Abstract

Magnetism of materials may be adjusted by varying the adjacent magnetic ions in materials, such as Ru4+ in SrRuO3. We here report a study of the structure, electro-transport and magnetic properties of poly-crystallized SrRuxO3, which is synthesized by solid-state reaction. Results show that all the synthesized SrRuxO3 samples remain the single phase, and the grain size increases with increasing the Ru content. A semiconducting behavior with x ≤ 1 and a Fermi Liquid behavior with x > 1 are observed and determined. At 10 K, the saturated magnetic moment increases with x from 21.02 to 29.82 (emu/g), while the coercivity decreases from 5100 to 910 (Oe), which are also confirmed by the first principle calculations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the coupling of charge, spin, orbit, and lattice in perovskite-like oxides, lots of interesting physical properties, such as high-temperature superconductivity [1] and giant magnetoresistance effect [2], appear in such materials. Perovskite oxides also have significant application in new type of information storage, material of energy, and other fields. Recently, SrRuO3 has caused the extensive concern due to its unique physical properties [3,4,5,6,7,8,9,10,11,12]. For example, SrRuO3 shows itinerant ferromagnetism [3, 4], negative spin polarization [5], anomalous Hall effect [6, 7], and effect of the orbital ordering [8]; it also shows a non-Fermi Liquid behavior [9, 10], photostriction effect [11], and so on. Studies have shown that the electromagnetic properties of SrRuO3 are easily affected by the electron correlation between adjacent Ru atoms, so the electromagnetic properties of SrRuO3 may be regulated by thickness of the films, defects (such as Ru and O vacancies), and lattice distortion caused by different stress fields [13,14,15,16,17,18,19,20].

It is well known that SrRuO3 is a complex 4d metal oxide, a metallic ferromagnet (FM) with the Curie temperature TC ~ 160 K, and the electromagnetic properties might be attributed to Ru element. At room temperature, SrRuO3 has orthorhombic distorted perovskite-like structure with the space group of Pnma [21]. RuO2 is volatile, which may affect the form of SrRuO3 during the solid-state reaction process, which may result in a formation of non-stoichiometry SrRuO3 (or SrRu1-δO3-2δ), meaning Ru and O vacancies are among the materials. Similar situation has been found in the growth of single crystal of strontium ruthenates such as Sr2RuO4 and Sr3Ru2O7 [22, 23]. A thorough study on the process of forming the SrRuO3 via RuO2 content addition is very necessary. Few works [24, 25] reported how the Ru concentration influence on the physics properties of SrRuO3, which is still value to study further.

In the present, nominal formula of SrRuxO3 (0.9 ≤ x ≤ 1.1) materials has been synthesized by the conversional solid-state reactions. The variation of RuO2 stoichiometry would cause the change of structure of crystal grains since it is impossible to form a stoichiometry SrRuO3. The size of grains varies with x, which affects the physical properties, such as the magnetism and transportation. It is an important work in exploring the effects of stoichiometric ratio Ru/Sr on the structural, magnetic and electrical properties of SrRuxO3.

2 Experiment

Nominal compositions of SrRuxO3 (x = 0.9, 0.95, 1, 1.05, 1.1) materials are prepared by the solid-state reactions method. Briefly, stoichiometric amounts of SrCO3 and RuO2 are ground and mixed carefully. The mixed powers are first pre-sintered at 900 °C for 12 h, and after a second thoroughly regrinding, they are pressed into pellets, which are sintered at another 1100 °C for 24 h. Then the pellets are pulverized into powder, pressed into pellets again after fully regrinding, and sintered at 1200 °C for 24 h. This process is repeated twice to form a uniform phase.

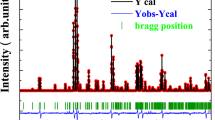

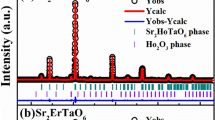

Phase content and crystal structure for all nominal materials have been checked by X-ray diffraction (XRD), which are performed on a Rigaku Dmax rB with Cu Kα radiation operating at 40 kV and 60 mA with a step scanning mode. The step size of 0.02° (2θ) and a counting time of 1 s per step are performed. XRD experiments are also confirmed at beamline BL14B1 located at Shanghai Synchrotron Radiation (SSRF) [26]. The sample powders are mounted into a flat holder to minimize any eventual preferential orientation of the obtained samples. XRD data are analyzed using Rietveld refinements based on the code of GSAS with an orthorhombic structure (Pnma) as the starting structural model.

The surface morphology and element composition are measured by a scanning electron microscope (SEM) equipped with an energy-dispersive spectroscopy (EDS). The transport properties are measured by a standard four-probe technique on a PPMS (Physical Property Measurement System) from Quantum Design (PPMS-9). The magnetic measurements are performed on a superconducting quantum interference device (SQUID, MPMS XL-7).

3 Result and Discussion

Figure 1a is the SEM images of SrRuxO3 (x = 0.9, 0.95, 1, 1.05, 1.1). The SrRuxO3 grains become bigger and bigger as x increases, as seen. The average grain size depends on x, which is shown in Fig. 1b. We believe that the Ru deficiency reduces the structural stability and leads to grain size decrease. Meanwhile, energy-dispersive spectroscopy (EDS) is carried out at three different places of each sample to identify the actual Sr/Ru ratio, the result shows that the detected Ru/Sr stoichiometric ratio of samples with x = 1 is about 95%, which means nearly 5% of RuO2 has volatilized during the solid-phase reaction. As for samples with x > 1, the surplus RuO2 may compensate the consumption and gives rise to a purer phase, better structure, and bigger grain size.

X-ray diffraction at room temperature and Rietveld refinements have been performed [27,28,29,30]. As shown in Fig. 2a. Results indicate that all the samples are single phase. The reflection full width at half maximum (FWHM) decreases with x increase (calibrated by silicon). The size of crystalline grain increases with the increase of x, which consists with the SEM result. Selected refined structural parameters are listed in Table 1. In addition, Rietveld refinement of powder XRD pattern for sample x = 1.1 is shown in Fig. 2b as an example. The unit cell parameters as well as the volume of a unit cell do not change monotonously, while the angle Ru_O1_Ru decreases apparently with x < 1.0, which means the tilting of RuO6 octahedron is enhanced by the defect of Ru. The O1_Ru bond length decreases with x > 1.0 as a response to the change of angle Ru_O1_Ru. The above results indicate that the structural distortion of SRO is enhanced by the Ru vacancy, which may induce the integrated role of the decrease of grain size, amorphous phase, and/or grain boundaries.

Figures 3a and b show the characteristic temperature dependence of electrical resistivity. The resistivity of the samples at room temperature decreases as x increases, which can be attribute to bigger grain size and less grain boundaries as well as stronger correlation between adjacent Ru atoms since less Ru vacancies are formed. For the whole temperature region, it is obvious that while x > 1, a classic SrRuO3 electrical transport behavior is observed, i.e., below 140 K, the R-T curve can be fitted by the function of \(\rho =a+{bT}^{2}\) which indicates a Fermi Liquid behavior [31]; higher than 140 K, the R is linearly increased as T increases which indicates a “bad metal” behavior [32]. However, for samples with x ≤ 1, the existence of the minimum of resistivity can be clearly observed, which can be seen as a metal–insulator transition. It is because Ru vacancies weaken the itinerant properties of Ru 4d electrons and lead to cationic disorder in SRO crystal, which causes localization of mobile electrons. In the presence of less disorder in metals, weak localization (WL) and electron–electron interaction (EEI) drive the insulating state at low temperature. Thus, a correction term has to be added to the fitting formula. Considering the WL and EEI [33,34,35], the R-T curve of all samples below Curie temperature can be well fitted by

where \({\rho }_{0}\) is the residual resistivity; the term \(a{T}^{p/2}\) is due to the WL in which p depends on the nature of interaction (p = 2 or 3 describes the electron–electron or electron–phonon interaction); \(b{T}^{1/2}\) describes the electron–electron interaction term; and the last term is due to the high-temperature electron–electron scattering (metallic) part.

Two (at least) behaviors complete with each other, which bring the minimum of resistivity. Both the residual resistivity and the temperature at which the minimum of resistivity appears to increase with Ru defects as well as tilting of RuO6 octahedron, which is similar to the case of doping SRO systems [36]. Combined with former analysis to structure, these can be well understood that Ru vacancies give rise to localization of mobile electrons and more grain boundaries and resulted in a semiconductor or insulator behavior.

a The temperature-dependent resistivity for SrRuxO3 (0.9 ≤ x ≤ 1.1). b Temperature dependence of relative resistivity ρ/ρ350K for SrRuxO3 (0.9 ≤ x ≤ 1.1). The inset in b shows the dρ/dT vs the Temperature curve. c Temperature dependence of FC dc magnetization for SrRuxO3 (0.9 ≤ x ≤ 1.1). The solid lines are the fitted curves according to M ∼ (Tc − T)β. d The temperature dependence of reciprocal magnetization for SrRuxO3 (x = 1.1 and 1.05). The inset shows the temperature dependence of reciprocal magnetization for SrRuxO3 (x ≤ 1). Solid lines show the Curie–Weiss linear fit

Temperature dependence of field cooled (FC) magnetization M (T) at an applied field of 1000Oe is displayed in Fig. 3c to demonstrate the nature of magnetic phase transition with Ru defects. The behavior of M (T) suggests an FM-like phase in all samples. The magnetic moment at 10 K is about 19 emu/g for samples with x ≥ 1, yet decreases to around 15 emu/g while x < 1. An obvious explanation is that Ru vacancies as well as tilting of RuO6 octahedron have weakened or even break the electron correlation between adjacent Ru atoms and lead to higher resistivity and smaller magnetism. On the other hand, Ru vacancies lead to smaller grain size which means more grain boundaries per unit volume, which gives rise to stronger magnetic anisotropy and weakens the magnetic moment. The high-temperature part is well fitted by the Curie–Weiss law as \(\chi =C/\left(T-{\Theta }_{CW}\right) \left(T>{T}_{C}\right)\), as shown in Fig. 3d, where \(C=N{\mu }_{eff}^{2}/3{k}_{B}\) is the Curie constant and \({\Theta }_{CW}\) is the Curie–Wiess temperature. The low-temperature part is fitted by the scaling law: \(M\left(T\right)=A{\left({T}_{C}-T\right)}^{\beta } \left(T<{T}_{C}\right)\), where β is the critical exponent of spontaneous magnetization near the phase transition temperature; it describes the divergence of the magnetic moment in the vicinity of TC. The fitted parameters are listed in Table 2. It is clear that samples with Ru vacancies as well as tilting of RuO6 octahedron have lower Curie–Wiess temperature and higher β, which implies the existence of both localized and itinerant moments in the system.

Figure 4 shows the M-H loop of our samples at 10 K. The inset (a) shows saturated magnetic moment (Ms), residual magnetic moment (Mr) and their ratio (Mr/Ms) as a function of Ru content x. The saturate moments of samples with x ≥ 1 are very close to each other, 28 ~ 30 emu/g, and the other two samples have smaller saturate moments, 21 ~ 22 emu/g. The residual magnetic moment also has a tendency of increasing with the increase of x. However, the ratio (Mr/Ms) gets lower when x > 1, indicating anisotropy is weakened. The sudden change of Ms and Mr/Ms is thought to be the result of titling of RuO6 octahedron, which is driven by the Ru vacancies. The inset (b) shows the coercive field as a function of Ru content. It is obvious that the coercive field increases with Ru vacancies, which confirms the stronger magnetic anisotropy in samples with more Ru vacancies. All the above evidence indicates that higher content of Ru element, which means less Ru vacancies and larger grain size and less structure distortion [37], can lead to higher saturated magnetic moment (Ms) and residual magnetic moment (Mr) and smaller coercive field.

First Principle Calculations is performed on SrRuxO3 system, assuming that the symmetry of SrRuxO3 remains the same. Calculation method and limitation obey our previous [38]. Calculation results show that the magnetism decreases with decreasing the Ru content, x. Ru vacancies induce the decrease of Ru moment, while increase the oxygen hybrid moment, which the total moment decreases. The magnetism may disappear with x = 0.25, based on the calculation. Results are consistent with that of the experiments here in qualitatively.

In summary, structure, electro-transport and magnetic properties are investigated in poly-crystallized metallic ferromagnet SrRuxO3 where x varies from 0.9 to 1.1. It is found that about 5% Ru volatilizes during synthesis. In the whole range, SrRuxO3 remains the single phase with space group of Pnma. Structural distortion of SrRuxO3 varies with Ru content. A semiconducting behavior with x ≤ 1 and a Fermi Liquid behavior with x > 1 are observed. The magnetic Curie temperature, Tc, varies slightly, while at 10 K, the saturated magnetic moment and the coercivity increase obviously. To conclude, certain amount of Ru rich before the solid-state reaction can lead to the produced poly stoichiometric close to SrRuO3 and leads to less defects and better electromagnetic properties.

References

Bednorz, J.G., Mller, K.A.: Possible highT c superconductivity in the Ba-La-Cu-O system. Zeitschrift fr Physik B Condensed Matter 64, 189–193 (1986). https://doi.org/10.1007/bf01303701

Ramirez, A.P.: Colossal magnetoresistance. J. Phys.: Condens. Matter 9, 8171–8199 (1997). https://doi.org/10.1088/0953-8984/9/39/005

Klein, L., et al.: Anomalous spin scattering effects in the badly metallic itinerant ferromagnet SrRuO3. Phys Rev Lett 77, 2774–2777 (1996). https://doi.org/10.1103/PhysRevLett.77.2774

Ziese, M., Vrejoiu, I. & Hesse, D.: Structural symmetry and magnetocrystalline anisotropy ofSrRuO3films onSrTiO3. Phys. Rev. B, 81 (2010). https://doi.org/10.1103/PhysRevB.81.184418.

Worledge, D.C., Geballe, T.H.: Negative spin-polarization of SrRuO3. Phys Rev Lett 85, 5182–5185 (2000). https://doi.org/10.1103/PhysRevLett.85.5182

Haham, N. et al.: Scaling of the anomalous Hall effect in SrRuO3. Physical Review B, 84 (2011). https://doi.org/10.1103/PhysRevB.84.174439.

Sohn, B., et al.: Hump-like structure in Hall signal from ultra-thin SrRuO3 films without inhomogeneous anomalous Hall effect. Curr. Appl. Phys. 20, 186–190 (2020). https://doi.org/10.1016/j.cap.2019.10.021

Jeng, H.T., Lin, S.H., Hsue, C.S.: Orbital ordering and Jahn-Teller distortion in Perovskite ruthenate SrRuO3. Phys Rev Lett 97, 067002 (2006). https://doi.org/10.1103/PhysRevLett.97.067002

Kostic, P., et al.: Non-Fermi-liquid behavior of SrRuO3: evidence from infrared conductivity. Phys. Rev. Lett. 81, 2498–2501 (1998). https://doi.org/10.1103/PhysRevLett.81.2498

Cao, G., Korneta, O., Chikara, S., DeLong, L.E., Schlottmann, P.: Non-Fermi-liquid behavior in single-crystal CaRuO3: comparison to ferromagnetic SrRuO3. Solid State Commun. 148, 305–309 (2008). https://doi.org/10.1016/j.ssc.2008.09.007

Wei, T.C., et al.: Photostriction of strontium ruthenate. Nat Commun 8, 15018 (2017). https://doi.org/10.1038/ncomms15108

Wang, K., et al.: Coupling among carriers and phonons in femtosecond laser pulses excited SrRuO3: a promising candidate for optomechanical and optoelectronic applications. ACS Applied Nano Materials 2, 3882–3888 (2019). https://doi.org/10.1021/acsanm.9b00728

Chang, S. H., et al.: Thickness-dependent structural phase transition of strained SrRuO3ultrathin films: the role of octahedral tilt. Phys. Rev. B, 84 (2011).https://doi.org/10.1103/PhysRevB.84.104101.

Qin, Q., Song, W., He, S., Yang, P. & Chen, J.: Magnetization reversal and magnetoresistance behavior of exchange coupled SrRuO3 bilayer. J. Phys. D: Appl. Phys., 50 (2017). https://doi.org/10.1088/1361-6463/aa6ad2.

Jeong, H., et al.: Thickness-dependent orbital hybridization in ultrathin SrRuO3 epitaxial films. Appl. Phys. Lett., 115 (2019). https://doi.org/10.1063/1.5110644.

Kan, D. & Shimakawa, Y.: Strain effect on thermoelectric properties of SrRuO3 epitaxial thin films. Appl. Phys. Lett., 115 (2019). https://doi.org/10.1063/1.5097927.

Toyota, D., et al.: Thickness-dependent electronic structure of ultrathin SrRuO3 films studied by in situ photoemission spectroscopy. Appl. Phys. Lett., 87 (2005). https://doi.org/10.1063/1.2108123.

Lu, W., Yang, P., Song, W. D., Chow, G. M. & Chen, J. S.: Control of oxygen octahedral rotations and physical properties inSrRuO3films. Phys. Rev. B, 88 (2013). https://doi.org/10.1103/PhysRevB.88.214115.

Gu, M., et al.: Magnetic ordering and structural phase transitions in a strained ultrathin SrRuO3/SrTiO3 superlattice. Phys Rev Lett 109, 157003 (2012). https://doi.org/10.1103/PhysRevLett.109.157003

Gu, M., et al.: Enhancement of orbital ordering and spin polarization by controlling the dimensionality of the octahedra network. npj Quan. Mater., 1 (2016). https://doi.org/10.1038/npjquantmats.2016.11.

Kennedy, B.J., Hunter, B.A.: High-temperature phases ofSrRuO3. Phys. Rev. B 58, 653–658 (1998). https://doi.org/10.1103/PhysRevB.58.653

Fittipaldi, R., et al.: Crystal growth of the new Sr2RuO4–Sr3Ru2O7 eutectic system by a floating-zone method. J. Cryst. Growth 282, 152–159 (2005). https://doi.org/10.1016/j.jcrysgro.2005.04.104

Perry, R.S., Maeno, Y.: Systematic approach to the growth of high-quality single crystals of Sr3Ru2O7. J. Cryst. Growth 271, 134–141 (2004). https://doi.org/10.1016/j.jcrysgro.2004.07.082

Dabrowski, B., et al.: Reduced ferromagnetic transition temperatures inSrRu1−vO3perovskites from Ru-site vacancies. Phys. Rev. B, 70 (2004). https://doi.org/10.1103/PhysRevB.70.014423.

Han, Z. H., et al.: Ru99,101NMR study of the Ru-site vacancies inSrRu1−xO3compounds. Phys. Rev. B, 71 (2005). https://doi.org/10.1103/PhysRevB.71.214432.

YANG Tie-Ying , W. W., YIN Guang-Zhi, LI Xiao-Long.: Introduction of the X-ray diffraction beamline of SSRF. Nuclear Sci. Techniques, 26, 1–5 (2015). https://doi.org/10.13538/j.1001-8042/nst.26.020101.

Larson, A.C., Dreele, R.B.V.: General structure analysis system (GSAS). Los Alamos National Laboratory Report LAUR 86, 748 (1994)

Toby, B.H.: EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 34, 210–213 (2001). https://doi.org/10.1107/s0021889801002242

Rietveld, H.M.: Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. A 22, 151–152 (1967). https://doi.org/10.1107/s0365110x67000234

Rietveld, H.M.: A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 2, 65–71 (1969). https://doi.org/10.1107/s0021889869006558

Luttinger, J. M. & Nozières, P.: Derivation of the Landau theory of Fermi liquids. II. Equilibrium Properties and Transport Equation. Phy. Rev., 127, 1431–1440 (1962). https://doi.org/10.1103/PhysRev.127.1431.

Emery, V.J., Kivelson, S.A.: Superconductivity in bad metals. Phys Rev Lett 74, 3253–3256 (1995). https://doi.org/10.1103/PhysRevLett.74.3253

Lee, P.A., Ramakrishnan, T.V.: Disordered electronic systems. Rev. Mod. Phys. 57, 287–337 (1985). https://doi.org/10.1103/RevModPhys.57.287

Kaveh, M., Wiser, N.: Electron-electron scattering in conducting materials. Adv. Phys. 33, 257–372 (2006). https://doi.org/10.1080/00018738400101671

Dai, P., Zhang, Y., Sarachik, M.P.: Electrical conductivity of metallic Si: B near the metal-insulator transition. Phys Rev B Condens Matter 45, 3984–3994 (1992). https://doi.org/10.1103/physrevb.45.3984

Sarkar, B., Dalal, B., De, S.K.: Correlation among disorder, electronic and magnetic phases of SrRuO3. J Phys Condens Matter 27, 116002 (2015). https://doi.org/10.1088/0953-8984/27/11/116002

He, J., Borisevich, A., Kalinin, S.V., Pennycook, S.J., Pantelides, S.T.: Control of octahedral tilts and magnetic properties of perovskite oxide heterostructures by substrate symmetry. Phys Rev Lett 105, 227203 (2010). https://doi.org/10.1103/PhysRevLett.105.227203

Wang, Y., et al.: Modulating the electronic and optical properties for SrTiO3/LaAlO3 bilayers treated as the 2D materials by biaxial strains. J Phys Condens Matter 32, 215701 (2020). https://doi.org/10.1088/1361-648X/ab70c3

Funding

This work was supported by the National Natural Science Foundation of China [Grant number 11874200] and by the Major Research Plan [Grant number 2017YFA0303202].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, Z., Yang, X., Wang, Y. et al. Adjustment of Electromagnetic Properties in SrRuO3 via Ru Content. J Supercond Nov Magn 35, 261–267 (2022). https://doi.org/10.1007/s10948-021-06041-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-021-06041-3