Abstract

Optimisation of REBCO coated conductor tapes specifically for use in nuclear fusion will help improve the magnet component lifetimes in future tokamak reactor power plants. The focus of this work was exploration of a novel approach to irradiation studies on REBCO tapes, utilising multiple magnetic measurements to probe evolution of the REBCO flux-pinning landscape more deeply than reported in other studies, for the purpose of identifying primary limiting factors affecting performance. Gamma irradiation experiments were conducted, and pre-/post-irradiation results from DC and AC magnetic measurements using a Physical Property Measurement System (PPMS) are discussed. Magnetisation critical current density (Jc) decreased in all samples with increasing dose, except for the silver overlayer-only samples which did not contain artificial pinning centres (APCs), where Jc increased with dose. Removal of the copper stabiliser coupled with the presence of APCs allowed gamma irradiation to induce pinning force maximum peak shifts, from above 14 T before irradiation to below 9 T afterwards. Flux creep rate varied with the evolving pinning landscape, and the degree of Jc degradation directly correlated with creep rate fluctuations post-irradiation. Changes in critical temperature and diamagnetic saturation also corresponded with changes in Jc and flux creep rate. The major conclusion from this study was that minimisation of flux creep rate is the key to maintenance of performance under fusion-relevant operating conditions. Flux creep manifests as problematic AC losses in all high-temperature superconducting machines; therefore, future work will focus on reduction/prevention of the phenomenon to enhance longevity of performance in any application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The favourable properties of REBCO coated conductor tapes and the well-established production methods have brought these tapes to the forefront of tokamak fusion research [1, 2]. Magnet materials experience harsh conditions inside a tokamak: high magnetic fields, high input currents, and intense neutron and gamma radiation [3]. Under these conditions, magnet longevity is an issue due to short expected lifetimes, high costs associated with replacement, and supply chain concerns.

In the literature, it is established that under high applied magnetic fields, fast neutrons can enhance critical current density (Jc) via the introduction of nm-scale collision cascades up to a maximum fluence, often around 1–2 × 1022 neutrons/m2 above 10 T, before degradation when further exposed [4,5,6]. The onset of degradation occurs at lower fluences when tape REBCO layers have a higher pristine sample defect density, due to the presence of artificial pinning centres (APCs) [7]. Literature on the effects of gamma rays is inconclusive [8,9,10].

For optimisation of REBCO tapes in fusion applications, performance testing under fusion-relevant operating conditions (20 K and very high magnetic fields above 10 T) before and after irradiation is required. Critical parameters in REBCO are very sensitive to irradiation [11], and the evolution of functionality in a tape is dependent on applied temperature and field. Magnetometry probes the flux-pinning landscape, providing insight into screening capability and flux dynamics [12]. The combination of multiple magnetic property analyses will improve our understanding of the underlying mechanisms behind irradiation-induced performance evolution in REBCO tapes, with the aim of this work being identification of the key performance-limiting factors at low temperatures and high fields.

There is extensive literature on the effects of irradiation on REBCO functional properties [4,5,6,7,8,9,10,11, 13,14,15,16,17,18,19,20,21,22,23]. Therefore, the purpose of this study was to take a different direction, using the knowledgebase acquired through previous REBCO irradiation work, but moving away from solely improving mechanistic understanding of irradiation effects by beginning to address the irradiation-induced issues. This study was intended as a relatively quick piece of work to evaluate the universal issues affecting degradation of performance in any REBCO tape sample under fusion-relevant conditions, acting as a compass pointing towards the most urgent direction necessary for fusion-tape development.

Gamma irradiation was chosen in this study because gamma rays are expected to bombard tokamak magnets, yet gamma effects on REBCO tapes are poorly understood. Pre-/post-irradiation magnetic testing comprised of DC moment versus field hysteresis loop, DC magnetic relaxation, and AC susceptibility measurements.

The results from magnetic testing on gamma irradiated tape samples are discussed. Overarching themes affecting degradation of performance after irradiation, irrespective of pristine flux-pinning landscape in the tape, and the connections between different types of measurement data are also explored. This work demonstrates the complex relationship between pristine pinning landscape and evolution of performance under irradiation.

2 Methods

2.1 Samples and Irradiation

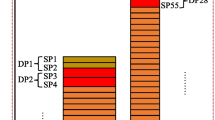

The tapes examined in this work were 3 SuperPower 4-mm wide SCS4050 GdYBCO samples (Fig. 1).

Schematic diagram of a SuperPower SCS4050 REBCO coated conductor tape [24]

Each had 0, 7.5, or 15% additional Zr by weight within the REBCO layer for BaZrO3 nanocolumn APC generation, and sections of the tapes were chemically etched after receipt to remove the Cu stabiliser prior to irradiation, providing analogous Ag-only samples (in total, 6 samples for post-irradiation analysis).

Gamma irradiation experiments were carried out at the Dalton Cumbrian Facility. The REBCO tape samples were irradiated with Co-60 gamma rays up to 1 kGy and 1 MGy doses. The irradiation angle was parallel to the REBCO c-axis. With the assumption that damage introduced to the microstructure and/or electronic structure is isotropic, it is also assumed that the angle of irradiation does not influence post-irradiation changes in functionality [5].

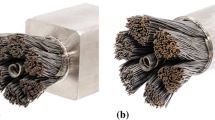

2.2 Measurement Setup

Magnetometry measurements were conducted on the tape samples using the AC magnetic susceptibility (ACMS) operational mode of the Quantum Design PPMS® DynaCool™ Physical Property Measurement System (PPMS) at the UKAEA Materials Research Facility (MRF). The PPMS in the MRF is intended for characterisation of functional properties in radioactive/irradiated materials. For all measurements, 3-mm disk samples were cut from the tapes prior to irradiation (and for the Ag-only samples, after chemical etching of the Cu stabiliser) using a SPI Supplies #17,001-AB precision TEM disk punch, and magnetic fields were applied parallel to the REBCO c-axis.

During AC susceptibility measurements, a 0.001 T AC drive field with a frequency of 777 Hz was also applied along with the DC field. The applied temperature (20 K) in the DC measurements and applied field (14 T) in the AC (and DC magnetic relaxation) measurements were chosen to simulate fusion-operating conditions most accurately. The magnetometry measurements thus probed gamma-induced changes to the flux-pinning landscape within the REBCO ab-axis under these conditions.

Different samples from each tape were used for pre-/post-irradiation magnetometry examination, with analysis based on the assumption of REBCO thickness uniformity. To verify that measured post-irradiation changes were induced by the gamma rays, repeat measurements were conducted on 3 non-irradiated samples from the 7.5% tape, and the data were collated in Figs. 2, 3, 4, 5, and 6 and Tables 1 and 2. Calculated Jc values for the repeat samples were higher than in the pre-irradiation sample from the same tape shown in Figs. 8 and 11; the samples in Figs. 2, 3, 4, 5, and 6 were measured ~ 10 months later after a renewed ACMS mode calibration.

Pre-irradiation, 3 tape samples were analysed: 1 sample from each of the parent tapes. Post-irradiation, 12 tape samples were analysed: 4 samples from each of the parent tapes; 1 Cu-stabilised and 1 Ag-only sample at both 1 kGy and 1 MGy gamma doses.

All profiles for each specific sample were generated from measurements on that same individual sample in a single experimental sequence, and the consistent trends in functional property changes seen across all the irradiated samples will be discussed in Sect. 3.

2.3 Data Analysis Calculations

Magnetisation-Jc values were calculated from DC magnetic moment versus applied magnetic field hysteresis loops using Bean’s critical state model for a thin film: Jc = (15 × Δm)/(V × r), where Δm is the magnetic moment difference, V is REBCO layer volume, and r is the sample radius (Figs. 2 and 3) [25]. Overall pinning force values (Fp) were calculated using the following equation: Fp = Jc × B, where B is magnetic field (Fig. 4). Flux creep rates were calculated from DC magnetic relaxation measurements using the (− d ln M)/(d ln t) line of best fit gradient, where M is the volume magnetisation and t is time (Fig. 5) [26, 27].

3 Results and Discussion

3.1 DC Magnetic Data

3.1.1 Magnetisation Critical Current Density

After gamma irradiation, there were patterns in Jc changes for each tape. Error values for the calculated Jc values were assumed to be the same as in Table 1.

Figures 7, 8, 9, 10, 11, and 12 present the gamma-induced changes in Jc across all 3 tapes. For the 0% tape, Jc decreased with increasing dose in the Cu-stabilised samples whilst Jc increased in the Ag-only samples.

For the APC-containing tapes, Jc decreased in all 4 irradiated samples, to a greater extent in the Ag-only samples. The post-irradiation reduction in Jc was larger in the 15% tape relative to the 7.5% tape. Interestingly, for the 15% tape, Jc in the Cu-stabilised samples increased between 1 kGy and 1 MGy irradiation; in the 7.5% Cu-stabilised and all 4 APC Ag-only samples, Jc decreased between 1 kGy and 1 MGy irradiation at very high fields (below 10 T, Jc in the 7.5% Cu-stabilised samples was higher after 1 MGy, but above 13 T, Jc was lower after 1 MGy).

In the upcoming sections, the underlying mechanisms behind these changes in Jc will be investigated.

3.1.2 Overall Pinning Force

To supplement the Jc analysis, overall Fp versus field profiles were calculated. A theory that will be discussed in this section is the idea of Fp profiles probing changes in dominant pinning centre within the overall flux-pinning landscape via shifts in the field strength at which Fp max was observed pre-versus post-irradiation. For pristine REBCO, the field strength corresponding to Fp max is known to signify the dominant pinning centre, and the plateau of the profile curve slope indicates the transition between strong core-interaction flux-pinning to weak elastic vortex-vortex interactions: in work by Galstyan et al. on pristine REBCO thick films, it was concluded that at low temperatures below 30 K and at high fields above 8 T, there was a transition from strong correlated pinning by the BaZrO3 nanocolumn APCs present in the produced films to weak uncorrelated pinning by Frenkel pair point defects [28]. Profiles for the pre-irradiation APC-containing samples similarly plateau at ~ 8 T.

In pristine APC-containing tapes, APCs act as the dominant pinning centre in a landscape also occupied by other microstructural defects of varying pinning strengths (in the order of APCs > nm-sized defects > point defects) [27]. Transitions in the overall pinning mechanism dominating the landscape, from strong individual pinning by nm-scale microstructural defects (such as APCs, grain boundaries, and dislocations) to weak collective pinning by point defects, are also caused by the reduction in ab-axis coherence length with increasing radiation dose [13, 27, 29].

For the 0% sample, the overall Fp profile did not visibly change post-irradiation (Fig. 13). Fp max was not observed below 14 T in all 4 irradiated samples.

In all 4 APC-containing Cu-stabilised samples, the Fp profile curve did not clearly change post-irradiation, and Fp max remained unobservable below 14 T (Figs. 14 and 15). However, in all 4 Ag-only samples, the Fp profile curvature increased to reveal a maximum and a decrease in Fp with increasing field, as Fp max dramatically shifted to lower field strengths below 9 T. After 1 MGy irradiation, both the 7.5% and 15% Ag-only sample Fp max peaks were found at higher field strengths than observed in the corresponding 1 kGy irradiated samples.

The shift in Fp max to lower field strengths below 9 T in the APC-containing Ag-only samples suggested that the onset of the overall pinning mechanism transition was occurring at greatly reduced fields after gamma irradiation. Previously, reduction in APC pinning energy has been accredited to irradiation-induced changes in coherence length [27]. The presence of APCs is also known to decrease the irradiation dose at which the transition in overall pinning mechanism occurs, leading to higher rates of degradation compared to non-APC tapes [7]. A gamma-induced transition to weak collective pinning by oxygen point defects present within the REBCO layer may explain the significant shift in Fp max to lower field strengths. Collating this information, it would then make sense why the 15% Ag-only samples displayed lower Fp max field strength peaks (after 1 kGy, 5.95 T; after 1 MGy, 6.4 T) relative to the analogous 7.5% samples (after 1 kGy, 6.1 T; after 1 MGy, 8 T). Though, the Fp max shift to higher field strengths after the 1 MGy dose in both APC-containing samples was unexpected.

Considering the above observations in tandem with the work of Galstyan et al. [28], it was established that Fp versus field profiles can indeed probe irradiation-induced changes to the dominant pinning centre within the overall REBCO pinning landscape.

From these profiles, connections between the presence/absence of the Cu stabiliser and presence/absence of APCs on resulting Fp max peak field strength shifts after gamma irradiation were noted. Removal of the two 20-µm thick Cu stabiliser layers in combination with the presence of APCs allowed gamma rays to alter the flux-pinning landscape, enabling the overall pinning mechanism transition onset at lower field strengths. The underlying cause of these observations is unclear.

3.1.3 Flux Creep Rate

Figures 16, 17, and 18 demonstrate the changes in calculated flux creep rates for the 3 sets of tape samples before and after irradiation. Error values for the calculated creep rates were assumed to be the same as in Table 2.

For the 0% tape, flux creep rate decreased in all 4 samples post-irradiation. In the Cu-stabilised samples, creep rate was higher after 1 MGy than 1 kGy. In the Ag-only samples, flux creep rate decreased with increasing dose.

For the APC-containing tapes, flux creep rate increased in all 4 samples post-irradiation. It was noted that for each set of APC-containing samples, creep rate was lower after 1 MGy than 1 kGy.

Increasing radiation dose causes superconducting volume fraction and superfluid density to decrease, and both quantities are connected to Jc [4, 7, 10, 14, 15, 17,18,19]. Creep rate drastically decreased in the 0% Cu-stabilised 1 kGy irradiated sample, enabling minimal loss in Jc despite reduction in superconducting volume fraction/superfluid density (Fig. 10). Similar phenomena were seen in the APC-containing Cu-stabilised samples as dose increased from 1 kGy to 1 MGy, where the flux creep rate improved significantly, limiting further Jc degradation in the 7.5% sample and markedly increasing Jc in the 15% sample (Figs. 11 and 12).

Despite the lower rate of flux creep after 1 MGy irradiation in both APC-containing Ag-only samples, Jc decreased more relative to the 1 kGy irradiated samples. Considering the comparatively minor decreases in Jc and substantial decreases in flux creep rate after increasing dose to 1 MGy, it was suggested that a trade-off exists between superfluid density and flux creep rate affecting Jc after irradiation. This trade-off would also explain the heightened Jc in the 0% Ag-only samples with dose.

3.1.4 Summary

In a study by Eley et al., it was established that transitions in dominant pinning mechanism caused by irradiation, from strong individual pinning to weak collective pinning, increase flux creep rate and decrease Jc [27]. Combining the analyses on Jc, overall Fp, and flux creep rate changes post-irradiation, the conclusion was that flux-pinning landscapes were more susceptible to gamma-induced modifications when the Cu-stabiliser was removed, and APCs (in increasing concentration) were present.

Regardless of APC concentration, the rate of flux creep appeared to be the more important factor affecting performance in the balance between creep rate and superfluid density; the creep rate acts to either enhance Jc or prevent more dramatic Jc degradation as superfluid density universally decreases with irradiation. The resultant Jc after irradiation is thus dependent on pristine landscape and dose.

3.2 AC Magnetic Data

AC susceptibility measurements supplement the DC data by providing insight into changes in superfluid density via Tc [30], superconducting volume fraction via diamagnetic saturation [31], and overall Fp caused by the additional AC field via the irreversibility temperature (Tirr) [32]; Tirr is found from the imaginary component maximum. Both superfluid density and superconducting volume fraction relate to Jc, as discussed in Sect. 3.1.

Figure 19 shows the effect of increasing gamma dose on AC susceptibility in the 0% Cu-stabilised sample. With increasing gamma dose, Tc and diamagnetic saturation decreased, which was consistent with Jc changes observed in Fig. 10 and the proposed mechanisms behind those changes (improved flux creep rate relative to pristine sample counteracting reduction in superfluid density to maintain a decent superconducting volume fraction).

Figure 20 shows the influence of the Cu stabiliser on induced AC susceptibility changes in the 7.5% sample. In the 7.5% Cu-stabilised sample, there was negligible change in superfluid density, but a significant loss in superconducting volume fraction; for the analogous Ag-only sample, the opposite was true. Comparing flux creep rates in the 7.5% Cu-stabilised and Ag-only samples, creep rate was higher after irradiation when the stabiliser was present. These observations were consistent with the theorised rationale behind calculated Jc after 1 MGy irradiation in Fig. 11, where flux creep was the critical factor in the balance of parameters affecting Jc post-irradiation. Greater rates of flux motion under the AC drive field may explain the dramatic weakening of the diamagnetic signal in the Cu-stabilised sample.

Figure 21 shows the influence of the Cu stabiliser on induced AC susceptibility changes in the 15% sample. By comparison to the 7.5% sample, the 15% Cu-stabilised sample had a greater loss in superfluid density but lesser decrease in superconducting volume fraction. The lower flux creep rate in the 15% Cu-stabilised sample is perhaps what allowed for the relatively well-maintained post-irradiation high field Jc (Fig. 12), despite the lower superfluid density present. In the 15% Ag-only sample, higher flux creep rate and slightly reduced superfluid density were likely the cause of both lower Jc and diamagnetic saturation than observed in the 7.5% Ag-only sample. Jc and flux creep rate were also worse in the 15% Ag-only sample relative to the 15% Cu-stabilised sample, possibly contributing to the smaller difference in saturation when compared to the analogous 7.5% sample profiles. The 15% Ag-only Jc at 14 T was only marginally smaller than the 7.5% Ag-only Jc value (as was superfluid density), indicative of the much higher flux creep rate relative to the 7.5% sample being the dominant factor leading to weakening of diamagnetic saturation.

The conclusion from magnetic data analysis is that reduction in superfluid density/superconducting volume fraction plays a role in performance degradation, but post-irradiation performance is more strongly dependent on how the rate of flux creep changes. For enhanced maintenance of maximal Jc under fusion-relevant conditions, minimisation of flux creep rate is the key.

4 Conclusion

The major conclusion from the magnetic data analysis discussed in this study is that flux creep is the performance limiting factor affecting REBCO coated conductor tapes at fusion-relevant temperatures and applied fields. At the tokamak magnet coil scale, flux creep manifests as AC losses, and AC losses have been identified as a primary issue hindering performance of the tapes in fusion.

The overall purpose of this work was to explore a novel approach towards understanding the evolution of REBCO tape performance under appropriate conditions for application in tokamaks. The use of multiple magnetic measurements on the same sample in a single experimental sequence, across different gamma-irradiated samples varying in APC concentration and presence/absence of the Cu-stabiliser, enabled the identification of flux creep as the universal problem affecting tape performance. The patterns in functional properties observed across each sample set post-irradiation were indicative of further investigation into gamma effects on tapes becoming a necessity in the future, bearing in mind the expected gamma flux on the magnets in tokamaks.

Moving forward beyond this study, the focus will be on implementation and verification of improvements to the tapes. The improvements themselves will be targeted towards reduction of irradiation-induced increases in flux creep rate and the lowering of flux creep rates generally in tapes. Enhanced prevention of flux creep/AC losses is desirable for any large-scale machine which employs superconductor technology [33], meaning this type of REBCO coated conductor tape development is transferable and would be beneficial more widely outside of tokamak research.

Change history

16 January 2024

A Correction to this paper has been published: https://doi.org/10.1007/s10948-023-06682-6

References

Bruzzone, P., Fietz, W.H., Minervini, J.V., Novikov, M., Yanagi, N., Zhai, Y., Zheng, J.: High temperature superconductors for fusion magnets. Nucl. Fusion 58(10), 103001 (2018)

Lee, T.S., Jenkins, I., Surrey, E., Hampshire, D.P.: Optimal design of a toroidal field magnet system and cost of electricity implications for a tokamak using high temperature superconductors. Fusion Eng. Des. 98–99, 1072–1075 (2015)

Windsor, C.G., Morgan, J.G.: Neutron and gamma flux distributions and their implications for radiation damage in the shielded superconducting core of a fusion power plant. Nucl. Fusion 57, 116032 (2017)

Chudy, M., Eisterer, M., Weber, H.W., Veterníková, J., Sojak, S., Slugeň, V.: Point defects in YBa2Cu3O7−x studied using positron annihilation. Supercond. Sci. Technol. 25(7), 075017 (2012)

Eisterer, M., Fuger, R., Chudy, M., Hengstberger, F., Weber, H.W.: Neutron irradiation of coated conductors. Supercond. Sci. Technol. 23(1), 014009 (2009)

Prokopec, R., Fischer, D.X., Weber, H.W., Eisterer, M.: Suitability of coated conductors for fusion magnets in view of their radiation response. Supercond. Sci. Technol. 28(1), 014005 (2014)

Fischer, D.X., Prokopec, R., Emhofer, J., Eisterer, M.: The effect of fast neutron irradiation on the superconducting properties of REBCO coated conductors with and without artificial pinning centers. Supercond. Sci. Technol. 31, 044006 (2018)

Kutsukake, T., Somei, H., Ohki, Y., Nagasawa, K., Kaneko, F.: Gamma-irradiation effect on high-Tc superconductor YBa2Cu3O7-x. Jpn. J. Appl. Phys 28(Part 2, No. 8), L1393-L1394 (1989)

El-Hamalawy, A.A.E.-S., El-Zaidia, M.M., Ghali, E.A.: The effects of gamma-radiation on the high Tc superconductors Er1Ba2Cu3O7-δ. Jpn. J. Appl. Phys 31(Part 1, No. 11), 3529–3532 (1992)

Akduran, N.: Gamma irradiation effects on EuBa2Cu3O7 high temperature superconductor. Radiat. Phys. Chem. 83, 61–66 (2013)

Sekitani, T., Miura, N., Ikeda, S., Matsuda, Y.H., Shiohara, Y.: Upper critical field for optimally-doped YBa2Cu3O7−δ. Physica B 346–347, 319–324 (2004)

Nikolo, M.: Flux dynamics in high-temperature superconductors. Supercond. Sci. Technol. 6, 618 (1993)

Choi, W.J., Ahmad, D., Seo, Y.I., Ko, R.K., Kwon, Y.S.: Effect of the proton irradiation on the thermally activated flux flow in superconducting SmBCO coated conductors. Sci. Rep. 10(1), 2017 (2020)

Egner, B., Geerk, J., Li, H.C., Linker, G., Meyer, O., Strehlau, B.: The influence of irradiation-induced defects on the superconductivity of YBa2Cu3O7. Jpn. J. Appl. Phys. 26(S3–3), 2141 (1987)

Antonova, L., Demikhov, T., Troitskii, A., Didyk, A., Kobzev, A., Yurasov, A., Samoilenkov, S., Mikhailova, G.: Effect of 2.5 MeV proton irradiation on the critical parameters of composite HTS tapes. Physica Status Solidi C 12(1‐2), 94–97 (2015)

Jia, Y., LeRoux, M., Miller, D.J., Wen, J.G., Kwok, W.K., Welp, U., Rupich, M.W., Li, X., Sathyamurthy, S., Fleshler, S., Malozemoff, A.P., Kayani, A., Ayala-Valenzuela, O., Civale, L.: Doubling the critical current density of high temperature superconducting coated conductors through proton irradiation. Appl. Phys. Lett. 103(12), 122601 (2013)

Xiong, G.C., Li, H.C., Linker, G., Meyer, O.: Transport properties, phase transition, and recovery near 200 K of proton-irradiated YBa2Cu3O7 thin films. Phys. Rev. B 38(1), 240–243 (1988)

Shiraishi, K., Itoh, H., Yoda, O.: Electron irradiation effects on a Ba2YCu3O7 superconductor. Jpn. J. Appl. Phys. 27(Part 2, No. 12), L2339-L2341 (1988)

Hor, P.H., Bechtold, J., Xue, Y.Y., Chu, C.W., Hungerford, E.V., Maruyama, X.K., Backe, H., Buskirk, F.R., Connors, S.M., Jean, Y.C., Farmer, J.W.: Irradiation effects of flux pinning and Jc in high temperature superconductors. Physica C 185–189, 2311–2312 (1991)

Hua, J., Welp, U., Schlueter, J., Kayani, A., Xiao, Z.L., Crabtree, G.W., Kwok, W.K.: Vortex pinning by compound defects in YBa2Cu3O7-δ. Phys. Rev. B 82(2), 024505 (2010)

Matsushita, T., Isobe, G., Kimura, K., Kiuchi, M., Okayasu, S., Prusseit, W.: The effect of heavy ion irradiation on the critical current density in DyBCO coated conductors. Supercond. Sci. Technol. 21(5), 054014 (2008)

Linden, Y., Iliffe, W.R., He, G., Danaie, M., Fischer, D.X., Eisterer, M., Speller, S.C., Grovenor, C.R.M.: Analysing neutron irradiation damage in YBa2Cu3O7-x high-temperature superconductor tapes. J. Microsc. 286, 3–12 (2022)

Iliffe, W., Peng, N., Brittles, G., Bateman, R., Webb, R., Grovenor, C., Speller, S.: In-situ measurements of the effect of radiation damage on the superconducting properties of coated conductors. Superconductor Science and Technology 34, 09LT01 (2021)

Superpower Furakawa, Superpower 2G HTS Coated Conductors. www.superpower-inc.com/content/2g-hts-wire (2013)

Seo, S., Noh, H., Li, N., Jiang, J., Tarantini, C., Shi, R., Jung, S., Oh, M. J., Liu, M., Lee J., Gu, G., Jung Jo, Y., Park, T., Hellstrom, E. E., Gao, P., Lee, S.: Artificially engineered nanostrain in FeSexTe1-x superconductor thin films for supercurrent enhancement. NPG Asia Materials 12(7), (2020)

Ivan, I., Miu, D., Popa, S., Jakob, G., Miu, L.: On the determination of vortex creep parameters in superconductors using standard magnetization relaxation data. Supercond. Sci. Technol. 24, 095005 (2011)

Eley, S., Leroux, M., Rupich, M.W., Miller, D.J., Sheng, H., Niraula, P.M., Kayani, A., Welp, U., Kwok, W.K., Civale, L.: Decoupling and tuning competing effects of different types of defects on flux creep in irradiated YBa2Cu3O7−δ coated conductors. Supercond. Sci. Technol. 30(1), 015010 (2016)

Galstyan, E., Pratap, R., Majkic, G., Kochat, M., Abraimov, D., Jaroszynski, J., Selvamanickam, V.: In-field critical current and pinning mechanisms at 4.2 K of Zr-added REBCO coated conductors. Superconductor Science and Technology 33, 074007 (2020)

Putti, M., Vaglio, R., Rowell, J.: Radiation damaged MgB2: a comparison with A15 superconductors. J. Phys. Conf. Ser. 97, 012327 (2008)

Uemura, Y.J., Luke, G.M., Sternlieb, B.J., Brewer, J.H., Carolan, J.F., Hardy, W.N., Kadono, R., Kempton, J.R., Kiefl, R.F., Kreitzman, S.R., Mulhern, P., Riseman, T.M., Williams, D.L., Yang, B.X., Uchida, S., Takagi, H., Gopalakrishnan, J., Sleight, A.W., Subramanian, M.A., Chien, C.L., Cieplak, M.Z., Xiao, G., Lee, V.Y., Statt, B.W., Stronach, C.E., Kossler, W.J., Yu, X.H.: Universal correlations between Tc and ns/m* (carrier density over effective mass) in high Tc cuprate superconductors. Phys. Rev. Lett. 62(19), 2317 (1989)

Srinivas, G., Howard, C.A., Bennington, S.M., Skipper, N.T., Ellerby, M.: Effect of hydrogenation on structure and superconducting properties of CaC6. J. Mater. Chem. 19, 5239 (2009)

Anderson, P.W., Kim, Y.B.: Hard superconductivity: theory of the motion of Abrikosov flux lines. Rev. Mod. Phys. 36, 39 (1964)

Zhang, H., Wen, Z., Grilli, F., Gyftakis, K., Mueller, M.: Alternating current loss of superconductors applied to superconducting electrical machines. Energies 14(8), 2234 (2021)

Acknowledgements

We acknowledge the support of The University of Manchester’s Dalton Cumbrian Facility (DCF), a partner in the National Nuclear User Facility, the EPSRC UK National Ion Beam Centre and the Henry Royce Institute. We recognise R. Edge for their assistance during the gamma irradiation experiments. The research used UKAEA’s Materials Research Facility, which has been funded by and is part of the UK’s National Nuclear User Facility and Henry Royce Institute for Advanced Materials. The authors would like to thank S. B. L. Chislett-McDonald, S. C. Wimbush, and A. London for their vital advice necessary for preparation of this article.

Funding

This study was funded by the UKAEA Spherical Tokamak for Energy Production (STEP) programme Materials for STEP section within the Materials Business Unit.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article has been revised to correct figures 20 and 21.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Campbell, H.J., Zhang, Y. & Fukushima, T. Probing Evolution of the Flux-Pinning Landscape in REBCO Coated Conductors Caused by Gamma Irradiation Using DC and AC Magnetometry: A Novel Approach to Tokamak Magnet Material Development. J Supercond Nov Magn 37, 41–55 (2024). https://doi.org/10.1007/s10948-023-06663-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-023-06663-9