Abstract

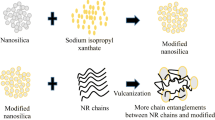

In an in-situ surface modification method, nano-silica (NS) underwent treatment with bis[3-(triethoxysilyl)propyl]tetrasulfide, often referred to as TESPT, a commercially available SCA (silane coupling agent). This produced surface-functionalized NS, also known as modified nanosilica (mNS). The influence of using this mNS as a filler in styrene-butadiene rubber/acrylonitrile-butadiene rubber (SBR/NBR) composites was examined in this study. The results show that the silanol groups in TESPT form chemical connections with the surface of the NS, which significantly increases the rubber-matrix nanocomposite's curing efficiency and improves its mechanical properties. The reason for this enhancement is the in-situ surface modification of the NS by the SCA, which significantly raises the filler's miscibility and compatibility with the rubber matrix. The SBR/NBR nanocomposites filled with NS and mNS exhibited notable enhancements in tensile and tear strength, demonstrating improvements of 161% and 70%, respectively, in comparison to SBR/NBR vulcanizates.

Similar content being viewed by others

Availability of data and materials

Not applicable.

References

Shokri AA, Bakhshandeh G, Farahani TD (2006) An investigation of mechanical and rheological properties of NBR/PVC blends: influence of anhydride additives, mixing procedure and NBR form. Iran Polym J 15:227–237

Mousa A, Ishiaku US, Ishak ZAM (2003) Rheological and mechanical properties of dynamically cured poly (vinyl chloride)/nitrile butadiene rubber thermoplastic elastomers. Polym Int 52(1):120–125

Srinivas J, Jagatheeshwaran MS, Vishvanathperumal S, Anand G (2023) The effect of nanosilica on mechanical and swelling resistance properties of ternary rubber (NR/SBR/NBR) blends nanocomposites with and without bis(Triethoxysilylpropyl)Tetrasulfane. Silicon. https://doi.org/10.1007/s12633-023-02800-0

Babu RR, Singha NK, Naskar K (2008) Studies on the influence of structurally different peroxides in polypropylene/ethylene alpha olefin thermoplastic vulcanizates (TPVs). Express Polym Lett 2:226–236

Arunkumar A, Srinivasan D, Vishvanathperumal S, Navaneethakrishnan V (2023) Effect of HNTs and modified HNTs nanotubes on the mechanical properties and swelling resistance of EPDM/SBR rubber blend nanocomposites. SILICON 15:7647–7667

Perera MCS, Ishiaku US, Ishak ZAM (2000) Thermal degradation of PVC/NBR and PVC/ENR50 binary blends and PVC/ENR50/NBR ternary blends studied by DMA and solid state NMR. Polym Degrad Stab 68(3):393–402

Lapa VLC, Visconte LLY, Affonso JES, Nunes RCR (2002) Aluminum hydroxide and carbon black filled NBR/PVC composites vulcanization and processability studies. Polym Test 21:443–447

Mansour AA, El-Sabagh S, Yehia AA (1994) Dielectric investigation of SBR/NBR and CR/NBR blends. J Elastomers Plast 26:367–378

Yehia AA, Doss NL, El-Nashar DE (1999) Effect of compatibilizers on the compatibility of NBR/SBR blends. Egypt J Text Polym Sci Technol 3:43–61

Sidkey MA, Yehia AA, Abd El-Malak NA, Gaafar MS (2002) Compatibility studies on some rubber blend systems by ultrasonic techniques. Mater Chem Phys 74:23–32

Yehia A, Mansour A, Stoll B (1997) Detection of compatibility of some rubber blends by DSC. J Therm Anal Calorim 48(6):1299–1310

Rafiee E, Shahebrahimi S, Feyzi M, Shaterzadeh M (2012) Optimization of synthesis and characterization of nanosilica produced from rice husk (a common waste material). Int Nano Lett 2:1–8

Liou TH (2004) Preparation and characterization of nano-structured silica from rice husk. Mater Sci Eng A 364(1–2):313–323

Hilonga A, Kim JK, Sarawade PB, Quang DV, Shao GN, Elineema G, Kim HT (2012) Synthesis of mesoporous silica with superior properties suitable for green tire. J Ind Eng Chem 18(5):1841–1844

Wolff S, Gorl U, Wang MJ, Wolff W (1994) Silica-based tread compounds. Eur Rubber J 176(1):16–19

Qu L, Yu G, Xie X, Wang L, Li J, Zhao Q (2013) Effect of silane coupling agent on filler and rubber interaction of silica reinforced solution styrene butadiene rubber. Polym Compos 34(10):1575–1582

Dohi H, Horiuchi S (2007) Locating a silane coupling agent in silica-filled rubber composites by EFTEM. Langmuir 23(24):12344–12349

Li Y, Han B, Wen S, Lu Y, Yang H, Zhang L, Liu L (2014) Effect of the temperature on surface modification of silica and properties of modified silica filled rubber composites. Compos A Appl Sci Manuf 62:52–59

Gauthier C, Reynaud E, Vassoille R, Ladouce-Stelandre L (2004) Analysis of the non-linear viscoelastic behaviour of silica filled styrene butadiene rubber. Polymer 45(8):2761–2771

Vishvanathperumal S, Navaneethakrishnan V, Anand G, Gopalakannan S (2020) Evaluation of crosslink density using material constants of ethylene-propylene-diene monomer/styrene-butadiene rubber with different nanoclay loading: finite element analysis-simulation and experimental. Adv Sci Eng Med 12(5):632–642

Dhanasekar S, Baskar S, Vishvanathperumal S (2023) Cure characteristics, compression set, swelling behaviors, abrasion resistance and mechanical properties of nanoclay (Cloisite 15A, Cloisite 20A and Cloisite 30B) filler filled EPDM/NBR blend system. J Polym Res 30(10):375

Zhang X, Sinha TK, Lee J, Ahn Y, Kim JK (2019) Temperature dependent amphoteric behavior of bis [3-(triethoxysilyl) propyl] tetrasulfide towards recycling of waste rubber: A triboelectric investigation. J Clean Prod 213:569–576

Dhanasekar S, Baskar S, Vishvanathperumal S (2023) Halloysite Nanotubes Effect on Cure and Mechanical Properties of EPDM/NBR Nanocomposites. J Inorg Organomet Polym Mater 33:3208–3220

CD, M.D., Begum, P.S., Joseph, R., Joseph, D., Kumar, P. and Ayswarya, E.P. (2013) Synthesis, characterization and appilcation of rice husk nanosilica in natural rubber. IJST 2(4):1027–1035

Tian Q, Mao Y, Zhang C, Wang Y, Ding T, Li X (2017) Preparation of nano-silica loaded N-cyclohexyl-2-benzothiazole sulphonamide and its application in solution styrene-butadiene rubber/butadiene rubber composites. Micro Nano Lett 12(12):949–954

Tian Q, Tang Y, Ding T, Li X, Zhang Z (2018) Effect of nano-silica surface-capped by bis [3-(triethoxysilyl) propyl] tetrasulfide on the mechanical properties of styrene-butadiene rubber/butadiene rubber nanocomposites. Compos Commun 10:190–193

Vishvanathperumal S, Anand G (2020) Effect of nanoclay/nanosilica on the mechanical properties, abrasion and swelling resistance of EPDM/SBR composites. SILICON 12(8):1925–1941

Vishvanathperumal S, Anand G (2022) Effect of nanosilica on the mechanical properties, compression set, morphology, abrasion and swelling resistance of sulphur cured EPDM/SBR composites. SILICON 14(7):3523–3534

Sundar R, Mohan SK, Vishvanathperumal S (2022) Effect of Surface Modified Halloysite Nanotubes (mHNTs) on the Mechanical Properties and Swelling Resistance of EPDM/NBR Nanocomposites. Polym Kor 46(6):728–743

Vishvanathperumal S, Gopalakannan S (2017) Swelling properties, compression set behavior and abrasion resistance of ethylene-propylene-diene rubber/styrene butadiene rubber blend nanocomposites. Polym Kor 41(3):433–442

Ragupathy K, Prabaharan G, Pragadish N, Vishvanathperumal S (2023) Effect of silica nanoparticles and modified silica nanoparticles on the mechanical and swelling properties of EPDM/SBR blend nanocomposites. SILICON 15:6033–6046

Das RK, Ragupathy K, Kumar TS, Vishvanathperumal S (2023) Effect of halloysite nanotubes (HNTs) on mechanical properties of EPDM/NBR blend-nanocomposites. Polym Kor 47(2):221–232

Vishvanathperumal S, Gopalakannan S (2016) Reinforcement of ethylene vinyl acetate with carbon black/silica hybrid filler composites. Appl Mech Mater 852:16–22

Ravi Theja MS, Kilari N, Vishvanathperumal S, Navaneethakrishnan V (2021) Modeling tensile modulus of nanoclay-filled ethylene–propylene–diene monomer/styrene–butadiene rubber using composite theories. J Rubber Res 24(5):847–856

Anand G, Vishvanathperumal S (2022) Properties of SBR/NR blend: the effects of carbon black/silica (CB/SiO2) hybrid filler and silane coupling agent. SILICON 14:9051–9060

Vishvanathperumal S, Gopalakannan S (2019) Effects of the nanoclay and crosslinking systems on the mechanical properties of ethylene-propylene-diene monomer/styrene butadiene rubber blends nanocomposite. SILICON 11(1):117–135

Senthilvel K, Vishvanathperumal S, Prabu B, John Baruch L (2016) Studies on the morphology, cure characteristics and mechanical properties of acrylonitrile butadiene rubber with hybrid filler (carbon black/silica) composite. Polym Polym Compos 24(7):473–480

Aravinth V, Gurumoorthi G, Vishvanathperumal S, Navaneethakrishnan V (2023) Effect of modified nanographene oxide on the mechanical and swelling properties of silicone rubber nanocomposites. Polym Kor 47(3):288–302

Aravinth V, Navaneethakrishnan V, Vishvanathperumal S, Gurumoorthi G (2024) Effect of modified nanographene oxide (mGO)/carbon nanotubes (CNTs) hybrid filler on the cure, mechanical and swelling properties of silicone rubber composites. J Inorg Organomet Polym Mater 34(1):282–301

Prakash PC, Gurumoorthi G, Navaneethakrishnan V, Vishvanathperumal S (2023) Effect of nanographene oxide on the mechanical properties of EPDM/SBR nano-composites. Polym Kor 47(4):427–439

Vishvanathperumal S, Anand G (2021) Effect of nanosilica and crosslinking system on the mechanical properties and swelling resistance of EPDM/SBR nanocomposites with and without TESPT. SILICON 13(10):3473–3497

Vishvanathperumal S, Roy JV, Anand G, Ramu KN, Praveenkumar S (2023) An investigation on the effect of the surface modifications and HNTs loading on the cure behaviours, abrasion resistance, mechanical and morphological properties of NR/EPDM Nanocomposites. Silicon. https://doi.org/10.1007/s12633-023-02837-1. (In-Press)

Vishvanathperumal S, Navaneethakrishnan V, Gopalakannan S (2018) The effect of Nanoclay and hybrid filler on curing characteristics, mechanical properties and swelling resistance of ethylene-vinyl acetate/styrene butadiene rubber blend composite. J Adv Microsc Res 13(4):469–476

Ganeche PS, Balasubramanian P, Vishvanathperumal S (2022) Halloysite nanotubes (HNTs)-filled ethylene-propylene-diene monomer/styrene-butadiene rubber (EPDM/SBR) composites: mechanical, swelling, and morphological properties. SILICON 14(12):6611–6620

Govindan K, Ramabalan S, Vishvanathperumal S, Chockalingam S (2023) Influence of halloysite nanotubes on mechanical and swelling properties of silicone rubber compound. J Polym Res 30(8):1–17

Prakash PC, Srinivasan D, Navaneethakrishnan V, Vishvanathperumal S (2023) Effect of modified nanographene oxide loading on the swelling and compression set behavior of EPDM/SBR nano-composites. J Inorg Organomet Polym Mater. https://doi.org/10.1007/s10904-023-02803-9. (In-Press)

Sundaravadivel G, Parthasarathy K, Vishvanathperumal S, Navaneethakrishnan V (2023) Effect of complex of resorcinol and hexamethylenetetramine modified halloysite nanotubes (RH-HNTs) on the mechanical and swelling characteristics of NR/EPDM nanocomposites. J Polym Res 30:383

Sundaravadivel G, Venkataraman SR, Vishvanathperumal S, Navaneethakrishnan V (2023) Influence of APTES modified HNTs on properties of NR/EPDM nanocomposites. SILICON 15(15):6715–6727

Dhanasekar S, Theja MR, Baskar S, Vishvanathperumal S (2023) Effects of nanosilica on the mechanical properties and swelling resistance of EPDM/NBR nanocomposites. Polym Kor 47(5):613–627

Bi Q, Chen J, Li X, Shi JJ, Wang X, Zhang J, Gao D, Zhai Y, Zhao Y, Weng S, Xu Y (2014) Investigation on the dipole–dipole interactions between tetramethylurea and acetonitrile by two-dimensional asynchronous spectroscopy. J Mol Struct 1069:264–271

Doma AS, Kamoun EA, Abboudy S, Belal MA, Khattab SN, El-Bardan AA (2018) Compatibilization of vulcanized SBR/NBR blends using cis-polybutadiene rubber: influence of blend ratio on elastomer properties. Eur J Eng Technol Res 3(12):135–143

Kumar SP, Prabhakaran G, Vishvanathperumal S (2024) Influence of modified nanosilica on the performance of NR/EPDM blends: cure characteristics, mechanical properties and swelling resistance. J Inorg Organomet Polym Mater. https://doi.org/10.1007/s10904-023-02985-2. (In-Press)

Govindan K, Ramabalan S, Vishvanathperumal S (2024) Enhancement of mechanical performance and swelling resistance in silicone rubber through reinforcement with γ-methacryloxypropyltrimethoxysilane-modified halloysite nanotubes. J Inorg Organomet Polym Mater. https://doi.org/10.1007/s10904-023-02962-9. (In-Press)

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Mr. K. Karthikeyan: Conducted experimental work, prepared all figures, and wrote the main manuscript text. Dr. Ajith Damodaran: Supervised the overall work and addressed plagiarism in the main manuscript. Dr. S. Vishvanathperumal: Addressed plagiarism in the main manuscript. All authors reviewed the main manuscript.

Corresponding author

Ethics declarations

Ethics approval

This research study has received formal approval and ethical clearance from the Institutional Review Boards to ensure adherence to the highest ethical standards, complying with all relevant guidelines and regulations.

Consent to participate

This research study was conducted without involving any human subjects or animals. Ethical considerations were meticulously addressed, and the study design and methodologies ensured that no human participants or animals were utilized in any aspect of the research process.

Consent for publication

The contents of this manuscript are entirely original and have not been previously published in any form, nor are they subject to any existing copyright restrictions.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Karthikeyan, K., Damodaran, A. & Vishvanathperumal, S. Effect of nano-silica surface-capped by bis[3-(triethoxysilyl)propyl] tetrasulfide on the cure behaviors, mechanical properties, swelling resistance and microstructure of styrene-butadiene rubber/acrylonitrile-butadiene rubber nanocomposites. J Polym Res 31, 79 (2024). https://doi.org/10.1007/s10965-024-03924-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03924-6