Abstract

It has been proposed by Müller and Shengelaya that underdoped ultrathin layers of copper-oxide high-temperature superconductors (HTSs) sandwiched between high-dielectric-constant insulator layers could manifest increased superconducting critical temperature \(T_c\). To check this hypothesis, we investigated structural and transport properties of YBa\(_{2}\)Cu\(_{3}\)O\(_{7-\delta }\) (YBCO) thin films sandwiched between SrTiO\(_{3}\) (STO) layers. Scanning transmission electron microscopy (STEM) showed that a high-quality interface is formed between YBCO and the top STO layers. An increase of \(T_c\) up to \(\Delta\)T\(\approx\)20 K was observed at these interfaces in case of underdoped YBCO films.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The HTSs based on hole-doped cuprate oxides have an universal doping dependence for the superconducting transition temperature (\(T_{c}\)) [2] showing a maximum at the optimal doping of about 15 mol%. In these compounds, it has been proposed that Jahn-Teller intersite bipolarons aggregate to form metallic clusters (or stripes) [3,4,5,6,7]. When a critical distribution of these clusters is reached, percolation takes place and the bulk superconducting phase is established [5, 8]. According to this model, opening of the so-called pseudogap (\(T^*\)) has been proposed to be associated with the formation of such clusters, which locally host the superconducting phase. These are charged regions that form and dissociate based on thermal fluctuations, and the Coulomb repulsion between these objects (see Fig. 1a) prevents from reaching percolation [7]. Therefore, in 2013 Müller and Shengelaya [1] proposed to apply the method of “Coulomb interaction engineering” [9] in ultrathin layers of copper-oxide HTSs sandwiched between high-dielectric-constant insulators(see Fig. 1b). The Coulomb repulsion between the clusters could be reduced due to the penetration of the electric field from the surrounding insulators with high dielectric constant. This might result in a smaller distances between the charged clusters and thus help to form a 3D percolation at higher temperatures, leading to a higher \(T_{c}\).

The possibility to modify the Coulomb interaction in a thin layer of a semiconductor or semimetal was pointed out for the first time by Keldysh [9]. Other authors showed how the dielectric mismatch of substrate and semiconductor layer could decrease the scattering term of Coulomb impurities, i.e., producing an improvement in mobility of carriers [10] or can be used for band gap tuning [11, 12].

Despite the simple idea behind the proposed oxide-HTS-oxide heterostructure, there are several challenges to create high-quality epitaxial interfaces. Superconductivity at interfaces is sensitive to many factors that can reduce \(T_c\) or even suppress the superconductivity: cation inter-diffusion, surface reconstruction caused by polar discontinuity, oxygen ion mobility at the interface, structural defects and strain effects due to lattice mismatch.

To search for the possible dielectric enhancement of \(T_c\), we prepared multilayer YBCO-STO heterostructures and studied their structural and transport properties.

2 Materials and Methods

Commercial (CRYSTAL, GmbH) high-quality single-crystalline (001)-oriented STO with a miscut angle \(\le 0.1\) \(^{\circ }\) was used as a substrate for films growth. Step-like TiO\(_2\)-terminated surfaces were obtained by a standard HF etching and oxygen annealing procedure as reported in Ref.[13]. Nominally pure YBa\(_{2}\)Cu\(_{3}\)O\(_{7-\delta }\) films were grown from commercial ceramic target by means of pulsed laser deposition (PLD) setup which uses a KrF (248 nm) excimer laser (Coherent LPX 300i). All the films were grown under 100 mTorr oxygen pressure at \(780\,^{\circ }\mathrm{C}\) with a laser fluency of 1.25 J/cm\(^2\) at 1 Hz. After the deposition, three different in situ annealing procedures were used to achieve different levels of oxygen doping. The cooling rate and partial pressure of O\(_2\) were selected as shown in Table 1 between 600 \(^\circ\)C and room temperature.

X-ray diffraction (XRD) experiments were performed on a Bruker D8 Discover, with a CuK\(_{\alpha }\) tube (\(\lambda =1.5406\) Å). Indium wires pushed on the YBCO surface were connected in a typical \(4-\)probe geometry with additional drops of Ag paint to guarantee a good electrical contact. In case of a STO top layer, a simple mechanical scratch by means of a diamond tip ensures the electrical contact to the bottom YBCO layer via the Ag paint. High-resolution images of the top surface were taken by means of an ORION He ion microscope (HIM) from Carl Zeiss (henceforth referred to as “He-microscope”). This microscope is based on a He-focused ion beam (FIB) that excites secondary electrons in the sample, which are then detected for image formation. We operated it with a beam current of 0.5 pA and 30 kV accelerating voltage. The film microstructures were characterized using a transmission electron microscope (TEM, JEOL 2200FS) operated at an accelerating voltage of 200 kV in scanning transmission mode using a high-angle annular dark-field detector. Lamellas for TEM analysis were prepared by Ga-focused ion beam instrument (FEI Strata 235).

3 Results and Discussion

3.1 Crystal Quality of YBCO-STO Interfaces

XRD measurements performed on our YBCO films show only (00l) reflections, which implies that the films are c-axis oriented, as shown on a selected sample in Fig. 2.

He-ion secondary electron emission imaging performed on the top surface (Fig. 3a) of a thick optimally doped YBCO film (\(\sim\)165 nm) shows evidence of a mosaic of rectangular domains. This texture is a consequence of the distribution of orientations of the ab plane of YBCO which form in different nucleation points during the growth of the first YBCO layer.

He-FIB images of bare YBCO film on STO substrate with a thickness of a 165 nm and b 50 nm. Here, \(90^{\circ }\) twinned domains [14] form on top TiO\(_{2}\)-terminated STO surface which has a \(4-\)fold symmetry. This tower-like growing becomes less evident for the thinner sample which has a smoother surface

Therefore, \(90^{\circ }\) twinned domains [14] form on top of a TiO\(_{2}\)-terminated STO surface which has a \(4-\)fold symmetry. For thin films below 50 nm (Fig. 3a) this texture is less evident. Here, the surface is smoother and more flat indicating that, in this range of thickness, a layer-by-layer growth (Frank–van der Merwe mode) dominates the deposition instead of a tower-like mode (Stranski–Krastanov growth). The latter gives rise to a difference in the height between the twinned domains which is undesired for the formation of good interfaces.

The quality of epitaxial YBCO thin films reported in the literature depends on the growing techniques. It was reported that thin films produced by magnetron sputtering are superconducting down to 2 unit cell (UC) layers [15], while in the case of PLD superconductivity is suppressed below 6 UC layers [16].

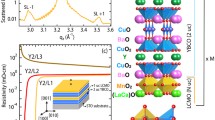

Other works [17, 18] addressed the so-called dead layers of YBCO at the interface with STO as the main responsible of suppression of \(T_{c}\). These layers originate from the lattice mismatch between the STO (a\(\approx 3.905\) Å, cubic) and the c-axis of YBCO (c\(\approx 11.70\)Å) as shown in Fig. 4a. The TiO\(_2\)-terminated atomically flat STO substrate contains steps between each TiO\(_2\) terraces, with a minimal height corresponding to its lattice parameter (3.905)Å which is about 1/3 of the c-axis unit cell parameter of YBCO. This mismatch generates anti-phase boundaries into the film (see schematic representation in Fig. 4c) which could be responsible for the suppression of the superconductivity in a few layers from the bottom interface [17, 18]. However, this difference of the lattice parameters between the two compounds does not generate defects in the STO-YBCO top interface (Fig.4b), because 3(n) UCs of STO can cover and adapt to each steps on the YBCO surface as shown schematically in Fig. 4d. In order to implement the heterostructure proposed by Müller and Shengelaya [1], it is clear from our findings that YBCO films must be sufficiently thick in order to avoid the initial 5 to 6 “dead layers,” but thinner than 50 nm in order to obtain a good interface with the STO deposited. Only the top interface (almost defect free) could be eligible for “Coulomb interaction engineering” effects.

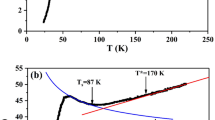

a Normalized resistance vs temperature of STO-YBCO optimally doped films with different thickness. The inset shows the comparison of the resistance for two YBCO films (11 nm) with and without STO top interface. b \(T_{c}\) vs YBCO thickness for optimally doped YBCO-STO (red closed circles) and STO-YBCO-STO (blue closed triangles). The picture includes data extracted from other papers where the films were produced by magnetron sputtering [15] (open circles) and PLD [16] (black closed circles)

3.2 Transport Measurements of Optimally Doped YBCO-STO Heterostructures

We have performed investigation on a series of optimally doped YBCO films with and without STO cap layers. The superconducting critical temperature \(T_{c}\) was extracted by the onset of resistance drop (see Fig. 5a). The films with thickness from 165 nm down to 11 nm do not show any substantial effect on \(T_{c}\) when top layers of STO were present (see inset in Fig. 5a). The quality of our epitaxial films down to a thickness of about 11 nm (with \(T_{c}\approx\)87 K) compares well with high-quality films produced by means of magnetron sputtering (see Fig. 5b) by Barriocanal et al. [15], while in case of PLD other authors report a decrease of \(T_{c}\) to about 65 K at 11nm [16]. The difference with our case could originate from the quality of the substrates selected for the growth. Indeed, the miscut angle of the substrate determines the amount of defects (surface steps) at the interface with YBCO grown onto the STO substrates as shown by TEM (Fig. 4a).

According to Müller and Shengelaya [1] the effect of the dielectric constant \(\epsilon\) of the insulator on \(T_c\) should be larger in the underdoped region where the pseudogap temperature is higher. Thus, it is not surprising that for the optimally doped films we did not detect \(T_c\) enhancement due to the STO cap layer.

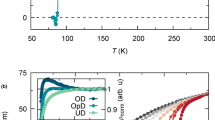

3.3 Transport Measurements of Underdoped YBCO-STO Heterostructures

While the slow cooling in a higher O\(_2\) pressure (\(\sim\)380 Torr) ensures the oxidation of the YBCO films (optimally doped), the two fast cooling with rates (5\(^{\circ }\)/min and \(\ge\)20\(^{\circ }\)/min) in 100 mTorr of O\(_2\) induces oxygen vacancies (V\(_o\)s) in the YBCO layer (Table 1). Therefore, underdoped YBCO thin films can be obtained by fast cooling in a reduced O\(_2\) pressure. A series of YBCO (20 nm) films with and without STO cap layer of 30 nm (Fig. 6a) were grown and thermally treated according to the annealing schemes described above.

Figure 6b shows resistivity curves for YBCO thin films (underdoped II in Table 1) with and without top STO layer. For comparison, in the same figure we included resistivity data extracted from Ref. [19] of YBCO thin films with different hole dopings. The curves with lower resistivity and higher \(T_c\) correspond to the optimally doped samples. In our case the higher resistivity and lower \(T_c\) is a clear evidence of underdoped YBCO films. Under same annealing conditions the bare YBCO film shows a similar resistivity (red line) at room temperature as compared with STO-capped film (blue line).

This indicates that both samples are underdoped with similar charge carrier concentrations. At the same time, a significant increase of \(T_c\sim\)10 K is observed in a YBCO film with top STO layer, as can be seen in Fig. 6b. We measured enhancement of \(T_c\) up to \(\sim\)20 K in STO-capped YBCO films compared to the bare films. The observed increase of \(T_c\) at the STO-YBCO interface is interesting and is consistent with the effect predicted by Müller and Shengelaya for the underdoped cuprate films. However, other possible explanations cannot be excluded at present. For example, it is known that \(T_c\) of YBCO is very sensitive to the oxygen stoichiometry. Oxygen diffusion from top STO layer to YBCO can also increase of \(T_c\). More work has to be done to establish whether such oxygen exchange takes place at the STO-YBCO interface under our experimental conditions.

4 Summary and Conclusions

We have grown multilayer YBCO-STO heterostructures to search for the possible dielectric enhancement of \(T_c\) proposed by Müller and Shengelaya. Analysis of the YBCO-STO bottom and top interfaces revealed the presence of extended structural defects only at bottom interface. This is due to the lattice mismatch between the STO and the c-axis lattice parameter of YBCO, which generates anti-phase boundaries. It was found a better crystal quality of the top STO-YBCO interface because 3(n) UC of STO can cover and adapt to each steps on the top YBCO surface without introducing defects. In general, if the ratio between the lattice parameters between an HTS cuprate and an insulating oxide is close to an integer number, then a good coating of the cuprate surface is expected. Having established this fact, we studied in detail transport properties of the top YBCO-STO interface.

We compared \(T_c\) of optimally doped and underdoped YBCO thin films without and with STO top layer. In case of optimally doped YBCO, we did not observe any detectable effects. However, in underdoped YBCO films, a significant increase of \(T_c\) up to 20 K was observed after depositing the top STO layer. This interesting effect can be interpreted in the framework of the model proposed by Müller and Shengelaya. However, other possible interpretations cannot be excluded at present. For example, the oxygen content might increase in YBCO layer next to the top interface due to the STO deposition. Therefore, a high-resolution interface study is required for the better understanding of the effects taking place at the boundary between YBCO and STO layers. Generally, high mobility of oxygen in YBCO makes it difficult to unambiguously interpret the increase of \(T_c\) observed at the YBCO-STO interface. In this respect, other cuprate systems such as LSCO might be preferable to demonstrate the effect of dielectric enhancement of \(T_c\) because LSCO doping is controlled by Sr doping and not by highly mobile oxygen ions.

References

Müller, K.A., Shengelaya, A.: J. Supercond Nov. Magn. 26, 491 (2013)

Hüfner, S., Hossain, M., Damascelli, A., Sawatzky, G.: Rep. Prog. Phys. 71, 062501 (2008)

Müller, K.A.: Journal of Superconductivity and Novel Magnetism 27, 2163 (2014)

Shengelaya, A., Bruun, M., Kochelaev, B.I., Safina, A., Conder, K., Müller, K.A.: Phys. Rev. Lett. 93, 017001 (2004)

Mihailovic, D., Kabanov, V.V., Müller, K.A.: EPL (Europhysics Letters) 57, 254 (2002)

Mertelj, T., Kabanov, V.V., Mihailovic, D.: Phys. Rev. Lett. 94, 147003 (2005)

Shengelaya, A., Müller, K.A.: EPL (Europhysics Letters) 109, 27001 (2015)

Kresin, V., Ovchinnikov, Y., Wolf, S.: Physics Reports 431, 231 (2006)

Keldysh, L.: Pis’ma. Zh. Eksp. Teor. Fiz. 29, 716 (1979)

Jena, D., Konar, A.: Phys. Rev. Lett. 98, 136805 (2007)

Raja, A., Chaves, A., Yu, J., Arefe, G., Hill, H.M., Rigosi, A.F., Berkelbach, T.C., Nagler, P., Schüller, C., Korn, T., Nuckolls, C., Hone, J., Brus, L.E., Heinz, T.F., Reichman, D.R., Chernikov, A.: Nat Commun 8(1), 15251 (2017)

Rösner, M., Lado, J.L.: Phys. Rev. Research 3(1), 013265 (2021)

Koster, G., Kropman, B.L., Rijnders, G.J.H.M., Blank, D.H.A., Rogalla, H.: Applied Physics Letters 73(20), 2920 (1998)

Sassa, Y., Radović, M., Månsson, M., Razzoli, E., Cui, X.Y., Pailhès, S., Guerrero, S., Shi, M., Willmott, P.R., Miletto Granozio, F., Mesot, J., Norman, M.R., Patthey, L.: Phys. Rev. B 83, 140511 (2011)

Garcia-Barriocanal, J., Perez-Munoz, A.M., Sefrioui, Z., Arias, D., Varela, M., Leon, C., Pennycook, S.J., Santamaria, J.: Phys. Rev. B 87, 245105 (2013)

Huijben, M., Koster, G., Blank, D.H.A., Rijnders, G.: Phase Transitions 81, 703 (2008)

Leng, X., Garcia-Barriocanal, J., Bose, S., Lee, Y., Goldman, A.M.: Phys. Rev. Lett. 107, 027001 (2011)

Leng, X., Garcia-Barriocanal, J., Yang, B., Lee, Y., Kinney, J., Goldman, A.M.: Phys. Rev. Lett. 108, 067004 (2012)

Wuyts, B., Moshchalkov, V.V., Bruynseraede, Y.: Phys. Rev. B 53, 9418 (1996)

Acknowledgements

We thank J.G. Bednorz for fruitful discussions and valuable suggestions over the entire project.

Funding

Open Access funding provided by Lib4RI – Library for the Research Institutes within the ETH Domain: Eawag, Empa, PSI & WSL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

In this paper we review the results of studies initiated under the guidance of Prof. K. A. Müller, who motivated us to implement the heterostructure that he proposed in his paper together with A. Shengelaya [1]. He actively participated in this project, following regular meetings every month for about one year.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

La Mattina, F., Erni, R., Rossell, M. et al. Coulomb Interaction Engineering at YBa\(_{2}\)Cu\(_3\)O\(_{7-\delta }\)-SrTiO\(_{3}\) Interface. J Supercond Nov Magn 35, 1801–1805 (2022). https://doi.org/10.1007/s10948-022-06286-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-022-06286-6