Abstract

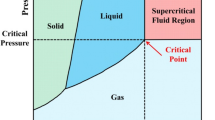

Melt strength is crucial in foam-processing of polymer materials, especially for linear molecular structured isotactic polypropylene (iPP), which has comparatively weak melt strength to hinder its foaming. In this study, a commercial high melt strength polypropylene (HMSPP) was added into the iPP matrix, cooperated with a thermal treatment, aiming to enhance the melt strength and microcellular foamability of iPP under supercritical CO2. Melt strength enhancement effect was proved by rheological and microcellular foaming results. The crystallization and batch foaming behaviors of iPP and its HMSPP added blends at different foaming conditions were investigated. It was observed that the addition of HMSPP could refine the crystals of the blends, and the crystal nucleation sites could be increased apparently. Cooperated with the suitable thermal control schedule during the batch foaming process, the introduced crystals could correspondingly improve the melt strength and cell nucleating ability of HMSPP added iPP. At a given HMSPP content of 20 wt.%, quite fine microcellular foams with the average cell size of 0.8 μm, and cell density up to 1012 cells/cm3 were fabricated.

Similar content being viewed by others

References

Lee S, Zhu L, Maia J (2015) The effect of strain-hardening on the morphology and mechanical and dielectric properties of multi-layered PP foam/PP film. Polymer 70:173–182. https://doi.org/10.1016/j.polymer.2015.06.029

Ding W, Chu RKM, Mark LH, Park CB, Sain M (2015) Non-isothermal crystallization behaviors of poly(lactic acid)/cellulose nanofiber composites in the presence of CO2. Eur Polym J 71:231–247. https://doi.org/10.1016/j.eurpolymj.2015.07.054

Kargarzadeh H, Huang J, Lin N, Ahmad I, Mariano M, Dufresne A, Thomas S, Gałęski A (2018) Recent developments in nanocellulose-based biodegradable polymers, thermoplastic polymers, and porous nanocomposites. Prog Polym Sci 87:197–227. https://doi.org/10.1016/j.progpolymsci.2018.07.008

Ding J, Ma W, Song F, Zhong Q (2012) Effect of nano-calcium carbonate on microcellular foaming of polypropylene. J Mater Sci 48(6):2504–2511. https://doi.org/10.1007/s10853-012-7039-1

Liu W, Pang Y, Wu M, Qin K, Zheng W (2019) Dependence of the foaming window of a polystyrene/poly(methyl methacrylate) blend on structural evolution driven by phase separation. Polymer 166:63–71. https://doi.org/10.1016/j.polymer.2019.01.050

Lee PC, Kaewmesri W, Wang J, Park CB, Pumchusak J, Folland R, Praller A (2008) Effect of die geometry on foaming behaviors of high-melt-strength polypropylene with CO2. J Appl Polym Sci 109(5):3122–3132. https://doi.org/10.1002/app.28204

Mi HY, Chen JW, Geng LH, Chen BY, Jing X, Peng XF (2016) Formation of nanoscale pores in shish-kebab structured isotactic polypropylene by supercritical CO2 foaming. Mater Lett 167:274–277. https://doi.org/10.1016/j.matlet.2015.12.116

Zhang X, Li B, Wang X, Li K, Wang G, Chen J, Park CB (2018) Modification of iPP microcellular foaming behavior by thermal history control and nucleating agent at compressed CO2. J Supercrit Fluid 133:383–392. https://doi.org/10.1016/j.supflu.2017.11.003

Jiang XL, Liu T, Xu ZM, Zhao L, Hu GH, Yuan WK (2009) Effects of crystal structure on the foaming of isotactic polypropylene using supercritical carbon dioxide as a foaming agent. J Supercrit Fluid 48(2):167–175. https://doi.org/10.1016/j.supflu.2008.10.006

Zhai W, Wang H, Yu J, Dong J, He J (2008) Cell coalescence suppressed by crosslinking structure in polypropylene microcellular foaming. Polym Eng Sci 48(7):1312–1321. https://doi.org/10.1002/pen.21095

Yu K, Jiang H, Zhou H, Mi J, He Y, Wang X (2018) Evolution of double crystal melting peak in polypropylene foam assisted by β-nucleating agent and supercritical CO2. J Appl Polym Sci 135(12):46007. https://doi.org/10.1002/app.46007

Zhai W, Wang H, Yu J, Dong J-Y, He J (2008) Foaming behavior of isotactic polypropylene in supercritical CO2 influenced by phase morphology via chain grafting. Polymer 49(13–14):3146–3156. https://doi.org/10.1016/j.polymer.2008.05.018

Yang C, Xing Z, Zhang M, Zhao Q, Wang M, Wu G (2017) Supercritical CO2 foaming of radiation crosslinked polypropylene/high-density polyethylene blend: cell structure and tensile property. Radiat Phys Chem 141:276–283. https://doi.org/10.1016/j.radphyschem.2017.07.028

Lee SH, Kontopoulou M, Park CB (2010) Effect of nanosilica on the co-continuous morphology of polypropylene/polyolefin elastomer blends. Polymer 51(5):1147–1155. https://doi.org/10.1016/j.polymer.2010.01.018

Li DC, Liu T, Zhao L, Yuan WK (2011) Foaming of linear isotactic polypropylene based on its non-isothermal crystallization behaviors under compressed CO2. J Supercrit Fluid 60:89–97. https://doi.org/10.1016/j.supflu.2011.07.015

Hung Yu Lan HCT (2002) Study on the rheological behavior of PP/supercritical CO2 mixture. J Appl Polym Sci 9:157–162

Yeh SK, Chen YR, Kang TW, Tseng TJ, Peng SP, Chu CC, Rwei SP, Guo WJ (2017) Different approaches for creating nanocellular TPU foams by supercritical CO2 foaming. J Polym Res 25(1). https://doi.org/10.1007/s10965-017-1419-9

Huang H-X, Wang J-K (2007) Improving polypropylene microcellular foaming through blending and the addition of nano-calcium carbonate. J Appl Polym Sci 106(1):505–513. https://doi.org/10.1002/app.26483

Ding J, Shangguan J, Ma W, Zhong Q (2013) Foaming behavior of microcellular foam polypropylene/modified nano calcium carbonate composites. J Appl Polym Sci 128(6):3639–3651. https://doi.org/10.1002/app.38416

Hu D, Chen J, Sun S, Liu T, Zhao L (2014) Solubility and diffusivity of CO2 in isotactic polypropylene/Nanomontmorillonite composites in melt and solid states. Ind Eng Chem Res 53(7):2673–2683. https://doi.org/10.1021/ie403580x

Zhai W, Park CB (2011) Effect of nanoclay addition on the foaming behavior of linear polypropylene-based soft thermoplastic polyolefin foam blown in continuous extrusion. Polym Eng Sci 51(12):2387–2397. https://doi.org/10.1002/pen.22011

Zheng WG, Lee YH, Park CB (2010) Use of nanoparticles for improving the foaming behaviors of linear PP. J Appl Polym Sci 117:2972–2979. https://doi.org/10.1002/app.32253

Miyamoto R, Yasuhara S, Shikuma H, Ohshima M (2014) Preparation of micro/nanocellular polypropylene foam with crystal nucleating agents. Polym Eng Sci 54(9):2075–2085. https://doi.org/10.1002/pen.23758

Cao X, Qiao Y, Chen Y, He G, Lin H (2016) Critical role of depressurization and effects of saturation conditions in the formation of β-crystal during isotactic polypropylene foaming with supercritical CO2. Polym Eng Sci 56(9):980–986. https://doi.org/10.1002/pen.24327

Saniei M, Tran M-P, Bae S-S, Boahom P, Gong P, Park CB (2016) From micro/nano structured isotactic polypropylene to a multifunctional low-density nanoporous medium. RSC Adv 6(109):108056–108066. https://doi.org/10.1039/c6ra22607h

Wang W, Zhou S, Xin Z, Shi Y, Zhao S, Meng X (2015) Preparation and foaming mechanism of foamable polypropylene based on self-assembled nanofibrils from sorbitol nucleating agents. J Mater Sci 51(2):788–796. https://doi.org/10.1007/s10853-015-9402-5

Wang L, Hikima Y, Ishihara S, Ohshima M (2017) Fabrication of lightweight microcellular foams in injection-molded polypropylene using the synergy of long-chain branches and crystal nucleating agents. Polymer 128:119–127. https://doi.org/10.1016/j.polymer.2017.09.025

Zhang R, Xiong Y, Liu Q, Hu S (2017) Improved cell morphology and thermal properties of expanded polypropylene beads by the addition of PP with a high melting point. J Appl Polym Sci 134(30):45121. https://doi.org/10.1002/app.45121

Liao X, Nawaby AV, Whitfield PS (2010) Carbon dioxide-induced crystallization in poly(L-lactic acid) and its effect on foam morphologies. Polym Int 59(12):1709–1718. https://doi.org/10.1002/pi.2910

Chang YW, Lee D, Bae SY (2006) Preparation of polyethylene-octene elastomer/clay nanocomposite and microcellular foam processed in supercritical carbon dioxide. Polym Int 55(2):184–189. https://doi.org/10.1002/pi.1936

Huang HX, Xu HF (2011) Preparation of microcellular polypropylene/polystyrene blend foams with tunable cell structure. Polym Advan Technol 22(6):822–829. https://doi.org/10.1002/pat.1584

Rizvi A, Andalib ZKM, Park CB (2017) Fiber-spun polypropylene/polyethylene terephthalate microfibrillar composites with enhanced tensile and rheological properties and foaming ability. Polymer 110:139–148. https://doi.org/10.1016/j.polymer.2016.12.054

Rizvi A, Park CB, Favis BD (2015) Tuning viscoelastic and crystallization properties of polypropylene containing in-situ generated high aspect ratio polyethylene terephthalate fibrils. Polymer 68:83–91. https://doi.org/10.1016/j.polymer.2015.04.081

Zhang P, Wang XJ, Yang Y, Zhou N (2009) Effect of dynamic shear on the microcellular foaming of polypropylene/high-density polyethylene blends. J Appl Polym Sci 114(2):1320–1328. https://doi.org/10.1002/app.30646

Rachtanapun P, Selke SEM, Matuana LM (2004) Effect of the high-density polyethylene melt index on the microcellular foaming of high-density polyethylene/polypropylene blends. J Appl Polym Sci 93(1):364–371. https://doi.org/10.1002/app.20428

Rachtanapun P, Selke SEM, Matuana LM (2004) Relationship between cell morphology and impact strength of microcellular foamed high-density polyethylene/polypropylene blends. Polym Eng Sci 44(8):1551–1560. https://doi.org/10.1002/pen.20152

Moscoso-Sánchez FJ, Ríos Díaz OJ, Flores J, Martínez L, Fernández VVA, Barrera A, Canché-Escamilla G (2012) Effect of the cellulose of Agave tequilana weber onto the mechanical properties of foamed and unfoamed polypropylene composites. Polym Bull 70(3):837–847. https://doi.org/10.1007/s00289-012-0878-8

Zhou S, Zhao S, Xin Z, Wang W (2014) A novel strategy for achieving high melt strength polypropylene and an investigation of its Foamability. J Macromol Sci B 53(10):1695–1714. https://doi.org/10.1080/00222348.2014.965379

Raps D, Köppl T, de Anda AR, Altstädt V (2014) Rheological and crystallisation behaviour of high melt strength polypropylene under gas-loading. Polymer 55(6):1537–1545. https://doi.org/10.1016/j.polymer.2014.01.036

Zhou S, Zhao S, Xin Z (2015) Preparation and foamability of high melt strength polypropylene based on grafting vinyl polydimethylsiloxane and styrene. Polym Eng Sci 55(2):251–259. https://doi.org/10.1002/pen.23889

Li YG, Park CB (2009) Effects of branching on the pressure-volume-temperature behaviors of PP/CO2 solutions. Ind Eng Chem Res 48:6633–6640. https://doi.org/10.1021/ie8015279

Li Y, Pan C, Xin Z, Zhou S, Meng X, Zhao S (2018) Rheological, crystallization and foaming behaviors of high melt strength polypropylene in the presence of polyvinyl acetate. J Polym Res 25(2). https://doi.org/10.1007/s10965-018-1439-0

Tabatabaei A, Barzegari MR, Mark LH, Park CB (2017) Visualization of polypropylene's strain-induced crystallization under the influence of supercritical CO2 in extrusion. Polymer 122:312–322. https://doi.org/10.1016/j.polymer.2017.06.052

Wong A, Guo Y, Park CB (2013) Fundamental mechanisms of cell nucleation in polypropylene foaming with supercritical carbon dioxide—effects of extensional stresses and crystals. J Supercrit Fluid 79:142–151. https://doi.org/10.1016/j.supflu.2013.02.013

Tabatabaei A, Mark LH, Park CB (2016) Visualization of polypropylene crystallites formed from a stressed melt in extrusion. Polymer 101:48–58. https://doi.org/10.1016/j.polymer.2016.08.036

Zhang X, Wang X, Sun B, Cheng H, Chen J, Shen C, Park CB (2018) Broadened foaming scope of iPP adjusted by its self-enhancement and nucleating agent under compressed CO2. Mater Today Commun 17:501–510. https://doi.org/10.1016/j.mtcomm.2018.10.023

Jurczuk K, Galeski A, Morawiec J (2017) Effect of poly(tetrafluoroethylene) nanofibers on foaming behavior of linear and branched polypropylenes. Eur Polym J 88:171–182. https://doi.org/10.1016/j.eurpolymj.2017.01.024

Peng X, Xin Z, Zhao S, Zhou S, Shi Y, Ye C (2018) Unique crystallization behavior of isotactic polypropylene in the presence of l-isoleucine and its inhibition and promotion mechanism of nucleation. J Appl Polym Sci 135(10):45956. https://doi.org/10.1002/app.45956

Li S, Xiao M, Guan Y, Wei D, Xiao H, Zheng A (2012) A novel strategy for the preparation of long chain branching polypropylene and the investigation on foamability and rheology. Eur Polym J 48(2):362–371. https://doi.org/10.1016/j.eurpolymj.2011.11.015

Xu ZM, Jiang XL, Liu T, Hu GH, Zhao L, Zhu ZN, Yuan WK (2007) Foaming of polypropylene with supercritical carbon dioxide. J Supercrit Fluid 41(2):299–310. https://doi.org/10.1016/j.supflu.2006.09.007

Li DC, Liu T, Zhao L, Yuan WK (2009) Solubility and diffusivity of carbon dioxide in solid-state isotactic polypropylene by the pressure-decay method. Ind Eng Chem Res 48(15):7117–7124. https://doi.org/10.1021/ie8019483

Luo Y, Xin C, Zheng D, Li Z, Zhu W, Wu S, Zheng Q, He Y (2015) Effect of processing history on the rheological properties, crystallization and foamability of branched polypropylene. J Polym Res 22(6). https://doi.org/10.1007/s10965-015-0763-x

Li S, Xiao M, Zheng S, Xiao H, Guan Y, Zheng A (2009) The characterization of rheological properties of melt grafting polypropylene for foaming. Polym Bull 63(1):111–123. https://doi.org/10.1007/s00289-009-0069-4

Wang Y, Ni Q, Liu Z, Zou J, Zhu X (2011) Grafting modification and properties of polypropylene with pentaerythritol tetra-acrylate. J Polym Res 18(6):2185–2193. https://doi.org/10.1007/s10965-011-9629-z

Masirek R, Szkudlarek E, Piorkowska E, Slouf M, Kratochvil J, Baldrian J (2010) Nucleation of isotactic polypropylene crystallization by gold nanoparticles. J Polym Sci PolPhys 48(4):469–478. https://doi.org/10.1002/polb.21908

Tian J, Yu W, Zhou C (2006) The preparation and rheology characterization of long chain branching polypropylene. Polymer 47(23):7962–7969. https://doi.org/10.1016/j.polymer.2006.09.042

Zhao S, Pan C, Xin Z, Li Y, Qin W, Zhou S (2019) 13X zeolite as Difunctional nucleating agent regulating the crystal form and improving the Foamability of blocked copolymerized polypropylene in supercritical CO2 foaming process. J Polym Res 26(3). https://doi.org/10.1007/s10965-019-1719-3

Li Z, Chen M, Ma W (2016) Promoting effect of crystallization on the foaming behavior in polypropylene homopolymer/polypropylene block copolymer blends. Polym Eng Sci 56(10):1175–1181. https://doi.org/10.1002/pen.24351

Liao R, Yu W, Zhou C (2010) Rheological control in foaming polymeric materials: II. Semi-crystalline polymers. Polymer 51(26):6334–6345. https://doi.org/10.1016/j.polymer.2010.11.001

Acknowledgements

The authors sincerely thank the National Natural Science Foundation of China (11872338), and the Henan Province Natural Science Projects of China (18B430016, 192102210024, 19B430011), for their financial supports.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 1209 kb)

Rights and permissions

About this article

Cite this article

Shi, Q., Fu, L., Yang, Y. et al. A facile methodology to effectively improve the melt strength and microcellular foamability of isotactic polypropylene. J Polym Res 27, 118 (2020). https://doi.org/10.1007/s10965-020-02101-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02101-9