Abstract

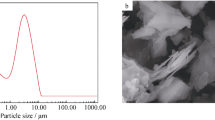

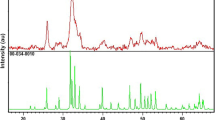

Polymer infiltrated ceramic network (PICN) composites, which combine the flexibility of resin materials with the rigidity of ceramic materials, have become a hot spot for research and development because of their structural and mechanical features that are similar to those of real teeth. In this paper, the porous feldspar ceramic part sintered body is used as the inorganic skeleton to composite with resin, and the preparation processes of porous feldspar ceramic were investigated, including the effects of different sintering temperature and holding time on the pore diameter and porosity of porous feldspar ceramic, and the effects on the properties of resin infiltration ceramic composites. The results show that when the sintering temperature is 750 ℃ and the holding time is 0 min, it has the most suitable porosity and pore size for resin infiltration. The hardness, flexural strength and flexural modulus of PICN composites were 125.5 N/mm2, 162.85 MPa, and 27.01 GPa respectively and the water absorption value and water solubility value are 10.51 μg/mm3 and 2.29 μg/mm3.

Similar content being viewed by others

References

Kawajiri Y, Ikeda H, Nagamatsu Y, Masaki C, Hosokawa R, Shimizu H (2021) PICN nanocomposite as dental CAD/CAM block comparable to human tooth in terms of hardness and flexural modulus. Materials 14:1182. https://doi.org/10.3390/ma14051182

Alghazzawi TF (2016) Advancements in CAD/CAM technology: Options for practical implementation. J Prosthodont Res 60:72–84. https://doi.org/10.1016/j.jpor.2016.01.003

Spitznagel FA, Boldt J, Gierthmuehlen PC (2018) CAD/CAM Ceramic Restorative Materials for Natural Teeth. J Dent Res 97:1082–1091. https://doi.org/10.1177/0022034518779759

Yamaguchi S, Lee C, Karaer O, Ban S, Mine A, Imazato S (2019) Predicting the debonding of CAD/CAM composite resin crowns with AI. J Dent Res 98:1234–1238. https://doi.org/10.1177/0022034519867641

Peutzfeldt A (1997) Resin composites in dentistry: the monomer systems. Eur J Oral Sci 105:97–116. https://doi.org/10.1111/j.1600-0722.1997.tb00188.x

Bowen RL (1963) Properties of a silica-reinforced polymer for dental restorations. J Am Dent Assoc 66:57–64. https://doi.org/10.14219/jada.archive.1963.0010

Riva YR, Rahman SF (2019) Dental composite resin: A review. AIP Conf Proc 2193:020011. https://doi.org/10.1063/1.5139331

Zhang X, Zhang Q, Meng X, Ye Y, Feng D, Xue J, Wang H, Huang H, Wang M, Wang J (2021) Rheological and mechanical properties of resin-based materials applied in dental restorations. Polymers 13:2975. https://doi.org/10.3390/polym13172975

Yu B, Liu D, Liu F, He J (2014) Preparation and characterization of light-cured dental resin without methacrylate monomers derived from bisphenol A. Adv Polym Technol 33:1082–1088. https://doi.org/10.1002/adv.21417

Heintze SD, Cavalleri A, Forjanic M, Zellweger G, Rousson V (2008) Wear of ceramic and antagonist—A systematic evaluation of influencing factors in vitro. Dent Mater 24:433–449. https://doi.org/10.1016/j.dental.2007.06.016

Sobrinho LC, Cattell MJ, Glover RH, Knowles JC (1998) Investigation of the dry and wet fatigue properties of three all-ceramic crown systems. Int J Prosthodont 11:255–262

Bottino M, Snellaert A, Bergoli C, Özcan M, Bottino M, Valandro L (2015) Effect of ceramic etching protocols on resin bond strength to a feldspar ceramic. Oper Dent 40:E40–E46. https://doi.org/10.2341/13-344-l

Talibi M, Kaur K, Parmar H (2022) Do you know your ceramics? Part 2: feldspathic ceramics. Br Dent J 232:80–83. https://doi.org/10.1038/s41415-022-3874-x

Facenda JC, Borba M, Corazza PH (2018) A literature review on the new polymer-infiltrated ceramic-network material (PICN). J Esthet Restor Dent 30:281–286. https://doi.org/10.1111/jerd.12370

Coldea A, Swain MV, Thiel N (2013) Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent Mater 29:419–426. https://doi.org/10.1016/j.dental.2013.01.002

Kang L, Zhou Y, Lan J, Yu Y, Cai Q, Yang X (2020) Effect of resin composition on performance of polymer-infiltrated feldspar-network composites for dental restoration. Dent Mater J 39:900–908. https://doi.org/10.4012/dmj.2019-180

Cui B-C, Li J, Lin Y-H, Shen Y, Li M, Deng X-L, Nan C-W (2019) Polymer-infiltrated layered silicates for dental restorative materials. Rare Met 38:1003–1014. https://doi.org/10.1007/s12598-019-01267-6

Harris JJ, Marquis PM (2002) Comparison of the deformation and failure characteristics of morphologically distinct metal-glass interpenetrating phase composites. J Mater Sci 37:2801–2810. https://doi.org/10.1023/A:1015841721720

Dirxen C, Blunck U, Preissner S (2013) Clinical performance of a new biomimetic double network material. Open Dent J 7:118–122. https://doi.org/10.2174/1874210620130904003

Della Bona A, Corazza PH, Zhang Y (2014) Characterization of a polymer-infiltrated ceramic-network material. Dent Mater 30:564–569. https://doi.org/10.1016/j.dental.2014.02.019

Steier V, Koplin C, Kailer A, Reinecke H (2011) Investigation of the adhesion promoter distribution in porous ceramic precursors. ISRN Mech Eng 2011:1–9. https://doi.org/10.5402/2011/304129

Jiang L, Liao Y, Wan Q, Li W (2011) Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci - Mater Med 22:2429–2435. https://doi.org/10.1007/s10856-011-4438-9

Shi J-L, Gao J-H, Lin Z-X, Yen T-S (1991) Sintering behavior of fully agglomerated zirconia compacts. J Am Ceram Soc 74:994–997. https://doi.org/10.1111/j.1151-2916.1991.tb04333.x

Jia D, Kim D, Kriven WM (2007) Sintering behavior of gehlenite. Part I: Self-forming, macro-/mesoporous gehlenite? Pore-forming mechanism, microstructure, mechanical, and physical properties. J Am Ceram Soc 90:1760–1773. https://doi.org/10.1111/j.1551-2916.2007.01704.x

Ortengren U, Wellendorf H, Karlsson S, Ruyter IE (2001) Water sorption and solubility of dental composites and identification of monomers released in an aqueous environment. J Oral Rehabil 28:1106–1115. https://doi.org/10.1046/j.1365-2842.2001.00802.x

Braden M, Causton EE, Clarke RL (1976) Diffusion of water in composite filling materials. J Dent Res 55:730–732. https://doi.org/10.1177/00220345760550050501

Chuenarrom C, Benjakul P, Daosodsai P (2009) Effect of indentation load and time on knoop and vickers microhardness tests for enamel and dentin. Mater Res 12:473–476. https://doi.org/10.1590/s1516-14392009000400016

Hayashi-Sakai S, Sakai J, Sakamoto M, Endo H (2012) Determination of fracture toughness of human permanent and primary enamel using an indentation microfracture method. J Mater Sci - Mater Med 23:2047–2054. https://doi.org/10.1007/s10856-012-4678-3

He LH, Swain MV (2007) Nanoindentation derived stress–strain properties of dental materials. Dent Mater 23:814–821. https://doi.org/10.1016/j.dental.2006.06.017

Wang H, Cui B, Li J, Li S, Lin Y, Liu D, Li M (2017) Mechanical properties and biocompatibility of polymer infiltrated sodium aluminum silicate restorative composites. Journal of Advanced Ceramics 6:73–79. https://doi.org/10.1007/s40145-016-0214-0

Fuentes V, Toledano M, Osorio R, Carvalho RM (2003) Microhardness of superficial and deep sound human dentin. J Biomed Mater Res 66A:850–853. https://doi.org/10.1002/jbm.a.10064

Vieira C, Silva-Sousa YTC, Pessarello NM, Rached-Junior FAJ, Souza-Gabriel AE (2012) Effect of high-concentrated bleaching agents on the bond strength at dentin/resin interface and flexural strength of dentin. Braz Dent J 23:28–35. https://doi.org/10.1590/s0103-64402012000100005

Plotino G, Grande NM, Bedini R, Pameijer CH, Somma F (2007) Flexural properties of endodontic posts and human root dentin. Dent Mater 23:1129–1135. https://doi.org/10.1016/j.dental.2006.06.047

Fong H, Sarikaya M, White SN, Snead ML (1999) Nano-mechanical properties profiles across dentin–enamel junction of human incisor teeth. Mater Sci Eng, C 7:119–128. https://doi.org/10.1016/S0928-4931(99)00133-

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (NSFC) (51874079, 52104291), Natural Science Foundation of Hebei Province (E2018501091, E2020501001, E2021501029), Hebei Province Key Research and Development Plan Project (19211302D), the Fundamental Research Funds for the Central Universities (N2123035, N2023040), S&T Program of Hebei (22567627H), the Science and Technology Project of Hebei Education Department (ZD2022158) and the Central Guided Local Science and Technology Development Fund Project of Hebei Province (226Z4401G).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Luo, Sh., Dou, Y. et al. Preparation and mechanical properties of polymer infiltrated feldspar ceramic for dental restoration materials. J Polym Res 29, 464 (2022). https://doi.org/10.1007/s10965-022-03311-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03311-z