Abstract

Particle size determination in optically dense systems requires costly techniques or dilution of collected samples. Against this background, turbidimetry was investigated as a potentially robust as well as inexpensive alternative. Emulsion copolymerisations of vinyl acetate and VeoVa10® with solid contents up to 48 wt% were examined time resolved with respect to mean particle size at different temperatures, solid contents and with different co-monomer ratios and emulsifier concentrations. The mean hydrodynamic diameters were validated by dynamic light scattering (DLS). Precise number mean hydrodynamic diameters in the range from 100 to 250 nm were obtained in-line for polyvinyl acetate dispersions with deviations in particle sizes below ± 5%. In addition, the turbidity values were recorded by means of a nephelometry process probe and thus a robust, system-related calibration was created, which was subsequently able to reliably track the number mean hydrodynamic diameter inline time-resolved.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In emulsion polymerisation an inline or online analytical measurement procedure for the determination of the mean particle size would be advantageous over established offline procedures [1]. Several approaches can be found in literature for inline measurement of the mean particle size, but very few of them are commercially available and established. Moreover, most methods are not related to polymer dispersions, but rather to dusts, powders and aerosols with different particle size ranges [1]. Typical analytical methods for this are dynamic light scattering (DLS) or photon density wave spectroscopy (PDW) light scattering methods or measurements via the disc centrifuge.

Swithenbank et al. reported a laser diffractometric method that detect particles and droplets in liquid phase inline. Due to the used wavelength of the laser, their method is limited to the micrometre range and cannot detect particles below one micrometre [2]. For crystallisation processes, several methods of inline particle size measurement were also investigated and compared, whereby the shape of the particles as well as their influence on the measured size are of interest, since crystallisation processes do not usually produce spherical particles. Here, both ultrasound techniques and laser scattering methods (3D-object-relational mapping and Focused Beam Reflectance Measurement) were successfully used for inline particle size determination in the range between 80–200 μm, whereby the sensitivity of the method to the particle shape varied. However, use of the measurement methods for particles in the submicrometric range has not been described [3].

Regarding to the submicron-range a frequently described solution is the use of an at line analysis, in which a sample is taken continuously and automatically diluted, prepared and fed to a light scattering analysis via an autosampler. The dilution step is essential to eliminate multiple scattering, to which dynamic light scattering reacts very sensitively [4,5,6]. Therefore, different particle sizing methods were compared in the nanometre range with regard to their suitability for mapping polydisperse as well as multimodal distributions of polymer latices. It was shown that all the methods investigated (Tunable Resistive Pulse Sensing (TRPS), disk centrifuge (CPS) and dynamic light scattering (DLS)) can correctly determine the particle size for monomodal distributions, but that DLS fails for multimodal distributions. Referenced studies were carried out against an electron microscopy evaluation [7]. One method for the inline measurement of submicron mean particle sizes is the photon density wave spectroscopy, which is suitable to measure hydrodynamic diameters even in high solid dispersions. Unfortunately, the method is expensive [8, 9].

The usage of turbidity measurement in emulsion polymerisation was investigated as well. Bloch et al. investigated the changes in turbidity during the emulsion polymerisation of styrene, especially during the early phases of emulsion polymerisation to obtain nucleation and inhibition times of the polymerisation. Moreover he showed the sensitivity of the method to changes in the polymerisation system, which goes along with differences in particle sizes [10] Houben et al. reported that a Raman spectroscopy could be used to monitor particle sizes during emulsion polymerisation of styrene copolymers by computer-based partial least-squares (PLS) models basing on changes in chain-expansion vibrations [11]. Gao et al. showed a dependence of the turbidity values of N-isopropylacrylamide dispersions on the concentration of the particles as well as the particle size [12]. Moreover Tauer et al. performed numerous studies on the changes in characteristic properties during emulsion polymerisation, including the change in turbidity values of the system during particle growth but never used this data to predict particle sizes by turbidity measurement [13, 14]. Kiparissides et al. [15] have also shown that the particle size of polyvinyl acetate emulsions can be mathematically derived from the turbidity and thus inline turbidity measurement could be a suitable method for tracking particle size in the polymerisation process. They never proved this mathematical approach by experiment or determined the limitations and deviations of the method [15]. The general methodological suitability of a turbidity probe was also shown by Liu et al. [16] who used turbidity to track the adsorption of polymer particles on modified cellulose. Here, the suspension's content of 40 nm polymer particles could be quantitatively tracked up to 0.2% solid content [16].

All these works have in common that industrially relevant solid contents are not investigated.

Turbidity in polymer dispersions could be described by Mie scattering theory or Rayleigh scattering, because the particle sizes are in range of 0.1 λ ≤ d ≤ 0.3 λ, so it is the transition area of both theories. Both theories describe that at a constant concentration of particles c, the scattering intensity I is directly proportional to the particle volume V and consequently correlates cubically proportional with the particle diameter (Eq. 1) [17].

With scattering intensity I, particle concentration c, a concentration independent term F1, the wavelength of the irradiated light λ, the particle volume V and the refractive exponent m.

Following to previous work this paper uses turbidity measurement as analytical approach for inline measurements in high solid content polyvinyl acetate copolymer dispersions. In contrast to previous work, this paper takes a lab-based approach to develop a cheap and experimentally easy-to-implement method for in-line measurement of mean hydrodynamic diameter in polyvinyl acetate dispersions with a large formulation window up to more than 48 wt% solids content. Moreover, the polymer system related calibration reduces the effects of additives to the obtained data, so that the method could also be used for industrial processes. Even differences in formulation could be easily implemented in this method by calibrating the system to the new formulation within hours.

Exp. section

All reactions were carried out in a cylindrical jacket-tempered 500 mL batch reactor produced by Colaver (type: 49CL4005), which was stirred at 250 rpm using an eliptical magnetic stirrer bar (d = 50 mm). The precise setup is shown in Fig. 1. Turbidity was measured using a Mettler Toledo InPro 8200 process probe and Trb 8300 transmitter and recorded via LabView. The internal reactor temperature was recorded using a type K temperature probe via NuDam boxes and LabView software. The final turbidity was determined after the polymerisation was complete and the temperature had stabilised back to the initial value.

A comonomer stock system containing vinyl acetate and vinyl neodecanoate (trade name VeoVa10®) was used for emulsion polymerisation, with 10 wt% VeoVa10® based on total monomer content. Polymerisation was carried out with a monomer content of 23.8 wt%, unless otherwise stated. Polyvinyl alcohol was used as emulsifier in different weight proportions (Mowiol 4–88®, 2 – 20 wt% based on monomer). The initiation was carried out by a redox initiator system consisting of tert-butyl hydroperoxide, ascorbic acid and ammonium iron(III) sulphate dodecahydrate in a molar ratio of 1:1:0.03 [18].

Results

Calibration of the turbidity probe against DLS

To establish the calibration between turbidity and particle size, a series of tests was carried out in which the emulsifier content was changed in order to be able to set variable particle sizes. All other parameters, especially the solids content, were left the same so that the tests could be compared. The mean particle size was described by the mean hydrodynamic diameter, which could be determined by dynamic light scattering (DLS) of the diluted final sample. In addition, the turbidity values measured inline by the process probe were averaged and the particle size was plotted against the turbidity value (Fig. 2).

Plot of the mean particle sizes measured by DLS including device-specific error against the turbidity values determined inline for the reactions with solid contents about 23.8 wt% at 20 °C. A cubic fit was chosen as the calibration function. Calibration functions for other solid contents are shown in Fig. 3

The particle size correlates with the turbidity and can be described by a cubic function, which shows high agreement (R2 = 0.97). The cubic calibration function shows a high agreement as well as a good accordance to the Mie scattering functions, which expects a cubic dependency (Eq. 1). The precision amounts to ± 5 nm deviation between calibration function and measured samples for particle sizes in the range between 120 and 250 nm. For particle sizes above 250 nm the turbidity values are close to the detector saturation and fluctuations around the mean value can be distorted as a result.

The influence of the solids content was investigated, as this is a parameter that, according to the underlying Lorenz-Mie scattering theory, has a strong influence. For this purpose, emulsion polymerisations were carried out with solids contents between 10 wt% and 48 wt% and the measured data were plotted as a function of this (Fig. 3).

From the Fig. 3, the influence of the solids content on the turbidity can be confirmed, so that it is important that the calibration used was measured for the same solids content. For deviations in the solids content, up to approx. 5%, the calibration can still be used with a deviation between measured sample particle sizes and calibration of ± 15 nm. For larger deviations above 5% solid content deviation an adjustment of the calibration to the new system is essential to obtain valid particle sizes.

To validate the calibration function obtained by a different experimenter with 23.8 wt% solid content new polymerisations were carried out. A new calibration curve was determined and compared with those of Fig. 2.

The independent set of reactions has a high agreement with the calibration function obtained above (Fig. 4) (R2 = 0.96). Deviations between the determined mean particle size by the originally calibration function (red) and fit of validation experiments (black) are below 3%, which is in range of the errors set by experiment. The mean hydrodynamic diameter could be measured inline in the measurement range between 120 and 250 nm with a deviation of less than ± 10 nm to the calibration function.

Measured particle sizes by DLS vs turbidity for independent experiments at 24 wt% at 20 °C temperature. The calibration function (Fig. 2) is compared with a fit function of the validation experiments

Influence of various process and recipe parameters on the validity of the calibration

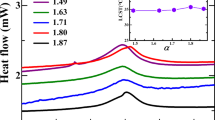

The impact of the temperature on the turbidity values obtained was also investigated as a potentially relevant influencing variable that could falsify correlated particle sizes (Fig. 5).

The temperature has a subordinate influence on the average turbidity. Although the temporal fluctuation of the turbidity values increases somewhat with increasing temperature, the average remains the same for the same solids content and particle size, so that a change in the process temperature does not necessarily require a new calibration, as long as no other changes occur in the material system that could influence the product properties.

The influence of the co-monomer composition on the turbidity of the emulsion was also investigated. (Fig. 6) The vinyl acetate content was varied between 80 and 100% by weight.

In the window of the ratio Vac:Veova10 from 10:0 to 8:2, the differences in particle size caused by co-monomer composition changes of ± 10%, so that the same calibration could be used for a similar formulation with deviations in predicted particle sizes smaller than 5%. Thus, individual screening experiments can be evaluated with the universal calibration, but for a longer-term use it is worthwhile to prepare a calibration specially for the system.

Measurement limits

The measurement limits of the method were previously established by the particle sizes achieved in the formulation window used and no precise limit values were determined. Therefore, in the following, these measurement limit values for the mean particle size at 23.8 wt% were determined mathematically from the calibration and the measuring range of the detector as well as confirmed by experiments. The lower measurement limit of the detectable particle size results mathematically from the calibration function and the background value of the turbidity (4.22 a.u. for clear water) at around 110 nm. This agrees with the experimental findings where particle sizes of 98 nm could not yet be reliably distinguished from the background noise, but at a mean hydrodynamic diameter of 105 nm detection was possible due to a small increase in turbidity. Consequently, in practice, the detection of particles from a particle size of approx. 110 nm is possible.

The upper measurement limit of the measurable hydrodynamic diameter also has a technical limitation, which is given by the detector saturation of the turbidity probe. This is at an absolute turbidity of 22.6 a.u., which corresponds to a mean hydrodynamic diameter of about 270 nm. This also corresponds to experiments in which particles with a particle size of around 250 nm or more reach the detector saturation. However, the upper measurement limit can be determined less precisely, since the temporal turbidity fluctuations are greater there than in the range of small particles due to the substance system. Above 250 nm, no statement can be obtained with the detector used; with another detector, the range could most likely be extended. The lower measurement limit could be lowered by a shorter wavelength of the light used. Due to different calibration functions for other solid contents the measurement limits will be dependent from the solid content and cannot be determined universally.

Application in practice

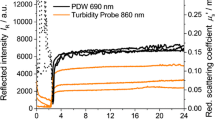

The created calibration was used to follow emulsion polymerisations with different solid contents about 24 wt% and 48 wt% inline. For this purpose, the turbidity course during the reaction was recorded and converted into a particle size course by means of the calibration. In parallel, samples were taken from the reaction solution and measured using DLS and disc centrifuge. The course and the obtained particle sizes of the offline methods are plotted in Figs. 7 and 8.

Plot of the calculated temporal particle size course of the inline turbidity measurement and the particle sizes determined offline from intermediate samples taken, including error bars. Especially during the fast reaction in the beginning, differences between DLS and turbidity may be caused by delays in sampling and stopping the reaction. The reaction was carried out at 24 wt% solid content

Plot of the calculated temporal particle size course of the inline turbidity measurement and the particle sizes determined offline from intermediate samples taken, including error bars. Especially during the fast reaction in the beginning, differences between DLS and turbidity may be caused by delays in sampling and stopping the reaction. The reaction was carried out at 48 wt% solid content

The particle sizes calculated by means of calibration agree within ± 10 nm with the particle sizes of the samples taken at the time points. Even for dispersions with high solids contents of over 48 wt%, the particle sizes can be determined in real time. Small deviations can be explained by the fact that intermediate samples continued to react despite the immediate addition of inhibitor solution and thus falsified the particle size at the time of sampling.

Summary

Turbidity measurement for polymer dispersions with solid contents between 10 and 48 wt% is a suitable method for in-line measurement of mean hydrodynamic diameters in polymer dispersions in the range between 100 and 250 nm. For this purpose, a universal calibration related to the system is necessary, which is robust against common variances in a procedure. The calibration shows significant dependencies on the solids content of the system, while no significant dependency on temperature or stirrer speed/flow or minor recipe changes could be found. The tracking of the particle size development of a complete emulsion polymerisation could also be successfully established for solid contents up to 48 wt%.

References

Merkus HG (2009) Particle Size Measurements. Springer

Swithenbank J, Beer J, Taylor D, Abbot D, McCreath G (1976). A laser diagnostic technique for the measurement of droplet and particle size distribution. https://doi.org/10.2514/6.1976-69

Mostafavi M, Petersen S, Ulrich J (2014) Effect of particle shape on inline particle size measurement techniques. Chem Eng Technol 37:1721–1728. https://doi.org/10.1002/ceat.201400212

Sacoto P, Lanza F, Suarez H, Garcia-Rubio LH (1998) A Novel Automatic Dilution System for On-Line Particle Size Analysis. ACS Symp Ser 693:23–29. https://doi.org/10.1021/bk-1998-0693.ch003

Al Z (2018) et: United States Patent : 5861366 United States Patent : 5861366. N Y 2:1–29

Celis M-T, Garcia-Rubio LH (2002) Continuous Spectroscopy Characterization of Emulsions. J Dispers Sci Technol 23:293–299. https://doi.org/10.1080/01932690208984205

Anderson W, Kozak D, Coleman VA, Jämting ÅK, Trau M (2013) A comparative study of submicron particle sizing platforms: Accuracy, precision and resolution analysis of polydisperse particle size distributions. J Colloid Interface Sci 405:322–330. https://doi.org/10.1016/j.jcis.2013.02.030

Jacob LI, Pauer W (2020) In-line monitoring of latex-particle size during emulsion polymerizations with a high polymer content of more than 60%. RSC Adv 10:26528–26534. https://doi.org/10.1039/d0ra02523b

Bressel L, Hass R, Reich O (2013) Particle sizing in highly turbid dispersions by Photon Density Wave spectroscopy. J Quant Spectrosc Radiat Transf 126:122–129. https://doi.org/10.1016/j.jqsrt.2012.11.031

Bloch D (2017) Etablierung der Inline-Trübungsmessung zur Prozessüberwachung von Emulsionspolymerisationen

Houben C, Nurumbetov G, Haddleton D, Lapkin AA (2015) Feasibility of the Simultaneous Determination of Monomer Concentrations and Particle Size in Emulsion Polymerization Using in Situ Raman Spectroscopy. Ind Eng Chem Res 54:12867–12876. https://doi.org/10.1021/acs.iecr.5b02759

Gao J, Hu Z (2002) Optical properties of N-isopropylacrylamide microgel spheres in water. Langmuir 18:1360–1367. https://doi.org/10.1021/la011405f

Tauer K, Padtberg K, Dessy C (2002) On-line monitoring of emulsion polymerization. ACS Symp Ser 801:93–112. https://doi.org/10.1002/cite.202055476

Tauer K, Deckwer R, Kühn I, Schellenberg C (1999) A comprehensive experimental study of surfactant-free emulsion polymerization of styrene. Colloid Polym Sci 277:607–626. https://doi.org/10.1007/s003960050433

Kiparissides C, Macgregor JF, Singh S, Hamielec AE (1980) Continuous emulsion polymerization of vinyl acetate. Part III: Detection of reactor performance by turbidity-spectra and liquid exclusion chromatography. Can J Chem Eng 58:65–71. https://doi.org/10.1002/cjce.5450580110

Liu D, Hao L, Fang K (2014) Adsorption of cationic copolymer nanospheres onto cotton fibers investigated by a facile nephelometry. Colloids Surfaces A Physicochem Eng Asp 452:82–88. https://doi.org/10.1016/j.colsurfa.2014.03.079

Mie G (1908) Beiträge zur Optik trüber Medien, speziell kolloidaler Metallösungen. Ann Phys 330:377–445. https://doi.org/10.1002/andp.19083300302

Schroeter BL (2018) Kinetik von Redoxinitiatoren für die Emulsionspolymerisation. University Hamburg, Hamburg

Funding

Open Access funding enabled and organized by Projekt DEAL. The work has been funded by the German Federal Ministry for Economic Affairs and Climate Action as part of the ENPRO Initiative (KoPPonA 2.0, FKZ: 03EN2004M).

Author information

Authors and Affiliations

Contributions

All authors conceived the experiments, Sören Rust performed the experiments and analysed the data. The first draft of the manuscript was written by Sören Rust and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest for the submitted work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rust, S., Pauer, W. Determination of inline-particle sizes by turbidity measurement in high solid content emulsion polymerisations. J Polym Res 29, 307 (2022). https://doi.org/10.1007/s10965-022-03141-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03141-z