Abstract

In this work, reverse atom transfer radical copolymerization of styrene and acrylonitrile was investigated at 65 °C in ionic liquid microemulsion using 2,2’-azobis(isobutyronitrile) (AIBN) as initiator, FeCl3·6H2O/succnic acid as catalyst complex, and hexadecyl trimethyl ammonium bromide as surfactant. The copolymers of styrene and acrylonitrile (SAN) with predetermined molecular weights and narrow molecular weight distribution were obtained. Results showed that the polymerization proceeded in a controlled/‘living’ process in which the molecular weight of SAN increased with increasing the monomer conversion. The size of the resulting SAN particle was investigated. The monomer reactivity ratios increased with increasing the molar ratio of acrylonitrile to styrene. The obtained polymer was characterized by 13C nuclear magnetic resonance and gel permeation chromatography. The living characteristics were demonstrated by chain extension experiment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The living radical polymerization offers an attractive route to synthesize polymers with well-defined structures [1]. Three radical polymerization techniques have been extensively studied: nitroxide-mediated living radical polymerisation (NMP) [2, 3], atom transfer radical polymerization mediated by a transition metal complex (ATRP) [4–6] and reversible addition fragmentation chain transfer polymerization (RAFT) [7, 8]. Among them, ATRP was a robust technique and has been applied under heterogeneous conditions in suspension [9, 10], dispersion [11], ab initio emulsion [12], seeded emulsion [13], miniemulsion [14, 15] and microemulsion [12, 16, 17].

Microemulsions are clear, thermodynamically stable, isotropic liquid mixtures of oil, water and surfactant, frequently in combination with a cosurfactant. In contrast to ordinary emulsions, microemulsions form upon simple mixing of the components and do not require the high shear conditions generally used in the formation of ordinary emulsions. However, there are some limits on conducting ATRP in microemulsion, for example, higher amount of surfactant compared with conventional emulsion polymerization and solubility limitations for apolar solutes remains. The limits can be overcome by ionic liquid microemulsion due to the combined advantages of both ionic liquids and microemulsions.

Ionic liquid is a salt in which the ions are poorly coordinated, resulting in these solvents being liquid below 100 °C, or even at room temperature (room temperature ionic liquids, RTIL’s). RTILs are developed to replace traditional organic solvents and used in microemulsion to widen the application fields of ionic liquid. Ionic liquid microemulsion as a ‘green solvent’ has been extensively investigated in varied fields of biocatalysis [18], polymerization [19–22], nanoparticle [23] and organic synthesis [24].

Reverse atom transfer radical polymerization (RATRP) is one of improved ATRP techniques. In a RATRP system, it was not sensitive to air due to higher oxidation transition metals used. Iron complex catalyst is one of the most commonly transition metals and has been applied in controlled/living polymerization [25–28]. Iron was easily complexed with more environmentally friendly organic acid [29–31].

Copolymers (SAN) of styrene (St) and acrylonitrile (AN) have been applied in numerous fields due to its outstanding chemical and mechanical properties. Its application would be further enhanced by an additional control of molecular weights, molecular weight distribution (MWD), and chain topology. There are some reports about controlled/living copolymerization of styrene and acrylonitrile [32–34]. To the authors’ knowledge, there are no reports about controlled/living copolymerization of styrene and acrylonitrile in ionic liquid microemulsion.

In this study, copolymerizations of styrene and acrylonitrile were conducted in ionic liquid microemulsion under reverse atom transfer radical polymerization using 2,2’-azobis(isobutyronitrile) (AIBN) as initiator, FeCl3·6H2O/Succinic acid (SA) as complex catalyst, cetytrimethylammonium bromide (CTAB) as surfactant and 1-butyl-3-methylimidazolium hexafluorophate ([bmim][PF6]) as ionic liquid. The end-functionality of the copolymers was estimated from the chain extension reaction.

Experimental

Materials

The ionic liquid [bmim][PF6] was purchased from Aladdin Reagents Co., Ltd, Shanghai, China. Styrene (Analytic Reagent grade, AR grade) was purchased from Tianjin Fuchen Chemical Reagents Factory, China. It was distilled under reduced pressure prior to use. Acrylonitrile (Analytic Reagent grade, AR grade) was purchased from Tianjin Bodi Chemical Holding Co., Ltd., China. It was distilled under reduced pressure prior to use. AIBN, obtained from Shanghai Chemical Holding Co., Ltd, China, was recrystallized twice from methanol. Ferric chloride hexahydrate was purchased from Shanghai Qingfeng Chemical Factory, China. Succinic acid (SA, Analytic Reagent grade, AR grade), was purchased Chongqing Chuangdong Chemical (Group) Co., Ltd, China. Benzoyl peroxide (BPO) and hexadecyl trimethyl ammonium bromide (CTAB) was obtained from Sinopharm Chemical Reagent Co., Ltd., Shanghai, China. BPO was recrystallized twice from ethanol. Other regents were used as received.

Polymerization procedure

The microemulsion systems were prepared by dissolving CTAB in ionic liquid in a 100 mL three-neck round-bottom flask equipped with magnetic stirring bar. Then the monomer, FeCl3·6H2O and succinic acid were added. Finally, AIBN was added. The mixture was mildly stirred until the transparent homogeneous phase was reached. The flask was degassed three times under vacuum, and flushed with nitrogen. Then the flask was placed in an oil bath held by a thermostat at 65 °C. After the desired time, the polymerizations were stopped by immersing into ice water. The copolymer samples were precipitated by a large quantity of methanol. The obtained copolymers were purified by repeated washing with methanol, and then vacuum-dried at 60 °C for 1 day until constant weight.

In a typical experiment, the molar ratio of [AN+St]:[AIBN]:[FeCl3·6H2O]:[SA] was fixed at 500:1:1:2, and the molar ratio of AN to St was 0.45:0.55. Thus, a dry flask was charged with 6.2520 g [bmim][PF6] (22 mmol) and 2.5000 g CTAB (7 mmol) and mixed, then 0.4775 g AN (9 mmol), 1.1440 g St (11 mmol), 0.0108 g FeCl3·6H2O (0.04 mmol), 0.0094 g Succinic acid (0.08 mmol) and 0.0066 g AIBN (0.04 mmol) were in turn added to the flask.

Measurements

Monomer conversion was determined by gravimetric analysis at different intervals. The conversion (C) was determined by the following formula:

Where W1 was the initial weight of the comonomers and W2 was the weight of the obtained copolymer.

The number-average molecular weights (Mn,GPC) and MWDs of the resulting SAN were determined by gel permeation chromatography (GPC), conducted with a Waters 1515 equipped with refractive index detector using tetrahydrofuran (THF) as a mobile phase at a flow rate of 1.0 mL/min at 35 °C. Linear polystyrene standards were used to calibrate the columns.

13C NMR spectrum was recorded for the polymer samples on a Bruker 400 MHz Spectrometer using CDCl3 as the solvent at ambient temperature and tetramethylsilane as the internal standard.

Particle size was determined by using Malvern Mastersizer 2000 equipment. The particle size distribution obtained was based on volume, i.e., the particle size interval obtained represented the total volume (%) of all particles with a diameter included in this interval in relation to the total volume of all particles in the distribution.

Results and discussion

Reverse atom transfer radical copolymerization of St and AN in ionic liquid microemulsion

The feasibility of reverse atom transfer radical copolymerization of St and AN was investigated in ionic liquid microemulsion. SAN copolymer was prepared by RATRP process using FeCl3/succinic acid (SA)/AIBN catalyst system in ionic liquid microemulsion as described in Scheme 1.

Figure 1 shows the semilogarithmic kinetic plots for the reverse atom transfer copolymerization with varied molar ratios of St/AN. As shown in Fig. 1, a linear relationship between ln([M]0/[M]) and time was observed, indicating first-order kinetics with respect to monomer consumption and a constant radical concentration during the polymerization process. The copolymerization rate increased with the increase of AN monomer feed until the molar ratio of AN/St was 50:50, and then the copolymerization rate decreased with the increase of AN monomer feed. This is due to the formation of charge transfer complex. Similar results were reported by Hill et al. [33].

Figure 2 shows the dependence of the number average molecular weight (Mn) and the polydispersities (PDI) of the obtained SAN versus monomer conversion at different molar ratios of AN/St. As shown, the molecular weights of the resulting SAN copolymers measured by GPC increased with monomer conversion. Furthermore, in most cases, the molecular weight distributions were below 1.3. The results indicated that copolymerization of AN/St proceeded in a controlled/living fashion. However, at the beginning of copolymerization, some higher molecular weights were obtained due to incomplete decomposition of AIBN. The copolymerization proceeded in a conventional radical polymerization. This was further confirmed by broader molecular weight distribution during the initial polymerization.

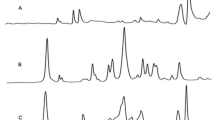

SAN copolymer for ionic liquid microemulsion system was determined using 13C nuclear magnetic resonance spectroscopy. Figure 3 shows 13C NMR spectrum of the resulting SAN copolymer. The peaks at 120.6–121.8 ppm were assigned to the group of CN. The signals at 126.1–130.4 ppm were attributed to the aromatic ring group. The signals at 25.3–27.3 ppm corresponded to the methine group of CH. The signals at 35.8–41.6 ppm were attributed to the methylene group of CH2.

The particle size distribution is shown in Fig. 4. Particle size showed a distribution between 5 and 60 nm, with irregular peaks between 10.1 and 20 nm.

Monomer reactivity ratios calculated from 13C NMR spectrum

According to the literature [34], Fineman-Ross and Kelen-Tudos methods were not used to calculate the reactivity ratios of copolymerization of St and AN because it was difficult to obtain linear plots. A series of experiments with different feed molar ratios were carried out under the same experimental conditions and the components were determined by 13C NMR (Fig. 5). The reactivity ratios can be calculated by the following equation:

Where

In Eq. (1), FAAA, FSAA, FSAS, FSSS, FSSA, and FASA were the amount of the assignments of the resonances of AN- and St-centered triads in the 13C NMR spectrum: AAA (δ = 118–119.2 ppm), SAA or AAS (δ = 119.2–120.8 ppm), SAS (δ = 120.8–122.5 ppm) for AN centered triads; SSS (δ = 143.7–146.8 ppm), SSA or ASS (δ = 141.2–143.7 ppm), ASA (δ = 138.7–1141.2 ppm) for St centered triads, respectively. And fAN and fSt are the feed ratios of AN and St, respectively.

The triads distributions were determined according to what was reported by Hill [33]. The triads distributions were calculated from the area under peaks for the respective triads. For example, the feed molar ratio of AN:St was 15:85, FSSS was equal to the ratio of the integral area of SSS (δ = 143.7–146.8 ppm) and total area of SSS (δ = 143.7–146.8 ppm), SSA or ASS (δ = 141.2–143.7 ppm) and ASA (δ = 138.7–1141.2 ppm). The results were summarized in Table 1. When the molar ratios of AN:St changed from 15:85 to 85:15, the reactivity ratios of AN and St were from 1.039 to 0.003 and from 1.084 to 2.149, respectively. The reactivity ratios calculated from Fig. 5 were shown in Fig. 6. The obtained reactivity ratios in this work are different from that of reported conventional microemulsion copolymerization of St and AN (rSt = 0.61–2.98, rAN = 0–0.039)[35]. The reported reactivity ratios for the controlled/living copolymerization of St and AN calculated by the Jaacks’s method were rSt = 0.46, rAN = 0.19[36]. The deviation of reactivity ratios may be due to different reaction media and different mechanism.

BPO as initiator in reverse atom transfer copolymerization of AN and St in ionic liquid microemulsion

In this work, AIBN was replaced by BPO. The molar ratio of [AN]:[St] was fixed at 0.45:0.55 and the molar ratio of [AN+St]:[FeCl3·6H2O]:[SA] was fixed at 500:1:2. A series of experiments were carried out with varying the molar ratio of [AN+St]:[BPO]. As listed in Table 2, a well-controlled copolymerization of AN and St was achieved in this system, as determined by the molecular weights of the resulting SAN increasing with monomer conversion and the MWD values below 1.30. It demonstrated that BPO can be served as efficient initiator in this system.

Chain extension of SAN

A predetermined quantity of SAN as macroinitiator (obtained in ionic liquid microemulsion) was added to ionic liquid microemulsion in a dried 100 mL three-neck flask. The molar ratio [St]:[macroinitiator]:[FeCl2]:[SA] was kept at 500:1:1:2. The chain extension of SAN was performed as follows: 6.2520 g [bmim][PF6] (22 mmol) and 2.5000 g CTAB (7 mmol) were fed and mixed, then 2.080 g St (20 mmol), 0.0051 g FeCl2 (0.04 mmol), 0.0094 g Succinic acid (0.08 mmol) and 0.5120 g macroinitiator (Mn = 12,800 g/mol, MWD = 1.23) (0.04 mmol) were in turn added to the flask. After degassed, N2 was charged. The cycle was three times. The polymerization was conducted at 65 °C. As shown in Fig. 7, the molecular weight increased from 12,800 g/mol to 36,400 g/mol and the MWD also increased from 1.23 to 1.33 indicating that the SAN with chlorine end groups synthesized by using these initiator/catalyst/ionic liquid microemulsion systems can initiate reverse atom transfer copolymerization quantitatively to prepare the well-defined SAN with narrow MWD.

Conclusion

Reverse atom transfer radical copolymerization of acrylonitrile and styrene were successfully carried out in ionic liquid microemulsion with AIBN as initiator in the presence of FeCl3·6H2O/SA complexes catalyst. The copolymerization proceeded in a controlled/living fashion, as evidenced by the first-order kinetics and the linear increase of the number-average molecular weight with conversion. The particle size distribution of the obtained SAN copolymer was about 10–20 nm determined by Malvern Mastersizer equipment. The monomer reactivity ratio of AN and St copolymerization in ionic liquid microemulsion was determined by 13C NMR spectroscopic analysis and varied from 1.039 to 0.003 for AN and from 1.084 to 2.149 for St when the monomer feed molar ratio of AN and St changed from 15:85 to 85:15. BPO was also an efficient in this system. The resulting SAN copolymer with a chlorine-terminated atom was activated during the chain extension experiment.

References

Braunecker WA, Matyjaszewski K (2007) Prog Polym Sci 32:93

Georges MK, Veregin RPN, Kazmaier PM, Hamer GK (1993) Macromolecules 26:2987

Hawker CJ, Bosman AW, Harth E (2001) Chem Rev 101:3661

Matyjaszewski K, Xia J (2001) Chem Rev 101:2921

Kamigaito M, Ando T, Sawamoto M (2001) Chem Rev 101:3689

Matyjaszewski K, Patten TE, Xia J (1997) J Am Chem Soc 119:674

Moad G, Rizzardo E, Thang SH (2005) Aust J Chem 58:379

Coote ML (2004) Macromolecules 37:5023

Granel C, Dubois P, Jerome R (1996) Macromolecules 29:8576

Nishikawa T, Kamigatio M, Sawamoto M (1999) Macromolecules 32:2204

Min K, Matyjaszewski K (2009) Cent Eur J Chem 7:657

Min K, Gao H, Matyjaszewski K (2006) J Am Chem Soc 128:10521

Okubo M, Minami H, Zhou J (2004) Colloid Polym Sci 282:747

Min K, Jakubowski W, Matyjaszewski K (2006) Macromol Rapid Commun 27:594

Khezrollah K, Vahid H-A, Hossein R-M, Mehdi S-K (2012) J Polym Res 19:1

Kagawa Y, Kawasaki M, Zetterlund P, Minami H, Okubo M (2007) Macromol Rapid Commun 28:2354

Min K, Matyjaszewski K (2005) Macromolecules 38:8131

Erbeldinger M, Mesiano AJ, Russell AJ (2000) Biotechnol Prog 16:1129

Lade O, Co CC, Cotts P, Strey R, Kaler EW (2005) Colloid Polym Sci 283:905

Chen Z, Yan F, Qiu L, Lu J, Zhou Y, Chen J, Tang Y, Texter J (2010) Langmuir 26:3803

Zhou Y, Qiu L, Deng Z, Texter J, Yan F (2011) Macromolecules 44:7948

Wang GX, Lu M, Zhong M, Wu H (2012) J Polym Res 19:9782

Li Z, Zhang J, Du J, Han B, Wang J (2006) Colloids Surf A 286:117

Zhang GP, Zhou HH, Hu JQ, Liu M, Kuang YF (2009) Green Chem 11:1428

Wang Y, Zhang Y, Parker B, Matyjaszewski K (2011) Macromolecules 44:4022

Wang Y, Matyjaszewski K (2011) Macromolecules 44:1226

Zhu GH, Zhang LF, Zhang ZB, Zhu J, Tu YF, Cheng ZP, Zhu XL (2011) Macromolecules 44:3233

Wang GX, Lu M, Wu H (2012) Polymer 53:1093

Zhang LF, Cheng ZP, Shi SP, Li QH, Zhu XL (2008) Polymer 49:3054

Wang GX, Wu H (2011) Polym Bull 67:1809

Chen H, Liang Y, Liu DL, Tan Z, Zhang SH, Zheng ML, Qu RJ (2010) Mater Sci Eng 30:605

Pietrasik J, Dong HC, Matyjaszewski K (2006) Macromolecules 39:6384

Al-Harthi M, Sardashti A, Soares JBP, Simon LC (2007) Polymer 48:1954

Tsarevsky NV, Sarbu T, Gobelt B, Matyjaszewski K (2002) Macromolecules 35:6142

Lee KC, Gan LM, Chew CH, Ng SC (1995) Polymer 36:3719

Fan DQ, He JP, Xu JT, Tang W, Liu Y, Yang YL (2006) J Polym Sci A Polym Chem 44:2260

Acknowledgments

The financial support from the Science and Technology Planning Project of Hunan Province, China (No. 2012FJ4272).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Wang, GX., Lu, M., Hou, ZH. et al. Reactivity ratios of controlled/living copolymerization of styrene and acrylonitrile in ionic liquid microemulsion. J Polym Res 20, 80 (2013). https://doi.org/10.1007/s10965-013-0080-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0080-1