Abstract

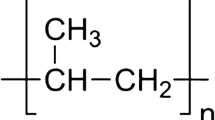

Multiwalled carbon nanotubes were introduced into both dispersed and co-continuous polycarbonate/polypropylene blends through melt compounding in an internal mixer. Both the neat blends and blend nanocomposites showed viscoelastic phase separation process where phase in phase morphologies could be observed due to viscosity disparity and Tg differences between the component polymers. A strong compatibilising action was noticed up on the addition of a small quantity of MWCNT into both dispersed and co-continuous morphologies. Theoretical predictions based on thermodynamic considerations clearly indicated the preferential localisation of MWCNTs in the PC phase. However, because of the viscosity differences between the two polymers, we also found that some of the MWCNTs being localised at the blend interphase and in PP phase. From linear viscoelastic studies rheological percolation was observed at high concentration of the MWCNTs where carbon nanotubes formed a network-like structure leading to solid state behaviour at low frequencies.

Similar content being viewed by others

References

Utracki LA (1982) Economics of polymer blends. Polym Eng Sci 22:1166–1175

Utracki LA (1999) Polymer blends: fundamentals. Polypropylene, Polymer Sc. Springer, pp 601–605

Paul DR, Barlow JW (1980) Polymer blends. J Macromol Sci Macromol Chem 18:109–168

Machado JM, Lee CS (1994) Compatibilization of immiscible blends with a mutually miscible third polymer. Polym Eng Sci 34:59–68

Uemura T, Kaseda T, Sasaki Y, Inukai M, Toriyama T, Takahara A, Jinnai H, Kitagawa S (2015) Mixing of immiscible polymers using nanoporous coordination templates. Nat Commun 6:7473

Galloway JA, Koester KJ, Paasch BJ, Macosko CW (2004) Effect of sample size on solvent extraction for detecting cocontinuity in polymer blends. Polymer 45:423–428

Castro M, Carrot C, Prochazka F (2004) Experimental and theoretical description of low frequency viscoelastic behaviour in immiscible polymer blends. Polymer 45:4095–4104

Huang S, Bai L, Trifkovic M, Cheng X, Macosko CW (2016) Controlling the morphology of immiscible cocontinuous polymer blends via silica nanoparticles jammed at the interface. Macromolecules 49:3911–3918

Altobelli R, de Luna MS, Causa A et al (2016) Morphology stabilization of co-continuous polymer blends through clay nanoparticles. AIP conference proceedings. AIP Publishing, 20057

Li L, Miesch C, Sudeep PK, Balazs AC, Emrick T, Russell TP, Hayward RC (2011) Kinetically trapped co-continuous polymer morphologies through intraphase gelation of nanoparticles. Nano Lett 11:1997–2003

Popov VN (2004) Carbon nanotubes: properties and application. Mater Sci Eng R Reports 43:61–102

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Tao F, Auhl D, Baudouin A et al (2013) Influence of multiwall carbon nanotubes trapped at the interface of an immiscible polymer blend on interfacial tension. Macromol Chem Phys 214:350–360

Mamunya Y, Levchenko V, Boiteux G, Seytre G, Zanoaga M, Tanasa F, Lebedev E (2016) Controlling morphology, electrical, and mechanical properties of polymer blends by heterogeneous distribution of carbon nanotubes. Polym Compos 37:2467–2477

Pradhan B, Setyowati K, Liu H, Waldeck DH, Chen J (2008) Carbon nanotube− polymer nanocomposite infrared sensor. Nano Lett 8:1142–1146

Njuguna J, Pielichowski K (2003) Polymer nanocomposites for aerospace applications: properties. Adv Eng Mater 5:769–778

Singh BP, Saini P, Gupta T et al (2011) Designing of multiwalled carbon nanotubes reinforced low density polyethylene nanocomposites for suppression of electromagnetic radiation. J Nanopart Res 13:7065–7074

Poothanari MA, Abraham J, Kalarikkal N, Thomas S (2018) Excellent electromagnetic interference shielding and high electrical conductivity of Compatibilized polycarbonate/polypropylene carbon nanotube blend nanocomposites. Ind Eng Chem Res 57:4287–4297

Botelho EC, Costa ML, Braga CI, Burkhart T, Lauke B (2013) Viscoelastic behavior of multiwalled carbon nanotubes into phenolic resin. Mater Res 16:713–720

Cassagnau P (2013) Linear viscoelasticity and dynamics of suspensions and molten polymers filled with nanoparticles of different aspect ratios. Polymer 54:4762–4775

Pötschke P, Pegel S, Claes M, Bonduel D (2008) A novel strategy to incorporate carbon nanotubes into thermoplastic matrices. Macromol Rapid Commun 29:244–251

Koysuren O, Yesil S, Bayram G (2010) Effect of solid state grinding on properties of PP/PET blends and their composites with carbon nanotubes. J Appl Polym Sci 118:3041–3048

Liebscher M, Tzounis L, Pötschke P, Heinrich G (2013) Influence of the viscosity ratio in PC/SAN blends filled with MWCNTs on the morphological, electrical, and melt rheological properties. Polymer 54:6801–6808

Wu D, Zhang Y, Zhang M, Yu W (2009) Selective localization of multiwalled carbon nanotubes in poly(epsilon-caprolactone)/polylactide blend. Biomacromolecules 10:417–424

Cardinaud R, McNally T (2013) Localization of MWCNTs in PET/LDPE blends. Eur Polym J 49:1287–1297

Abbasi Moud A, Javadi A, Nazockdast H, Fathi A, Altstaedt V (2015) Effect of dispersion and selective localization of carbon nanotubes on rheology and electrical conductivity of polyamide 6 (PA6), polypropylene (PP), and PA6/PP nanocomposites. J Polym Sci Part B Polym Phys 53:368–378

Du F, Scogna RC, Zhou W et al (2004) Nanotube networks in polymer nanocomposites: rheology and electrical conductivity. Macromolecules 37:9048–9055

Mohammed Arif P, Sarathchandran C, Narayanan A, Saiter A, Terzano R, Allegretta I, Porfido C, Kalarikkal N, Thomas S (2017) Multiwalled carbon nanotube promotes crystallisation while preserving co-continuous phase morphology of polycarbonate/polypropylene blend. Polym Test 64:1–11

Favis B, Chalifoux J (1988) Influence of composition on the morphology of polypropylene/polycarbonate blends. Polymer 29:1761–1767

Zhihui Y, Yajie Z, Xiaomin Z, Jinghua Y (1998) Effects of the compatibilizer PP-g-GMA on morphology and mechanical properties of PP/PC blends. Polymer 39:547–551

Xu Y, Sun Z, Chen X, Chen M, Hu S, Zhang Z (2013) Mechanical properties and crystallization behavior of polycarbonate/polypropylene blends. J Macromol Sci Part B 52:716–725

Babu RR, Singha NK, Naskar K (2011) Phase morphology and melt rheological behavior of uncrosslinked and dynamically crosslinked polyolefin blends: role of macromolecular structure. Polym Bull 66:95–118

Shi W, Chen F, Zhang Y, Han CC (2012) Viscoelastic phase separation and interface assisted crystallization in a highly immiscible iPP/PMMA blend. ACS Macro Lett 1:1086–1089

Paukszta D, Garbarczyk J, Sterzyński T (1995) Structure of polypropylene/polycarbonate blends crystallized under pressure. Polymer 36:1309–1313

Chandran N, Chandran S, Maria HJ, Thomas S (2015) Compatibilizing action and localization of clay in a polypropylene/natural rubber (PP/NR) blend. RSC Adv 5:86265–86273

Wu S (1987) Formation of dispersed phase in incompatible polymer blends: interfacial and rheological effects. Polym Eng Sci 27:335–343

Galloway JA, Macosko CW (2004) Comparison of methods for the detection of cocontinuity in poly (ethylene oxide)/polystyrene blends. Polym Eng Sci 44:714–727

Li C, Tian G, Zhang Y, Zhang Y (2002) Crystallization behavior of polypropylene/polycarbonate blends. Polym Test 21:919–926

Filippone G, Dintcheva NT, La Mantia FP, Acierno D (2010) Using organoclay to promote morphology refinement and co-continuity in high-density polyethylene/polyamide 6 blends–effect of filler content and polymer matrix composition. Polymer 51:3956–3965

Bose S, Bhattacharyya AR, Khare RA, Kulkarni AR, Umasankar Patro T, Sivaraman P (2008) Tuning the dispersion of multiwall carbon nanotubes in co-continuous polymer blends: a generic approach. Nanotechnology 19:335704

Parpaite T, Otazaghine B, Taguet A, Sonnier R, Caro AS, Lopez-Cuesta JM (2014) Incorporation of modified Stöber silica nanoparticles in polystyrene/polyamide-6 blends: coalescence inhibition and modification of the thermal degradation via controlled dispersion at the interface. Polymer 55:2704–2715

Chow WS, Ishak ZA (2015) Polyamide blend-based nanocomposites: a review. Express Polym Lett 9:211–232

Zhang L, Wan C, Zhang Y (2009) Morphology and electrical properties of polyamide 6/polypropylene/multi-walled carbon nanotubes composites. Compos Sci Technol 69:2212–2217

Liu X-Q, Yang W, Xie B-H, Yang M-B (2012) Influence of multiwall carbon nanotubes on the morphology, melting, crystallization and mechanical properties of polyamide 6/acrylonitrile–butadiene–styrene blends. Mater Des 34:355–362

Zhou J, Min BG (2013) Interfacial localization of multiwalled carbon nanotubes in immiscible blend of poly (ethylene terephthalate)/polyamide 6. Fibers Polym 14:518–524

Solid surface energy data (SFE) for common polymers. In: http://www.surfacetension.de/solid-surface-energy.htm (Accessed: 25.02.2016)

Nuriel S, Liu L, Barber AH, Wagner HD (2005) Direct measurement of multiwall nanotube surface tension. Chem Phys Lett 404:263–266

Barber AH, Cohen SR, Wagner HD (2004) Static and dynamic wetting measurements of single carbon nanotubes. Phys Rev Lett 92:186103

Nair ST, Vijayan PP, Xavier P et al (2015) Selective localisation of multi walled carbon nanotubes in polypropylene/natural rubber blends to reduce the percolation threshold. Compos Sci Technol 116:9–17

Favis BD, Le Corroller P Polymeric material and process for recycling plastic blends. US 9,670,344

Feng J, Chan C, Li J (2003) A method to control the dispersion of carbon black in an immiscible polymer blend. Polym Eng Sci 43:1058–1063

Guo C, Zhou L, Lv J (2013) Effects of expandable graphite and modified ammonium polyphosphate on the flame-retardant and mechanical properties of wood flour-polypropylene composites. Polym Polym Compos 21:449–456

Vo L, Giannelis E (2007) Compatibilizing poly (vinylidene fluoride)/nylon-6 blends with nanoclay. Macromolecules 40:8271–8276

Zhao X, Zhao J, Cao J-P, Wang X, Chen M, Dang ZM (2013) Tuning the dielectric properties of polystyrene/poly (vinylidene fluoride) blends by selectively localizing carbon black nanoparticles. J Phys Chem B 117:2505–2515

Weis C, Leukel J, Borkenstein K, Maier D, Gronski W, Friedrich C, Honerkamp J (1998) Morphological and rheological detection of the phase inversion of PMMA/PS polymer blends. Polym Bull 40:235–241

Vinckier I, Laun HM (1999) Manifestation of phase separation processes in oscillatory shear: droplet-matrix systems versus co-continuous morphologies. Rheol Acta 38:274–286

López-Barrón CR, Macosko CW (2012) Rheological and morphological study of cocontinuous polymer blends during coarsening. J Rheol 56:1315–1334

Li R, Yu W, Zhou C (2006) Rheological characterization of droplet-matrix versus co-continuous morphology. J Macromol Sci Part B 45:889–898

Bianchi O, Zattera AJ, Canto LB (2010) Dynamic vulcanization of hdpe/eva blend using silane. J Elastomers Plast 42:561–575

Salehiyan R, Ray SS, Bandyopadhyay J, Ojijo V (2017) The distribution of nanoclay particles at the interface and their influence on the microstructure development and rheological properties of reactively processed biodegradable polylactide/poly(butylene succinate) blend nanocomposites. Polymers 9:350

Moniruzzaman M, Winey KI (2006) Polymer nanocomposites containing carbon nanotubes. Macromolecules 39:5194–5205

Freeman GM, Marshall Jr CJ, Lackey WO, Onizawa M (2001) Hydrous clay slurry mixture containing a silane-treated clay. US 6,197,105

Rostami A, Masoomi M, Fayazi MJ, Vahdati M (2015) Role of multiwalled carbon nanotubes (MWCNTs) on rheological, thermal and electrical properties of PC/ABS blend. RSC Adv 5:32880–32890

Kasgoz A, Akın D, Durmus A (2012) Rheological behavior of cycloolefin copolymer/graphite composites. Polym Eng Sci 52:2645–2653

Acknowledgments

This project is funded by Ministry of Electronics and Information Technology-MeitY (F. No. 1(2)/2012-EMCD), Govt. of India, New Delhi. The authors also would like to acknowledge the financial support from DST-Nanomision – Govt. of India and UGC – Govt. of India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Poothanari, M.A., Xavier, P., Bose, S. et al. Compatibilising action of multiwalled carbon nanotubes in polycarbonate/polypropylene (PC/PP) blends: phase morphology, viscoelastic phase separation, rheology and percolation. J Polym Res 26, 178 (2019). https://doi.org/10.1007/s10965-019-1833-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1833-2