Abstract

The present investigation focuses on the incorporation of synthetic motor oil as an inexpensive, rich carbon source in bulk MgB2 superconductor and its effect on superconducting and flux pinning properties. A set of three MgB2 bulk samples were prepared from commercial high-purity powders of Mg metal and amorphous B powder utilizing a conventional in situ solid-state reaction process. Before sintering, the MgB2 samples were immersed in used and new synthetic motor oil for a standby time of 30 min and sintered in pure Ar atmosphere at 775 °C for 3 h. X-ray powder diffractometer (XRD) analysis confirmed that single-phase formation of MgB2 with a small shift in X-ray diffraction peaks especially at (110) towards the peak position due to the effect of carbon substitution into the boron sites in lattice for samples immersed in new and used synthetic oil. The magnetization measurements indicated the Tc (onset) value to somewhat decrease to 37.5 K as a result of carbon doping. Microstructural observations with scanning electron microscopy (SEM) suggested that fine nano-sized MgB2 grains improved self-field critical current density around 3.8 × 105 A/cm2 at 20 K for all samples studied. Further, the high-field critical current density (Jc) was improved especially for the sample immersed in used synthetic motor oil with the value of 2.7 × 104 A/cm2, 6 × 103 A/cm2 at 20 K, and at 3 T and 4 T, which is higher as compared to pure-MgB2 sample. In essence, the results signify that the bulk MgB2 samples immersed with used synthetic motor oil would improve the bulk performance at high magnetic fields indicating to be a viable option for industrial applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In January 2001, the discovery of a superconducting phenomenon with the transition temperature of 39 K in MgB2 compound had ignited a renaissance of interest in solid-state physics community as it had proposed a simple, binary intermetallic superconductor with a groundbreaking superconducting transition temperature recorded for non-60-based compounds and non-oxides [1]. MgB2 exhibits a wide range of attractive features including small anisotropy, large coherence length, simple crystal structure, transparent grain boundaries, and easy processing allowing it to be a desirable candidate for numerous industrial and commercial applications [2, 3]. The essential application areas of bulk MgB2 are NMR devices, MRI systems, particle accelerators, maglev transport technology, wind turbine generators, etc. [4, 5]. However, additional enhancement of flux pinning and critical current density (Jc) is significant for material compatibility at high-field applications as MgB2 superconducting material consists of weak flux pinning and poor grain connectivity which would further lead to a sharp fall in critical current density at higher magnetic fields around 20 K [6, 7]. In particular, doping and chemical addition with C or C-based compounds in MgB2 contributed towards the improvement of critical current density performance due to amelioration of intra-band scattering and grain connectivity as well as the induction of extra pinning centers [8]. In fact, numerous groups in the past had investigated the simultaneous enhancement of Jc in MgB2 by introducing carbon-containing dopants where Yang et al. showed that polymer doping in MgB2 enhanced both irreversibility field and critical current density at high-field region due to the parameters of percolation threshold and anisotropy; whereas improved effects of Jc were much weaker at high temperature ranges due to effect of less reduction of anisotropy at similar temperature [9]. De Silva et al. noted that graphene doping in MgB2 notably enhanced the superconducting properties under a small reduction of Tc; further, improved flux-flow activation energy, low resistivity, and high critical fields were observed for the optimal doped bulk and flux pinning mechanism referred to spatial fluctuation in transition temperature for graphene doped MgB2 sample [10]. Dou et al. conveyed that nano-SiC doping in MgB2 crucially improved Hirr and Jc while decreasing Tc by 1.5 K as intragrain pinning centers were introduced at high temperatures and fields [11]. Kim et al. presented that carbohydrate doping with the usage of malic acid in MgB2 bulks showed numerous advantages such as prevention of expensive nano-additives, enablement of homogenous mixing of precursor powders, and an exceptional improvement in Hc2, Hirr, and Jc when differentiated from pure MgB2 sample; in fact, MgB2 + 30 wt % C4H6O5 bulk sample’s Jc tremendously increased by a factor of 21 under 5 K and 8 T with the absence of degradation of self-field Jc [12]. Also, Kim et al. inferred that doping effect of two types of multi-wall carbon nanotubes (CNTs) showed a slight decrease in Tc as the sintering temperature increased and Tc values for long CNT doped bulk samples showed an increase. The following result explains that small aspect ratio enabled stronger reactivity between short CNT and MgB2 where carbon C from short CNT substituted for boron B. The short CNT samples which were sintered at high temperature ranges of 900 °C and 1000 °C showed that magnificent Jc value of 104 A/cm2 within the fields up to 8 T at 5 K. Strong flux pinning centers were formed due to substitution of C into MgB2 lattice along with the inclusion of nano-sized MgO particles [13]. Qin et al. suggested that hydrocarbon doping in MgB2 samples via citric acid showed gradual decrease in anisotropy of upper critical field with an aberration of experimental data from grain boundary pinning theory with a reduction of increasing doping level as temperature approaches Tc [14]. Yamamoto et al. indicated that B4C doping in MgB2 bulks effected substantial improvement in Jc especially under high magnetic fields at 5 K due to strengthened flux pinning properties at grain boundaries due to carbon substitution with a decrease of a-axis length and Tc with deterioration of crystallinity [15]. Moreover, carbon would be substituted at boron (B) sites in the MgB2 lattice that further increases impurity scattering between π and σ bands resulting in improved upper critical field (Bc2) [16]. Nevertheless, a uniform distribution in the matrix tends to be a drawback if the dopants presented above were incorporated. In order to overcome this issue, researchers had introduced carbon-encapsulated boron for a batch production of MgB2 samples and proved to be successful. In contrast, carbon-encapsulated boron powder was considered to be expensive making the entire fabrication process costly and was not a preferable option for a commercial production of bulk MgB2 super-magnets [7]. Due to the following reasons, “synthetic motor oil” was utilized because it was considered to be a rich source of carbon since it could be easily accessed at a relatively cheaper price and was suggested to be a viable alternative towards low cost processing for industrial approach; as a matter of fact, synthetic motor oil produces a high tolerance towards aging and heat as it poses high oxidative and high thermal stability. Consequently, it was pivotal to study the effects of used and new synthetic motor oil towards the flux pinning and superconducting properties of bulk MgB2 samples at a high field to be compared with a reference sample without incorporation of synthetic motor oil.

In this present investigation, a set of three MgB2 samples were prepared where two samples were immersed in used and new synthetic motor oil, while third sample was a reference sample without any exposure to synthetic motor oil addition. The following samples were characterized utilizing X-ray powder diffractometer (XRD) and superconducting quantum inference device (SQUID) magnetometer to report superconducting transition temperature (Tc) and critical current density (Jc); in essence, it was observed that flux pinning performance was enhanced especially in high magnetic fields at 20 K via an immersion of used synthetic motor oil.

2 Materials and Methods

First of all, the bulk polycrystalline MgB2 samples were synthesized by utilizing conventional in situ solid-state reaction methodology. High purity commercial powders of Mg metal of 99.9%, 200 meshes from Furuuchi Chemical Corporation, and nano-sized amorphous B powder of 98.5% purity, 200 nm from Pavezyum Advanced Chemicals, Turkey, were utilized to produce a set of three bulk MgB2 samples; additionally, the following powders were mixed with a stoichiometric ratio of Mg:B = 1:2. Note that the starting powders were thoroughly ground in a glove box setting under the conditions of argon atmosphere. Then, the powder mixture was compressed into pellets with the dimension of 10 mm in diameter and 5 mm in thickness via usage of uniaxial press under the load of 20 kN. The pellet samples were distinguished into three separate specimens where (i) u-MgB2 was noted as a MgB2 sample immersed in used synthetic motor oil for a standby time of 30 min; (ii) n-MgB2 was referred as a MgB2 sample submerged in new synthetic motor oil for a standby time of 30 min; (iii) pure-MgB2 was a reference pellet sample of without any synthetic motor oil addition. Note that the following pellets were instantly wrapped with tantalum foils [17] and were put through heat treatment under argon atmosphere in a tube furnace. All of the samples were heated at a temperature of 775 °C for 5 h and kept constant for a period of 3 h with flow of Ar gas. Then, the samples were cooled under the room temperature at a rate of 100 °C/h.

Secondly, SQUID magnetometer (Quantum Design MPMS5) was used to characterize and evaluate the superconducting properties of the samples such as Jc and Tc. The specimens from bulk MgB2 samples were cut with the dimensions of 1.5 × 1.5 × 0.5 mm.3 to acquire the measurements of critical temperature (Tc) in addition to magnetization hysteresis loops (M-H loops) within an applied magnetic field range of − 1 to + 5 T at 20 K. The extended Bean critical state formula was applied to estimate the critical current density as given below

where d is the sample thickness, l and w are cross-sectional dimensions, w ≥ l, and \(\Delta\) m difference of magnetic moments on the descending and ascending field branches of M − H loop [18]. Furthermore, X-ray powder diffractometer (RINT2200) was employed to identify constituent phases of the samples at a high resolution and field emission scanning electron microscope (FE-SEM) (JEOL/JSM-7610F) for studying the microstructural features.

3 Results and Discussion

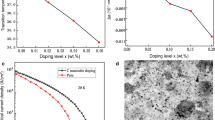

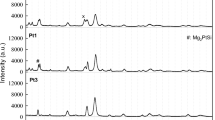

XRD of the bulks reveal the complete single-phase formation of MgB2, with scare MgO impurity that is generally observed in this system due to the high oxidizing nature of Mg (see Fig. 1, left). The close study of (110) diffraction peaks enabled to determine a slight shift in the peak position usually a sign of carbon substitution into the lattice (see Fig. 1, right). Further, the (002) peak was noted to be the same observed in all samples.

Lattice parameter calculations using Bragg’s law (see Table 1) revealed that the value of “a” decreased from pure-MgB2 to n-MgB2 and then to u-MgB2, while the value of “c” remained almost constant for all samples. This points out to carbon-boron substitutions in the boron honey comb (in ab-plane) layer without disturbing the interlayer interactions [19]. The c/a calculations are used to estimate the carbon substitution using Eq. (2) [20]. Our calculations show that u-MgB2 has highest Δ(c/a) value which corresponds to x = 0.0015 in MgB2-xCx or 0.075% carbon doped into the MgB2 lattice.

While the likes of [NMgB2] showed only 0.0325% of carbon doping. This is expected as the used oil has experience more heating cycles during the course of its uses and then results in breakdown of compound into a number of different chemicals species such as aldehydes, ketones, and carboxylic acids which are carbon-based.

Critical transition temperatures (Tc) of pure-MgB2 bulks were around 38.1 K, and the transition width is less than 0.5 K indicating a sharp superconducting transition (see Fig. 2). Tc,onset of u-MgB2 seem to be slightly lower than pure-MgB2, around 37.5 K which is to be expected from carbon substitution as suggested from earlier reports on carbon encapsulated boron powder for MgB2 fabrication [22, 30] (see Fig. 2).

Various studies also show that the Tc depreciates in proportion with amount of carbon doped, for instance, 4 and 5% of nano-carbon substitution has dropped the Tc to 34.68 and 34.35 K, respectively [21]. In general, the depreciation is proportional to carbon doping amount [22]. Critical current densities of MgB2 bulks have shown to be improved via carbon doping in several instances such as using carbon nanotubes (2.5–10 at.%) where they found Jc increase up to 5 × 104 A/cm2 at 5 T and 5 K, similarly for 10% SiC-doped sample showed Jc of 3.6 × 104 A/cm2 at 4 T (20 K), and 3% GO-doped samples showed Jc of 0.5 × 104 A/cm2 at 4 T (20 K) [23,24,25]. On similar note, the incorporation of carbon into MgB2 via suspending the bulks in synthetic oil was attempted. To our surprise, the carbon substitution took place as confirmed by XRD results, and this resulted in improved high-field critical current density especially over magnetic fields of 3 T and 4 T as shown in Fig. 3. However, it was observed that critical current density was slightly improved in n-MgB2 as compared to u-MgB2 (see Fig. 3). To understand high-field critical current densities, the Jc estimated at self-field, 2 T, 3 T, and 4 T for three samples are summarized inset of Fig. 3. It is clear that the critical current density remained constant for all samples in self-field and u-MgB2 showed a clear increase in Jc at 2 T, 3 T, and 4 T (see inset of Fig. 3). At 20 K, the Jc value for u-MgB2 at 2 T, 3 T, and 4 T was around 9.2 × 104, 2.7 × 104, and 6 × 103 A/cm2 which were all above the values for pure-MgB2 and n-MgB2 bulk.

This suggests that the enough carbon substitution has taken place in u-MgB2 resulted in high-field flux pinning, while this effect is not clearly visible in n-MgB2 probably due to insufficient carbon doping. Similar behavior has been observed in n-SiC doping as well as nano-carbon doping where the Jc value at low fields is high in undoped bulks rather than doped ones [26]. The self-field Jc values of pure-MgB2, n-MgB2, and u-MgB2 are around 3.8 × 105 A/cm2. The enhancement of Jc at high fields indicates the pinning from carbon substitution. Various studies have already elucidated that carbon substation can enhance upper critical fields which is especially due to its nature of flux pinning that specifically acts at high fields. On the other hand, this self-field Jc of pure-MgB2, n-MgB2, and u-MgB2 is much higher than some of the previously reported results [27]. This is due to amorphous nano boron precursor that was used. The nano boron precursor results in nano-sized MgB2 grains in the final bulk leading to high grain boundary pinning which acts specifically at low fields [7].

Microstructural images are obtained using FE-SEM to understand the grain structure and morphology. Figure 4 presents the low and high magnification SEM images for the pure-MgB2, n-MgB2, and u-MgB2 bulks. It is clear that MgB2 matrix comprises of several voids in numerous sizes and shapes (see Fig. 4, top), as highlighted in previous reports [27]. Much higher magnification reveals that the grain size is ranged from 50 to 300 nm as a consequence of using nano boron precursor (see Fig. 4, bottom). One can note the nature of similar grain size in three bulks due to utilization of same nano-boron and same sintering condition. Such fine grains mean that the matrix has more grain boundaries that are low-field pinning centers thereby enhancing the low-field flux pinning and subsequently high self-field Jc. As a result, we had attained similar critical current density values at self-field which was presented in set of Fig. 3.

Low (top) and high (bottom) magnification FE-SEM micrographs of fractured surface of bulk MgB2 samples. pure-MgB2 (left), n-MgB2 (middle), and u-MgB2 (right). It can be lucidly indicated that higher magnification showing the nano-sized grains ranged from 50 to 300 nm which are responsible for high self-field Jc

Consequently, in order to comprehend more on critical current (Jc) performance at 20 K of MgB2 samples immersed in used synthetic motor oil, the data has been compared with literature with samples produced utilizing carbon-coated boron, addition of carbon nanotubes, nano-boron, ultrasonicated boron, silver, and various sintering conditions as more details are highlighted in Table 2. It is intriguing to note that critical current density attained at 20 K and 1 T is close to the reported value of carbon-coated boron powder that was utilized to fabricate bulk MgB2 samples, and the value indicated to be less than the samples produced utilizing carbon nanotubes or ultrasonicated boron. Furthermore, high critical current performance was slightly higher when compared to samples produced without oil immersion or samples immersed in new synthetic motor oil (see Fig. 3, inset). Additionally, a similar Jc behavior at 25 K was also observed in optimal 4.0 wt% C4H6O5 added MgB2 sample that was produced by two-step solid-state reaction method [37]. This is indeed a simple trial attempting to utilize the optimum sintering condition combined with used synthetic motor oil to reduce the cost of fabrication of bulk superconducting materials and improvement of high-field performance.

To clearly show the influence of carbon based flux pining. The flux pinning diagrams were plotted based on the Dew-Hughes general expression [38]

where fp is normalized flux pinning force, fp = Fp/Fp,max, and h is reduced magnetic field, h = H/Hirr, where the irreversibility field, Hirr, was determined as the field, where Jc in the Jc(H) dependence fell down to 100 A/cm2, a standard practice in our works. The fp(h) dependence was analyzed at 20 K and plotted for all the bulks (see Fig. 5). In general, the dominant pinning mechanism in MgB2 bulk materials is from grain boundaries with a peak position (fp = 1) at lying at h = 0.19–0.2 as observed for the pure-MgB2 specimen. When magnified, it can be seen that the peak of flux pinning diagrams has shifted towards higher values (see inset figure in Fig. 5) for the u-MgB2 as compared to pure-MgB2 bulk. The peak position of u-MgB2 is around 0.23, which points out to slight increase flux pinning contribution from carbon substitution, which is similar to bulk MgB2 produced utilizing the carbon encapsulated boron powders [22].

Surprisingly, the peak position for n-MgB2 was located at 0.2 indicating a dominant grain boundary pinning, which is most likely due to insufficient carbon doping. However, the pinning behavior at h > 0.5 for u-MgB2 and n-MgB2 have shifted towards right indicating the high-field pinning showing the signs of flux pinning from carbon-substitution. These results are in accordance with some previous reports [39]. Optimization of bulk MgB2 material with dipping in synthetic motor oil before sintering in long duration would further improve the performance of material, which would be considered to be the next task, as it would serve to be useful for day to life applications.

4 Conclusions

To summarize, high purity single-phase bulk MgB2 samples were successfully fabricated and was able to dope carbon into the lattice via suspending the pellets in synthetic oil before sintering. A slight shift in XRD peaks was observed especially in (110) peak which points out to 0.55 and 0.89% carbon substitution into the lattice when suspended in new and used synthetic oil. Also, the (002) peak position had remained unchanged for all samples. Simultaneously, a slight drop in Tc,onset up to 37.5 K was observed as expected from carbon substitution. This substitution resulted in high-field Jc improvement, especially in field region of H > 2 T. The Jc value reached for u-MgB2 at 2 T, 3 T, and 4 T was around 9.2 × 104, 2.7 × 104, and 6 × 103 A/cm2, which is higher than undoped bulk. Further, the self-field Jc is also huge due to the nano-boron precursor which resulted in fine nano-sized MgB2 grains as confirmed by FE-SEM. Finally, the flux pinning diagrams indicated that dominant pinning comes from grain boundaries, but there was also a considerable effect from increased electron impurity scattering caused by carbon substitution. The present results suggest that the bulk MgB2 material performance can be further improved by optimizing the used synthetic motor oil for longer time duration, as it will serve to be useful for low cost and high performance superconducting super-magnet production for several day-to-life applications.

References

Nagamatsu, J., Nakagawa, N., Muranaka, T., Zenitani, Y., Akimitsu, J.: Nature 410, 63 (2001)

Glowacki, B.A., Majaros, M., Vickers, M., Evetts, J.E., Shi, Y., McDougall, I.: Supercond. Sci. Tech. 14, 193 (2001)

Larbalestier, D.C., Cooley, L.D., Rikel, M.O., Polyanskii, A.A., Jiang, J., Patnaik, S., Cai, X.Y., Feldmann, D.M., Gurevich, A., Squitieri, A.A., Naus, M.T., Eom, C.B., Hellstrom, E.E., Cava, R.J., Regan, K.A., Rogado, N., Hayward, M.A., He, T., Slusky, J.S., Khalifah, P., Inumaru, K., Haas, M.: Nature 410, 186 (2001)

Zhao, Y.: Appl. Phys. Lett. 79, 1154 (2001)

Muralidhar, M., Murakami, M.: J. Supercond. Nov. Magn. 31, 2677 (2018)

Batalu, D., Aldica, G., Burdusel, M., Badica, P.: Key. Eng. Mat. 638, 357 (2015)

Muralidhar, M., Higuchi, M., Kitamoto, K., Koblischka, M., Jirsa, M., Murakami, M.: IEEE. T. Appl. Supercon. 28, 1 (2018)

Giunchi, G., Ripamonti, G., Cavallin, T., Bassani, E.: Cryogenics 46, 237 (2006)

Yang, Y., Wang, L., Sun, H.H., Cheng, C.H., Zhao, Y.: J. Phys. Chem. Solids. 72, 593 (2011)

De Silva, K.S.B., Xu, X., Gambhir, S., Wang, X.L., Li, W.X., Wallace, G.G., Scripta, S.X.: Mater. 65, 634 (2011)

Dou, S.X., Soltanian, S., Horvat, J., Wang, X.L., Zhou, S.H., Ionescu, M., Liu, H.K.: J. Appl. Phys. 81, 3419 (2002)

Kim, J.H., Zhou, S., Hossain, M.S.A., Pan, A.V., Dou, S.X.: J. Appl. Phys. 89, 142505–142511 (2006)

Kim, J.H., Yeoh, W.K., Qin, M.J., Xu, X., Dou, S.X.: J. Appl. Phys. 100, 013908–013911 (2005)

Qin, J.J., Yang, Y., Wang, L., Sun, H.H., Liu, Y.T., Ke, C., Cheng, C.H., Zhao, Y.: J. Supercond. Nov. Magn. 35, 415 (2022)

Yamamoto, A., Shimoyama, J., Ueda, S., Iwayama, I., Horii, S., Kisho, K.: Supercond. Sci. Tech. 18, 1323 (2005)

Gao, Z., Wang, D., Zhang, X., Ma, Y., Awaji, S., Nishijima, G., Watanabe, K., Flukiger, R.: Supercond. Sci. Tech. 23, 043024 (2010)

Serquis, A., Liao, X.Z., Zhu, Y.T., Coulter, J.Y., Huang, J.Y., Willis, J.O., Peterson, D.E., Mueller, F.M.: J. Appl. Phys. 92, 351 (2002)

Bean, C.P.: Phys. Rev. Lett. 8, 250 (1962)

Takenobu, T., Ito, T., Chi, D.H., Prassides, K., Iwasa, Y.: Phys. Rev. B. 64, 134513 (2001)

Avdeev, M., Jorgensen, J.D., Ribeiro, R.A., Bud’ko, S.L., Canfield, P.C.: Physica C. 387, 301 (2003)

Mudgel, M., Awana, V.P.S., Kishan, H., Bhalla, G.L.: Solid. State. Commun. 146, 330 (2008)

Sai Srikanth, A., Muralidhar, M., Sunsanee, P., Jirsa, M., Sakai N., Oka, T., Murakami, M.: Adv. Eng. Mater. 22, 2000478 (2020)

Serquis, A., Serrano, G., Moreno, S.M., Civale, L., Maiorov, B., Balakirev, F., Jaime, M.: Supercond. Sci. Tech. 20, L12 (2007)

Dou, S.X., Soltanian, S., Horvat, J., Wang, X.L., Zhou, S.H., Ionescu, M., Liu, H.K.: Appl. Phys. Lett. 81, 3419 (2002)

Sudesh, Kumar, N., Das, S., Bernhard, C., Varma, G.D.: Supercond. Sci. Tech. 26, 095008 (2013)

Awana, V.P.S., Vajpayee, A., Mudgel, M., Rawat, R., Acharya, S., Kishan, H., Takayama-Muromachi, E., Narlikar, A.V., Felner, I.: Physica C. 467, 67 (2007)

Muralidhar, M., Inoue, K., Koblischka, M.R., Tomita, M., Murakami, M.: J. Alloy. Compd. 608, 102 (2014)

Noudem, J.G., Aburras, M., Bernstein, P., Chaud, X., Muralidhar, M., Murakami, M.: J. Appl. Phys. 116, 163916 (2014)

Muralidhar, M., Inoue, K., Koblischka, M., Murakami, A., Murakami, M.: Adv. Eng. Mater. 17, 831 (2015)

Muralidhar, M., Higuchi, M., Jirsa, M., Diko, P., Kokal, I., Murakami, M.: IEEE. T. Appl. Supercon. 27, 6201104 (2017)

Taylan Koparan, E., Savaskan, B., Yanmaz, E.: Physica C. 527, 36 (2016)

Sai Srikanth, A., Muralidhar, M., Jirsa, M., Sakai, N., Murakami, M.: J. Supercond. Nov. Magn. 34, 1297 (2021)

Muralidhar, M., Kenta, N., Koblischka, M., Murakami, M.: Phys. Status. Solidi. A. 212, 2141 (2015)

Hapipi, N.M., Chen, S.K., Shaari, A.H., Kechik, M.M.A., Lim, K.P., Tan, K.B., Lee, O.J., Sai Srikanth, A., Muralidhar, M.: J. Mater. Sci. Mater. 33, 11257 (2022)

Kaya, N., Cavdar, S., Ozturk, O., Yildirim, G., Koralay, H.: J. Mater. Sci. Mater. 33, 3786 (2022)

Zhang, J.Y., Zhang, Y.F., Lou, Z.W., Zhang, P.H., Li, C.Y., Yuan, J.W., Peng, L., Ma, Y.X., Noudem, J.G., Izumi, M.: Supercond. Sci. Tech. 34, 0455011 (2021)

Cakir, B., Koparan, E.T., Savaskan, B.: J. Mater. Sci. Mater. 32, 20317 (2021)

Dew Hughes, D., Philos. Mag. 30, 293 (1974)

Ghorbani, S.R., Farshidnia, G., Wang, X.L., Dou, S.X.: Supercond. Sci. Tech. 27, 125003 (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Santosh, M., Sai Srikanth, A. & Muralidhar, M. Enhanced Flux Pinning Performance of Bulk MgB2 via Immersion of Synthetic Motor Oil. J Supercond Nov Magn 35, 2785–2791 (2022). https://doi.org/10.1007/s10948-022-06337-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-022-06337-y