Abstract

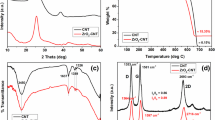

Isotactic polypropylene (PP) composites achieved high impact strength by melt mixing with complex titanate whiskers/multiwalled carbon nanotubes (MWCNTs). The complex fillers, obtained via coupling agent γ-aminopropyl triethoxysilane, triggered additional reinforcement with stiff backup of whiskers and strengthened interfacial adhesion generated from MWCNTs, forwarding positive synergy on the PP composites. In presence of compatibilizer maleic anhydride-grafted polypropylene, 5 wt% of the complex fillers brought about impact strength 6.3 ± 0.3 kJ/m2 to the composite, which was 103% higher than PP. Meanwhile, tensile strength was also improved with 34.8 ± 0.5 MPa as compared with that of PP (32.6 ± 0.3 MPa). Morphology witnessed by scanning electron microscope revealed that the complex fillers favored dispersion of MWCNTs in polymer matrix, fulfilling bridging for reinforcement. Detection of differential scanning calorimetry also indicated that the complex fillers facilitated crystallization of PP in the composites. Upon high impact strength and improved tensile property, the PP composites could find potentials with facile processing manipulation in applications.

Similar content being viewed by others

References

Liang JZ (2002) Toughening and reinforcing in rigid inorganic particulate filled poly(propylene): a review. J Appl Polym Sci 83:1547–1555

Pérez E, Alvarez V, Pérez CJ, Bernal C (2013) A comparative study of the effect of different rigid fillers on the fracture and failure behavior of polypropylene based composites. Compos Part B-Eng 52:72–83

Liang JZ (2017) Impact fracture toughness and flow properties of polypropylene composites. Polym Test 60:381–387

Mohanty S, Nayak SK, Verma SK. Tripathy SS (2004) Effect of MAPP as a coupling agent on the performance of jute-PP composites. J Reinf Plast Compos 23: 625–637

Zhuang G, Sui G, Meng H, Sun Z, Yang R (2007) Mechanical properties of potassium titanate whiskers reinforced poly(ether ether ketone) composites using different compounding processes. Compos Sci Technol 67:1172–1181

Wang L-L, Dong X, Wang X-R, Zhu G-Y, Li H-Q, Wang D-J (2016) High performance long chain polyamide/calcium silicate whisker nanocomposites and the effective reinforcement mechanism. Chin J Polym Sci 34:991–1000

Bettini SHP, Bicudo ABLC, Augusto IS, Antunes LA, Morassi PL, Condotta R, Bonse BC (2010) Investigation on the use of coir fiber as alternative reinforcement in polypropylene. J Appl Polym Sci 118:2841–2848

Franciszczak P, Bledzki AK (2016) Tailoring of dual-interface in high tenacity PP composites -toughening with positive hybrid effect. Compos Part A-Appl S 83:185–192

Wang XC, Song RF, Chen YJ, Zhao YH, Zhu KY, Yuan XY (2018) Mechanical properties of polypropylene by diversely compatibilizing with titanate whiskers in composites. Compos Sci Technol 164:103–109

Hua Y, Li F, Liu Y, Huang G-W, Xiao H-M, Li Y-Q, Hu N, Fu S-Y (2017) Positive synergistic effect of graphene oxide/carbon nanotube hybrid coating on glass fiber/epoxy interfacial normal bond strength. Compos Sci Technol149: 294–304

Mondal S, Khastgir D (2017) Elastomer reinforcement by graphene nanoplatelets and synergistic improvements of electrical and mechanical properties of composites by hybrid nano fillers of graphene-carbon black & graphene-MWCNT. Compos Part A-Appl S 102:154–165

Jenifer A, Rasana N, Jayanarayanan K (2018) Synergistic effect of the inclusion of glass fibers and halloysite nanotubes on the static and dynamic mechanical, thermal and flame retardant properties of polypropylene. Mater Res Express 5:065308

Li T-T, Chen A-P, Hwang P-W, Pan Y-J, Hsing W-H, Lou C-W, Chen Y-S, Lin J-H (2018) Synergistic effects of micro−/nano-fillers on conductive and electromagnetic shielding properties of polypropylene nanocomposites. Mater Manuf Process 33:149–155

Jia XL, Li G, Liu BY, Luo YM, Yang G, Yang XP (2013) Multiscale reinforcement and interfacial strengthening on epoxy-based composites by silica nanoparticle-multiwalled carbon nanotube complex. Compos Part A-Appl S 48:101–109

Jiang S, Li QF, Wang JW, He ZL, Zhao YH, Kang MQ (2016) Multilscale graphene oxide-carbon fiber reinforcements for advanced polyurethane composites. Compos Part A-Appl S 87:1–9

Wang P-H, Gulgunje P, Ghoshal S, Odeh IN, Verghese N, Kumar S (2019) Effect of interfacial chemistry on crystallization of polypropylene/multiwall carbon nanotube nanocomposites. Polym Eng Sci 59:1570–1584

Krause B, Rzeczkowski P, Pötschke P (2019) Thermal conductivity and electrical resistivity of melt-mixed polypropylene composites containing mixtures of carbon-based fillers. Polymers 11:1073

Herrera-Ramírez LC, Castell P, Castillo-Rodríguez M, Fernández Á, de Villoria RG (2017) The effect of a semi-industrial masterbatch process on the carbon nanotube agglomerates and its influence in the properties of thermoplastic carbon nanotube composites. J Polym Sci B Polym Phys 55:189–197

Wang P-H, Sarkar S, Gulgunje P, Verghese N, Kumar S (2018) Fracture mechanism of high impact strength polypropylene containing carbon nanotubes. Polymer 151:287–298

Wang XC, Song RF, Guo K, Chen YJ, Zhao YH, Zhu KY, Yuan XY (2019) High impact strength for polypropylene/titanate whisker composites with dual compatibilizing agents. Polym Compos 40:3421–3428

Hu P, Gao S, Zhang Y, Zhang L, Wang C (2018) Surface modified BaTiO3 nanoparticles by titanate coupling agent induce significantly enhanced breakdown strength and larger energy density in PVDF nanocomposite. Compos Sci Technol 156:109–116

Yu DM, Wu JS, Zhou LM, Xie DR, Wu SZ (2000) The dielectric and mechanical properties of a potassium-titanate-whisker-reinforced PP/PA blend. Compos Sci Technol 60:499–508

Xu JW, Manepalli PH, Zhu LJ, Narayan-Sarathy S, Alavi S (2019) Morphological, barrier and mechanical properties of films from poly(butylene succinate) reinforced with nanocrystalline cellulose and chitin whiskers using melt extrusion. J Polym Res 26:188

Šajgalik P, Dusza J, Hoffmann MJ (1995) Relationship between microstructure, toughening mechanisms, and fracture toughness of reinforced silicon nitride ceramics. J Am Ceram Soc 78:2619–2624

Ghoshal S, Wang P-H, Gulgunje P, Verghese N, Kumar S (2016) High impact strength polypropylene containing carbon nanotubes. Polymer 100:259–274

Siddiqui NA, Sham M-L, Tang BZ, Munir A, Kim J-K (2009) Tensile strength of glass fibres with carbon nanotube-epoxy nanocomposite coating. Compos Part A-Appl S 40:1606–1614

Charifou R, Gouanvé F, Fulchiron R, Espuche E (2015) Polypropylene/layered double hydroxide nanocomposites: synergistic effect of designed filler modification and compatibilizing agent on the morphology, thermal, and mechanical properties. J Polym Sci B Polym Phys 53:782–794

Fu X, He B, Chen X (2010) Effects of compatibilizers on mechanical properties of long glass fiber-reinforced polypropylene. J Reinf Plast Compos 29:936–949

Clark EJ, Hoffman JD (1984) Regime III crystallization in polypropylene. Macromolecules 17:878–885

Jain S, Goossens H, van Duin M, Lemstra P (2005) Effect of in situ prepared silica nano-particles on non-isothermal crystallization of polypropylene. Polymer 46:8805–8818

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, K., Wang, T., Wang, X. et al. High impact strength of polypropylene composites with complex titanate whiskers/multiwalled carbon nanotubes. J Polym Res 27, 233 (2020). https://doi.org/10.1007/s10965-020-02171-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02171-9