Abstract

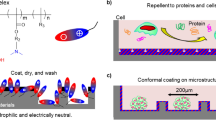

The incorporation of the structural fibrous scleroprotein keratin into synthetic polymers may be a solution for the development of biomaterials with advanced properties. This study aimed to develop micro-patterned membranes based on poly(ε-caprolactone)(PCL) polymer blended with native or polyethylene glycol diglycidyl ether (PEGDE) cross-linked keratin, suitable for guiding cell attachment and orientation for potential biotechnological applications. First, human hair keratin was extracted; its biochemical composition and physicochemical properties were analyzed. Then, micropatterned membrane constructs from PCL blended with 20% and 40% by mass of keratin were created using phase separation micromolding for the first time. Four different mold micropatterns were evaluated; the one applicable to all polymer compositions was determined [(channel:20μm)x(height:10μm)x(ridge:10μm)]. The constructs were extensively investigated for their physicochemical (FTIR, XRD), thermal (DSC,TGA), morphological (SEM), mechanical (compressive-tensile strength, degradation) and in vitro biological (hemocompatibility, cytocompatibility) properties. While blending PCL with keratin did not affect the physicochemical and melting temperature of PCL, it significantly affected the mechanical properties of the constructs. Compressive strength increased linearly with the addition of keratin, especially with cross-linked keratin. All constructs were found to be highly hemocompatible (<0.2% hemolysis). Stem cell interactions showed cross-linked keratin-blended PCL constructs could be suitable substrates for cell alignment and proliferation.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Williams DF (2009) On the nature of biomaterials. Biomaterials 30:5897–5909. https://doi.org/10.1016/j.biomaterials.2009.07.027

Rahmati M, Silva EA, Reseland JE, Heyward CA, Haugen HJ (2020) Biological responses to physicochemical properties of biomaterial surface. Chem Soc Rev 49:5178–5224. https://doi.org/10.1039/d0cs00103a

Öztürk S, Ayanoğlu FB, Parmaksiz M, Elçin AE, Elçin YM (2020) Clinical and surgical aspects of medical materials’ biocompatibility. In: Mozafari M (ed) Handbook of Biomaterials Biocompatibility. Elsevier, Cambridge, pp 219–250. https://doi.org/10.1016/B978-0-08-102967-1.00012-8

Guo Z, Poot AA, Grijpma DW (2021) Advanced polymer-based composites and structures for biomedical applications. Eur Polymer J 149:110388. https://doi.org/10.1016/j.eurpolymj.2021.110388

Huang G, Li F, Zhao X, Ma Y, Li Y, Lin M, Jin G, Lu TJ, Genin GM, Xu F (2017) Functional and biomimetic materials for engineering of the three-dimensional cell microenvironment. Chem Rev 117(20):12764–12850. https://doi.org/10.1021/acs.chemrev.7b00094

Şeker Ş, Arslan YE, Durkut S, Elçin AE, Elçin YM (2014) Nanotechnology for tissue engineering and regenerative medicine, in: K. Iniewski, S. Selimovic (Eds.). Nanopatterning and Nanoscale Devices for Biological Applications, CRC Press, Boca Raton, FL, pp. 339–367, ISBN: 9781466586314

Joyce K, Fabra GT, Bozkurt Y, Pandit A (2021) Bioactive potential of natural biomaterials: identification, retention and assessment of biological properties. Signal Transduct Target Therapy 6:122. https://doi.org/10.1038/s41392-021-00512-8

Lodish H, Berk A, Zipursky SL, Matsudaira P, Baltimore D, Darnell J (2000) Molecular Cell Biology 4th Edition, W. H. Freeman, New York, ISBN: 9780716737063

Shavandi A, Silva TH, Bekhit AA, Bekhit AEA (2017) Keratin: dissolution, extraction and biomedical application. Biomaterials Sci 5(9):1699–1735. https://doi.org/10.1039/c7bm00411g

Feroz S, Muhammad N, Ranayake J, Dias G (2020) Keratin-based materials for biomedical applications. Bioactive Mater 5(3):496–509. https://doi.org/10.1016/j.bioactmat.2020.04.007

Rajabinejad H, Zoccola M, Patrucco A, Montarsolo A, Rovero G, Tonin C (2018) Physicochemical properties of keratin extracted from wool by various methods. Text Res J 88(21):2415–2424. https://doi.org/10.1177/0040517517723028

Cecil R, McPhee JR (1959) The sulfur chemistry of proteins. Adv Protein Chem 14:255–389. https://doi.org/10.1016/S0065-3233(08)60613-0

Bragulla HH, Homberger DG (2009) Structure and functions of keratin proteins in simple, stratified, keratinized and cornified epithelia. J Anat 214(4):516–559. https://doi.org/10.1111/j.1469-7580.2009.01066.x

Lee H, Noh K, Lee SC, Kwon IK, Han DW, Lee IS, Hwang YS (2014) Human hair keratin and its-based biomaterials for biomedical applications. Tissue Eng Regenerative Med 11(4):255–265. https://doi.org/10.1007/s13770-014-0029-4

Tanabe T, Okitsu N, Tachibana A, Yamauchi K (2002) Preparation and characterization of keratin–chitosan composite film. Biomaterials 23(3):817–825. https://doi.org/10.1016/S0142-9612(01)00187-9

Rouse JG, Van Dyke ME (2010) A review of keratin-based biomaterials for biomedical applications. Materials 3(2):999–1014. https://doi.org/10.3390/ma3020999

Hardin J, Bertoni GP, Kleinsmith LJ (2017) Becker's World of the Cell, Global Edition, 9th Edition, Pearson, London, ISBN: 9781292177694

Izawa I, Inagaki M (2006) Regulatory mechanisms and functions of intermediate filaments: a study using site-and phosphorylation state‐specific antibodies. Cancer Sci 97(3):167–174. https://doi.org/10.1111/j.1349-7006.2006.00161.x

Sierpinski P, Garrett J, Ma J, Apel P, Klorig D, Smith T, Koman LA, Atala A, Van Dyke M (2008) The use of keratin biomaterials derived from human hair for the promotion of rapid regeneration of peripheral nerves. Biomaterials 29(1):118–128. https://doi.org/10.1016/j.biomaterials.2007.08.023

Barati D, Kader S, Shariati SRP, Moeinzadeh S, Sawyer RH, Jabbari E (2017) Synthesis and characterization of photo-cross-linkable keratin hydrogels for stem cell encapsulation. Biomacromolecules 18(2):398–412. https://doi.org/10.1021/acs.biomac.6b01493

Yue K, Liu Y, Byambaa B, Singh V, Liu W, Li X, Sun Y, Zhang YS, Tamayol A, Zhang P, Ng KW, Annabi N, Khademhosseini A (2018) Visible light crosslinkable human hair keratin hydrogels. Bioeng Translational Med 3(1):37–48. https://doi.org/10.1002/btm2.10077

Elçin YM, Elçin AE, Pappas GD (2003) Functional and morphological characteristics of bovine adrenal chromaffin cells on macroporous poly(D,L-lactide-co-glycolide) scaffolds. Tissue Eng 9(5):1047–1056. https://doi.org/10.1089/107632703322495682

Jang JH, Castano O, Kim HW (2009) Electrospun materials as potential platforms for bone tissue engineering. Adv Drug Deliv Rev 61(12):1065–1083. https://doi.org/10.1016/j.addr.2009.07.008

Bonilla CEP, Trujillo S, Demirdogen B, Perilla JE, Elçin YM, Ribelles JIG (2014) New porous polycaprolactone-silica composites for bone regeneration. Mater Sci Eng C 40:418–426. https://doi.org/10.1016/j.msec.2014.04.024

Boakye MA, Rijal NP, Adhikaria U, Bhattarai N (2015) Fabrication and characterization of electrospun PCL-MgO-keratin-based composite nanofibers for biomedical applications. Materials 8(7):4080–4095. https://doi.org/10.3390/ma8074080

Lin Y-C, Ramadan M, Van Dyke M, Kokai LE, Philips BJ, Rubin JP, Marra KC (2012) Keratin gel filler for peripheral nerve repair in a rodent sciatic nerve injury model. Plast Reconstr Surg 129(1):67–78. https://doi.org/10.1097/PRS.0b013e3182268ae0

Li P, Wang Y, Jin X, Dou J, Han X, Wan X, Yuan J, Shen J (2020) Fabrication of PCL/keratin composite scaffolds for vascular tissue engineering with catalytic generation of nitric oxide potential. J Mater Chem B 8:6092–6099. https://doi.org/10.1039/d0tb00857e

Wu P, Dai X, Chen K, Li R, Xing Y (2018) Fabrication of regenerated wool keratin/polycaprolactone nanofiber membranes for cell culture. Int J Biol Macromol 114:1168–1173. https://doi.org/10.1016/j.ijbiomac.2018.03.157

Mori H, Hara M (2018) Transparent biocompatible wool keratin film prepared by mechanical compression of porous keratin hydrogel. Mater Sci Eng C 91:19–25. https://doi.org/10.1016/j.msec.2018.05.021

Vogelaar L, Lammertink RG, Barsema JN, Nijdam W, Bolhuis-Versteeg LA, Van Rijn CJ, Wessling M (2005) Phase separation micromolding: a new generic approach for microstructuring various materials. Small 1(6):645–655. https://doi.org/10.1002/smll.20040012

Papenburg BJ, Vogelaar L, Bolhuis-Versteeg LA, Lammertink RG, Stamatialis D, Wessling M (2007) One-step fabrication of porous micropatterned scaffolds to control cell behavior. Biomaterials 28(11):1998–2009. https://doi.org/10.1016/j.biomaterials.2006.12.023

Agarwal V, Panicker AG, Indrakumar S, Chatterjee K (2019) Comparative study of keratin extraction from human hair. Int J Biol Macromol 133:382–390. https://doi.org/10.1016/j.ijbiomac.2019.04.098

Tüzün-Antepli B, Elçin AE, Elçin YM (2022) Construction of micro-grooved PCL/nanohydroxyapatite membranes by non-solvent induced phase separation method and its evaluation for use as a substrate for human periodontal ligament fibroblasts. Chem Eng Sci 248:117120. https://doi.org/10.1016/j.ces.2021.117120

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685. https://doi.org/10.1038/227680a0

Elçin AE, Parmaksiz M, Dogan A, Şeker Ş, Durkut S, Dalva K, Elçin YM (2017) Differential gene expression profiling of human adipose stem cells differentiating into smooth muscle-like cells by TGFb1/BMP4. Exp Cell Res 352:207–217. https://doi.org/10.1016/j.yexcr.2017.02.006

Ergün C, Parmaksiz M, Vurat MT, Elçin AE, Elçin YM (2022) Decellularized liver ECM-based 3D scaffolds: compositional, physical, chemical, rheological, thermal, mechanical, and in vitro biological evaluations. Int J Biol Macromol 200:110–123. https://doi.org/10.1016/j.ijbiomac.2021.12.086

Hill P, Brantley H, Van Dyke M (2010) Some properties of keratin biomaterials: kerateines. Biomaterials 31(4):585–593. https://doi.org/10.1016/j.biomaterials.2009.09.076

Aluigi A, Zoccola M, Vineis C, Tonin C, Ferrero F, Canetti M (2007) Study on the structure and properties of wool keratin regenerated from formic acid. Int J Biol Macromol 41(3):266–273. https://doi.org/10.1016/j.ijbiomac.2007.03.002

Kakkar P, Madhan B, Shanmugam G (2014) Extraction and characterization of keratin from bovine hoof: A potential material for biomedical applications. SpringerPlus 3:596. https://doi.org/10.1186/2193-1801-3-596

Kadirvelu K, Fathima NN (2016) Self-assembly of keratin peptides: Its implication on the performance of electrospun PVA nanofiber. Sci Rep 6:36558. https://doi.org/10.1038/srep36558

Clogston JD, Patri AK (2011) Zeta potential measurement. Methods Mol Biol 697:63–70. https://doi.org/10.1007/978-1-60327-198-1_6

Kunjiappan S, Chowdhury A, Somasundaram B, Bhattacharjee C, Periyasamy S (2016) Optimization, preparation and characterization of rutin-quercetin dual drug loaded keratin nanoparticles for biological applications. Nanomed J 3(4):253–267. https://doi.org/10.22038/nmj.2016.7615

Silva OA, Pella MG, Popat KC, Kipper MJ, Rubira AF, Martins AF, Follmann HDM, Silva R (2022) Rod-shaped keratin nanoparticles extracted from human hair by acid hydrolysis as photothermally triggered berberine delivery system. Adv Powder Technol 33:103353. https://doi.org/10.1016/j.apt.2021.11.005

Cardamone JM (2010) Investigating the microstructure of keratin extracted from wool: Peptide sequence (MALDI-TOF/TOF) and protein conformation (FTIR). J Mol Struct 969(1–3):97–105. https://doi.org/10.1016/j.molstruc.2010.01.048

Edwards A, Jarvis D, Hopkins T, Pixley S, Bhattarai N (2014) Poly (ε-caprolactone)/keratin‐based composite nanofibers for biomedical applications. J Biomedical Mater Res Part B: Appl Biomaterials 103(1):21–30. https://doi.org/10.1002/jbm.b.33172

Elzein T, Nasser-Eddine M, Delaite C, Bistac S, Dumas P (2004) FTIR study of polycaprolactone chain organization at interfaces. J Colloid Interface Sci 273(2):381–387. https://doi.org/10.1016/j.jcis.2004.02.001

Chuc-Gamboa MG, Vargas-Coronado RF, Cervantes-Uc JM, Cauich-Rodríguez JV, Escobar-García DM, Pozos-Guillén A, San Román del Barrio J (2019) The effect of PEGDE concentration and temperature on physicochemical and biological properties of chitosan. Polymers 11(11):1830. https://doi.org/10.3390/polym11111830

Kim DH, Kim P, Song I, Cha JM, Lee SH, Kim B, Suh KY (2006) Guided three-dimensional growth of functional cardiomyocytes on polyethylene glycol nanostructures. Langmuir 22(12):5419–5426. https://doi.org/10.1021/la060283u

Moffa M, Sciancalepore GA, Passione GL, Pisignano D (2014) Combined nanoand micro-scale topographic cues for engineered vascular constructs by electrospinning and imprinted micro-patterns. Small 10:2439–2450. https://doi.org/10.1002/smll.201303179

Avérous L, Moro L, Dole P, Fringant C (2000) Coaxial and emulsion electrospinning of extracted hyaluronic acid and keratin based nanofibers for wound healing applications. Polymer 41(11):4157–4167. https://doi.org/10.1016/S0032-3861(99)00636-9

Su S, Bedir T, Kalkandelen C, Basar AO, Sasmazel T, Ustundag H, Sengor CB, Gunduz O (2021) Coaxial and emulsion electrospinning of extracted hyaluronic acid and keratin based nanofibers for wound healing applications. Eur Polymer J 142:110158. https://doi.org/10.1016/j.eurpolymj.2020.110158

Doh G-H, Lee S-Y, Kang I-A, Kong Y-T (2005) Thermal behavior of liquefied wood polymer composites (LWPC). Compos Struct 68:103–108. https://doi.org/10.1016/j.compstruct.2004.03.004

Aisyah HA, Paridah MT, Sapuan SM, Khalina A, Berkalp OB, Lee SH, Lee CH, Nurazzi NM, Ramli N, Wahab MS, Ilyas RA (2019) Thermal properties of woven kenaf/carbon fibre-reinforced epoxy hybrid composite panels. International Journal of Polymer Science 2019:5258621. https://doi.org/10.1155/2019/5258621

Liu Y, Yu X, Li J, Fan J, Wang M, Lei TD, Huang D (2015) Fabrication and properties of high-content keratin/poly (ethylene oxide) blend nanofibers using two-step cross-linking process. Journal of Nanomaterials 2015:803937. https://doi.org/10.1155/2015/803937

Ghasemi-Mobarakeh L, Prabhakaran MP, Morshed M, Nasr-Esfahani M-H, Ramakrishna S (2008) Electrospun poly(epsilon-caprolactone)/gelatin nanofibrous scaffolds for nerve tissue engineering. Biomaterials 29:4532–4539. https://doi.org/10.1016/j.biomaterials.2008.08.007

Choi JS, Lee SJ, Christ GJ, Atala A, Yoo JJ (2008) The influence of electrospun aligned poly(epsilon-caprolactone)/collagen nanofiber meshes on the formation of self-aligned skeletal muscle myotubes. Biomaterials 29:2899–2906. https://doi.org/10.1016/j.biomaterials.2008.03.031

Li Y, Wang Y, Ye J, Yuan J, Xiao Y (2016) Fabrication of poly(ε-caprolactone)/keratin nanofibrous mats as a potential scaffold for vascular tissue engineering. Mater Sci Eng C 68:177–183. https://doi.org/10.1016/j.msec.2016.05.117

Moonsri P, Watanesk R, Watanesk S, Niamsup H, Deming RL (2008) Fibroin membrane preparation and stabilization by polyethylene glycol diglycidyl ether. J Appl Polym Sci 108(3):1402–1406. https://doi.org/10.1002/app.27528

Zhao X, Lui YS, Choo CKC, Sow WT, Huang CL, Ng KW, Tan LP, Loo JSC (2015) Calcium phosphate coated Keratin–PCL scaffolds for potential bone tissue regeneration. Mater Sci Eng C 49:746–753. https://doi.org/10.1016/j.msec.2015.01.084

Lin C-W, Chen Y-K, Tang K-C, Yang K-C, Cheng N-C, Yu J (2019) Keratin scaffolds with human adipose stem cells: Physical and biological effects toward wound healing. Tissue Eng Regenerative Med 13(6):1044–1058. https://doi.org/10.1002/term.2855

Vineis C, Maya IC, Mowafi S, Varesano A, Ramírez DOS, Taleb MA, Tonetti C, Guarino V, El-Sayed H (2021) Synergistic effect of sericin and keratin in gelatin based nanofibers for in vitro applications. Int J Biol Macromol 190:375–381. https://doi.org/10.1016/j.ijbiomac.2021.09.007

Choi WS, Kim JH, Ahn CB, Lee JH, Kim YJ, Son KH, Lee JW (2021) Development of a multi-layer skin substitute using human hair keratinic extract-based hybrid 3D printing. Polym (Basel) 13(16):2584. https://doi.org/10.3390/polym13162584

Baykan E, Elçin KA, Elçin AE (2014) Evaluation of a biomimetic poly(epsilon-caprolactone)/beta-tricalcium phosphate multispiral scaffold for bone tissue engineering: In-vitro and in-vivo studies. Biointerphases 9(2):029011. https://doi.org/10.1116/1.4870781

Siddiqui N, Asawa S, Birru B, Baadhe R, Rao S (2018) PCL-based composite scaffold matrices for tissue engineering applications. Mol Biotechnol 60:506–532. https://doi.org/10.1007/s12033-018-0084-5

Author information

Authors and Affiliations

Contributions

Serap Sezer: Conceptualization, Investigation, Data curation, Formal analysis, Writing. Burcu Tüzün-Antepli: Data curation, Writing. Mahmut Parmaksiz: Data curation, Writing. Burcu Bayramli-Öner: Data curation. Ayşe Eser Elçin: Data curation, Writing. Yaşar Murat Elçin: Supervising, Resources, Conceptualization, Writing – review & editing.

Corresponding author

Ethics declarations

Conflict of interest

Y.M.E. is the founder and shareholder of Biovalda Health Technologies, Inc. (Ankara, Turkey). The authors declare no competing financial interests in relation to this particular article. The authors are alone responsible for the content and writing of the paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sezer, S., Tüzün-Antepli, B., Parmaksiz, M. et al. Development of a micro-patterned membrane consisting of a PCL/Keratin/PEGDE ternary blend using PSµM for potential biotechnological applications. J Polym Res 30, 320 (2023). https://doi.org/10.1007/s10965-023-03671-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03671-0