Abstract

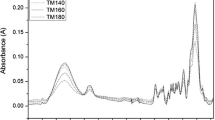

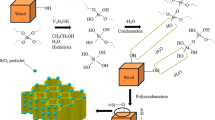

Hydrothermal treatment was considered as a method for modification of oriental beech wood to be used as reinforcing filler for natural rubber. Surface energy of treated wood fibers and their interaction with natural rubber were studied by water contact angle of wood and dynamic-mechanical-thermal analysis of formed bio-composites and compared with those for untreated and silane-treated wood fibers. Hydrothermal treatment of wood was performed at two temperatures of 140 °C and 160 °C, and bio-composites were prepared by melt mixing method. Results showed that water contact angle of untreated wood increases by hydrothermal treatment and silane modification of wood fibers, which the latter has the highest value. Dynamic-mechanical-thermal analysis of bio-composites showed that hydrothermal treatment reduced interactions between wood fibers and increased interaction between fibers and rubber which resulted in better dispersion of fibers, observed by scanning electron microscopy. In order to investigate reinforcing effect of hydrothermally treated wood fibers, mechanical properties of bio-composites in tension was studied, and improvement in tensile strength and elongation at break for bio-composites containing treated fibers was observed, which was correlated to the stronger wood fiber-rubber interface compared to untreated ones. Wood fibers treated at 140 °C showed better mechanical properties, which was comparable with silane modified fibers.

Similar content being viewed by others

References

Abdelmouleh M, Boufi S, Belgacem MN, Dufresne A (2007) Short natural-fiber reinforced polyethylene and natural rubber composites: effect of Silane coupling agents and fibers loading. Compos Sci Technol 67:1627–1639

Maya J, Bejoy F, Varughese KT, Thomas S (2008) Effect of chemical modification on properties of hybrid fiber biocomposites. Compos: A 39:352–363

Mohanty AK, Misra M, Drzal LT (2002) Sustainable bio-composites from renewable resources: opportunities and challenges in the green materials world. Polym Environ 10:19–26

Drzal LT, Mohanty AK, Misra M (2000) Bio-composite materials as alternatives to petroleum-based composites for automotive applications. Magnesium 40:1–3

Nabi Saheb D, Jog JP (1999) Natural fiber polymer composites: a review. Adv Polym Technol 18:351–363

Ooi ZX, Ismail H, Abu Bakar A (2013) Synergistic effect of oil palm ash filled natural rubber compound at low filler loading. Polym Test 32:38–44

Pantamanatsopaa P, Ariyawiriyanana W, Meekeawa T, Suthamyonga R, Arruba K, Hamadab H (2014) Effect of modified jute fiber on mechanical properties of green rubber composite. Energy Proced 56:641–647

Ortiz-Serna P, Díaz-Calleja R, Sanchis MJ, Riande E, Nunes R, Martins A, Visconte L (2011) Dielectric spectroscopy of natural rubber-cellulose II nanocomposites. Non-Cryst Sol 357:598–604

Ismail H, Jaffri RM, Rozman HD (2000) Oil palm short fiber filled natural rubber composites: fatigue and hysteresis behavior. Polym Int 49:618–622

Xie Y, Hill CAS, Xiao Z, Militz H, Mai C (2010) Silane coupling agents used for natural fiber/polymer composites: a review. Compos Part A 41:806–819

Ismail H, Rusli A, Rashid AA (2005) Maleated natural rubber as a coupling agent for paper sludge filled natural rubber composites. Polym Test 24:856–862

Maya J, Sabu T, Varughese KT (2004) Novel woven sisal fabric reinforced natural rubber composites: tensile and swelling characteristics. Compos. Mater 00:1–14

Maya J, Sabu T, Varughese KT (2005) Mechanical properties of short flax fibre bundle/polypropylene composites: influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos Sci Technol 65:1582–1592

Ooi ZX, Ismail H, Abu BA (2014) Thermal properties and aging characteristics of chemically modified oil palm ash-filled natural rubber composites. Iran Polym 23:723–730

Maya J, Varughese KT, Sabu T (2005) Water sorption studies of hybrid biofiber-reinforced natural rubber biocomposites. Biomacromolecules 6:2969–2979

Ismail H, Edyham MR, Wirjosentono B (2001) Dynamic properties and swelling behaviour of bamboo filled natural rubber composites: the effect of bonding agent. Iranian Polym 10:377–383

Cantero G, Arbelaiz A, Llano-Ponte R, Mondragon I (2003) Effects of fiber treatment on wettability and mechanical behavior of flax/polypropylene composites. Compos Sci Technol 63:1247–1254

Hussain H, Abdel-Kader A, Ibrahim A (2010) Effect of modified linen fiber waste on Physico-mechanical properties of polar and non-polar rubber. Natur Sci 8:82–93

Li X, Tabil LG, Satyanarayan P (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. Polym Environ 15:25–33

Mansour SH, El-Nashar DE, Abd-El-Messieh SL (2006) Effect of chemical treatment of wood flour on the properties of styrene butadiene rubber/polystyrene composites. App Polym Sci 102:5861–5870

Ismail H, Muniandy K, Othman N (2012) Fatigue life, morphological studies and thermal aging of rattan powder-filled natural rubber composite as a function of filler loading and a Silane coupling agent. Bio. Resources 7:841–858

John ZL, Wu Q, McNabb HS (2000) Chemical coupling in wood fiber and polymer composites: a review of coupling agents and treatments. Wood Fib Sci 32:88–104

Bisanda ETN, Ansell MP (1991) The effect of silane treatment on the mechanical and physical properties of sisal–epoxy composites. Compos Sci Technol 41:165–178

Zhao Y, LU W, Chen J, Zhang X, Wang H (2014) Research progress on hydrothermal dissolution and hydrolysis of lignocellulose and lignocellulosic waste. Front Environ Sci Eng 8:151–161

Garrote G, Domõ H, Ânguez J, Paraj C (1999) Hydrothermal processing of lignocellulosic materials. Holz Roh Werkst 57:191–202

Rezayati Charani P, Mohammadi Rovshandeh J, Mohebby B, Ramezani O (2007) Influence of hydrothermal treatment on the dimensional stability of beech wood. Caspian J Environ Sci 5(1):25–131

Mirzaei G, Mohebby B, Tasooji M (2012) The effect of hydrothermal treatment on bond shear strength of beech wood. Eur J Wood Prod 70:705–709

Tjeerdsma BF, Militz H (2005) Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Eur J Wood Prod 63:102–111

Yildiz S, Gümüșkaya E (2007) The effects of thermal modification on crystalline structure of cellulose in soft and hardwood. Build Environ 42:62–67

Ayrilmis N, Jarusombuti S, Fueangvivat V, Bauchongkol P (2011) Effect of thermal-treatment of wood fibres on properties of flat-pressed wood plastic composites. Polym Degrad Stab 96:818–822

Ibbett R, Gaddipati S, Davies S, Hill S, Tucker G (2011) The mechanisms of hydrothermal deconstruction of lignocellulose: new insights from thermal–analytical and complementary studies. J. Bioresour Technol 102:9272–9278

Hakkou M, Petrissans M, Zoulalin A, Gerardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Deg Stab 89:1–5

Mohebby B, Ilbeighi F, Kazemi-NajafiS (2008) Influence of hydrothermal modification of fibers on some physical and mechanical properties of medium density fiberboard (MDF). Holz Roh Werkst 66: 213–218

Tjeerdsma BF, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterization of thermal modified wood: molecular reasons for wood performance improvement NMR. Holz Roh Werkst 56:149–153

Dwianto W, Tanaka F, Inoue M, Norimoto M (1996) Crystallinity changes of wood by heat or steam treatment. Wood Research 83:47–49

Valadez-Gonzalez A, Cervantes-Uc JM, Olayo RJ, Herrera-Franco PJ (1999) Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites. Compos Part B 30(3):309–320

Zierdt P, Theumer T, Kulkarni G, Däumlich V, Klehm J, Hirsch U, Weber A (2015) Sustainable wood-plastic composites from bio-based polyamide 11 and chemically modified beech fibers. Sustain. Mater Technol 6:6–14

Ichazo MN (2006) Herna’ndez M, Albano C. Curing and Physical Properties of Natural Rubber/Wood Flour Composites Polym Test 21:139–144

Vladkova T, Vassileva St, Natov M (2003) Wood Flour: A New Filler for the Rubber Processing Industry I Cure Characteristics and Mechanical Properties of Wood Flour-Filled NBR and NBR/PVC Compounds .J App Polym Sci 90:2734–2739

Maya J, Thomasa S, Varugheseb KT (2004) Mechanical properties of sisal/oil palm hybrid fiber reinforced natural rubber composites. Compos Sci Technol 64:955–965

Gindl M, Sinn G, Gindl W, Reiterer A, Tschegg S (2001) A comparison of different methods to calculate the surface free energy of wood using contact angle measurements colloids. Surf A: Physicochem Eng Aspects 181:279–287

Hosseini SM, razzaghi Kashani M (2014) Vulcanization kinetics of nano-silica filled styrene butadiene rubber. Polym 55:6426–6434

Sundqvist B, Kalrsson O, Westermark U (2006) Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness. Wood Sci Technol 40(7):549–561

Ohlmeyer M, Lukowsky D (2004) Wood-based panels produced from thermal-treated materials: Properties and perspectives. Conference on Wood Frame Housing Durability and Disaster Issue, 4–6th Oc, Las Vegas, pp 127–131

Paul W, Ohlmeyer M, Leithoff H, Boonstra MJ, Pizzi A (2006) Optimising the properties of OSB by a one-step heat pre-treatment process. Holz Roh-Werkst 64(3):227–234

Rowell R, editor (2005) Handbook of wood chemistry and wood composites, vol. 1. New York: CRC Press; p. 330

Frohlich J, Niedermeier W, Luginsland HD (2005) The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos Part A 36:449–460

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tavassoli, F., Razzaghi-Kashani, M. & Mohebby, B. Hydrothermally treated wood as reinforcing filler for natural rubber bio-composites. J Polym Res 25, 3 (2018). https://doi.org/10.1007/s10965-017-1394-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1394-1