Abstract

Flexible scaffolds made of polycaprolactone (PCL), and multi-walled carbon nanotubes (MWCNTs) were created and chemically verified through RAMAN. The most suitable coupling percentages for PCL were 1%, 3%, and 5% MWCNT. The scaffolds were very stable with high hardness values (10–12 GPa). The PCL/MWCNT 5% scaffold was the most flexible and least resistant, with adequate porosity, pore size, and interconnectivity for cell anchoring. Moreover, the scaffold exhibited low cytotoxicity with a cell viability of 90%. These flexible PCL/MWCNT scaffolds were developed to support tissue engineering by providing a mechanical response with flexibility and elasticity like the surrounding tissue.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biomaterials used in tissue engineering must meet specific requirements to be effective. They must be resorbable, biocompatible with the tissue, and not cause rejection. They should also minimize the hostility of the local microenvironment, last long enough for the cells they carry to integrate into the biomaterial and have adequate porosity to exchange nutrients. Furthermore, they must anchor to the tissue and act as a natural reservoir for biomolecules to interact with cells [1]. Due to its excellent physical properties, polycaprolactone (PCL) is a polymer widely used in medical and pharmaceutical applications. PCL is highly biocompatible, degrades rapidly, and has low cytotoxicity and excellent mechanical properties [2, 3]. As a result, PCL is a promising candidate for biomedical applications such as controlled drug release, tissue engineering, and packaging materials [4]. The semicrystalline structure of PCL is composed of ester bonds, which makes it susceptible to hydrolytic degradation, either by breaking these bonds or by enzymatic degradation. However, due to its hydrophobicity, enzymatic degradation is functional in tissue engineering as it has lower degradation kinetics than other polyester polymers. This allows the design of more durable scaffolds and better cell adhesion, proliferation, and differentiation [3, 5]. The surface of scaffolds, especially those made from PCL, should provide cell anchoring sites. Therefore, it is necessary to combine other compounds, such as carbon nanotubes, that have excellent thermal, mechanical, and electrical properties. It is essential that these scaffolds when functionalized with other materials such as carbon nanotubes (MWCNT), remain biocompatible and contribute to cell proliferation and osteogenic differentiation [6].

In this research, we have functionalized multilayer nanotubes with amino groups (MWCNT-NH2) to provide stability and hydrophilicity for cell colonization. The scaffold’s porosity is critical for promoting the diffusion of gases and nutrients and vascularization. However, controlling porosity is challenging, but techniques such as 3D printing can control it [3, 1]. Adequate porosity with interconnectivity plays a vital role in cell anchoring, allowing cells to grow and integrate into the damaged tissue by exchanging nutrients with the medium.

Materials and methods

The functionalization process of PCL (synthesized by ROP) with MWCNT (Multi-Walled Carbon Nanotubes-Rich in NH2; www.cheaptubes.com) was carried out as follows: First, 5 g of PCL was weighed and then added to a 250 mL Erlenmeyer flask containing 60 mL of chloroform (CHCl3). The flask was then placed under constant stirring at 600 rpm at room temperature (25°C) for one hour. Once the PCL was observed to have completely dissolved, 1%, 3%, and 5% of the MWCNTs were weighed separately (These percentages were taken because, above these results, the MWCNTs create agglomerates through the PCL matrix, affecting the thermal and mechanical properties of the PCL/MWCNT scaffolds). These weighted percentages were then stirred at 600 rpm for one hour, after which 60 mL of chloroform was added, and the mixture was taken to a Lab-Companion UCP-10 brand ultrasound machine for 30 min. After 30 min, the PCL/chloroform and MWCNT/chloroform solutions were taken separately to the ultrasound equipment for an additional hour. After one hour of ultrasound, the PCL was mixed with the MWCNTs using the following percentages: 1% PCL/MWCNT, 3% PCL/MWCNT, and 5% PCL/MWCNT. The mixture was left in the ultrasound equipment for two hours at a temperature of 47°C under short pulses every three seconds. Once the duration of two hours was over, the mixture was precipitated with 50 mL of methanol (MeOH). Finally, the chloroform was evaporated in a fume hood until the desired composite material was obtained, as shown in Fig. 1.

The PCL/MWCNT scaffolds were structurally characterized through RAMAN Spectroscopy. The measurements and RAMAN spectra were processed using a backscattering geometry by the Thermo Scientific DXR equipment and a LEICA invia RAMAN microscope. The equipment used an Ar + excitation source of 514 nm wavelength. The spectra were run from 1000 cm−1 to 2000 cm−1, known as the PCL fingerprint range, where the main bands are. The surface characterization was conducted by scanning electron microscopy (SEM). The PCL/MWCNT scaffolds were conditioned with a gold coating using an auto-sputtering Cressington Sputter Coater 108 system to improve their electrical conductivity. After that, they were brought to a cryogenic high vacuum environment and placed at a 4 to 10 kV voltage on a NeoScope JCM-5000 brand SEM. Images of the surface were captured at 50, 100, and 200X resolutions.

The PCL/MWCNT scaffolds’ crystalline structure was determined through high-angle X-ray diffraction (XRD) using the PANalytical X’pert proTM reference X-ray diffractometer. The equipment used a Cu radiation source, with Kα having a wavelength of λ = 1.5405 Å, an accelerating voltage of 40 kV, and a current of 50 mA. The measurements were conducted at room temperature, using a secondary monochromator to eliminate Kβ radiation and fluorescence.

The PCL/MWCNT scaffolds have been analyzed using differential scanning calorimetry (DSC) with Mettler Toledo equipment. The analysis was conducted in a nitrogen atmosphere with a flow rate of 80 mL/min, with a heating rate of 10°C/min, in the temperature range of 20 to 400°C. The thermal analyses of PCL and PCL/MWCNT were performed using the TGA technique. The analysis was conducted in a nitrogen atmosphere with a flow rate of 80 mL/min, with a heating rate of 10°C/min, in the temperature range of 20 to 400°C.

To determine the hardness of PCL/MWCNT scaffolds, a Ubil-Hysitrom nanoindent device with a 150 nm Berkovich pyramidal tip was used for nanoindentation. Each sample was indented five times in various parts of its surface, with a few millimeters of separation between each indentation, to obtain the elastic modulus, maximum load, and hardness.

The tensile modulus of PCL/MWCNT scaffolds was determined by conducting a tensile test according to the ASTM D3822/D3822M-14 standard. Three samples were selected for each percentage (1%, 3%, and 5%). The test was performed using a TINIUS OLSEN H50Ks universal testing machine with special pneumatic jaws and a 500 N load cell. The specimens were prepared using the ASTM D638-22 standard. A 5 mm/min jaw displacement speed was used to calculate the composite material’s maximum tensile strength, modulus of elasticity, and % deformation at the maximum load. The minimum gap between the jaws was set to 300 millimeters.

The measurements of the samples in the failure section before starting the test are as follows:

In vitro cytotoxicity assays of the PCL/MWCNT scaffolds were performed with fibroblasts of L929 cell lines as follows:

The L929 fibroblast cell line was placed in a T-75 culture flask (Thermo Scientific, Mouse fibroblast cell line, ATCC # CCL-1 CCL-1 is NCTC clone 929 of strain L, derived in 1948 from a C3H/A male mouse). DMEM supplemented with 10% FBS from Lonza (Cat. No. 14-501F) was added and incubated at 37 ± 1°C. The cells were evaluated microscopically shortly before the end of the incubation period, and an XTT reagent (CyQUANT™ XTT Cell Viability Assay) and an electron coupling reagent were added. This fibroblast cell line was seeded in a 24-well plate (Corning™ 3526) and left to culture for 24–48 h in an incubator at 37°C with a 5% CO2 atmosphere.

After the incubation period, 100 µL of the supernatant was taken from each of the wells containing the cells. Then, each previously sterilized material was added to the corresponding wells in a 96-well plate (Merck PSHT004R5). The culture medium was removed, and XTT was added again.

The plate was incubated at room temperature and protected from light with aluminum for three hours. After that, the medium was removed, and 150 µL of XTT was added. To perform the cytotoxicity test, an ELISA microplate reader, STAT-FAX 2100, was used at a wavelength of 456 nm with a reference filter of 492 nm.

Results and discussion

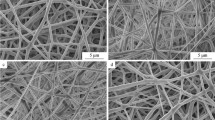

The PCL/MWCNT scaffolds with 1%, 3%, and 5% were created using the coupling method, resulting in porous structures (Fig. 2). The process was refined to produce superior-quality scaffolds for this study.

Adding MWCNTs to the PCL resulted in creating more porous scaffolds in proportion to the quantity of MWCNT added. This is because MWCNTs form agglomerates, which create the pores.

Verification of chemical coupling between PCL/MWCNT using ROP by RAMAN

It is necessary to verify whether the functionalization of MWCNTs with PCL has resulted in physical or chemical coupling. Physical coupling produces poor fiber-matrix interaction and suboptimal thermal and mechanical properties. On the other hand, chemical coupling forms chemical bonds that lead to solid fiber-matrix interaction and optimal thermal and mechanical properties. To perform this verification, we must conduct the pure MWCNTs’ RAMAN spectrum to determine the main bands. The RAMAN spectrum of MWCNTs shows three main bands: G, D, and 2D (Fig. 3). The G band is present at 1586 cm−1 and represents the in-plane bending motion of the sp2 hybridized carbon atoms in the nanotube. The MWCNTs reported in this research are highly crystalline because this G band is very sharp and highly defined. The D band in the MWCNTs appears at 1347 cm−1 and represents the measure of the disorder within the MWCNTs and the tensile movement of the Van der Waals forces (ring breathing) of the sp2 hybridized carbons. These bands were like those Zeng et al. [7] reported at 1322.2 cm−1 for the D band and 1574 cm−1 for the G band of a pristine PCL/MWCNT composite material. Kong et al. [8] reported the G band at 1550 cm−1 in carbon nanotubes. For its part, Flores-Cedillo et al. [9] reported the D bands at 1610 cm−1 and the G band of the MWCNTs at 1590 cm−1.

The 2D band value of 2410 cm−1 provides information about the thickness of carbon nanotube graphene layers.

The RAMAN analysis confirmed the chemical coupling of MWCNTs to PCL (Fig. 4). However, an increase in the number of MWCNTs led to a decrease in the intensity of PCL bands. The RAMAN spectrum of the 1%, 3%, and 5% PCL/MWCNT scaffolds show a band at 1744 cm−1, respectively, of symmetrical elongation vibration characteristic of the C = O group of the PCL. Furthermore, at 1639 cm−1, an elongation vibration band attributed to the chemical coupling of the C = O group of the PCL with the amino group (-NH2) of the MWCNTs is observed. The G band of the MWCNTs is observed at 1531 cm−1, undergoing a downfield shift of 55 cm−1 concerning the G band of the pure MWCNTs. The D band of this scaffold overlaps with the PCL band recorded at 1357 cm−1, which is attributable to the asymmetric deformation vibration of the -C-H groups of the PCL molecule and the MWCNTs. Zeng et al. [7] reported a shift of the D and G bands of the MWCNTs due to their bond with the composite material. The composite material exhibited a band shift of 11 cm−1 compared to the original MWCNTs.

In the PCL/MWCNT 3% and PCL/MWCNT 5% scaffolds, the band at 1744 cm−1 is still present, but the band at 1639 cm−1 is no longer visible. This indicates that the D and G bands of the MWCNTs have shifted towards the low field with greater intensity. Through RAMAN analysis, it was confirmed that the coupling between the MWCNT and PCL was achieved chemically. Additionally, it was observed that the amount of MWCNT in the scaffolds has a significant impact on their structure.

DSC Spectrum of thermal comparison between PCL and PCL/MWCNT scaffolds

The DSC spectrum of Fig. 5 showed that PCL has a Tm of 64°C. Comparing it with the PCL/MWCNT 1% scaffolds, it was found that they have the same Tm, so the MWCNTs did not exert any alteration effect. This result is corroborated by Jecg et al. [11], who reported a Tm for PCL of 62°C and reported no changes in Tm for his scaffolds of PCL/MWCNT 0.05%, PCL/MWCNT 0.1%, PCL/MWCNT 0.3%, PCL/MWCNT 0.5%, and PCL/MWCNT 1%, but until their PCL/MWCNT 3% scaffolds, where they recorded a higher Tm of 63°C. The PCL/MWCNT, 3% scaffolds, recorded a Tm of 62°C, lower than that of the PCL/MWCNT 1% scaffolds, consistent with what was reported in this work with PCL scaffolds but contradictory with what was reported by Jecg et al. [11]. For the PCL/MWCNT 5% scaffolds, a Tm of 61°C is recorded, much lower than the PCL, with 3°C difference, but this Tm coincides precisely with that reported by Jecg et al. [11] of 61°C. Concerning the Tc of the crystalline and amorphous parts, these increase their temperature in the PCL/MWCNT 3% and PCL/MWCNT 5% scaffolds, and due to the interaction with the MWCNTs, the same occurs for the Td.

TGA spectra of comparison between PCL and PCL/MWCNT

The PCL/MWCNT scaffolds displayed similar weight loss patterns across all their percentages, as shown in Fig. 6. The weight loss occurred at temperatures ranging from 377°C (4% weight loss) to 450°C (99% weight loss). These degradation temperatures are like the findings reported by George et al. [10], who recorded a weight loss of 75% for his 1% PCL/MWCNT scaffold, with an initial degradation temperature of 338°C and a final temperature of 412°C.

This study shows that the addition of multi-walled carbon nanotubes (MWCNTs) to poly(ε-caprolactone) (PCL) scaffolds does not affect the thermal stability of PCL. This is evidenced by the similar molecular weight loss in all PCL/MWCNT scaffolds, as demonstrated in Fig. 7 [10, 11].

The scaffolds are suitable for tissue engineering applications as they maintain thermal stability.

Determination of the internal structure of PCL/MWCNT scaffolds using XRD

After manufacturing the PCL/MWCNT scaffolds, we used the XRD technique to determine their internal structure. This helped us identify the crystalline phase in the solid state of the PCL and the PCL/MWCNT (1%, 3%, and 5%). X-ray diffraction tests were carried out for the PCL and PCL/MWCNT 1%, PCL/MWCNT 3%, and PCL/MWCNT 5% scaffolds to determine the crystalline phase (Fig. 8).

It became possible to identify the scaffolds’ crystalline system and cell parameters using a specific method. The x-ray diffractograms displayed in Fig. 8 show the characteristic PCL diffraction peaks at 19.6, 23.76, and 36.32, indicating the semi-crystalline nature of the PCL/MWCNT scaffolds. Moreover, the reflections at 26.6 and 43.5, related to the (002) and (100) planes of the MWCNT, are also visible.

The maximum geometry of the diffraction pattern allowed for determining the crystal structure of the PCL/MWCNT scaffolds, as shown in Fig. 9.

In Fig. 9, an increase in the intensity of the peak associated with the (002) plane of the MWCNT can be observed to the extent that higher concentrations of MWCNT were used, with the 5% concentration being where the highest intensity in the peak was presented. It is worth highlighting that the diffractograms show the semi-crystalline nature of the PCL. However, specific changes were noted in the diffraction peaks associated with the percentage of MWCNT used. The above agrees with the research reported by Hudecki et al. [12], and this structural synergy can be evidence of the effective interaction between MWCNT and PCL, with the 5% PCL/MWCNT scaffold being the most crystalline, which is corroborated with SEM images.

DSC and TGA corroborated this semi-crystalline nature of PCL/MWCNT scaffolds found by XRD. Therefore, its surface pore morphology is reviewed.

Determination of porosity of PCL/MWCNT scaffolds by SEM

Through optical microscopy, it was verified that the pores generated in the scaffolds were interconnected and had sufficient diameter so that the cells could hold onto them and allow them to perform their specific functions. What was intended by SEM was to see the morphology of these pores in all percentages of the scaffolds (Fig. 10); as can be seen in Fig. 10, the PCL/MWCNT 1% scaffold has non-interconnected micropores between 10 and 50 μm.

The surface of the scaffolds was examined using SEM, regardless of whether they had interconnected pores. Notably, the pores of PCL/MWCNT 1% scaffolds (as shown in Fig. 10) are tiny and mostly do not have interconnectivity, resulting in a low cell viability of 51.12%. On the other hand, the PCL/MWCNT 3% scaffold has larger pores with interconnectivity, ranging in size from 25 to 100 μm (as shown in Fig. 11).

Figure 11 shows that the PCL/MWCNT 3% scaffolds had more extensive and interconnected pores, which resulted in a cell viability rate of 57.74%, like that of the PCL/MWCNT 1% scaffolds. The PCL/MWCNT 5% scaffold had large pores with interconnectivity, ranging from 50 to 800 μm, as shown in Fig. 12.

For the PCL/MWCNT 5% scaffolds (Fig. 12), a much more porous surface was visualized, with many interconnected pores, which made its cell viability very high at 89.71%.

Tensile test of PCL/MWCNT scaffolds

Tensile experiments assessed the ultimate strength (σT) and mechanical parameters of deformation of PCL/MWCNT scaffolds. These tests were used to calculate Young’s modulus (E), representing the rigidity degree. The material is stiffer when the E value is higher. Tensile tests were conducted on scaffolds with varying percentages of PCL/MWCNT (1%, 3%, and 5%) to ascertain the precise maximum resistance and E values, as shown in Fig. 13.

The slope value was obtained by calculating the E using the graphs’ linear relationship between stress and strain. (Table 1).

In Fig. 14, a comparison was made between the elasticity (E) of PCL/MWCNT scaffolds at three different percentages. The study revealed that the scaffold with PCL/MWCNT 1% is the most flexible, with an E of 0.74 MPa. On the other hand, the scaffold with PCL/MWCNT 5% is the most rigid, with an E of 3.59 MPa. The PCL/MWCNT scaffold with 3% showed intermediate flexibility with an E value of 1.29 MPa.

The data recorded for the E of the PCL/MWCNT scaffolds coincide with those recorded by Meng et al. [13], where results of E between 1.4 and 6 MPa are reported for PCL/MWCNT 0.1% and PCL/MWCNT 0.2% scaffolds with a deformation percentage of 20%, similar to the deformation percentage of PCL/MWCNT 1% scaffolds, but very different from PCL/MWCNT 5% which have a deformation percentage of almost 80%. On the other hand, Flores-Cedillo et al. [9] reports a much higher E between 172 and 608 MPa. This is because the scaffolds manufactured constitute a mixture of PCL, hydroxyapatite, chitosan, and MWCNT for dental implants. Therefore, they must be rigid and have high E.

The maximum resistance of PCL/MWCNT scaffolds was estimated to be the highest value within the elastic zone that the material can withstand before fatigue (Table 2).

The comparisons between σT of the manufactured PCL/MWCNT scaffolds are consistent with the E found; the scaffold with the lowest resistance would be the PCL/MWCNT 1% scaffold with a value of 5.23 MPa, followed by the PCL/MWCNT 3% scaffold with a value of 7.64 MPa and the one with the highest resistance would be the PCL/MWCNT 5% with a value of 14.7 MPa. This means that the PCL/MWCNT 1% scaffold, if subjected to a force greater than 5.23 MPa, breaks, while the PCL/MWCNT 5% scaffold has a much higher σT than the other scaffolds (see Fig. 15).

This σT value of the PCL/MWCNT 5% scaffold would be favorable for tissue engineering applications and tissues that had to support high loads, such as knees and bones. As evidence, Flores-Cedillo et al. [9] reported σT close to those reported, between 18 and 42 MPa, for scaffolds that can be used in bone regeneration.

Mechanical analysis through instrumented indentation (nanoindentation) to the PCL/MWCNT scaffolds

Nanoindentation tests are commonly used to measure two critical parameters: the hardness of a material and the amount of displacement scaffolds undergo when subjected to a load. PCL/MWCNT scaffolds exhibit an impressive hardness around a gigapascal (GPa). Meanwhile, the displacement parameter tends to increase as the percentage of carbon nanotubes in the PCL/MWCNT scaffolds increases, as depicted in Fig. 16.

An increase in the hardness parameters of the PCL/MWCNT scaffolds was found as the percentage of MWCNT increased (Fig. 17).

The results of the nanoindentation tests establish that, as the amount of MWCNT in the scaffolds increases, its hardness (the resistance of a material to being plastically deformed) increases. Consequently, the PCL/MWCNT 5% scaffold has the highest hardness, indicating a rigid scaffold, while the PCL/MWCNT 1% scaffold is the softest. This is corroborated by Huang et al. [6], who recorded an increase in the hardness of the scaffolds as the amount of MWCNT increased. Huang recorded for his PCL/MWCNT 0.25% scaffolds a hardness of 0.04 GPa, for the 0.7 PCL/MWCNT 0.75% scaffolds, a hardness of 0.05 GPa, and a similar hardness for the PCL/MWCNT 3% scaffolds. These results are far below those recorded in this research, indicating that the MWCNTs used not only serve as reinforcement of the PCL matrix but also contribute significantly to the mechanical properties of the scaffolds [6].

The hardness results obtained are verified with the displacement curves (Fig. 16), where the displacement for the PCL/MWCNT 5% scaffold is less than the displacement in nm recorded for the PCL/MWCNT 3% scaffolds and the PCL/MWCNT 1% scaffolds. PCL/MWCNT 1% is the softest of all scaffolds. The above is inconsistent with the elastic modulus reported for the PCL/MWCNT scaffolds 5%, which was 0.74 MPa, indicating a flexible material. This is explained because the tensile test is a macro measurement, where the entire system is evaluated, while when nanoindentation is done, the areas taken by the measurement are very small. On the other hand, the nanoindentation equipment may have taken a region with an agglomeration of MWCNTs whose hardness is higher and recorded that data.

With nanoindentation, the E of the PCL/MWCNT scaffolds of the nanoindented portion is also calculated (see Fig. 18).

As shown in Fig. 18, the elastic modulus is very high in the order of 220 GPa, which increases as the number of nanotubes increases. This same trend is visualized in calculating the resistance of the plastic region of the scaffolds. The carbon nanotubes exert an increase in this resistance as they increase (see Fig. 19).

Figure 19 shows that the scaffolds made of PCL/MWCNT 1% have the least resistance to plastic deformation. As the percentage of carbon nanotubes in the scaffolds increases, their resistance to plastic deformation also increases. This implies that materials with a higher percentage of nanotubes will have better plastic resistance, making them more durable and capable of withstanding greater force loads.

It is essential to analyze the PCL/MWCNT scaffolds for the percentage of plastic recovery (%R) (Fig. 20). The recovery is measured using Eq. 1 and is calculated based on the percentage of MWCNT contained in the fabricated scaffolds.

In which:

δmax = Maximum Displacement

δp = Plastic Displacement

The results of plastic recovery are consistent across all percentages of the PCL/MWCNT scaffolds, as shown in Fig. 20. However, an increase in MWCNTs in the scaffolds decreases plastic recovery, as the added MWCNTs make the scaffolds more rigid [14]. The PCL/MWCNT 5% scaffold is the most rigid, meaning it undergoes minimal elastic deformation.

Determination of MTT Cytotoxicity of PCL/MWCNT scaffolds

After completing the scaffold characterizations, we conducted cytotoxicity tests using the MTT method for all scaffold percentages (Fig. 21).

The experiment showed that the PCL synthesized in the laboratory had a cell viability of 97.24%, while the commercial PCL had a lower viability of 81.24%. Regarding the scaffolds, the PCL/MWCNT 1% and PCL/MWCNT 3% scaffolds had similar cell viability rates of 51.12% and 57.74%, respectively. The PCL/MWCNT 5% scaffold had a significantly higher cell viability of 89.71%. These results indicate that the number of live cells is proportional to the formazan produced. Therefore, formazan indicates that the cells are alive and carrying out catalytic activity.

The results of the MTT cytotoxicity test were consistent with those obtained by Mattioli-Belmonte et al. [15] for the 5% PCL/MWCNT scaffolds.

Conclusions

Ultrasound was used to functionalize PCL with MWCNTs, creating PCL/MWCNT composite materials. Three different percentages of MWCNT (1%, 3%, and 5%) were used to obtain the most suitable couplings with PCL. The correct chemical coupling of the PCL/MWCNT composite materials was verified using RAMAN. The thermal properties of the PCL/MWCNT scaffolds decreased as the amount of MWCNT increased. The most flexible scaffold was the PCL/MWCNT 1%, while the most rigid was the PCL/MWCNT 5%. The PCL/MWCNT 5% scaffold had the highest resistance, while the PCL/MWCNT 1% had the lowest resistance. The PCL/MWCNT scaffolds have a very high hardness of 10 to 12 GPa, making them very stable when implanted. They also showed viscoelastic properties with a high recovery percentage in displacement tests. The XRD analysis showed that the scaffolds became more crystalline as the amount of MWCNT increased, which improved their thermal and mechanical properties. The MTT cytotoxicity test determined that PCL is not cytotoxic, with a viability value of 82%. However, the PCL/MWCNT 1% and PCL/MWCNT 3% scaffolds showed toxicity with 58% viability. On the other hand, the PCL/MWCNT 5% scaffolds recorded very low cytotoxicity, with a viability of 90%.

References

Cui Z, Yang B, Ren-Ke L (2016) Application of Biomaterials in Cardiac Repair and Regeneration. Engineering 2: 141–14

Darensbourg DJ, Karroonnirum O (2010) Ring-opening polimerization of L-Lactide and ε-caprolactone utilizing Biocompatible Zinc Catalyst. Random Copolymerization of L-Lactide and ε-caprolactone. Macromolecules 43:1 8880-8886

Anwaar-Nazeer M, Yilgor E, Yilgor I (2019) Electrospun polycaprolactone/silk fibroin nanofibrous bioactive scaffolds for tissue engineering applications. Polymer 168:86–94

Oledzka E, Narine SS (2011) Organic acids catalyzed polymerization of ε-caprolactone synthesis and characterization. J Appl Polym Sci 119:1873–1882

Atzet S, Curtin S, Trinh P, Bryant S, Ratner B (2008) Degradable poly (2-hydroxyethyl methacrylate)-co- polycaprolactone hydrogels for tissue Engineering Scaffolds. Biomacromol 9:3370–3377

Huang B, Vyas G, Roberts I, Poutrel Q-A et al (2019) Fabrication and characterization of 3D printed MWCNT composites porous scaffolds for bone regeneration. Mater Sci Eng C 98:266–278

Zeng H, Gao C, Yan D (2006) Poly(ε-caprolactone)-Functionalized Carbon nanotubes and their Biodegradation Properties. Adv Funct Mater 16:812–818

Kong Y, Yuan J, Qiu J (2012) Preparation and characterization of aligned carbon nanotubes/polylactic acid composite fibers. Phys B 407:2451–2457

Flores-Cedillo ML, Alvarado-Estrada KN, Pozos-Guillén AJ et al (2016) Multiwall carbon nanotubes/polycaprolactone scaffolds seeded with human dental pulp stem cells for bone tissue regeneration. J Mater Sci Mater Med 27:351–312

George N, Varghese GA, Joseph R (2019) Improved mechanical and barrier properties of Natural rubber-Multiwalled carbon nanotube composites with segregated network structure. Materials today: proceedings 9(1):13–20

Jecg S, Vempati S, Dawson P, Knite M, Linarts A et al (2015) Electrical conduction and rheological behavior of composites of poly(ε-caprolactone) and MWCNTs. Polymer 58:209–221

Hudecki A, Lyko-Morawska D, Likus W, Skonieczna M (2019) Composite nanofibers containing Multiwall Carbon nanotubes as biodegradable membranes in Reconstructive Medicine. Nanomaterials 9:63

Meng ZX, Zheng W, Li L, Zheng YF (2010) Fabrication and characterization of three-dimensional nanofiber membrance of PCL-MWCNTs by electrospinning. Mater Sci Eng C 30:1014–1021

Piedrahita WF, Aperador W, Caicedo JC, Prieto P (2017) Evolution of physical properties in hafnium carbonitride thin films. J Alloys Compd 690:1

Mattioli-Belmonte M, Vozzi G, Whulanza Y, Seggiano M et al (2012) Tuning polycaprolactone-carbon nanotube composites for bone tissue engineering scaffolds. Mater Sci Eng C 32:152–159

Funding

Open Access funding provided by Colombia Consortium The authors claim that no funding was received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interests

The authors of this manuscript declare no conflict of interest or competing interests if published.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Peñaranda-Armbrecht, J., Correa-Quiceno, M.J., Caicedo-Angulo, J.C. et al. Fabrication of multi-walled carbon nanotube/polycaprolactone scaffolds for possible application in tissue engineering. J Polym Res 31, 64 (2024). https://doi.org/10.1007/s10965-024-03875-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03875-y