Abstract

The improvement of flexural properties of polypropylene (PP) could be achieved by blending it with a stiffer polymer like poly(ethylene terephthalate) (PET). The main problem is the compatibilization between a saturated, apolar structure with a polar polyester. Copolymers of glycidyl methacrylate (GMA) and 2-ethylhexyl acrylate (EHA) were prepared, characterized and used as compatibilizers in PP/PET (70/30 wt%) blends at different feed ratios. The effects of compatibilization of these polymers were analyzed by SEM, which shows reduction of the size of PET granules, and by TGA, with an increase in the thermal stability of the compatibilized blends. Thermal properties corresponding to melting and crystallization events were also changed by the introduction of the compatibilizers. The DMTA shows that the Tg of the PET domain is affected by compatibilization, contrary to the Tg of PP domain. The compatibilization efficiency was further confirmed by an increase in flexural strain at flexural strength (εFM).

Similar content being viewed by others

References

Van Bruggen EPA, Koster RP, Picken SJ, Ragaert K (2016) Influence of processing parameters and composition on the effective Compatibilization of polypropylene–poly(ethylene terephthalate) blends. Int Polym Process 31(2):179–187

Champagne MF, Huneault MA, Roux C, Peyrel W (1999) Reactive compatibilization of polypropylene/polyethylene terephthalate blends. Polym Eng Sci 39(6):976–984

Gnatowski A, Koszkul J (2005) Investigations of the influence of compatibilizer and filler type on the properties of chosen polymer blends. J Mater Process Technol 162–163:52–58

Inuwa IM, Hassan A, Samsudin SA, Haafiz MKM, Jawaid M (2017) Interface modification of compatibilized polyethylene terephthalate/polypropylene blends: effect of compatibilization on thermomechanical properties and thermal stability. J Vinyl Addit Technol 23(1):45–54

Abdul Razak NC, Inuwa IM, Hassan A, Samsudin SA (2013) Effects of compatibilizers on mechanical properties of PET/PP blend. Compos Interfaces 20(7):507–515

Oswald HJ, Turi E (1965) The deterioration of polypropylene by oxidative degradation. Polym Eng Sci 5(3):152–158

Maier C, Calafut T (1998) Polypropylene: the definitive User's guide and Databook. William Andrew Inc, New York

Schoolenberg GE, Vink P (1991) Ultra-violet degradation of polypropylene: 1. Degradation profile and thickness of the embrittled surface layer. Polymer 32(3):432–437

Xanthos M, Young MW, Biesenberger JA (1990) Polypropylene/polyethylene terephthalate blends compatibilized through functionalization. Polym Eng Sci 30(6):355–365

White JL, Yang J (2008) In: Domasius N., thein K. (eds) polyolefin blends. Wiley, New York

Cheung MK, Chan D (1999) Mechanical and rheological properties of poly(ethylene terephthalate)/ polypropylene blends. Polym Int 43(3):281–287

Barlow JW, Paul DR (1984) Mechanical compatibilization of immiscible blends. Polym Eng Sci 24(8):525–534

Santos P, Pezzin SH (2003) Mechanical properties of polypropylene reinforced with recycled-PET fibres. J Mater Process Technol 143–144:517–520

Heino M, Kirjava J, Hietaoja P, Seppa J (1997) Compatibilization of polyethylene terephthalate / polypropylene blends with styrene – ethylene / butylene – styrene (SEBS) block copolymers. J Appl Polym Sci 65(2):241–249

Moad G (1999) The synthesis of polyolefin graft copolymers by reactive extrusion. Prog Polym Sci 24(1):81–142

Ciardelli F, Aglietto M, Coltelli M, Passaglia E, Giacomo R, Coiai S (2004) In: Ciardelli F., Penczek S. (eds) Modification and Blending of Synthetic and Natural Macromolecules. Kluwer Academic Publ, Pisa

Amanizadeh F, Naderi A, Jarestani Y, Kaptan N (2014) Rheologically determined phase behavior and miscibility of reactively compatibilized poly(ethylene terephthalate)/polypropylene blends. Polym Bull 71(6):1315–1329

Papadopoulou CP, Kalfoglou NK (2000) Comparison of compatibilizer effectiveness for PET/PP blends: their mechanical, thermal and morphology characterization. Polymer 41(7):2543–2555

Pang YX, Jia DM, Hu HJ, Hourston DJ, Song M (2000) Effects of a compatibilizing agent on the morphology, interface and mechanical behaviour of polypropylene / poly (ethylene terephthalate) blends. Polymer 41(1):357–365

Chiu HT, Hsiao YK (2006) Compatibilization of of poly (ethylene terephthalate)/ polypropylene blends with maleic anhydride grafted polyethylene-octene elastomer. J Polym Res 13(2):153–160

Wang Y, Run M (2009) Non-isothermal crystallization kinetic and compatibility of PTT/PP blends by using maleic anhydride grafted polypropylene as compatibilizer. J Polym Res 16:725–737

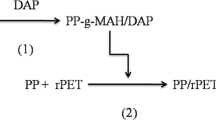

Jazani OM, Rastin H, Formela K, Hejna A, Shahbazi M, Farkiani B, Saeb MR (2017) An investigation on the role of GMA grafting degree on the efficiency of PET/PP-g-GMA reactive blending: morphology and mechanical properties. Polym Bull 74:4483–4497. https://doi.org/10.1007/s00289-017-1962-x

Jerenec S, Šimić M, Savnik A, Podgornik A, Kolar M, Turnšek M, Krajnc P (2014) Glycidyl methacrylate and ethylhexyl acrylate based polyHIPE monoliths: morphological, mechanical and chromatographic properties. React Funct Polym 78:32–37

Haloi DJ, Roy S, Singha NK (2009) Copper catalyzed atom transfer radical copolymerization of glycidyl methacrylate and 2-ethylhexyl acrylate. J Polym Sci Part A Polym Chem 47:6536–6533

Khelifa F, Habibi Y, Bénard F, Dubois P (2012) Effect of cellulosic nanowhiskers on the performances of epoxidized acrylic copolymers. J Mater Chem 22:20520–20528

Khelifa F, Druart ME, Habibi Y, Bénard F, Leclère P, Olivier M, Dubois P (2013) Sol–gel incorporation of silica nanofillers for tuning the anti-corrosion protection of acrylate-based coatings. Prog Org Coatings 76(5):900–911

Daniel H, Pavlo S (2000) Reactive poly(glycidyl methacrylate) microspheres prepared by dispersion polymerization. J Polym Sci Part A Polym Chem 38(21):3855–3863

Vidts KRM, Dervaux B, Du Prez FE (2006) Block, blocky gradient and random copolymers of 2-ethylhexyl acrylate and acrylic acid by atom transfer radical polymerization. Polymer 47(17):6028–6037

Dhal PK, Ramakrishna MS, Babu GN (1982) Copolymerization of glycidyl methacrylate with alkyl acrylate monomers. J Polym Sci Part A Polym Chem 20(6):1581–1585

Tsai CH, Chang FC (1996) Polymer blends of PBT and PP Compatibilized by ethylene-co-glycidyl methacrylate copolymers. J Appl Polym Sci 61(2):321–332

Souza AMC, Caldeira CB (2015) An investigation on recycled PET/PP and recycled PET/PP-EP compatibilized blends: Rheological,morphological, and mechanical properties. J App Polym Sci 132:41892

Wang X, Yu W, Nie Q, Guo Y, Du J (2011) A real-time study on the evolution of the degradation of polypropylene during mixing process. J App Polym Sci 121:1220–1243

Duarte IS, Tavares AA, Lima PS, Andrade DLACS, Carvalho LH, Canedo EL, Silva SML (2016) Chain extension of virgin and recycled poly(ethylene terephthalate): effect of processing conditions and reprocessing. Polym Degrad Stab 124:26–34

Luongo JP (1960) Infrared study of polypropylene. J Appl Polym Sci 3(9):302–309

Miyake A (1959) The infrared spectrum of polyethylene terephthalate. I the effect of crystallization. J Polym Sci 38(134):479–495

Daniels WW, Kitson RE (1958) Infrared spectroscopy of polyethylene terephthalate. J Polym Sci 33(126):161–170

Erol I, Poyraz B, Koroglu MA, Cifci C (2009) Copolymerization of 2-methyl-N-1,3-thiazole-2-ylacrilamide with glycidyl methacrylate:synthesis, characterization, reactivity ratios and biological activity. J Polym Res 16(1):19–28

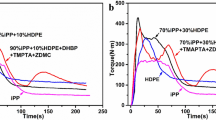

Kalfoglou NK, Skafidas DS, Kallitsis J, Lambert JC, Stappen LV (1995) Comparison of compatibilizer effectiveness for PET/HDPE blends. Polymer 26(23):4453–4462

Berti C, Bonora V, Colonna M, Lotti N, Sisti L (2003) Effect of carboxyl end groups content on the thermal and electrical properties of poly(propylene terephthalate). Eur Polym J 39(8):1595–1601

Jabarin SA, Lofgren EA (1984) Thermal stability of polyethylene terephthalate. Polym Eng Sci 24(13):1056–1063

Al-AbdulRazzak S, Jabarin SA (2002) Processing characteristics of poly(ethylene terephthalate): hydrolytic and thermal degradation. Polym Int 51(2):164–173

Zhu Y, Liang C, Bo Y (2015) Non-isothermal crystallization behavior of compatibilized polypropylene / recycled polyethylene terephthalate blends. J Therm Anal Calorim 119(3):2005–2013

Zhu Y, Liang C, Bo Y, Xu S (2015) Compatibilization of polypropylene/recycled polyethylene terephthalate blends with maleic anhydride grafted polypropylene in the presence of diallyl phthalate. J Polym Res 22:35

Inoya H, Leong YW, Klinklai W, Thumsorn S, Makata Y, Hamada H (2011) Compatibilization of recycled poly(ethylene terephthalate) and polypropylene blends: effect of polypropylene molecular weight on homogeneity and compatibility. J Appl Polym Sci 124(5):3947–3955

Kunimune N, Yamada K, Leong YW, Thumsorn S, Hamada H (2010) Influence of the reactive processing of recycled poly(ethylene terephthalate)/poly(ethylene-co-glycidyl methacrylate) blends. J Appl Polym Sci 120(1):50–55

Jayanarayanan K, Thomas S, Joseph K (2011) In situ microfibrillar blends and composites of polypropylene and poly (ethylene terephthalate): morphology and thermal properties. J Polym Res 18(1):1–11

Coelho JFJ, Carreira M, Popov AV, Gonçalves PMOF, Gil MH (2006) Thermal and mechanical characterization of poly(vinyl chloride)-b-poly(butyl acrylate)-b-poly(vinyl chloride) obtained by single electron transfer – degenerative chain transfer living radical polymerization in water. Eur Polym J 42(10):2313–2319

Coelho JFJ, Carreira M, Gonçalves PMOF, Popov AV, Gil MH (2006) Processability and characterization of poly(vinyl chloride)-b-poly(n-butyl acrylate)-b-poly(vinyl chloride) prepared by living radical polymerization of vinyl chloride. Comparison with a flexible commercial resin formulation prepared with PVC and dioctyl phthalate. J Vinyl Addit Technol 12(4):156–165

Schlesing W, Buhk M, Osterhold M (2004) Dynamic mechanical analysis in coatings industry. Prog Org Coatings 49(3):197–208

Yasaku W, Yasuko H, Ryuji S (1968) Glass transition and relaxation in the amorphous phase of isotactic polypropylene. J Polym Sci Part C Polym Symp 23(2):583–595

Inoya H, Leong YW, Klinklai W, Takai Y, Hamada H (2012) Compatibilization of recycled poly(ethylene terephthalate) and polypropylene blends: effect of compatibilization on blend toughness, dispersion of minor phase and thermal stability. J Appl Polym Sci 124:5260–5269

Acknowledgments

The authors acknowledge project Flexmodulo, POCI-01-0247-FEDER-003362 for financial support. The 1H NMR data was collected at the UC-NMR facility which is supported in part by FEDER –European Regional Development Fund through the COMPETE Programme (Operational Programme for Competitiveness) and by National Funds through FCT – Fundação para a Ciência e a Tecnologia (Portuguese Foundation for Science and Technology) through grants REEQ/481/QUI/2006, RECI/QEQ-QFI/0168/2012, CENTRO-07-CT62-FEDER-002012, and Rede Nacional de Ressonância Magnética Nuclear (RNRMN).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 7415 kb)

Rights and permissions

About this article

Cite this article

Lima, M.S., Matias, Á.A., Costa, J.R.C. et al. Glycidyl methacrylate-based copolymers as new compatibilizers for polypropylene/ polyethylene terephthalate blends. J Polym Res 26, 127 (2019). https://doi.org/10.1007/s10965-019-1784-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1784-7