Abstract

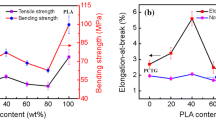

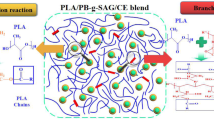

Polyoxymethylene (POM) qualifies as a best comprehensive performance engineering plastics used abundantly in many fields. Treatment by blending with elastomer so far has became the most important way to improve the toughness of POM to meet the demand of specific engineering design. Unfortunately, a prominent toughening efficiency fails to reach if POM blends contain low levels of elastomer, and the degradation temperature of those blends shows a frequently downward trend after the hybridization. Herein, we report a reactive extrusion processing for elastomer toughened POM in the absence of any other compatibilizer securing both advantages of excellent toughness and thermal stability. Blends were prepared by a one-pot melt-blending method from POM and Ethylene–acrylic ester-glycidyl methacrylate random copolymer (E-MA-GMA). During the above process, the end-blocking reaction of unstable POM hydroxyls occurred in the blend systems. The maximum elongation break at room temperature of the POM/E-MA-GMA (90/10) blend reached 94.5% with higher toughening efficiency over previous literature. Synchronously, the value of maximum mass loss temperature (Tmax) for the 90/10 (POM/E-MA-GMA) blend was 77.3 °C higher than that of pure POM. The high toughness and thermal stability of the POM/E-MA-GMA blend demonstrates the advantage of melt graft polymerization, which improves the interfacial compatibility of the blend and stabilizes the hydroxyl group of POM. This work presents a strategy for synchronously toughening and thermal stabilizing POM by constructing a simple binary reactive blending system.

Similar content being viewed by others

References

Qiu J, Guan J, Wang H, Zhu S, Cao X, Ye Q, Li Y (2014) Enhanced crystallization rate of poly (L-lactic acid)(PLLA) by polyoxymethylene (POM) fragment crystals in the PLLA/POM blends with a small amount of POM. J Phys Chem B 118:7167–7176

Yang J, Yang W, Wang X, Dong M, Liu H, Wujcik EK, Shao Q, Wu S, Ding T, Guo Z (2019) Synergistically toughening polyoxymethylene by methyl methacrylate-butadiene-styrene copolymer and thermoplastic polyurethane. Macromol Chem Phys 220:1800567

Haniff M, Bijarimi M, Zaidi MS, Sahrim A (2018) Preparation and characterization of poly (lactic acid) (PLA)/polyoxymethylene (POM) blends. Mater Sci Forum 917:3–6. https://doi.org/10.4028/www.scientific.net/MSF.917.3

Liang JZ (2018) Melt die-swell behavior of polyoxymethylene blended with ethylene-vinyl acetate copolymer and high-density polyethylene. Polym Test 68:213–218

Takamatsu S, Kobayashi T, Komoto T, Sugiura M (1994) Morphology of polyoxymethylene-based polymer alloys. Polymer 35(17):3598–3603

Tang W, Wang H, Tang J, Yuan H (2013) Polyoxymethylene/thermoplastic polyurethane blends compatibilized with multifunctional chain extender. J Appl Polym Sci 127(4):3033–3039

Lüftl S, Visakh P M, Chandran S (2014) Polyoxymethylene handbook: structure, properties, applications and their nanocomposites. Wiley, London, p 53–105. https://doi.org/10.1002/9781118914458.ch3

Fang W, Fan X, Li R, Hu L, Zhou T (2021) Polyoxymethylene/thermoplastic polyamide elastomer blends: Morphology, crystallization, mechanical, and antistatic properties. High Perform Polym 33(8):969–977

Wacharawichanant S, Amorncharoen P, Wannasirichoke R (2014) Effects of compatibilizer on the properties of polyoxymethylene/acrylonitrile-butadiene-styrene blends. Adv Mat Res 1052:220–225

Pan GQ, Chen JY, Li HL (2007) Gel acrylonitrile-butadiene elastomer toughened polyoxymethylene blends. Plast Rubber Compos 36(7–8):291–296

Wang X, Cui X (2005) Effect of ionomers on mechanical properties, morphology, and rheology of polyoxymethylene and its blends with methyl methacrylate-styrene-butadiene copolymer. Eur Polym J 41(4):871–880

Wang J, Zhang X, Jiang L, Qiao J (2019) Advances in toughened polymer materials by structured rubber particles. Prog Polym Sci 98:101160

Mehrabzadeh M, Rezaie D (2002) Impact modification of polyacetal by thermoplastic elastomer polyurethane. J Appl Polym Sci 84(14):2573–2582

Pielichowski K, Leszczyńska A (2004) TG-FTIR study of the thermal degradation of polyoxymethylene (POM)/thermoplastic polyurethane (TPU) blends. J Therm Anal Calorim 78(2):631–637

Kawaguchi K, Tajima Y (2006) Interfacial reaction and its influence on phase morphology and impact properties of modified-polyacetal/thermoplastic polyurethane blends. J Appl Polym Sci 100(6):4375–4382

Kumar G, Arindam MR, Neelakantan NR, Subramanian N (1993) Stress relaxation behavior of polyacetal-thermoplastic polyurethane elastomer blends. J Appl Polym Sci 50(12):2209–2216

Cheng ZG, Wang Q, Gao F, Cai L, Ke X, Yu GC (2006) Formation Mechanism of Thermoplastic Polyurethane(TPU) Morphology in Polyoxymethylene(POM) Matrix Blended in Twin-screw Extruder. Polym Eng Sci 22(5):201–204

Gao X, Qu C, Fu Q (2004) Toughening mechanism in polyoxymethylene/thermoplastic polyurethane blends. Polym Int 53(11):1666–1671

Gao X, Qu C, Zhang Q, Peng Y, Fu Q (2004) Brittle-ductile transition and toughening mechanism in POM/TPU/CaCO3 ternary composites. Macromol Mater Eng 289(1):41–48

Utracki L A (1998) Polyoxymethylene (acetal resins). Commercial polymer blends. Springer, Boston, p 300–406. https://doi.org/10.1007/978-1-4615-5789-0_19

Andrzejewski J, Skórczewska K, Kloziński A (2020) Improving the toughness and thermal resistance of polyoxymethylene/poly (lactic acid) blends: Evaluation of structure-properties correlation for reactive processing. Polymers 12(2):307

Yang W, Wang XL, Li J, Yan X, Ge S, Tadakamalla S, Guo Z (2018) Polyoxymethylene/ethylene butylacrylate copolymer/ethylene-methyl acrylate-glycidyl methacrylate ternary blends. Polym Eng Sci 58(7):1127–1134

Uthaman RN, Pandurangan A, Majeed SSMA (2007) Mechanical, thermal, and morphological characteristics of compatibilized and dynamically vulcanized polyoxymethylene/ethylene propylene diene terpolymer blends. Polym Eng Sci 47(6):934–942

Ren X, Chen L, Zhao H, Dan Y, Cai XF (2007) Acrylate elastomer toughened and UV stabilized polyoxymethylene. J Macromol Sci 46(2):411–421

Zheng X, Zhang C, Luo C, Tian G, Wang L, Li Y (2016) TPU inclusion complex modified POM: fabrication of high performance POM composites with both excellent stiffness-toughness balance and Thermostability. Ind Eng Chem Res 55(11):2983–2991

Guerra ÉSS (2017) Study of the addition of poly (ethylene-co-methyl acrylate-co-glycidyl methacrylate) thermoplastic to epoxy resin for use in self-healing composites. MS thesis, Brasil. https://repositorio.ufrn.br/handle/123456789/23776

Kongkhlang T, Tashiro K, Kotaki M (2008) Electrospinning as a new technique to control the crystal morphology and molecular orientation of polyoxymethylene nanofibers. J Am Chem Soc 130:15460–15466

Saligheh O, Forouharshad M, Arasteh R, Eslami-Farsani R, Khajavi R, Roudbari BY (2013) The effect of multi-walled carbon nanotubes on morphology, crystallinity and mechanical properties of PBT/MWCNT composite nanofibers. J Polym Res 20:65–71

Iguchi M (1976) Melting and degradation behaviour of needle-like poly (oxymethylene) crystals. Macromol Chem Phys 177(2):549–566

Martin P, Devaux J, Legras R (2001) Competitive reactions during compatibilization of blends of polybutyleneterephthalate with epoxide-containing rubber. Polymer 42(6):2463–2478

Sun YJ, Hu GH, Lambla M (1996) In situ compatibilization of polypropylene and poly(butylene terephthalate) polymer blends by one-step reactive extrusion. Polymer 37(18):4119–4127

Penco M, Pastorino M-A, Occhiello E (1995) High-impact poly(ethylene terephthalate) blends. J Appl Polym Sci 57(3):329–334

Kalfoglou NK, Skafidas DS, Kallitsis JK (1995) Comparison of compatibilizer effectiveness for PET/HDPE blends. Polymer 36(23):4453–44628

Ditta A, Laurandel H, Breynaert F, Travert A, Pluart LL (2016) Effect of organoclays on the degradation of polyoxymethylene homopolymer during melt processing. Polym Degrad Stabil 131:122–131

Dunina LA, Zharova TE, Karmilova LV, Yenikolopyan NS (1964) The kinetics of thermal-oxidative degradation of polyformaldehyde. Polym Sci U S S R 6(11):2132–2137

Wang K, Chen Y, Zhang Y (2009) Effects of reactive compatibilizer on the core-shell structured modifiers toughening of poly(trimethylene terephthalate). Polymer 50(6):1483–1490

Lee MP, Hiltner A, Baer E (1992) Fractography of injection molded polycarbonate acrylonitrile-butadiene-styrene terpolymer blends. Polym Eng Sci 32(13):909–919

Dong W, He M, Wang H (2015) PLLA/ABS blends compatibilized by reactive comb polymers: double Tg depression and significantly improved toughness. ACS Sustain Chem Eng 3:32542–32550

Chang F, Yang MY (1990) Mechanical fracture behavior of polyacetal and thermoplastic polyurethane elastomer toughened polyacetal. Polym Eng Sci 30(9):543–552

Cheng Z, Wang Q (2006) Morphology control of polyoxy-methylene/thermoplastic polyurethane blends by adjusting their viscosity ratio. Polym Int 55(9):1075–1080

Bozza J, Kolakowski NA, Jenkins DJ, Gilbert NG (2006) Product information sheet. Veritastk co jp 32(1):817–820

Bai S, Wang Q (2012) Effect of injection speed on phase morphology, crystallization behavior, and mechanical properties of polyoxymethylene/poly (ethylene oxide) crystalline/crystalline blend in injection processing. Polym Eng Sci 52(9):1938–1944

Bai S, Wang Q (2016) Miscible crystalline/crystalline polymer blends of polyoxymethylene copolymer/poly (ethylene oxide) with interpenetrated spherulites and enhanced properties. Vinyl Addit Techn 22(4):479–486

Zhou D, You B, Wu G (2012) Mechanical properties and surface morphology of photodegraded polyoxymethylene modified by a core-shell acrylate elastomer with UV stabilization. Polym Int 61(6):971–981

Qiu J, Xing C, Cao X, Wang H, Wang L, Zhao L, Li Y (2013) Miscibility and double glass transition temperature depression of poly (l-lactic acid)(PLLA)/poly (oxymethylene)(POM) blends. Macromolecules 46(14):5806–5814

Chen J, Cao Y, Li H (2006) Investigation of the friction and wear behaviors of polyoxymethylene/linear low-density polyethylene/ethylene-acrylic-acid blends. Wear 260(11–12):1342–1348

Hu Y, Ye L, Zhao X (2006) Synthesis of the melamine-formaldehyde polycondensate and its thermal stabilization effect on polyoxymethylene. Polymer 47(8):2649–2659

Das AK, Suin S, Shrivastava NK, Maiti S, Mishra JK, Khatua BB (2014) Effect of nanoclay on the morphology and properties of acrylonitrile butadiene styrene toughened polyoxymethylene (POM)/clay nanocomposites. Polym Compos 35(2):273–282

Yang W, Wang XL, Yan X, Guo Z (2017) Toughened polyoxymethylene by polyolefin elastomer and glycidyl methacrylate grafted high-density polyethylene. Polym Eng Sci 57(10):1119–1126

You B, Wu G, Zhang S, Yang F, Ren X (2012) Synthesis of a core-shell polyacrylate elastomer containing ultraviolet stabilizer and its application in polyoxymethylene. Polym Eng Sci 52(11):2403–2409

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interests

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work. There is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, A., Luo, F., Chen, R. et al. Toward supertough and heat-resistant binary blend: polyoxymethylene/elastomer via in-situ graft copolymer formation during one-pot reactive melt blending. J Polym Res 30, 101 (2023). https://doi.org/10.1007/s10965-023-03481-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03481-4