Abstract

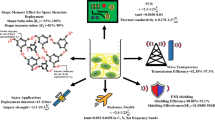

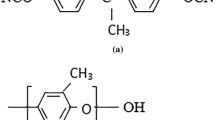

A high performance modified cyanate ester (CE) resin system with significantly improved toughness, water resistance and dimensional stability was developed by copolymerizing CE resin with liquid crystalline epoxy resin (LCE) for electronic packaging. Four LCE/CE resins with different contents of LCE were prepared to systemically evaluate the effect of the content of LCE on the key properties of the modified system such as mechanical, dielectric and thermal properties as well as water resistance. Results reveal that the addition of LCE to CE can not only decrease the curing temperature of CE, but also significantly improve the integrated properties including mechanical and dielectric properties, thermal resistance as well as water resistance of cured resin. For example, compared with the whole exothermic peak of CE, that of LCE10/CE significantly shifts toward low temperature with a gap of about 15°C. On the other hand, the impact strength of cured LCE10/CE resin (22 kJ/m2) is about 2.1 times of that of CE resin; while the water absorption of the former is only 81.2% of that of the latter. In addition, cured LCE/CE resins also exhibit lower and more stable dielectric loss than CE resin over the whole frequency range from 10 to 106 Hz. All these improvements in macro-performance by the addition of LCE to CE resin are not only ascribed to the cross-linked chemical structure, but also attributed to the rigid structure of liquid crystalline resin. The outstanding integrated properties of LCE/CE resins suggest great potential to be applied in the field of high performance electronic packaging.

Similar content being viewed by others

References

Brownlee K, Raj PM, Bhattacharya Sk, Shinotani K, Wong CP, Tummala RR (2002) Evaluation of Liquid Crystal Polymers for High Performance SOP Applications in ‘52nd Electronic Components and Technology Conference San Diego, USA, 16: 676-680

Guo Y (2004) Handbook of Moire measurement. Chemical, Beijing

Ling W, Gu AJ, Liang GZ, Yuan L, Liu J (2010) Polym Adv Technol 21:365–370

Snow AW, Buckley LJ (1999) In: Nalwa H (ed) Handbook of low and high dielectric constant materials and their applications, 2nd edn. Academic, San Diego

Badrinarayanan P, Mac Murray B, Kessler MR (2009) J Mater Res 24:2235–2242

Hamerton I, Howlin BJ, Klewpatinond P, Takeda S (2009) Macromolecules 42:7718–7735

Wooster TJ, Abrol S, Hey JM, MacFarlane DR (2004) Composites Part A 35:75–82

Karad SK, Attwood D, Jones FR (2005) Composites Part A 36:764–771

Gu AJ (2006) Compos Sci Technol 66:1749–1755

Zhou C, Gu AJ, Liang GZ, Yuan L (2009) Polym Adv Technol. doi:101002/pat1570

Ren PG, Liang GZ, Zhang ZP (2006) Polym Compos 27:402–409

Zhan GZ, Yu YF, Tang XL, Tao QS, Li SJ (2006) J Polym Sci Part B: Polym PhysH 44:517–523

Suman JN, Kathi J, Taammishetti S (2005) Euro Polym J 41:2963–2972

Yang CZ, Gu AJ, Song HW, Xu ZB, Fang ZP, Tong LF (2007) J Appl Polym Sci 105:2020–2026

Kard SK, Attwood D, Rjones F (2005) Composites Part A 36:764–771

Galina H, Leszczak MB (2007) J Appl Polym Sci 105:224–228

Liu GL, Zhou B, Zhao DM, Li Q, Gao JG (2008) Macromol Chem Phys 209:1160–1169

Lee JY, Jang J (2006) Polymer 47:3036–3042

Jang J, Lee JY (2007) J Appl Polym Sci 106:2198–2203

Yu YF, Gan WJ, Liu XY, Li SJ (2008) J Appl Polym Sci 109:2964–2972

Jahromi S, Lub J, Mol GN (1994) Polymer 35:622–629

Braun D, Cherdron H, Kern W, Huan B (1981) Translation, Techniques of Polymer Syntheses and Characterization. Chin Sci Publ, Beijing

Dai SK, Gu AJ, Liang GZ, Yuan L (2009) Polym Adv Technol. doi:101002/pat1528

Zeng MF, Lu CY, Wang BY, Qi CZ (2010) Radiat Phys Chem 79:966–975

Premkumar R, Karikalchozhan C, Alagar M (2008) Eur Polym J 44:2599–2607

Musto P, Martuscelli E, Ragosta G, Russo P, Scarinzi G (1998) J Appl Polym Sci 69:1029–1042

Keating MY, Sauer BB, Flexman EA (1997) J Macrol Sci B 36:717–732

Ferry JD (1980) Viscoelastic properties of polymers. Wiley, New York

Nagendiran S, Premkumar S, Alagar M (2007) J Appl Polym Sci 106:1263–1273

Goertzen WK, Kessler MR (2008) Composites Part A 39:761–768

Arthur WS, Leonard JB (1999) In: Nalwa H (ed) Handbook of low and high dielectric constant materials and their applications, 4th edn. Academic, San Diego H

Liang GZ, Zhang MX (2002) J Appl Polym Sci 85:2377–2381

Konecny P, Cerny M, Voldanova J, Malac J, Simonik J (2007) Polym Adv Technol 18:122–127

Khonakdar HA, Wagenknecht U, Jafari SH, Hassler R, Eslami H (2004) Adv Polym Technol 23:307–315

Thomas S, George A (1992) Eur Polym J 28:1451–1458

Acknowledgments

The authors thank the National Natural Science Foundation of China (Grant No. 20974076), “Qin Lan Project” (2008), “333 Talent Project” (2008), and “Six Talent Peaks” (2008) of Jiangsu Province in China for financially supporting this project.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, X., Gu, A., Liang, G. et al. Liquid crystalline epoxy resin modified cyanate ester for high performance electronic packaging. J Polym Res 18, 1441–1450 (2011). https://doi.org/10.1007/s10965-010-9549-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9549-3