Abstract

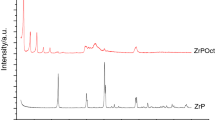

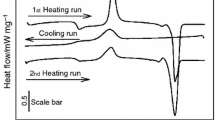

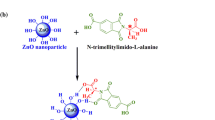

Poly(ε-caprolactone) (PCL)/polyamide 6 (PA6) composites were fabricated by dispersing PA6 powder into PCL. The SEM results show good dispersion of PA6 in the PCL matrix. Crystallization behavior, crystal structure and spherulitic morphology of pure PCL and the PCL/PA6 composites, as well as their thermal stability and dynamic mechanical properties, were characterized using various techniques including differential scanning calorimeter, X-ray diffraction (XRD), polarized light microscope (PLM), thermal gravimetric analysis (TGA) and dynamic mechanical analyzer (DMA). The PCL/PA6 composite showed increased storage modulus and glass transition temperature (Tg). PA6 powder functions as a heterogeneous nucleate to promote PCL crystallization but does not alter orthorhombic crystal form, crystallization mechanism and thermal stability of PCL.

Similar content being viewed by others

References

Gross RA, Kalra B (2002) Biodegradable polymers for the environment. Science 297(5582):803–807

Laycock B, Nikolić M, Colwell JM et al (2017) Lifetime prediction of biodegradable polymers. Prog Polym Sci 71:144–189

Woodruff MA, Hutmacher DW (2010) The return of a forgotten polymer-polycaprolactone in the 21st century. Prog Polym Sci 35:1217–1256

Eastmond G (1999) Poly(ε-caprolactone) blends. Adv Polym Sci 149:59–223

Qiao X, Li W, Sun K et al (2009) Isothermal crystallization kinetics of silk fibroin fiber-reinforced poly(ε-caprolactone) biocomposites. Polym Int 58:530–537

Liang J, Zhou L, Tang C (2013) Crystallization properties of polycaprolactone composites filled with nanometer calcium carbonate. J Appl Polym Sci 128(5):2940–2944

Azevedo MC, Reis RL, Claase MB et al (2003) Development and properties of polycaprolactone/hydroxyapatite composite biomaterials. J Mater Sci Mater M 14:103–107

Hajiali F, Tajbakhsh S, Shojaei A (2018) Fabrication and properties of polycaprolactone composites containing calcium phosphate-based ceramics and bioactive glasses in bone tissue engineering: A review. Polym Rev 58(1):1–44

Harrane A, Belbachir M (2007) Synthesis of biodegradable polycaprolactone/montmorillonite nanocomposites by direct in-situ polymerization catalyzed by exchanged clay. Macromol Symp 247:379–384

Sayyar S, Murray E, Thompson BC et al (2013) Covalently linked biocompatible graphene/polycaprolactone composites for tissue engineering. Carbon 52:296–304

Chin SJ, Doherty M, Vempati S et al (2019) Solvothermal synthesis of graphene oxide and its composites with poly(ε-caprolactone). Nanoscale 11:18672–18682

Zhuravlev E, Wurm A, Potschke P et al (2014) Kinetics of nucleation and crystallization of poly(ε-caprolactone)-multiwalled carbon nanotube composites. Eur Polym J 52:1–11

Vacková T, Kratochvíl J, Ostafinska A et al (2017) Impact of particle morphology on structure, crystallization kinetics, and properties of PCL composites with TiO2-based particles. Polym Bull 74:445–464

Guan W, Qiu Z (2012) Isothermal crystallization Kinetics, morphology, and dynamic mechanical properties of biodegradable poly(ε-caprolactone) and octavinyl-polyhedral oligomeric silsesquioxanes nanocomposites. Ind Eng Chem Res 51:3203–3208

Ali Akbari Ghavimi S, Ebrahimzadeh MH, SolatiHashjin M et al (2015) Polycaprolactone/starch composite: Fabrication, structure, properties, and applications. J Biomed Mater Res Part A 103:2482–2498

Cai J, Xiong Z, Zhou M et al (2014) Thermal properties and crystallization behavior of thermoplastic starch/poly(ε-caprolactone) composites. Carbohyd Polym 102:746–754

Zhang H, Luo X, Lin X et al (2016) Polycaprolactone/chitosan blends: simulation and experimental design. Mater Design 90:396–402

Wu CS (2004) Analysis of mechanical, thermal, and morphological behavior of polycaprolactone/wood flour blends. J Appl Polym Sci 94:1000–1006

Aguiar VO, Marques MFV (2016) Composites of polycaprolactone with cellulose fibers: morphological and mechanical evaluation. Macromol Symp 367(1):101–112

Bai Y, Jiang C, Wang Q et al (2013) A novel high mechanical strength shape memory polymer based on ethyl cellulose and polycaprolactone. Carbohyd Polym 96(2):522–527

Boujemaoui A, Cobo Sanchez C, Engström J, Bruce C et al (2017) Polycaprolactone nanocomposites reinforced with cellulose nanocrystals surface-modified via covalent grafting or physisorption-A comparative study. ACS Appl Mater Interfaces 9(40):35305–35318

Lönnberg H, Larsson K, Lindstrom T et al (2011) Synthesis of polycaprolactone-grafted microfibrillated cellulose for use in novel bionanocomposites-influence of the graft length on the mechanical properties. ACS Appl Mater Interfaces 3(5):1426–1433

Sanlı S, Durmus A, Ercan N (2012) Effect of nucleating agent on the nonisothermal crystallization kinetics of glass fiber- and mineral-filled polyamide-6 composites. J Appl Polym Sci 125:E268–E281

Richardson NE, Meakin BJ (1974) The sorption of benzocaine from aqueous solution by nylon 6 powder. J Pharm Pharmac 26:166–174

Suteu D, Bilba D, Dan F (2007) Synthesis and characterization of polyamide powders for sorption of reactive dyes from aqueous solutions. J Appl Polym Sci 105:1833–1843

Chen Z, Liu C, Wang Q (2001) Solid-phase preparation of ultra-fine PA6 powder through pan-milling. Polym Eng Sci 41(7):1187–1195

Takahashi T, Inamura M, Tsujimoto I (1970) Epitaxial growth of polymer crystals on uniaxially drawn polymers. J Polym Sci Part B: Polym Lett 8:651–657

Avrami M (1940) Kinetics of phase change. II. Transformation-time relations for random distribution of nuclei. J Chem Phys 8:212–224

Avrami M (1941) Granulation, phase change, and microstructure kinetics of phase change. III J Chem Phys 9:177–184

Liu H, Huang Y, Yuan L et al (2010) Isothermal crystallization kinetics of modified bamboo cellulose/PCL composites. Carbohyd Polym 79:513–519

Acknowledgements

Funding support from the National Natural Science Foundation of China (21,204,018, U1204518, U1704144) and China Scholarship Council (201,708,410,015) is acknowledged.

Author information

Authors and Affiliations

Contributions

M.Q. Li and Y.D. Zhang contribute equally as co-first author

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicts of financial or non-financial competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, M., Zhang, Y., Zhu, F. et al. Influence of PA6 particle filler on morphology, crystallization behavior and dynamic mechanical properties of poly(ε-caprolactone) as an efficient nucleating agent. J Polym Res 28, 461 (2021). https://doi.org/10.1007/s10965-021-02814-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02814-5