Abstract

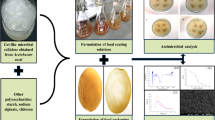

Antimicrobial film is one of the most promising active packaging materials that can maintain the quality and extend the shelf life of food products. It can be prepared by incorporating antimicrobial agents into films. In this work, antimicrobial films were fabricated by blending bacterial cellulose (BC) suspension as a matrix, chitosan as a natural antimicrobial agent, carboxymethyl cellulose (CMC) as a homogeniser and glycerol as a plasticiser. All components were mixed and degassed before casting and drying at 40°C in an oven. As a control, film without chitosan was also cast. Scanning electron microscopy (SEM) revealed smooth and dense surface morphologies for BC-based films containing chitosan. Fourier transform infrared spectroscopy (FT-IR) confirmed the presence of chitosan in BC-based films, while X-ray diffraction (XRD) revealed that adding chitosan influenced their crystallinity. Furthermore, incorporating chitosan increased the insoluble matter and water vapour transmission rate (WVTR) of the films. The tensile strength was slightly increased, while the elongation at break was slightly decreased by adding chitosan. Antimicrobial testing demonstrated that incorporating chitosan into BC-based films successfully reduced the growth of microbes. Based on this result, BC/chitosan films can be considered as a potential candidate for antimicrobial films.

Similar content being viewed by others

References

de Moura IG, de Sá AV, Abreu ASLM, Machado AVA (2017) Bioplastics from agro-wastes for food packaging applications. In: Grumezrscu MA (ed) Food Packaging. Academic Press, Amsterdam, Elsevier, pp 223–263

Shit SC, Shah PM (2014) Edible polymers: Challenges and opportunities. J Polym 2014:427259

Moghimi R, Aliahmadi A, Rafati H (2017) Antibacterial hydroxypropyl methyl cellulose edible films containing nanoemulsions of Thymus daenensis essential oil for food packaging. Carbohydr Polym 175:241–248

Šuput D, Lazić V, Pezo L, Markov S, Vaštag Ž, Popović L, Radulović A, Ostojić S, Zlatanović S, Popović S (2016) Characterization of starch edible films with different essential oils addition. Pol J Food Nutr Sci 66(4):277–285

Acevedo-fani A, Salvia-trujillo L, Rojas-graü MA, Martín-belloso O (2015) Edible films from essential-oil-loaded nanoemulsions: Physicochemical characterization and antimicrobial properties. Food Hydrocolloids 47:168–177

Han JH (2014) Innovations in Food Packaging, 2nd edn. Elsevier, Academic Press, Amsterdam

Hassan B, Ali S, Chatha S, Hussain AI, Zia KM (2018) Recent advances on polysaccharides, lipids an dprotein based edible films and coatings: A review. Int J Biol Macromol 109:1095–1107

Saucedo-pompa S, Rojas-molina R, Aguilera-carbó AF, Saenz-galindo A, La HD, Jasso-cantú D, Aguilar CN (2009) Edible film based on candelilla wax to improve the shelf life and quality of avocado. Food Res Int 42(4):511–515

Salgado PR, López-caballero ME, Gómez-guillén MC, Mauri AN, Montero MP (2013) Sunflower protein films incorporated with clove essential oil have potential application for the preservation of fish patties. Food Hydrocolloids 33(1):74–84

Singh P, Magalhães S, Alves L, Antunes F, Miguel M, Lindman B, Medronho B (2019) Cellulose-based edible films for probiotic entrapment. Food Hydrocolloids 88:68–74

Castro C, Zuluaga R, Putaux J-L, Caro G, Mondragon I, Gañán P (2011) Structural characterization of bacterial cellulose produced by Gluconacetobacter swingsii sp. from Colombian agroindustrial wastes. Carbohydr Polym 84:96–102

Jeong SI, Lee SE, Yang H, Jin YH, Park CS, Park YS (2010) Toxicologic evaluation of bacterial synthesized cellulose in endothelial cells and animals. Mol Cell Toxicol 6(4):373–380

Phisalaphong M, Jatupaiboon N (2008) Biosynthesis and characterization of bacterial cellulose-chitosna film. Carbohydr Polym 74:482–488

Cheng KC, Catchmark JM, Demirci A (2009) Enhanced production of bacterial cellulose by using a biofilm reactor and its material property analysis. J Biol Eng 3:12

Lin WC, Lien CC, Yeh HJ, Yu CM, Hsu SH (2013) Bacterial cellulose and bacterial cellulose-chitosan membranes for wound dressing application. Carbohydr Polym 94:603–611

Saibuatong O, Phisalaphong M (2010) Novo aloe vera-bacterial cellulose composite film from biosynthesis. Carbohydr Polym 79:455–460

Indriyati, Indrarti L (2018) Preparation and characterization of bacterial cellulose-beeswax films. IOP Conf Ser: Earth Environ Sci 160:012010

Indrarti L, Indriyati (2017) Incorporation of citrus essential oils into bacterial cellulose-based edible films and assessment of their physical properties. IOP Conf Ser: Earth Environ Sci 60:012018

Goy RC, Morais STB, Assis OBG (2016) Evaluation of the antimicrobial activity of chitosan and its quaternized derivative on E. coli and S. aureus growth. Rev Bras Framacogn 26:122–127

Ziani K, Fernandez-Pan I, Royo M, Mate JI (2009) Antifungal activity of films and solutions based on chitosan against typical seed fungi. Food Hydrocolloids 23:2309–2314

Malinowska-pañczyk E, Staroszczyk H, Gottfried K, Koodziejska I (2015) Antimicrobial properties of chitosan solutions, chitosan films and gelatin-chitosan films. Polymery 60:735–741

Clasen C, Wilhelms T, Kulicke W (2006) Formation and characterization of chitosan membranes. Biomacromolecules 7:3210–3222

Ciechanska D (2004) Multifunctional bacterial cellulose/chitosan composite materials for medical applications. Fibres Text East Eur 12(4):69–72

Kim J, Cai Z, Lee HS, Choi GS, Lee DH, Jo C (2011) Preparation and characterization of a bacterial cellulose/chitosan composite for potential biomedical application. J Polym Res 18(4):739–744

Rohaeti E, Laksono EW, Rakhmawati A (2018) Mechanical properties and antibacterial activity of cellulose composite based coconut water with addition glycerol, chitosan, and silver nanoparticle. Orient J Chem 34:1341–1349

Kingkaew J, Kirdponpattara S, Sanchavanakit N, Pavasant P, Phisalaphong M (2014) Effect of molecular weight of chitosan on antimicrobial properties and tissue compatibility of chitosan-impregnated bacterial cellulose films. Biotechnol Bioprocess Eng 19:534–544

Indrarti L, Indriyati Syampurwadi A, Pujiastuti S (2016) Physical and mechanical properties of modified bacterial cellulose composite films. AIP Conf Proc 1711:050007

Zeng M, Laromaine A, Roig A (2014) Bacterial cellulose films: influence of bacterial strain and drying route on film properties. Cellulose 21:4455–4469

Jouki M, Yazdi FT, Mortazavi SA, Koocheki A (2013) Physical, barrier and antioxidant properties of a novel plasticized edible film from quince seed mucilage. Int J Biol Macromol 62:500–507

Yu D, Li P, Xu Y, Jiang Q, Xia W (2017) Physicochemical, microbiological, and sensory attributes of chitosancoated grass carp (Ctenopharyngodon idellus) fillets stored at 4°C. Int J Food Prop 20(2):390–401

Yano S, Maeda H, Nakajima M, Hagiwara T, Sawaguchi T (2008) Preparation and mechanical properties of bacterial cellulose nanocomposites loaded with silica nanoparticles. Cellulose 15:111–120

Mohammadkazemi F (2017) Surface properties of bacterial nanocellulose using spectroscopic methods and X-ray diffraction. Am J Appl Indu Chem 1(1):10–13

Wang SS, Han YH, Ye YX, Shi XX, Xiang P, Chen DL, Li M (2017) Physicochemical characterization of highquality bacterial cellulose produced by Komagataeibacter sp. strain W1 and identification of the associated genes in bacterial cellulose production. RSC Adv 7:45145

Halib N, Amin MCIM, Ahmad I (2012) Physicochemical properties and characterization of nata de coco from local food industries as a source of cellulose. Sains Malays 41(2):205–211

Sun Y, Meng C, Zheng Y, Xie Y, He W, Wang Y, Qiao K, Yue L (2018) The effects of two biocompatible plasticizers on the performance of dry bacterial cellulose membrane: a comparative study. Cellulose 25:5893–5908

Yang J, Kwon GJ, Hwang K, Kim DY (2018) Cellulose-chitosan antibacterial composite films prepared from LiBr solution. Polymers 10:1058

Jung HZ, Benerito RR, Berni RJ, Mitcham D (1977) Effect of low temperature on polymorphic structures of cotton cellulose. J Appl Polym Sci 21:1981–1988

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Hong L, Wang YL, Jia SR, Huang Y, Wan Gao C, YZ, (2006) Hydroxyapatite/bacterial cellulose composites synthesized via a biomimetic route. Mater Lett 60:1710–1713

Jia Y, Wang X, Huo M, Zhai X, Li F, Zhong C (2017) Preparation and characterization of a novel bacterial cellulose/chitosan bio-hydrogel. Nanomater Nanotechnol 7:1–8

Qin C, Li H, Xiao Q, Liu Y, Zhu J, Du Y (2006) Water-solubility of chitosan and its antimicrobial activity. Carbohydr Polym 63(3):367–374

Shapi’i RA, Othman RA, (2016) Effect of concentration of chitosan on the mechanical, morphological and optical properties of tapioca starch film. Int Food Res J 23:187–193

Rabea E, Badawy MET, Stevens CV, Smagghe G, Steurbaut W (2003) Chitosan as antimicrobial agent: applications and mode of action. Biomacromolecules 4:1457–1465

Kong M, Chen XG, Xing K, Park HJ (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144:51–63

Li Z, Yang F, Yang R (2015) Synthesis and characterization of chitosan derivatives with dual-antibacterial functional groups. Int J Biol Macromol 75:378–387

Acknowledgment

The authors gratefully acknowledge financial support from Indonesian Institute of Sciences. We also would like to thank Research Unit for Clean Technology for instrumentation facilities throughout the experimental session.

Author information

Authors and Affiliations

Contributions

Indriyati contributed as the main contributor for this work. All authors read and approved the final paper.

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Indriyati, Dara, F., Primadona, I. et al. Development of bacterial cellulose/chitosan films: structural, physicochemical and antimicrobial properties. J Polym Res 28, 70 (2021). https://doi.org/10.1007/s10965-020-02328-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02328-6