stability of solvent in PUREX process. Atomic Energy Press, China

Lane ES (2017) Performance and degradation of diluents for TBP and the cleanup of degraded solvents. Nucl Sci Eng 17:620–625

Song FL, Li JY, Zhou CX, Li HB, Lin CS (2011) Analysis of radiolytic products of TBP extraction system. J Nucl Radiochem 33:12–17

Tian M-K, Tang S-L, Tang H-B, Ju X-H, Martinho JMG (2020) Theoretical study on the mechanism for the formation of nitro compounds in red oil. J Chem 2020:1–10

Rochon AM (1980) Study on composition of zirconium binding compounds in irradiated PUREX-solvents. Radiochem Radioanalytic Lett 44:277–285

Maya L, Bopp CD (1978) Studies of Zr complexes with butyl lauryl phosphoric acid. United States

Maya L (1981) Zirconium behavior in the system HNO3-30% tributyl phosphate-dodecane in the presence of monobutyl phosphoric acid. J Inorg Nucl Chem 43:379–384

Chen P, Wang X (1991) Extraction and retention behaviour of zirconium by monoalkyl long chain acidic phosphate. J Nuclear Radiochem 13(11):12–17

Hongbin LU (2016) Density functional theoretical analysis of complexes of tributylphosphate and dibutylphosphate of Pu(IV). J Nuclear Radiochem 38:282–287

Uetake N (1989) Precipitation formation of zirconium-dibutyl phosphate complex in Purex process. J Nucl Sci Technol 26:329–338

Liu Z, Zhang H, Liu F, Zhou X, Wang R, Li L (2016) Chemical behavior of neptunium in the system of 30%TBP/kerosene-nitric acid solution. J Nuclear Radiochem 38:337–341

Milonjić SK, Bošković MR, Ćeranić TS (2006) Adsorption of uranium(VI) and zirconium(IV) from acid solutions on silica gel. Sep Sci Technol 27:1643–1653

George K, Masters AJ, Livens FR, Sarsfield MJ, Taylor RJ, Sharrad CA (2022) A review of technetium and zirconium extraction into tributyl phosphate in the PUREX process. Hydrometallurgy 211:105892. https://doi.org/10.1016/j.hydromet.2022.105892

Tripathi SC, Gupta KK, Bindu M, Gandhi PM (2012) Studies on the changes in the composition of solvent during photochemical generation of uranous ions in uranium loaded 30 % TBP-n-dodecane-HNO3 system. J Radioanal Nucl Chem 295:657–661

Ekatova TY, Kazakov AG (2019) Extraction-chromatographic behavior of Zr(IV) and Hf(IV) on TRU and LN resins in mixtures of HNO3 and HF. J Radioanal Nucl Chem 321:557–563

Zhang W, Yu S, Zhang S, Zhou J, Ning S, Wang X, Wei Y (2019) Separation of scandium from the other rare earth elements with a novel macro-porous silica-polymer based adsorbent HDEHP/SiO2-P. Hydrometallurgy 185:117–124

Srinivasan TG, Suresh A, Prasanna R, Jayanthi N, Rao PRV (2007) Metal-solvate stoichiometry evaluation in extractions by solvating type neutral extractants-a novel approach. Solvent Extr Ion Exch 14:443–458

El-Sweify FH, Abdel-Fattah AA, Ali SM (2008) Extraction thermodynamics of Th(IV) in various aqueous organic systems. J Chem Thermodyn 40:798–805

Nayak PK, Kumaresan R, Venkatesan KA, Antony MP, Vasudeva Rao PR (2013) A new method for partitioning of trivalent Actinides from high-level liquid waste. Sep Sci Technol 48:1409–1416

Lumetta GJ, Gelis AV, Vandegrift GF (2010) Review: solvent systems combining neutral and acidic extractants for separating trivalent lanthanides from the transuranic elements. Solvent Extr Ion Exch 28:287–312

Puzikov EA, Zilberman BY, Fedorov YS, Blazheva IV, Krinitsyn AP, Sytnik LV, Ryabkov DV, Goletskii ND (2015) Interaction of zirconium with pertechnetic acid in the course of extraction from nitric acid solutions with tributyl phosphate in diluent in the presence of uranyl nitrate at various temperatures and its mathematical description. Radiochemistry 57:273–284

Luo J, Wang CZ, Lan JH, Wu QY, Zhao YL, Chai ZF, Nie CM, Shi WQ (2015) Theoretical studies on the AnO2(n+) (An = U, Np; n = 1, 2) complexes with di-(2-ethylhexyl)phosphoric acid. Dalton Trans 44:3227–3236

Schueller W, Huppert KL, Rv A, Baumgaertel G, Baumgaertner F (1977) Fuel reprocessing and waste treatment at Karlsruhe Nuclear Research Centre. IAEA, International Atomic Energy Agency (IAEA)

Gao S, Sun T, Chen Q, Shen X (2016) Characterization of reversed micelles formed in solvent extraction of thorium(IV) by bis(2-ethylhexyl) phosphoric acid. Transforming from rodlike to wormlike morphology. Radiochim Acta 104:457–469

Abe R, Nagoshi K, Arai T, Watanabe S, Sano Y, Matsuura H, Takagi H, Shimizu N, Koka M, Sato T (2017) Microscopic analyses of complexes formed in adsorbent for Mo and Zr separation chromatography. Nucl Instrum Methods Phys Res, Sect B 404:173–178

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhou, L., Zhou, Y., Jiao, C. et al. Study of irradiation decomposition products of PUREX solvents on zirconium metal retention behavior. J Radioanal Nucl Chem 332, 907–916 (2023). https://doi.org/10.1007/s10967-022-08677-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08677-4