Abstract

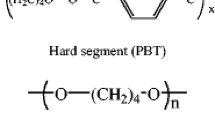

The changes in performance characteristics, such as tenacity and elastic recovery, of copolyether-ester fibers were compared for different post-heat treatments (with or without tension). The differences in the mechanical behaviour were linked to changes in the microstructure which are obtained from wide angle X-ray scattering (WAXS), small X-ray scattering (SAXS) and birefringence techniques. The obtained results showed that the performance of the fibers is strongly dependent on the heat-treatment conditions. The treatment with tension proved to be an effective and viable approach for comprehensively improving the performance characteristics of the fibers, such as tenacity, elasticity and stability. A clear distinction is observed for the treatment without tension, which increases the elasticity but lowers the tenacity of the fibers. Heat treatments without tension lead to small crystal formations and partial crystal fusion between some small crystalline regions within the fibers. The lower molecular orientation during this process leads to the loss of tenacity. When heat treated with tension, a small amount of amorphous hard segments began to crystallize under the tensile stress, resulting in larger phase separation, and part of the amorphous region became oriented, improving the tenacity and elastic recovery of the fibers.

Similar content being viewed by others

References

Chen J, Pan H, Li G, Jiang J (2002) Spinning process and properties of polyether ester elastic fiber, China synthetic fiber industry 25: 20-23. (Chinese)

Zhao Q, Xia H (1994) Polyether ester elastic fibers. Textile Sci Research 1:18–22 (Chinese)

Richeson GC, Spruiell JE (1990) Preparation, structure, and properties of copolyester-ether elastic filaments. J Appl Polym Sci 41:845–875

Zhou J, Li Y, Yin H, Wu T, Zhang D (2000) Study on the improvement of the elastic recovery of polyetherester elastic filaments, China synthetic fiber industry 23: 23-26. (Chinese)

Abhiraman AS, Kim YW, Wagener KB (1987) Evolution of structure and properties in fiber formation from a thermoplastic polyester-polyether segmented copolymer. J Polym Sci Polym Phys 25:205–228

Yan T, Yao Y, Jin H, Yu J, Zhang Y, Wang H (2016) Elastic response of copolyether-ester fiber on its phase morphology under different heat-treatment condition. J Polym Res 23:226

Lan J, Wu D, Yang D, Jian X (2002) Influence of heat setting on the structure and properties of block poly(ether ester) elastic fiber, China synthetic fiber industry 25: 12-15. (Chinese)

Fakirov S, Fakirov C, Fischer EW, Stamm M, Apostolov AA (1993) Reversible morphological changes in poly (ether ester) thermorplastic elastomers during deformation as revealed by small-angle x-ray scattering. Colloid Polym Sci 271:811–823

Fakirov S, Fakirov C, Fischer EW, Stamm M (1991) Deformation behaviour of poly(ether ester) thermoplastic elastomers as revealed by small-angle X-ray scattering. Polymer 32:1173–1780

Stribeck N, Apostolov AA, Zachmann HG, Fakirov C, Stamm M, Fakirov S (1994) Small angle X-ray scattering of segmented block copolyetheresters during stretching. Int J Polym Mater 25:185–200

Cho DH, Yub WR, Yoo JH (2007) Formation of micro-crystals in poly(ethylene terephthalate) fiber by a short heat treatment and their influence on the mechanical properties. Eur Polym J 43:3562–3572

Lee KG, Schultz JM (1993) The development of structure and mechanical properties in poly(ethylene terephthalate) fibers during heat treatment under stress. Polymer 34:4455–4470

Simal AL, Martin AR (1998) Structure of heat-treated nylon 6 and 6.6 fibers. II. Recrystallization mechanism. J Appl Polym Sci 68:453–474

Murthy NS, Bednarczyk C, Moore RAF, Grubb DT (2015) Analysis of small-angle X-ray scattering from fibers: structural changes in nylon 6 upon drawing and annealing. J Polym Sci Polym Phys 34:821–835

Vasanthan N, Salem DR (2015) FTIR spectroscopic characterization of structural changes in polyamide-6 fibers during annealing and drawing. J Polym Sci Polym Phys 39:536–547

Nadella HP, Spruiell JE, White JL (2010) Drawing and annealing of polypropylene fibers: structural changes and mechanical properties. J Appl Polym Sci 22:3121–3133

Somani RH, Hsiao BS, Nogales A, Fruitwala H, Srinivas S, Tsou AH (2001) Structure development during shear flow induced crystallization of i-PP: in situ wide-angle X-ray diffraction study. Macromolecules 34:5902–5909

Zhang Y, Wang H, Chen S, Wang X, Fang D, Burger C, Che J, Li X, Hsiao BS (2013) Determination of poly(4,4′-diphenylsulfonyl terephthalamide) crystalline structure via WAXD and molecular simulations. Macromol Chem Phys 214:2432–2438

Yu J, Tian F, Chen S, Wang X, Zhang Y, Wang H (2015) Structure and property development of aromatic copolysulfonamide fibers during wet spinning process. J Appl Polym Sci 132:42343

Murthy NS, Grubb DT (2010) Tilted lamellae in an affinely deformed 3D macrolattice and elliptical features in small-angle scattering. J Polym Sci Polym Phys 44:1277–1286

Murthy NS, Grubb DT, Zero K (2000) Structural implications of the elliptical form of small-angle reflections in oriented semicrystalline polymers. Macromolecules 33:1012–1021

Murthy NS, Zero K, Grubb DT (1996) Full-pattern parameterization of two-dimensional diffraction and scattering data from oriented polymers. Acta Crystallogr 52:480–486

Zhou RJ, Burkhart T (2011) Thermal and mechanical properties of poly(ether ester)-based thermoplastic elastomer composites filled with TiO2 nanoparticles. J Mater Sci 46:2281–2287

Ran S, Fang D, Zong X, Hsiao BS, Chu B, Cunniff PM (2001) Structural changes during deformation of kevlar fibers via on-line synchrotron saxs/waxd techniques. Polymer 42:1601–1612

Jiang G, Huang W, Lin L, Xiao W, Pang F, Zhang Y, Wang H (2012) Structure and properties of regenerated cellulose fibers from different technology processes. Carbohydr Polym 87:2012–2018

Li H, White JL (2000) Structure development in melt spinning filaments from polybutylene terephthalate based thermoplastic elastomers. Polym Eng Sci 40:917–928

Yoshihara N, Ishihara H, Yamada T (2003) Effect of dry-spinning and post-treatment conditions on structure and properties of segmented poly(urethane-urea) elastic fibers. J Polym Eng 23:259–280

Acknowledgements

This work was supported by China Postdoctoral Science Foundation (2017 M620125) and the Fundamental Research Funds for the Central Universities (17D110622).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 1359 kb)

Rights and permissions

About this article

Cite this article

Yu, J., Yan, T., Ji, H. et al. The evolution of structure and performance in copolyether-ester fibers with different heat-treatment process. J Polym Res 26, 50 (2019). https://doi.org/10.1007/s10965-019-1714-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1714-8