Abstract

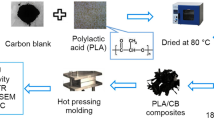

In this work, highly electrically and thermally conductive biopolymer composites were prepared by low-temperature expandable graphite (EG) filling Poly(L-lactic acid) (PLLA) via an in situ exfoliation melt blending process. The electrical conductivity of the composites with various graphite contents was measured by a four-point probe resistivity determiner and a high value of 0.37 S/cm was obtained at 70 wt.% EG content. A hot-disk method was used to evaluate the thermal conductivity of the composites. At EG loading fraction of 70%, thermal conductivity of PLLA/EG composites reached to the highest 26.87 W/mK, which is 100 times higher than neat PLLA. The electrical percolation was observed in the vicinity of the thermal percolation threshold concentration. The expansion of EG was crucial to the overall conductivity of the blends, which was confirmed by X-ray diffraction (XRD) analysis and scanning electron microscope (SEM). Dynamic rheology analysis was applied to study the structural change by the interconnection of the exfoliated graphite flakes and the formation of the networks in the blends. Thermogravimetric analysis (TGA) was employed to determine the thermal properties of the investigated PLLA/EG composites.

Similar content being viewed by others

References

Chang J, Ho A, Chin WK (2007) J Polym Sci Part B Polym Phys 45:322–329

Luo Y, Liu Y, Yu Q (2007) Thin Solid Films 515:4016–4023

Zhou S, Chen Y, Zou H, Liang M (2013) Thermochim Acta 566:84–91

Zhou S, Lei Y, Zou H, Liang M (2013) Polym Compos 34:1816–1823

Kasgoz A, Akın D, Durmus A (2012) Polym Eng Sci 52:2645–2653

Han Z, Fina A (2011) Prog Polym Sci 36:914–944

Narkis M, Ram A, Flashner F (1978) Polym Eng Sci 18:649–653

Dai K, Xu XB, Li ZM (2007) Polymer 48:849–859

Zribi K, Feller JF, Elleuch K, Bourmaud A, Elleuch B (2006) Polym Adv Technol 17:727–731

Jouni M, Boudenne A, Boiteux G, Massardier V, Garnier B, Serghei A (2013) Polym Compos 34:778–786

Wu X, Qi S, He J, Chen B, Duan G (2010) J Polym Res 17:751–757

Agari Y, Ueda A, Nagai S (1994) J Appl Polym Sci 52:1223–1231

Shi SL, Zhang LZ, Li JS (2009) J Polym Res 16:395–399

Kim DJ, Seo KH, Hong KH, Kim SY (1999) Polym Eng Sci 39:500–507

Yi XS, Zhang JF, Zheng Q, Pan Y (2000) J Appl Polym Sci 77:494–499

Xue B, Feng T, Zhou S, Bao J (2014) J Poly Res 21:1–8

Gao JF, Yan DX, Huang HD, Zeng XB, Zhang WQ, Li ZM (2011) J Polym Res 18:2239–2243

Saleem A, Frormann L, Iqbal A (2007) J Polym Res 14:121–127

McCullen SD, Stano KL, Stevens DR, Roberts WA, Monteiro-Riviere NA, Clarke LI, Gorga RE (2007) J Appl Polym Sci 105:1668–1678

Villmow T, Pötschke P, Pegel S, Häussler L, Kretzschmar B (2008) Polymer 49:3500–3509

Fina A, Han Z, Saracco G, Gross U, Mainil M (2012) Polym Adv Technol 53:2412–2421

Uhl FM, Yao Q, Wilkie CA (2005) Polym Adv Technol 16:533–540

Lee Y, Kim D, Seo J, Han H, Khan SB (2013) Polym Int 62:1386–1394

Pan YX, Yu ZZ, Ou YC, Hu GH (2000) J Polym Sci Part B Polym Phys 38:1626–1633

Zhao YF, Xiao M, Wang SJ, Ge XC, Meng YZ (2007) Compos Sci Technol 67:2528–2534

Liu X, Wu Q (2002) Eur Polym J 38:1383–1389

Chiu HT, Hsiao YK (2006) J Polym Res 13:153–160

Yu J, Wang N, Ma X (2008) Biomacromolecules 9:1050–1057

Vainionpää S, Rokkanen P, Törmälä P (1989) Prog Polym Sci 14:679–716

Mehta R, Kumar V, Bhunia H, Upadhyay SN (2005) Polym Rev 45:325–349

He F, Li S, Vert M, Zhuo R (2003) Polymer 44:5145–5151

Leenslag JW, Pennings AJ, Bos RRM, Rozema FR, Boering G (1987) Biomaterials 8:311–314

Kricheldorf HR, Boettcher C, Tönnes KU (1992) Polymer 33:2817–2824

Lunt J (1998) Polym Degrad Stabil 59:145–152

Bos RRM, Rozema FB, Boering G, Nijenhius AJ, Pennings AJ, Verwey AB, Nieuwenhuis P, Jansen HWB (1991) Biomaterials 12:32–36

Penning JP, Dijkstra H, Pennings AJ (1993) Polymer 34:942–951

Penning JP, Grijpma DW, Pennings AJ (1993) J Mater Sci Lett 12:1048–1051

Fambri L, Pegoretti A, Fenner R, Incardona SD, Migliaresi C (1997) Polymer 38:79–85

Chen Y, Zou H, Liang M, Liu P (2013) J Appl Polym Sci 129:945–953

Ling W, Gu A, Liang G, Yuan L (2010) Polym Compos 31:307–313

Yasmin A, Luo JJ, Daniel IM (2006) Compos Sci Technol 66:1182–1189

Uhl FM, Yao Q, Nakajima H, Manias E, Wilkie CA (2005) Polym Degrad Stabil 89:70–84

Ying Z, Lin X, Qi Y, Luo J (2008) Mater Res Bull 43:2677–2686

Pötschke P, Fornes TD, Paul DR (2002) Polymer 43:3247–3255

Miyata T, Masuko T (1997) Polymer 38:4003–4009

King JA, Jhonson BA, Via MD, Ciarkowski CJ (2010) Polym Compos 31:497–506

Kasgoz A, Akın D, Durmus A (2012) Polym Eng Sci 52:2645–2653

Zhao YF, Xiao M, Wang SJ, Ge XC, Meng YZ (2007) Compos Sci Technol 67:2528–2534

Acknowledgments

The authors would like to express their thanks to the Analytical and Testing Center of Sichuan University for providing dynamic rheological tests and SEM observations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, B., Ye, J. & Zhang, J. Highly conductive Poly(L-lactic acid) composites obtained via in situ expansion of graphite. J Polym Res 22, 112 (2015). https://doi.org/10.1007/s10965-015-0755-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-015-0755-x