Abstract

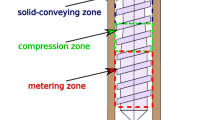

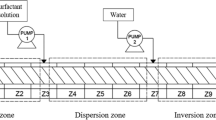

An empirical method was developed to study the dynamic mixing characteristics of a single-screw extrusion process. The method basically involved a modified version of the visible extruder developed by Wong et al. (Plast Rubb Comp Proc Appl 26:78, 1997). Digitized films of the molten polymer web emerging from the slit flow cells attached to the “windows” of the visible extruder’s barrel were captured in bitmap file format. Subsequent statistical analysis (largely variance) on the pixel intensity of the cropped films had made quantification of mixing quality possible. The higher the average variance of the pixel intensity, the poorer the mixing quality. The focus of this investigation was on the effects of temperature and screw speed. For the selected single-flighted conventional screw, it was found that, in general, the higher the screw speed, the shorter the residence time and, hence, poorer mixing quality. High screw speed also generated erratic average variance data. The results suggested that a critical screw speed for optimized mixing might have been present. For the equipment used in the current project, this critical screw speed lied between 50 and 80 rpm. However, unlike screw speed, melt temperature alone appeared to have relatively little effect on the mixing quality during extrusion.

Similar content being viewed by others

References

Wong AC-Y, Zhu F, Lui W (1997) Plast Rubber Compos Process Appl 26:78

Maddock BH (1959) SPE J 15:383

Elbirli B, Lindt JT, Gottgetreu SR, Baba SM (1983) In: SPE ANTEC’83

Bigio DI, Boyd JD, Erwin L, Gailus DW (1985) Polym Eng Sci 25:305

Benkreira H, Shales RW, Edwards MF (1992) Intern Polym Proc 7:126

White JL, Coran AY, Moet A (2001) Polymer mixing technology and engineering. Hanser, Munich

Rauwendaal C (1998) Polymer mixing - a self-study guide. Hanser, Munich

Alemaskin K, Camesasca M, Manas-Zloczower I, Kaufman M, Kim EK, Spalding MA, Trumbull WA, Swain RD (2004) In: SPE ANTEC ‘04

Alemaskin K, Manas-Zloczower I, Kaufman M (2005) Polym Eng Sci 45:1011

Alemaskin K, Manas-Zloczower I, Kaufman M (2005) Polym Eng Sci 45:1031

Camesasca M, Kaufman M, Manas-Zloczower I (2006) Micromol Theory Simol 15:595

Wong AC-Y, Lam Y (2005) In: PPS-21, Leipzig, Germany

Wong AC-Y, Zhu F, Liu R, Liu T (1997) Plast Rubber Compos Process Appl 26:336

Wong AC-Y, Liu T, Lam JCM, Zhu F (1999) Int Polym Proc 16:35

Wong AC-Y, Liu T, Zhu F, Lam JCM (2000) Adv Polym Tech 19:1

Acknowledgement

The authors are grateful for the Research Grant Council of Hong Kong SAR government for their financial support to this research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wong, A.CY., Lam, Y. Visualization study on the dynamic mixing quality during single-screw extrusion. J Polym Res 15, 11–19 (2008). https://doi.org/10.1007/s10965-007-9138-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-007-9138-2