Abstract

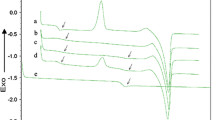

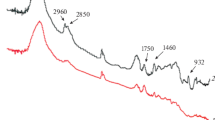

The Fourier transform infrared results suggest that the carboxylic acid groups of poly(lactic acid) (PLA) molecules react with the epoxy groups of molecules of Ethylene Glycidyl Methacrylate Copolymer (EGMC) during the reactive extrusion processes of PLAxEGMCy specimens. The tensile and tear strength values of PLAxEGMCy blown-film specimens in machine and transverse directions improve significantly, and reach their maximal values as their EGMC contents approach an optimum value of 6 wt.%. The melt shear viscosity values of PLAxEGMCy resins, measured at varying shear rates, are significantly higher than those of the PLA resin, and increase consistently with their EGMC contents. Differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA) of PLA and PLAxEGMCy specimens reveal that the percentage crystallinity, peak melting temperature, and onset re-crystallization temperature values of PLAxEGMCy specimens reduce gradually as their EGMC contents increase. In contrast, the glass transition temperatures of PLAxEGMCy specimens increase gradually in conjunction with their EGMC contents. Demarcated porous morphology with several connected fungi-decomposed cavities was found on the surfaces of the PLAxEGMCy specimens after being buried for specific amounts of time, in which the sizes of the fungi-decomposed cavities found on the surfaces of buried PLAxEGMCy specimens reduce significantly as their EGMC contents increase. Further DMA and morphological analysis of PLAxEGMCy specimens reveal that the EGMC molecules are compatible with PLA molecules at EGMC contents equal to or less than 2 wt.% because no phase-separated EGMC droplets and tan δ transitions were found on fracture surfaces and tan δ curves of PLAxEGMCy specimens, respectively. The possible reasons for these remarkable properties of the PLA/EGMC specimens are proposed in this study.

Similar content being viewed by others

References

Meinander K, Niemi M, Hakola JS, Selin JF (1997) Macromol Symp 1123:147

Rashkov I, Manolova N, Li SM, Espartero JL, Vert M (1996) Macromolecules 29:50

Chen XH, McCarthy SP, Gross RA (1997) Macromolecules 30:4295

Maglio G, Migliozzi A, Palumbo R (2003) Polymer 44:369

Chon D, Hotovely-Salomon A (2005) Polymer 46:2068

Choi NS, Kim SH, Cho KY, Park JK (2002) J Appl Polym Sci 86:1892

Na YH, He Y, Shuai X, Kikkawa Y, Doi Y, Inoue Y (2002) Biomacromolecules 3:1179

Blűmm E, Owen AJ (1995) Polymer 36:4077

Zhang LL, Deng XM, Zhao SJ, Huang ZTJ (1997) Appl Polym Sci 65:1849

Focarete ML, Scandola M, Dobrzynski P, Kowalczuk M (2002) Macromolecules 35:8472

Zhang LL, Xiong CD, Deng XM (1996) Polymer 37:235

Nijenhuis AJ, Colstee E, Grijpma DW, Pennings A (1996) J Polymer 37:5849

Wang L, Ma W, Gross RA, McCarthy SP (1998) Polym Degrad Stab 59:161

Groeninckx G, Maglio G, Malinconico M, Migliozzi A (2001) Polymer 42:831

Chen CC, Chueh JY, Tseng H, Huang HM, Lee SY (2003) Biomaterials 24:2297

Gajria AM, Dave V, Gross RA (1996) Polymer 37:437

Koyama N, Doi Y (1997) Polymer 38:1589

Ohkoshi I, Abe H, Doi Y (2000) Polymer 41:5985

Park JW, Im SS (2002) J Polym Sci Part B: Polym Phys 40:931

Park JW, Im SS (2002) J Appl Polym Sci 86:647

Yeh JT, Chai WL, Huang CY, Chen KN (2009) Appl Polym Sci 112:2757

Yeh JT, Tsou CH, Huang CH, Chen KN, Wu CS, Chai WL (2010) J Appl Polym Sci 116:680

Yeh JT, Tsou CH, Lu W, Li YM, Xiao HW, Huang CH, Chen KN, Wu CS, Chai WL (2010) J Polymer Sci: Part B: Polymer Phys 48:913

Fischer EW, Sterzel HJ, Wegner G, Kolloid ZZ (1973) Polymer 251:980

Wool RP, Raghavan D, Wagner GD, Billieux SJ (2000) Appl Polym Sci 77:1643

Goheen SM, Wool RP (1991) J Appl Polym Sci 42:2691

Rezgui F, Swistek M, Hiver JM, G’Sell C, Sadoun T (2005) Polymer 46:7370

Martin O, Averous L (2001) Polymer 42:6209

Fischer EW, Sterzel HJ, Wegner G, Koloid ZZ (1973) Polymer 251:980

Acknowledgements

The authors would like to express their appreciation to the Department of Industrial Technology, Ministry of Economic Affairs (95-EC-17-A-11-S1-057, 96-EC-17-A-11-S1-057, 97-EC-17-A-11-S1-057 and 99-EC-17-A-11-S1-155) and 99-2622-E-011-003-CC3 for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeh, Jt., Tsou, Ch., Li, Ym. et al. The compatible and mechanical properties of biodegradable poly(Lactic Acid)/ethylene glycidyl methacrylate copolymer blends. J Polym Res 19, 9766 (2012). https://doi.org/10.1007/s10965-011-9766-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-011-9766-4