Abstract

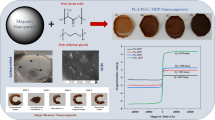

In recent years, there has been a significant demand for shape memory materials due to their smart characteristics. NiMnGa has special interest because of its magnetic shape memory features which can be used in actuators, sensors, dampers, and energy harvesting. The production of NiMnGa has a substantial cost resulting in usage of a shape memory polymer composite with the alloy which brings advantages such as size, and shape structure. For this purpose, a new multifunctional smart material was studied by combining Poly lactic acid (PLA)/Poly ethylene glycol (PEG) blend obtained with Ni49.5Mn29.5Ga21 (in % atomic). Different ratios of the alloy were doped into the blend to investigate the effect of the alloy on the characteristic features of the composite. Physicochemical properties of NiMnGa enriched composites were analyzed by attenuated total reflectance infrared spectroscopy (ATR-IR), differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), X-ray diffraction (XRD), scanning electron microscopy (SEM), and vibrating sample magnetometer (VSM). From DSC analysis it is concluded that the magnetically enhanced PLA/PEG films with the alloy had two important phase transformations. Although NiMnGa shape memory alloy did not affect the initial decomposition temperature (Ti) of the PLA/PEG blend much, the residue ratio increased with increasing alloy content. The characteristic XRD signal of the alloy becomes observable with the increasing amount of NiMnGa in the composite. In addition, the diamagnetic PLA/PEG blend gained magnetic properties with addition of the alloy. It is also observed that NiMnGa had a positive effect on the shape memory feature of the polymer blend.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Costanza G, Tata ME (2020) Shape memory alloys for aerospace, recent developments, and new applications: a short review. Materials 13(8):1856

Savi MA, Paiva A, Araujo, CJd (2016) Paula ASd. Shape memory alloys. Dynamics of smart systems and structures. Springer, pp 155–188

Aversa R, Tamburrino F, Petrescu RV, Petrescu FI, Artur M, Chen G, Apicella A (2016) Biomechanically inspired shape memory effect machines driven by muscle like acting NiTi alloys. Am J Appl Sci 13(11):1264–1271

Dasgupta R (2014) A look into Cu-based shape memory alloys: Present scenario and future prospects. J Mater Res 29(16):1681–1698

Lu H, Yu K, Sun S, Liu Y, Leng J (2010) Mechanical and shape-memory behavior of shape‐memory polymer composites with hybrid fillers. Polym Int 59(6):766–771

Hearon K, Wierzbicki MA, Nash LD, Landsman TL, Laramy C, Lonnecker AT, Gibbons MC, Ur S, Cardinal KO, Wilson TS (2015) A processable shape memory polymer system for biomedical applications. Adv Healthc Mater 4(9):1386–1398

Wei H, Zhang Q, Yao Y, Liu L, Liu Y, Leng J (2017) Direct-write fabrication of 4D active shape-changing structures based on a shape memory polymer and its nanocomposite. ACS Appl Mater Interfaces 9(1):876–883

Liu Y, Li Y, Yang G, Zheng X, Zhou S (2015) Multi-stimulus-responsive shape-memory polymer nanocomposite network cross-linked by cellulose nanocrystals. ACS Appl Mater Interfaces 7(7):4118–4126

Defize T, Riva R, Raquez JM, Dubois P, Jérôme C, Alexandre M (2011) Thermoreversibly crosslinked poly (ε-caprolactone) as recyclable shape‐memory polymer network. Macromol Rapid Commun 32(16):1264–1269

Tsuji H, Arakawa Y (2018) Synthesis, properties, and crystallization of the alternating stereocopolymer poly (l-lactic acid-alt-d-lactic acid)[syndiotactic poly (lactic acid)] and its blend with isotactic poly (lactic acid). Polym Chem 9(18):2446–2457

Jing X, Mi HY, Peng XF, Turng LS (2015) The morphology, properties, and shape memory behavior of polylactic acid/thermoplastic polyurethane blends. Polym Eng Sci 55(1):70–80

Leonés A, Sonseca A, López D, Fiori S, Peponi L (2019) Shape memory effect on electrospun PLA-based fibers tailoring their thermal response. Eur Polymer J 117:217–226

Ehrmann G, Ehrmann A (2021) 3D printing of shape memory polymers. J Appl Polym Sci 138(34):50847

Boyacioglu S, Kodal M, Ozkoc G (2020) A comprehensive study on shape memory behavior of PEG plasticized PLA/TPU bio-blends. Eur Polymer J 122:109372

Bijarimi M, Ahmad S, Rasid R, Khushairi M, Zakir M (eds) (2016) Poly (lactic acid)/Poly (ethylene glycol) blends: Mechanical, thermal and morphological properties. AIP Conference Proceedings; AIP Publishing LLC

Yilmaz M, Pekdemir ME, Öner E (2023) Evaluation of Pb doped Poly (lactic acid)(PLA)/Poly (ethylene glycol)(PEG) blend composites regarding physicochemical and radiation shielding properties. Radiat Phys Chem 202:110509

Li F-J, Liang J-Z, Zhang S-D, Zhu B (2015) Tensile properties of polylactide/poly (ethylene glycol) blends. J Polym Environ 23:407–415

Pekdemir ME, Kök M, Kanca MS, Özen Öner E, Pekdemir S, Inci Ş, Kirbağ S, Tatar B (2023) B2O3 reinforced polylactic acid/thermoplastic polyethylene glycol shape memory composites. Polym Adv Technol 34(2):605–612

Kök M, Aydoğdu Y (2013) Effect of composition on the thermal behavior of NiMnGa alloys. J Therm Anal Calorim 113:859–863

Galaev IY, Mattiasson B (1999) Smart’polymers and what they could do in biotechnology and medicine. Trends Biotechnol 17(8):335–340

Miller SA (2013) Sustainable polymers: opportunities for the next decade. ACS Publications

Manickam M, Feuchtwanger J, O’Handley RC (2008) Acoustic energy absorption in ferromagnetic Ni-Mn-Ga shape memory alloy polymer composites. Adv Mater Res 52:87–94

Feuchtwanger J, Michael S, Juang J, Bono D, O’Handley RC, Allen SM, Jenkins C, Goldie J, Berkowitz A (2003) Energy absorption in Ni-Mn-Ga-polymer composites. J Appl Phys 93(10):8528–8530

Sun X, Song J, Jiang H, Zhang X, Xie C (eds) (2011) Damping behavior of polymer composites with high volume fraction of NiMnGa powders. 2011:SPIE

Choi K-m, Choi M-C, Han D-H, Park T-S, Ha C-S (2013) Plasticization of poly (lactic acid)(PLA) through chemical grafting of poly (ethylene glycol)(PEG) via in situ reactive blending. Eur Polymer J 49(8):2356–2364

Özen Öner E, Pekdemir ME, Ercan E, Say Y, Kök M, Aydoğdu Y (2022) Novel of (PLA/PCL blend)/Gd2O3 rare earth oxide nanocomposites: Shape memory effect, thermal, magnetic, and mechanical properties. Polym Compos

Kister G, Cassanas G, Vert M (1998) Effects of morphology, conformation and configuration on the IR and Raman spectra of various poly (lactic acid) s. Polymer 39(2):267–273

Herrera-Kao W, Loría-Bastarrachea M, Pérez-Padilla Y, Cauich-Rodríguez J, Vázquez-Torres H, Cervantes-Uc JM (2018) Thermal degradation of poly (caprolactone), poly (lactic acid), and poly (hydroxybutyrate) studied by TGA/FTIR and other analytical techniques. Polym Bull 75(9):4191–4205

Chieng BW, Ibrahim NA, Wan Yunus WMZ, Hussein MZ (2013) Poly (lactic acid)/poly (ethylene glycol) polymer nanocomposites: Effects of graphene nanoplatelets. Polymers 6(1):93–104

Ma X, Yu J, Wang N (2006) Compatibility characterization of poly (lactic acid)/poly (propylene carbonate) blends. J Polym Sci Part B: Polym Phys 44(1):94–101

McNeill I, Leiper H (1985) Degradation studies of some polyesters and polycarbonates—1. Polylactide: General features of the degradation under programmed heating conditions. Polym Degrad Stab 11(3):267–285

Younes H, Cohn D (1988) Phase separation in poly (ethylene glycol)/poly (lactic acid) blends. Eur Polymer J 24(8):765–773

Pekdemir ME, Qader IN, Öner E, Aydoğmuş E, Kök M, Dağdelen F (2021) Investigation of structure, mechanical, and shape memory behavior of thermally activated poly (ε-caprolactone): azide-functionalized poly (vinyl chloride) binary polymer blend films. Eur Phys J Plus 136(8):1–14

Fenni S, Monticelli O, Conzatti L, Doufnoune R, Stagnaro P, Haddaoui N, Cavallo D (2018) Correlating the morphology of poly (L-lactide)/poly (butylene succinate)/graphene oxide blends nanocomposites with their crystallization behavior. Express Polym Lett 12(1)

Quental A, de Carvalho F, Rezende M, Rosa D, Felisberti M (2010) Aromatic/aliphatic polyester blends. J Polym Environ 18(3):308–317

Ozdemir E, Hacaloglu J (2017) Characterizations of PLA-PEG blends involving organically modified montmorillonite. J Anal Appl Pyrol 127:343–349

Kök M, Pirge G, Aydoğdu Y (2013) Isothermal oxidation study on NiMnGa ferromagnetic shape memory alloy at 600–1000 C. Appl Surf Sci 268:136–140

Kok M (2011) Investigation of the effect of alloy content and heat treatment on physical properties of Ni–Mn–Ga ferromagnetic shape memory alloys: Ph. D. Thesis, Firat University, Elazig

Kök M, Aydoğdu Y (2013) A comparative study on thermal and microstructural properties of different types of NiMnGa magnetic shape memory alloys. J Supercond Novel Magn 26(5):1697–1701

Chu Z, Zhao T, Li L, Fan J, Qin Y (2017) Characterization of antimicrobial poly (lactic acid)/nano-composite films with silver and zinc oxide nanoparticles. Materials 10(6):659

Loh XJ, Sng KBC, Li J (2008) Synthesis and water-swelling of thermo-responsive poly (ester urethane) s containing poly (ε-caprolactone), poly (ethylene glycol) and poly (propylene glycol). Biomaterials 29(22):3185–3194

Taşgin Y, Pekdemir ME, Yilmaz M, Kanca MS, Kök M (2023) Physical and shielding properties of Er2O3 rare earth oxide compound content on PCL/PEG blend. Polym Bull 1–17

Darabian B, Bagheri H, Mohammadi S (2020) Improvement in mechanical properties and biodegradability of PLA using poly (ethylene glycol) and triacetin for antibacterial wound dressing applications. Prog Biomater 9:45–64

Chen BY, Wang YS, Mi HY, Yu P, Kuang TR, Peng XF, Wen JS (2014) Effect of poly (ethylene glycol) on the properties and foaming behavior of macroporous poly (lactic acid)/sodium chloride scaffold. J Appl Polym Sci 131(23)

Zhao X, Hu H, Wang X, Yu X, Zhou W, Peng S (2020) Super tough poly (lactic acid) blends: a comprehensive review. RSC Adv 10(22):13316–13368

Aziz B, Shakoor A, Qureshi AK, Ali K, Niaz NA, Farid MT, Ali I (2018) Structural, electrical, and magnetic properties of ferrite–polymer composites. J Electron Mater 47(11):6437–6442

Gall K, Yakacki CM, Liu Y, Shandas R, Willett N, Anseth KS (2005) Thermomechanics of the shape memory effect in polymers for biomedical applications. Journal of Biomedical Materials Research Part A: an Official Journal of the Society for Biomaterials, vol 73. The Japanese Society for Biomaterials, and The Australian Society for Biomaterials and the Korean Society for Biomaterials, pp 339–348. 3

Acknowledgements

We would like to thank the financial support provided by the Management Unit of the Scientific Research Projects of Firat University (FUBAP) (Project Number: FF.23.01 and ADEP.23.02).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing fnancial interests or personal relationships that could have appeared to infuence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pekdemir, M.E., Kaya, M., Coşkun, M. et al. Physicochemical properties of magnetically enhanced shape memory polymer composites doped with NiMnGa. J Polym Res 30, 293 (2023). https://doi.org/10.1007/s10965-023-03679-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03679-6