Abstract

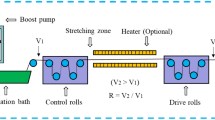

High mechanical property poly (vinyl alcohol) (PVA) fibers have attracted tremendous attentions because of their excellent mechanical properties and has a potential application in the field of building enhancement. In this article, PVA polymer with high polymerization degree (Pn) and high Syndiotacticity-diad content (S-diad) were synthesized using vinyl acetate (VAc) and vinyl pivalate (VPi) as monomers via emulsion polymerization with water as solvent, the GPC and 1H NMR were used to characterized the Pn and S-diad of PVA polymer. Then the lanthanum chloride (LaCl3) was chosen as cross-linking and the synthesized PVA polymer as raw material for dry-wet spinning, a series of PVA fibers with high strength and high modulus have been prepared. The final PVA-La fibers were characterized through a series of experiments including of FTIR, SEM, DSC, TGA, XRD and fiber tensile tester. It turned out that the Pn and S-diad of synthesized PVA polymer were 4817 ± 76 and 56.3 ± 0.7%. With the increasing of LaCl3 content, the -OH vibration absorption peak of PVA-La composite fiber gradually increased from 3462 cm-1 to 3484 cm-1; the strength, modulus, crystallinity and orientation all increased first and then decreased. Especially, the properties of PVA-La fiber exhibited an optimal LaCl3 content of 0.8 wt%, the denier was 5.4 ± 0.5 dtex, the tensile strength and highest elastic modulus of 15.19 ± 0.5 cN/dtex and 369.21 ± 9.1cN/dtex, the elongation at break was 3.72 ± 0.4%, the crystallinity was 53.9 ± 0.6%, the orientation was 95.6 ± 0.6%.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these finding cannot be shared at this time as the data also forms part of an ongoing study.

References

Wang J, Dai Q, Si R, Guo S (2018) Investigation of properties and performances of Polyvinyl Alcohol (PVA) fiber-reinforced rubber concrete. Constr Build Mater 193:631–642. https://doi.org/10.1016/j.conbuildmat.2018.11.002

Suzuki M, Tanigami T, Matsuzawa S, Yamaura K (2002) Influence of molecular weight and syndiotacticity on the structure of high-performance poly(vinyl alcohol) fibers prepared by gel spinning. J Appl Polym Sci 86:1970–1977. https://doi.org/10.1002/app.11118

Hong X, Zou L, Xu Y, Li YV, He J (2020) Preparation and study of Polyvinyl Alcohol/Attapulgite nanocomposite fibers with high strength and high Young’s modulus by gel spinning. Mater Rese Express 7:065303. https://doi.org/10.1088/2053-1591/ab9855

Zhao C, Liang N, Zhu X (2020) The influences of powder surface energy on the dispersibility technology of polyvinyl alcohol fiber. Asia-Pacific J Chem Eng 15(S1):e2451. https://doi.org/10.1002/apj.2451

Yin P, Dong X, Zhou W, Zha D, Xu J, Guo B, Li P (2020) A novel method to produce sustainable biocomposites based on thermoplastic corn-starch reinforced by polyvinyl alcohol fibers. RSC Adv 10:23632–23643. https://doi.org/10.1039/d0ra04523c

Ding C, Guo L, Chen B (2020) Orientation distribution of polyvinyl alcohol fibers and its influence on bridging capacity and mechanical performances for high ductility cementitious composites. Construct Build Mater 247:118491. https://doi.org/10.1016/j.conbuildmat.2020.118491

Bao Y, Huang X, Xu J, Cui S (2021) Effect of Intramolecular Hydrogen Bonds on the Single-Chain Elasticity of Poly(vinyl alcohol): Evidencing the Synergistic Enhancement Effect at the Single-Molecule Level. Macromolecules 54:7314–7320. https://doi.org/10.1021/acs.macromol.1c01251

Dong H, Liu G, Zhang H (2020) Preparation of photodeformable azobenzene polymer fibers by post-crosslinking strategy: Understanding the structure-property relationship. European Polym J 135:109863. https://doi.org/10.1016/j.eurpolymj.2020.109863

Liu K, Sun Y, Lin X, Zhou R, Wang J, Fan S, Jiang K (2010) Scratch-resistant, highly conductive, and high-strength carbon nanotube-based composite yarns. ACS Nano 4:5827–5834. https://doi.org/10.1021/nn1017318

Sun M, Chen Y, Zhu J, Sun T, Shui Z, Ling G, Zhong H (2018) Effect of Modified Polyvinyl Alcohol Fibers on the Mechanical Behavior of Engineered Cementitious Composites. Materials (Basel) 12(37):0037. https://doi.org/10.3390/ma12010037

Pham QL, Nguyen VH, Haldorai Y (2013) Polymerization of vinyl pivalate in supercritical carbon dioxide and the saponification for the preparation of syndiotacticity-rich poly(vinyl alcohol). Korean J Chem Eng 30:1153–1161. https://doi.org/10.1007/s11814-013-0019-6

Yan CW, Jia JQ, Zhang J, Jiang R (2010) Compressive Strength and Splitting Tensile Strength of Polyvinyl Alcohol Fiber Reinforced Ultra High Strength Concrete (PFRC). Adv Mater Res 150(151):996–999. https://doi.org/10.4028/www.scientific.net/AMR.150-151.996

Kumar SS, Raja VM (2021) Processing and determination of mechanical properties of Prosopis juliflora bark, banana and coconut fiber reinforced hybrid bio composites for an engineering field. Compos Sci Technol 208:108695. https://doi.org/10.1016/j.compscitech.2021.108695

Wang HJ, He JW, Zou LM, Wang C (2021) Synthesis of syndiotacticity rich high polymerization degree PVA polymers with VAc and VPa, fabrication of PVA fibers with superior mechanical properties by wet spinning. J Polym Res 28(10):02752. https://doi.org/10.1007/s10965-021-02752-2

Masci G, Husu I, Murtas S, Piozzi A, Crescenzi V (2003) Physical Hydrogels of Poly(vinyl alcohol) with Different Syndiotacticity Prepared in the Presence of Lactosilated Chitosan Derivatives. Macromol Biosci 3:455–461. https://doi.org/10.1002/mabi.200350017

Cui S, Li L, Wang Q (2020) Improved molecular chain constraint of poly (propylene carbonate) composites by the synergistic effect of poly (vinyl alcohol) and carbon nanotubes. Compos Part B: Eng 194:108074. https://doi.org/10.1016/j.compositesb.2020.108074

Yoshitaka N, Tamaki N, Yoshio O (2001) Properties of highly syndiotactic poly(vinyl alcohol). Polymer 42:9679–9686. https://doi.org/10.1016/S0032-3861(01)00493-1

Wang H, He J, Zou L, Wang C, Wang Y (2021) Synthesis of syndiotacticity-rich high polymerization degree PVA polymers with VAc and VPa, fabrication of PVA fibers with superior mechanical properties by wet spinning. J Polym Res 28(386):02752. https://doi.org/10.1007/s10965-021-02752-2

Han MH, Lyoo WS (2010) Preparation of syndiotacticity-rich high molecular weight poly(vinyl alcohol)/iodine polarizing film with high water resistance. J Appl Polym Sci 115:917–922. https://doi.org/10.1002/app.31192

Lee SG, Kim JP, Lyoo WS, Kwak JW (2005) Preparation of Novel Syndiotactic Poly(vinyl alcohol) Microspheres through the Low-Temperature Suspension Copolymerization of Vinyl Pivalate and Vinyl Acetate and Heterogeneous Saponification. J Appl Polym Sci 95:1503–1508. https://doi.org/10.1002/app.21296

Lyoo WS, Blackwell J (1998) Structure of Poly(vinyl alcohol) Microfibrils Produced by Saponification of Copoly(vinyl pivalate/vinyl acetate). Macromolecules 31:4253–4259. https://doi.org/10.1021/ma981985w

Shin Jo, Y.G., Lee, E.J., and Yoon, W.S. (2009) Effect of gel spinning accompanied with cross-linking using boric acid on the structure and properties of high-molecular-weight poly(vinyl alcohol) fiber. J Appl Polym Sci 113:1733–1738. https://doi.org/10.1002/app.30084

Zhu Y, Li HM, Wu CX, Zhao JX (2015) Preparation and characterisation of polyvinyl alcoholnano-SiO2 composite fibre with high initial modulus. Mater Res Innovations 18:825–825. https://doi.org/10.1179/1432891714Z.000000000789

Hong X, He J, Zou L, Wang Y, Li YV (2021) Preparation and characterization of high strength and high modulus PVA fiber via dry-wet spinning with cross-linking of boric acid. J Appl Polym Sci 138:51394. https://doi.org/10.1002/app.51394

Jiang X, Li H, Luo Y (2016) Studies of the plasticizing effect of different hydrophilic inorganic salts on starchpoly (vinyl alcohol) films. Int J Biol Macromol 82:223–230. https://doi.org/10.1016/j.ijbiomac.2015.11.046

Wang M, Yuan B, Bai S (2020) Preparation of Ag/C fiber with nanostructure through in situ thermally induced redox reaction between PVA and AgNO3 and its catalysis for 4-nitrophenol reduction. Polym Adv Technol 31:1312–1320. https://doi.org/10.1002/pat.4860

Wang D, Cheng Y, Jin H, Zhang J, Gao J (2013) Influence of LaCl3 addition on microstructure and properties of nickel-electroplating coating. J Rare Earths 31:209–214. https://doi.org/10.1016/s1002-0721(12)60260-9

Islam MN, Haldorai Y, Nguyen VH, Shim J-J (2014) Synthesis of poly(vinyl pivalate) by atom transfer radical polymerization in supercritical carbon dioxide. Eur Polymer J 61:93–104. https://doi.org/10.1016/j.eurpolymj.2014.09.003

Wang B, Bao X, Jiang M, Ye G, Xu J (2012) Synthesis of high-molecular weight poly(vinyl alcohol) by low-temperature emulsifier-free emulsion polymerization of vinyl acetate and saponification. J Appl Polym Sci 125:2771–2778. https://doi.org/10.1002/app.35464

Nisha MS, Singh D (2015) Manufacturing of Smart Nanomaterials for Structural Health Monitoring (SHM) in Aerospace Application Using CNT and CNF. J Nano Res 37:42–50. https://doi.org/10.4028/www.scientific.net/JNanoR.37.42

Abdollahi M, Bigdeli P, Hemmati M, Ghahramani M, Barari M (2015) Reverse iodine transfer polymerization of vinyl acetate and vinyl benzoate: synthesis and characterization of homo- and copolymers. Polym Int 64:1808–1819. https://doi.org/10.1002/pi.4985

Lin CA, Wu CR, Tsai HC (2012) Synthesis of ultra-high-molecular-weight PVA using two-stage photo-concentrated emulsion polymerization of vinyl acetate. Des Monomers Polym 9:305–315. https://doi.org/10.1163/156855506777351027

Yang Q, Gao C, Zhang X, Tsou C (2021) A Dual Physical Cross-Linking Strategy to Construct Tough Hydrogels with High Strength, Excellent Fatigue Resistance, and Stretching-Induced Strengthening Effect. Macromol Mater Eng 306:2100093. https://doi.org/10.1002/mame.202100093

Mandal S, Dasmahapatra AK (2021) Effect of aging on the microstructure and physical properties of Poly(vinyl alcohol) hydrogel. J Polym Res 28(269):02624. https://doi.org/10.1007/s10965-021-02624-9

Dou X, Li Q, Wu Q, Duan L, Zhou S, Zhang Y (2020) Effects of lactic acid and mixed acid aqueous solutions on the preparation, structure and properties of thermoplastic chitosan. European Polym J 134:109850. https://doi.org/10.1016/j.eurpolymj.2020.109850

Zhang S, Liu P, Zhao X, Xu J (2018) Enhanced tensile strength and initial modulus of poly(vinyl alcohol)/graphene oxide composite fibers via blending poly(vinyl alcohol) with poly(vinyl alcohol)-grafted graphene oxide. J Polym Res 25:1471. https://doi.org/10.1007/s10965-018-1471-0

Xinqiu H, Liming Z, Jiongxin Z (2018) Dry-wet spinning of PVA fiber with high strength and high Young’s modulus. Mater Sci Eng 439:1–5. https://doi.org/10.1088/1757-899X/439/4/042011

Cao JP, Zhao J, Zhao X, Dang ZM (2021) A facile route to prepare high−performance dielectric nanocomposites of poly(methyl methacrylate)/poly(vinylidene fluoride)/carbon nanotubes. Compos Sci Technol 209:108792. https://doi.org/10.1016/j.compscitech.2021.108792

Wei Y, Lai D, Zou L, Ling X (2018) Facile fabrication of PVA composite fibers with high fraction of multiwalled carbon nanotubes by gel spinning. Polym Eng Sci 58:37–45. https://doi.org/10.1002/pen.24528

Monyatsi O, Hutchinson RA (2016) Vinyl pivalate Propagation Kinetics in Radical Polymerization. Macromol Chem Phys 217:51–58. https://doi.org/10.1002/macp.201500285

Chen L, Qian Z, Li L, Fu M, Zhao H, Fu L, Li G (2019) Synergism of polyvinyl alcohol fiber to hydrogel for profile modification. Colloids Surf A: Physicochem Eng Aspects 578:123609. https://doi.org/10.1016/j.colsurfa.2019.123609

Xu J, Hong C, Geng J, Jin X, Pan Y, Wang H, Luo X, Zhang X (2021) Facile synthesis, mechanical toughening, low thermal conductivity and fire-retardant of lightweight quartz fiber reinforced polymer nanocomposites. Compos Sci Technol 211:108836. https://doi.org/10.1016/j.compscitech.2021.108836

Wang Z, Zhang J, Niu H, Wu D, Zhang M, Han E, Jing S, Sun X, Fan C (2021) Structure-Property Relationship of Polyimide Fibers with High Tensile Strength and Low Dielectric Constant by Introducing Benzimidazole and Trifluoromethyl Units. Macromol Mater Eng 306:2000705. https://doi.org/10.1002/mame.202000705

Nishikawa R, Aridome N, Ojima N, Yamaguchi M (2020) Structure and properties of fiber-reinforced polypropylene prepared by direct incorporation of aqueous solution of poly(vinyl alcohol). Polymer 199:122566. https://doi.org/10.1016/j.polymer.2020.122566

Lai DP, Wei YZ, Zou LM (2015) Wet spinning of PVA composite fibers with a large. Prog Namral Sci 25:445–452. https://doi.org/10.1016/j.pnsc.2015.10.003

Liu J, Gong W, Yao Y, Li Q (2018) Strengthening carbon nanotube fibers with semi-crystallized polyvinyl alcohol and hot-stretching. Compos Sci Technol 164:290–295. https://doi.org/10.1016/j.compscitech.2018.06.003

Noguchi T, Niihara KI, Kurashima A, Iwamoto R, Miura T, Koyama A, Endo M, Marubayashi H, Kumagai A, Jinnai H, Isogai A (2021) Cellulose nanofiber-reinforced rubber composites prepared by TEMPO-functionalization and elastic kneading. Compos Sci Technol 210:108815. https://doi.org/10.1016/j.compscitech.2021.108815

Li H, Wu CW, Wang S, Zhang W (2020) Mechanically strong poly (vinyl alcohol) hydrogel with macropores and high porosity. Mater Lett 266:127504. https://doi.org/10.1016/j.matlet.2020.127504

Peng M, Xiao G, Tang X, Zhou Y (2014) Hydrogen-Bonding Assembly of Rigid-Rod Poly(p-sulfophenylene terephthalamide) and Flexible-Chain Poly(vinyl alcohol) for Transparent, Strong, and Tough Molecular Composites. Macromolecules 47:8411–8419. https://doi.org/10.1021/ma501590x

Acknowledgements

This work is supported by National Key Research and Development Program of China (2016YFB0303200).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., He, J., Zou, L. et al. Preparation and characterization of high strength and high modulus PVA-La fiber with synthesized syndiotacticity-rich high polymerization degree PVA polymers as raw materials. J Polym Res 30, 216 (2023). https://doi.org/10.1007/s10965-023-03595-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03595-9