Abstract

In this work, a double network bovine serum albumin-polyacrylamide (BSA-PAM) adhesive hydrogel was fabricated, in which combination of physical interactions including hydrogen bonds and chain entanglements, and chemical covalent photo-crosslinking. The BSA-PAM hydrogel exhibited excellent mechanical and adhesive properties. The composite hydrogel not only demonstrated excellent tensile properties (maximum force elongation 1552%~2037%), but also displayed extremely high fatigue resistance even when subjected to compress strains of up to 85%. More importantly, the BSA-PAM hydrogel showed excellent adhesiveness to various substrates (90 kPa~150 kPa for glass and 9.74 kPa~35.09 kPa for pigskin). This work provided a facile way of fabricating tough, stretchable and adhesive BSA-PAM hydrogels.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Adhesive hydrogels were three-dimensional polymer networks that cross-linked either physically or chemically [1,2,3], which were used for tissue adhesion [4,5,6,7,8], hemostasis [9,10,11,12], and sealing against the leakage of air and body fluids during surgical procedures [13,14,15]. Various studies have been carried out to develop synthetic (e.g., cyanoacrylates) and protein [e.g., collagen,bovine serum albumin (BSA) and fibrin] adhesive products [16, 17]. However, synthetic and protein adhesives often exhibited limited bonding capacity and weak mechanical properties [18,19,20,21]. Therefore, adhesives owning high adhesive strength and mechanical properties were desired.

In the recent reports, Many efforts have been made to improve the adhesive and mechanical properties of hydrogels. Double network (DN) hydrogels have been fabricated [22,23,24,25]. The DN hydrogels were composed of a highly cross-linked network that endowed stiffness to the hydrogel, and a second loosely cross-linked one that endowed toughness to it [26]. For example, Huang and coworkers reported a series of tough and conductive DN hydrogels hybridized with 2,2,6,6-tetramethylpiperidine-1-oxy oxidized cellulose nanofiber (TOCN) and polypyrrole (Py), which exhibited high mechanical properties (the Young’s modulus ~1 MPa ) and better tensile strength and strain (σTb = 451 kPa and εTb = 107% ) [27]. However, a facile way of preparing multifunctional double network adhesive hydrogels was still lacking.

BSA is a typical natural globular protein with high water solubility, biocompatibility and low production cost, which has been proposed as a biomaterial with a range of biomedical and industrial applications [28, 29]. These properties made BSA a good candidate as a tissue adhesive. Previously, BioGlue was a well-known BSA based tissue adhesive product [30], in which glutaraldehyde was used as a cross-linker for both inter- and intra- protein molecular. Although this adhesive showed good adhesive to tissues, its inconvenience, special tools usage might limit its use in clinic [31]. Besides, BioGlue had relatively low mechanical properties [30]. There were several hydrogels based on BSA reported for improving its mechanical properties [32,33,34,35,36], for example, Matsudomi, Tang et al. obtained self-supporting BSA based double-network hydrogels with high tensile strength, but it still challenged to obtain for complex process [37].

Acrylamide (AAM) is a cheap, easily available and highly hydrophilic monomer, which exhibited improved hydrolytic stability. Incorporation of AAM into adhesive can improve its mechanical properties. For example, Rodrigues et al. reported an experimental adhesive resin containing hydroxyethyl acrylamide used for dental adhesive resin, which showed that the addition of acrylamide not only increased the material′s reactivity, but also improved the mechanical properties of dental adhesive resin [38, 39].

In this study, we have prepared double network adhesive hydrogels based on BSA and AAM by a facile one-pot synthesis method. All the reactants were mixed and stirred at R. T., and then AAM monomer was polymerized through UV curing method. The fabricated BSA-PAM hydrogel exhibited superior tensile properties and excellent adhesive properties. A series of studies were carried out to evaluate the mechanical, adhesive, swelling and rheological properties of BSA-PAM hydrogels.

Materials

BSA was purchased from Yuanye Bio-Technology Co., Ltd (Shanghai, China). Mw was 68 kD, with a purity of 98%. Acrylamide, N, N′-methylene diacrylamide (BIS) and lithium phenyl-2, 4, 6-trimethylbenzoylphosphinate (LAP) were purchased from Yuanye Biochemical Co., Ltd. (Shanghai, China). All reagents were used as received. Fresh porcine skin was bought from local market. The Gelatin-coated glass slides (25 mm × 75 mm) were purchased from Hito. Bio-Technology Co., Ltd. (Guangzhou, SMAT agent, China).

Synthesis of BSA-PAM hydrogels

BSA (5.0 g, 7.5 × 10-5 mol), AAm (2.5 g/1.7 g/1.3g, 3.5 × 10-2 mol/2.4 × 10-2 mol/1.8 × 10-2 mol), LAP (0.010g, 3.4 × 10-5 mol), BIS (0.0016 g/0.0011 g/0.0008g, 1.0 × 10-5 mol/0.71 × 10-5 mol/0.51 × 10-5 mol) were dissolved into distilled water (10 mL) in a reactor, and stirred about 30 min at R. T. Then, the above solution was exposed under UV light (365 nm, 30 mW cm-2) for 3 min. BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4 hydrogels were obtained.

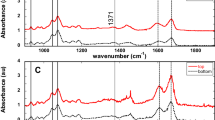

ATR-FTIR measurement

All infrared spectra were recorded in the range of 400–3500 cm-1 using total reflectance fourier transform infrared (ATR-FTIR) (Nicolet IS10). Each spectrum was acquired by accumulation of 32 scans with a resolution of 4 cm. Background measurements were subtracted from the sample readings.

SEM characterizations

The structures of the BSA-PAM hydrogels were examined using a scanning electron microscope (SEM, TESCAN MIRA4). Before examination, the hydrogels were freeze-dried at -60 °C for 48 h. Then, the hydrogels were fractured by liquid nitrogen to expose their inner structures, and the cross-sections were observed.

Lap shear test

The lap shear strength property of BSA-PAM adhesive hydrogels was tested as previously described [40, 41]. One glass slide (25 mm × 75 mm) and one fresh porcine skin (25 mm × 75 mm) were used to hold each sample. The top portion of the glass slide (20 mm × 25 mm) was coated with gelatin. The pre-polymer solution (20 ml) was added to one of the gelatin-coated regions in glass slide, and then fresh porcine skin was carefully put on the solution. After that, the gel was photo-crosslinked by UV light (365 nm, 30 mW cm-2). The sample was placed into a mechanical tester (KEJIAN, KJ-1065A, China) for shear testing by tensile loading with a strain rate of 1 mm/min. The lap shear strength was determined at the point of detaching.

Tensile stress test

Mechanical tensile stress-strain evaluation was conducted by a testing machine (KEJIAN, KJ-1065A, China) equipped with a 500 N tension sensor at room temperature. All gels (n≥4) were cast using polytetrafluoroethylene molds into dumbbell-shaped samples (1.5 mm thickness, 4.0 mm width at center). The tensile strength, elongation at rupture and Young’s modulus were measured with an extension rate of 30 mm s-1. The Young’s modulus was determined from the slope of the linear section stress-strain curve at 5%-10% strain.

Cyclic compress test

Cyclic loading-unloading tests were performed by a testing machine (KEJIAN, KJ-1065A, China). The hydrogels compressed to strains of 85% and then unloaded to zero force. The compress modulus was determined from the slope of the linear section stress-strain curve at 5%-10% strain.

Rheological measurements

Rheological testing was carried out as previously described [42]. The testing was conducted on a Modular Compact Rheometer (Anton paar, MCR 302, Austria) at 25 °C using a 8 mm diameter flat plate with the gap set to 0.5 mm. Excess sample was trimmed off the lower plate. The storage modulus (G′) and loss modulus (G′′) were measured and recored by performing a shear frequency-sweep test using a 1% strain and an angular frequency (ω) sweeping from 0.1 to 100 rad s-1.

Swelling test

For study of the swelling properties of the BSA-PAM hydrogel, the as-prepared cylindrical BSA-PAM hydrogels were dried, and weighed to find the initial dry weight (Wi). The pre-weighed dry BSA-PAM hydrogels were immersed in 10 ml distilled water or urea (5M) in distilled water separately. Samples were taken out from solution at each pre-determined time points and weighed again (Wt). Swelling ratio of the BSA-PAM hydrogel was determined by equation: Swelling ratio = (Wt-Wi)/Wi, where Wi was the original dry weight and Wt was the dry weight after incubation for a certain period.

Statistical analysis

All data were presented as means ± standard deviations. All experiments were carried out with at least 3 parallel samples.

Results and discussion

Preparation and characterization of BSA-PAM adhesive hydrogels

In this work, the BSA-PAM adhesive hydrogel was fabricated by a simple one-pot synthesis method (Scheme 1). Briefly, all reactants of BSA, AAm, UV-initiator (LAP) and cross-linker (BIS) were dissolved into water in a reactor. The precursor solution was stirred at room temperature for 30 min. Then, the double network BSA-PAM adhesive hydrogel was formed after UV irradiation (365 nm, 30 mW cm-2). As shown in Fig. 1a, the first network was formed through physical interactions including hydrogen bonds and chain entanglements between BSA chains and AAM molecules. The second network was fabricated through chemical covalent crosslinking of AAM monomers by the cross-linker (BIS) under UV irradiation. The two networks induced a synergetic effect in enhancing the mechanical and adhesive properties of the BSA-PAM hydrogels. ATR-FTIR was utilized to analyze the structure and network interactions of the obtained hydrogels. As shown in Fig. S1, compared to pure BSA, there was a new peak of 1114 cm-1 for BSA-PAM-2/BSA-PAM-3/BSA-PAM-4, which was assigned as the characteristic of C-N amide bond [36]. SEM micrographs showed that the pore size of the hydrogels gradually increased with weight ratio of BSA : AAM from 2:1 to 4:1 (Fig. 1).

The BSA-PAM adhesive hydrogel was prepared with different BSA: AAM weight ratios as listed in the supporting information (Fig. S2, Table S1). It was clear that the BSA-PAM hydrogel was well formed with weight ratio of BSA : AAM from 1 : 1 to 6 : 1, and we chose hydrogels formed with weight ratio of BSA : AAM from 2 : 1 to 4 : 1 as typical cases to study. Figure 1b showed proposed molecular structure of the BSA-PAM hydrogel. Due to BSA protein molecules contained numerous functional groups such as –NH2 group, –COOH group, –OH group, etc., multiple hydrogen bonds were formed between BSA chains and AAM monomer molecules. Besides, chain entanglements were also formed between BSA chains. After UV irradiation, AAM monomers was polymerized to form PAM backbone, which was covalently cross-linked by the cross-linker (BIS). PAM backbone served as the primary network, and BSA chains inter-diffused and got physically entangled within the PAM network [43,44,45]. The abundant hydrogen bonds between the BSA chains and PAM network equipped the obtained hydrogels with high stretchability. Numerous functional groups such as –NH2 group, –COOH group and –OH group on BSA-PAM hydrogel equipped the obtained hydrogels with high adhesive ability to different substrates.

To verify the hypothesis that `BSA-PAM hydrogels were largely cross-linked by hydrogen bonds between the BSA chains and PAM network, we used urea as hydrogen-bond-breaking agents to break hydrogen bonds existing in the BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4 hydrogel and studied their swelling kinetics. As shown in Fig. 7, all three hydrogels swelled obviously after soaking in water and urea (5 M) for 24 hours, and balanced after 48 hours. It was clear that all three hydrogels displayed much higher swelling ratio in urea than in water, due to the intermolecular hydrogen bonds had been destroyed, indicating that hydrogen bonding was an important driving force for the formation of BSA-PAM hydrogels.

Mechanical properties of the BSA-PAM hydrogels

The BSA-PAM hydrogels exhibited super stretchability and high toughness due to abundant physical interactions including hydrogen bonding and chain entanglements between BSA chains and PAM network. As shown in Fig. 2a, the BSA-PAM hydrogel could be easily stretched to 19 times and even twisted stretched (Fig. S3). To further quantitatively evaluate the mechanical behaviors of the prepared hydrogel, tensile tests were conducted. Figure 2b, c and d illustrate the typical tensile stress-strain curves of BSA-PAM hydrogels, corresponding maximum force elongation and Young’s modulus.

(a) Diagram of tensile stress test: the original length (above), and the length after tensile stress (under). (b) Representative strain-stress curves for tensile stress test of BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4. (c) The maximum force elongation of BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4. (d) The Young’s modulus of BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4

It was obvious that the maximum force elongation could be stretched 1923.05 ± 50.00%,2037.85 ± 54.00% and 1552.25 ± 66.75% beyond its initial length for BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4 respectively (Fig. 2c, Table 1). Increasing weight ratio of BSA : AAM would decrease the Young’s modulus from 2.56 ± 0.12 kPa, 2.24 ± 0.36 kPa to 1.20 ± 0.24 kPa for BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4 respectively, due to the low cross-linking degree of the BSA-PAM hydrogel network (Fig. 2d).

The compress tests showed that the BSA-PAM hydrogel automatically recovered its original shape after releasing the compression load (Fig. 3a), and the hysteresis loops of first cycle and second cycle almost coincided even when subjected to compress strains of up to 85%, indicating the BSA-PAM hydrogel had excellent fatigue resistance caused by the dynamic nature of the hydrogen bonds between the BSA chains and PAM network (Fig. 3b). In contrast, the pure PAM hydrogel ruptured, rather than recovered, during the second tensile test [46]. With increase weight ratio of BSA : AAM, The compress modulus was gradually decreased from 216.95 ± 6.67 kPa, 68.40 ± 5.56 kPa to 18.56 ± 4.24 kPa for BSA-PAM-2 hydrogel, BSA-PAM-3 hydrogel and BSA-PAM-4 hydrogel respectively (Table 2, Fig. 3c, d).

The super mechanical property of the BSA-PAM hydrogels can be owed to automatic breaking and recombining of hydrogen bonds between BSA chains and PAM network. In addition, the reversible association/dissociation of dynamic hydrogen bonds promoted energy dissipation when the hydrogel network was under strain testing [47].

Rheology tests were used to evaluate mechanical properties of the BSA-PAM-2 hydrogel, BSA-PAM-3 hydrogel, and BSA-PAM-4 hydrogel. As shown in Fig. 4, the storage modulus (G′) was obviously higher than the loss modulus (G′′) with prolonged time, indicating that elastic component of the BSA-PAM hydrogels dominated the viscous component. In addition, G′ of BSA-PAM-2 was obviously higher than that of the BSA-PAM-3 hydrogel or BSA-PAM-4 hydrogel, which was measured by performing a shear frequency-sweep test using a 1% strain and an angular frequency (ω) sweeping from 0.1 to 100 rad s-1 (Fig. 4a). Strain sweep test (γ = 0.1-100% at ω = 10 rad s-1) for three hydrogels was also investigated (Fig. 4b). In the linear viscoelastic region, all hydrogels displayed typically solid-like behavior with G′ > G′′. As strain increased, G′ and G′′ intersected, indicating that the physical crosslinking interactions in the hydrogel networks were broken. The γ value of the intersected points of the BSA-PAM-2 hydrogel was 100% strain, which was significantly higher than BSA-PAM-3 or BSA-PAM-4 hydrogels (8% strain and 6% strain), which further demonstrated that the BSA-PAM-2 hydrogel had a more stable network.

Adhesive property of the BSA-PAM hydrogels

The adhesive property of BSA-PAM hydrogels was evaluated, as shown in Fig. 5. The obtained BSA-PAM hydrogel showed remarkable adhesive properties to various substrates. Taken BSA-PAM-2 hydrogel as an example (Fig. 5a), BSA-PAM-2 hydrogel could directly adhere to various substrates including steel, ceramic, iron, glass, rubber and skin et al. Besides, the BSA-PAM hydrogel can firmly adhere a 200 g weight of steel. For quantitatively evaluating the adhesive strength, we used lap shear tests to systemically assess the adhesive strength of BSA-PAM-2 hydrogel, BSA-PAM-3 hydrogel and BSA-PAM-4 hydrogel to different substrates. Paper, glass, glass with gelatin and pigskin were selected as representative substrates and the results were displayed in Fig. 5b. The adhesion strength between the hydrogel and paper substrate was the highest, which was ~250 kPa, 150 kPa and 120 kPa for BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4 respectively due to the synergetic interactions of vander Waals interaction, hydrogen bonds et ac. Figure 5 showed that the content could significantly affect the adhesion strength of the BSA-PAM hydrogel. Taking glass as an example, increasing the weight ratio of BSA : AAM from 2:1 to 4:1 would decrease the adhesion strength from ~170 kPa to ~ 90 kPa. The decreased adhesion was likely caused by the low cross-linking degree the hydrogel network.

Fig. 6 illustrated the adhesion strength between the BSA-PAM hydrogel and pigskin surfaces. The BSA-PAM hydrogel were used to glue one glass gelatin slide and one fresh porcine skin, and then was photo-crosslinked by UV light (Fig. 6a). The representative strain-stress curves for lap shear tests were shown in Fig. 6b, and adhesion strength was 35.09 ± 4.01 kPa, 33.32 ± 5.00 kPa, 9.74 ± 4.20 kPa for BSA-PAM-2, BSA-PAM-3 and BSA-PAM-4 hydrogel respectively. For BSA-PAM-2, the adhesion strength was higher than commercial glues such as Bioglueand Fibrin (Table 3) [48,49,50].

The adhesive mechanism of BSA-PAM hydrogel may be owed to two factors: First, the interactions between BSA-PAM hydrogels and substrates contributed to formation of interfacial adhesion forces including vander Waals interaction, hydrogen bonding et al. [51,52,53]; The combination effect of physical interactions such as hydrogen bonds and covalent crosslinking created a dominant role for improving cohesion, which significantly regulating the adhesive property of the BSA-PAM hydrogels.

Swelling behavior

Swelling refers to an increase in the volume of a hydrogel after absorption of a liquid. Figure 7 demonstrated the result of the three BSA-PAM hydrogels at R. T. in water and urea. As shown, after 24 h of incubation, the BSA-PAM hydrogels exhibited varying degrees of swelling in water and urea. After 48 h incubation, swelling of the BSA-PAM hydrogels achieved equilibrium. It was clear that the swelling ratio of the BSA-PAM hydrogels in urea was obviously higher than those in water, due to the intermolecular hydrogen bonds had been destroyed, indicating that the hydrogen bonds were an important driving force for formation of BSA-PAM hydrogel (Fig. 7a–c).

Conclusions

This study presented BSA-PAM hydrogels which were constructed through combination of physical interactions including hydrogen bonding and chain entanglements, and chemical covalent photo-crosslinking. The BSA chains inter-diffused and got physically entangled within the PAM network. Results showed that BSA-PAM hydrogels displayed excellent mechanical and adhesive properties, and maximum force elongation reached 1552%~2037%, and the adhesiveness was 90 kPa~150 kPa for glass and 9.74 kPa~35.09 kPa for pigskin respectively. This work provided a facile way of fabricating high mechanical and adhesive hydrogels.

References

Bastings MMC, Koudstaal S, Kieltyka RE, Nakano Y, Pape ACH, Feyen DAM, van Slochteren FJ, Doevendans PA, Sluijter JPG, Meijer EW, Chamuleau SAJ, Dankers PYW (2014) A fast pH-switchable and self-healing supramolecular hydrogel carrier for guided, local catheter injection in the infarcted myocardium. Adv Healthc Mater 3:70–78

Wang WD, Narain R, Zeng H (2018) Rational design of self-healing tough hydrogels: A mini review. Front Chem 6:497

Wichterle O, Lim D (1960) Hydrophilic gels for biological use. Nature 185:117–118

Cai ZW, Saiding Q, Cheng L, Zhang LC, Wang Z, Wang F, Chen XL, Chen G, Deng LF, Cui WG (2021) Capturing dynamic biological signals via bio-mimicking hydrogel for precise remodeling of soft tissue. Bioact Mater 6:4506–4516

Yang Z, Yang XW, Long R, Li JY (2021) Stimulation modulates adhesion and mechanics of hydrogel adhesives. Langmuir 37:7097–7106

Yang Z, Ma ZW, Liu SY, Li JY (2021) Tissue adhesion with tough hydrogels: Experiments and modeling. Mech Mater 157:103800

Yang B, Song JL, Jiang YH, Li M, Wei JJ, Qin JJ, Peng WJ, Lasaosa FL, He YY, Mao HL, Yang J, Gu ZW (2020) Injectable adhesive self-healing multicross-linked double-network hydrogel facilitates full-thickness skin wound healing. ACS Appl Mater Inter 12:57782–57797

Sharifi S, Islam MM, Sharifi H et al (2021) Tuning gelatin-based hydrogel towards bioadhesive ocular tissue engineering applications. Bioact Mater 6:3947–3961

Qiao ZW, Lv XL, He SH et al (2021) A mussel-inspired supramolecular hydrogel with robust tissue anchor for rapid hemostasis of arterial and visceral bleedings. Bioact Mater 6:2829–2840

Han K, Bai Q, Wu WD, Sun N, Cui N, Lu TL (2021) Gelatin-based adhesive hydrogel with self-healing, hemostasis, and electrical conductivity. Int J Biol Macromol 183:2142–2151

Han W, Zhou B, Yang K et al (2020) Biofilm-inspired adhesive and antibacterial hydrogel with tough tissue integration performance for sealing hemostasis and wound healing. Bioact Mater 5:768–778

Preman NK, Priya SES, Prabhu A, Shaikh SB, Vipin C, Barki RR, Bhandary YP, Rekha PD, Johnson RP (2020) Bioresponsive supramolecular hydrogels for hemostasis, infection control and accelerated dermal wound healing. J Mater Chem B 8:8585–8598

Costa RR, da Costa DS, Reis RL, Pashkuleva I (2019) Bioinspired baroplastic glycosaminoglycan sealants for soft tissues. Acta Biomater 87:108–117

Kazemzadeh-Narbat M, Annabi N, Khademhosseini A (2015) Surgical sealants and high strength adhesives. Mater Today 18:176–177

Bal-Ozturka A, Cecen B, Avci-Adali M, Topkaya SN, Alarcin E, Yasayan G, Li Y CE, Bulkurcuoglu B, Akpek A, Avci H, Shi K, Shin SR, Hassan S (2021) Tissue adhesives: from research to clinical translation. Nano Today 36:101049

Mehdizadeh M, Yang J (2013) Design strategies and applications of tissue bioadhesives. Macromol Biosci 13:271–288

Yang JW, Bai RB, Chen BH, Suo ZG (2019) Hydrogel adhesion: a supramolecular synergy of chemistry, topology, and mechanics. Adv Funct Mater 30:1901693

Cerda DG, Ballester AM, Aliena-Valero A, Caraben-Redano A, Lloris JM (2015) Use of cyanoacrylate adhesives in general surgery. Surg Today 45:939–956

Spotnitz WD, Burks S (2012) Hemostats, sealants, and adhesives III: a new update as well as cost and regulatory considerations for components of the surgical toolbox. Transfusion 52:2243–2255

Bouten PJM, Zonjeea M, Bender J, Yauw STK, van Goor H, van Hest JCMV, Hoogenboom R (2014) The chemistry of tissue adhesive materials. Prog Polym Sci 39:1375–1405

Annabi N, Zhang YN, Assmann A, Sani ES, Cheng G, Lassaletta AD, Vegh A, Dehghani B, Ruiz-Esparza GU, Wang XC, Gangadharan S, Weiss AS, Khademhosseini A (2017) Engineering a highly elastic human protein-based sealant for surgical applications. Sci Transl Med 9:eaai7466

Tsai YL, Theato P, Huang C F, Hsu SH (2020) A 3D-printable, glucose-sensitive and thermoresponsive hydrogel as sacrificial materials for constructs with vascular-like channels. Appl Mater Today 20:100778

Wu CH, Tu CW, Aimi J, Zhang JW, Chen T, Wang CC, Huang CF (2020) Mechanochromic double network hydrogels as a compression stress sensor. Polym Chem 11:6423–6428

Cheng KC, Huang CF, Wei Y, Hsu SH (2019) Novel chitosan–cellulose nanofiber selfhealing hydrogels to correlate self-healing properties of hydrogels with neural regeneration effects. NPG Asia Mater 11:25

Hirsch M, Charlet A, Amstad E (2020) 3D printing of strong and tough double network granular hydrogels. Adv Funct Mater 31:2005929

Gong JP, Katsuyama Y, Kurokawa T, Osada Y (2003) Double-network hydrogels with extremely high mechanical strength. Adv Mater 15:1155–1158

Tu CW, Tsai FC, Chen JK, Wang HP, Lee RH, Zhang JW, Chen T, Wang CC, Huang CF (2020) Preparations of tough and conductive PAMPS/PAA double network hydrogels containing cellulose nanofibers and polypyrroles. Polymers 12:2835

Chen J, Ma XY, Dong QC, Song DH, Hargrove D, Vora SR, Ma AWK, Lu XL, Lei Y (2016) Self-healing of thermally-induced, biocompatible and biodegradable protein hydrogel. RSC Adv 6:56183–56192

Chen J, Dong QC, Ma X, Fan TH, Lei Y (2016) Repetitive biomimetic self-healing of Ca2+-induced nanocomposite protein hydrogels. Sci Rep 6:30804

Bahouth Z, Moskovitz B, Halachmi S, Nativ O (2017) Bovine serum albumin–glutaraldehyde (BioGlue®) tissue adhesive versus standard renorrhaphy following renal mass enucleation: a retrospective comparison. Ther Adv Urol 9:67–72

Hidas G, Kastin A, Mullerad M, Shental J, Moskovitz B, Nativ O (2006) Sutureless nephron-sparing surgery: use of albumin glutaraldehyde tissue adhesive (BioGlue). Urology 67:697–700

Zhu WZ, Peck Y, Iqbal J, Wang DA (2017) A novel DOPA-albumin based tissue adhesive for internal medical applications. Biomaterials 147:99–115

Rusu AG, Chiriac AP, Nita LE, Mititelu-Tartau L, Tudorachi N, Ghilan A, Rusu D (2019) Multifunctional BSA scaffolds prepared with a novel combination of UV-crosslinking systems. Macromol Chem Phys 220:1900378

Sun YL, Huang YB (2016) Disulfide-crosslinked albumin hydrogels. J Mater Chem B 4:2768–2775

Upadhyay A, Kandi R, Rao CP (2018) Injectable, self-healing, and stress sustainable hydrogel of BSA as a functional biocompatible material for controlled drug delivery in cancer cells. ACS Sustain Chem Eng 6:3321–3330

Liu Z, Tang ZQ, Zhu L, Lu SP, Chen F, Tang C, Sun H, Yang J, Qin G, Chen Q (2019) Natural protein-based hydrogels with high strength and rapid self-recovery. Int J Biol Macromol 141:108–116

Tang ZQ, Chen Q, Chen F, Zhu L, Lu SP, Ren BP, Zhang YX, Yang J, Zheng J (2019) General principle for fabricating natural globular protein-based double-network hydrogels with integrated highly mechanical properties and surface adhesion on solid surfaces. Chem Mater 31:179–189

Rodrigues SB, Collares FM, Leitune VCB, Schneider LFJ, Ogliari FA, Petzhold CL, Samuel SMW (2015) Influence of hydroxyethyl acrylamide addition to dental adhesive resin. Dent Mater 31:1579–1586

Fugolin APP, Navarro O, Logan MG, Huynh V, Franca CM, Ferracane JL, Pfeifer CS (2020) Synthesis of di- and triacrylamides with tertiary amine cores and their evaluation as monomers in dental adhesive interfaces. Acta Biomater 115:148–159

Li J, Celiz AD, Yang J, Yang Q, Wamala I, Whyte W, Seo BR, Vasilyev NV, Vlassak JJ, Suo Z, Mooney DJ (2017) Tough adhesives for diverse wet surfaces. Science 357:378–381

Sun JY, Zhao XH, Illeperuma WRK, Chaudhuri O, Oh KH, Mooney DJ, Vlassak JJ, Suo ZG (2012) Highly stretchable and tough hydrogels. Nature 489:133–136

Lang N, Pereira MJ, Lee Y et al (2014) A blood-resistant surgical glue for minimally invasive repair of vessels and heart defects. Sci Transl Med 6:218ra6

Adewunmi AA, Ismail S, Sultan AS, Ahmad Z (2017) Performance of fly ash based polymer gels for water reduction in enhanced oil recovery: gelation kinetics and dynamic rheological studies. Korean J Chem Eng 34:1638–1650

Yi Q, Li C, Manlai Z, Yuli L, Ruiquan L (2017) Dynamic thickening investigation of the gelation process of PAM/PEI system at high temperature and high pressure. J Disper Sci Technol 38:1640–1646

Adewunmi AA, Ismail S, Sultan AS (2015) Laboratory scale study on rheological behavior, morphological and structural properties of crosslinked polyacrylamide composite hydrogels embedded with date seed powder. J Appl Polym Sci 132:42110

Han L, Yan LW, Wang KF et al (2017) Tough, self-healable and tissue-adhesive hydrogel with tunable multifunctionality. NPG Asia Mater 9:e372

Chen JS, Liu JF, Thundat T, Zeng HB (2019) Polypyrrole-doped conductive supramolecular elastomer with stretchability, rapid self-healing, and adhesive property for flexible electronic sensors. ACS Appl Mater Interfaces 11:18720–18729

Sugiura Y, Okada M, Hirano K, Matsumoto T (2021) Bone mineral analogue ceramic block as an instant adhesive to biological soft tissue. Adv Mater Interfaces 8:2002032

Sierra DH, Feldman DS, Saltz R, Huang S (1992) A method to determine shear adhesive strength of fibrin sealants. J Appl Biomater 3:147–151

Chao HH, Torchiana DF (2003) BioGlue: albumin/glutaraldehyde sealant in cardiac surgery. J Card Surg 18:500–503

Xiao WQ, Qu XH, Li JL, Chen L, Tan YF, Li KJ, Li B, Li XL (2019) Synthesis and characterization of cell-laden double-network hydrogels based on silk fibroin and methacrylated hyaluronic acid. Eur Polym J 118:382–392

Matsuda M, Ueno M, Endo Y, Inoue M, Sasaki M, Taguchi T (2019) Enhanced tissue penetration-induced high bonding strength of a novel tissue adhesive composed of cholesteryl group-modified gelatin and disuccinimidyl tartarate. Colloids Surf B 91:48–56

Sun J, Su JJ, Ma C, Gostl R, Herrmann A, Liu K, Zhang HJ (2020) Fabrication and mechanical properties of engineered protein-based adhesives and fibers. Adv Mater 32:1906360

Acknowledgments

This research was supported by special fund of Guangdong academy of sciences (No. 2020GDASYL-20200103042, No. 2019GDASYL-0103020, 2019GDASYL-0402002 and 2019GDASYL-0105009), National Natural Science Foundation of China (No. 21907037).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Guo, C., Zeng, Z., Yu, S. et al. Highly stretchable, compressible, adhesive hydrogels with double network. J Polym Res 28, 417 (2021). https://doi.org/10.1007/s10965-021-02765-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02765-x