Abstract

In this work, we tried to improve the superconducting performance of bulk YBa2Cu3Oy (Y123) superconductors via Y2Ba1Cu1O5 (Y211) secondary phase refinement. A novel method of ultra-sonication was used to refine the Y211 secondary phase particles. The Y211 powder was treated by ultra-sonication for 0 to 80 min with steps of 20 min, keeping the power (300 W) and frequency (20 kHz) constant. For synthesis of the YBCO bulk, we employed top-seeded melt growth (TSMG) with Pt addition. Magnetization measurements showed a superconducting transition temperature at around 91 K, irrespective of ultra-sonication parameters. Interestingly, critical current density and trapped field were found to be proportional to the ultra-sonication duration. YBCO bulk sample (20 mm diameter, 7 mm in thickness) fabricated for 80 min ultra-sonicated Y211 showed a maximum trapped field of 0.42 T at 77 K, 0.3 mm above the top surface. The improved trapped field values are explained on the basis of improvements in the microstructure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

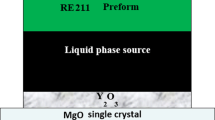

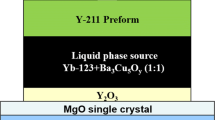

Top-seeded melt growth (TSMG) has emerged as a typical process for fabricating large single-grained (RE)Ba2Cu3Oy (REBCO) high-temperature superconductors (HTS), where RE refers to rare earth elements such as Nd, Gd, Er, and Y [1]. In the TSMG process, RE123 is heated above the peritectic temperature resulting in decomposition of RE123 into RE211 and liquid phase (BaCuO2 and CuO). The samples are then slowly cooled, when RE211 reacts with liquid phase to form RE123 bulk superconductor [2]. Bulk REBCO superconductors are mostly used in practical applications such as flywheel energy storage systems, magnetic bearings, trapped field magnets, etc. [3,4,5]. For achieving good superconducting performance, it is necessary to obtain high superconducting critical current density (Jc) and trapped flux density (BT) at high temperatures and high fields [6]. Critical current density in YBa2Cu3Oy (Y123) bulk superconductors can be improved by reducing the size of Y211 particles and by increasing the homogeneity of Y211 distribution in the matrix [7]. The microstructural defects also contribute to increase of magnetic flux pinning and hence enhance the critical current density (Jc) and trapped field (BT) [8]. The effect of Y211 precipitates is usually observed at low magnetic fields as they contribute as δl pinning and hence result in a high self-field critical current density. On the other hand, point-like defects and oxygen off-stoichiometric phases generally contribute as δTc pinning and result in peak effect or high critical current densities at high magnetic field [9, 10]. Several researchers have tried to avoid Y211 particles coarsening with help of chemical agents such as Pt, CeO2, etc. [11, 12]. In case of Pt and PtO2 addition, it was seen that a new Ba4CuPt2O9 phase forms, which acts as nucleating site for Y211, thereby restraining the Y211 growth [12]. In addition, there is also evidence that adding Pt/PtO2 results in more anisotropic and highly acicular Y211 particles. On the other hand, CeO2 aids in different manner. It forms BaCeO2 phase alongside the Y211 that contributes to additional pinning. Another alternative technique to control Y211 particles size in the initial powder is by introducing mechanical force to refine particle via ball milling technique, etc. [13, 14]. Although this technique results in particles of around 70 nm, it also imparts contamination into powder. To refine further and ensure uniform mixing, the precursor mixture of Y123 and Y211 is subjected to automatic grinding for 2–3 h. To avoid any contamination in the powders, we chose high energy ultra-sonication to refine the Y211 particles. The ultra-sonic waves increased disorder in the medium and lead to separation and size reduction of the particles [15, 16]. In summary, the nature of initial Y211 particles greatly influences properties of bulk YBCO (see in Table 1).

In our previous work, we tried to synthesize samples by infiltration growth using ultra-sonicated Y211 [15]. There we synthesized bulk with improved properties because of Y211 size reduction. In this paper, we studied the optimization of ultra-sonication process parameters for producing fine Y211 particles and effect of refined Y211 particles size on the superconducting properties of melt grown YBCO bulk superconductors. YBCO single grain superconductors of 20 mm were fabricated by top-seeded melt growth. Systematic study was done by varying the ultra-sonication time, and superconducting properties were compared with highlight the best processing conditions.

2 Experimental

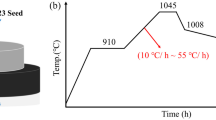

To prepare YBa2Cu3O7 (Y123) and Y2BaCuO5 (Y211), high-purity commercial powders of Y2O3, BaO2, and CuO were mixed in a nominal ratio. This Y123 raw mixture was calcined 4 times at around 870–940 °C for 24 h. Similarly, Y211 raw mixture was also calcined 4 times at 840–900 °C for 15 h. In order to reduce the particle size of the calcined Y211 powder, we used Mitsui ultrasonic homogenizer UX-300, while keeping constant power (300 w) and frequency (20 kHz). Y211 powders were dissolved into ethanol and ultra-sonicated systematically for various durations such as 0, 20, 40, 60, and 80 min and the corresponding final samples can be referred as Y0, Y20, Y40, Y60, and Y80, respectively. The Y211 and Y123 powders were mixed in 1:2 ratio along with 0.5 wt% of Pt and was pulverized for 2 h, which were then pressed into several pellets of 20 mm diameter. Nd-123 seed was placed on the top of pelletized precursor mixture. The temperature profile used for fabricating samples for TSMG is given in Fig. 1. After melt processing, the Y123 samples were annealed at 450 °C for 400 h in controlled oxygen atmosphere for oxygenation. The phases present in the bulk were identified by X-ray diffraction (XRD) using Rigaku X-ray diffractometer with Cu radiation and Bragg–Brentano geometry with 2θ from 10 to 80°. The diffraction peaks were indexed with the help of reference data from JCPDS (joint committee on powder diffraction standards). For trapped field measurements, we used permanent magnets of 0.5 and 1 T to activate Y123 bulk superconductor. Field distribution was measured by automatic scanning Hall probe sensor at a distance of 0.3 mm (surface touched) and 1.3 mm (1 mm above surface) above the superconductor surface. This is because of the 0.3 mm difference between probe’s epoxy surface and the hall probe. The microstructures were studied with a field emission scanning electron microscope (FE-SEM). For magnetic measurements, samples were cut 2 mm below the seed along the c-axis from the bulk samples 1.5 × 1.5 × 0.5 mm3 in dimension. Superconducting transition temperature (Tc) and magnetization loops in field from 0 to 5 T were measured at 77 K using a commercial SQUID magnetometer (model MPMS5). Superconducting critical current density (Jc) was estimated by using the extended Bean’s model [17].

where a and b are the cross sectional dimensions with b ≥ a, c is the thickness of sample, and ΔM is the difference of magnetic moment between decreasing and increasing field in the M-H loop.

3 Results and Discussion

Y211 secondary phase particles in bulk YBCO superconductors act as a non-superconducting phase and are crucial in the growth and improving the superconducting properties of bulk. The size of initial Y211 powder is very important for high flux pining and critical current density in final bulk superconductor. It is highly desirable to achieve a uniform dispersion of fine-sized 211 secondary phase particles throughout the final bulk samples. In previous studies where ball milling was employed, size refinement less than 0.1 μm was observed [18, 19]. However, the technique is expensive and there are several cases where contamination from the ceramic balls used for milling was observed. Although the contamination mostly has negative effects, fortunately in some cases, these contaminations can act as nano pinning centers that can enhance critical current density such as in case of Zirconia balls. When zirconia balls were used for long durations of ball milling, Zr-based contaminations are formed and helped in improving the performance [20]. Hence, we think that the ultra-sonication technique we employed in Y211 system refines the particles to submicron sizes cost-effectively with nearly no contamination. To achieve this, we tried to reduce the Y211 particles size via employing high energy ultrasonic waves. The FE-SEM images of ultra-sonicated Y211 particles (20, 40, 60, and 80 min) are compared with pristine Y211 powder as shown in Fig. 2. The average size of the pristine Y211 particles is around 3–5 μm. Until 80 min, the average particle size keeps decreasing with increase in ultra-sonication duration. After 80 min of ultra-sonication, we observed that the sizes are around 300~500 nm (seen in Fig. 3). We did not observe any decrease of the size upon further increase in ultra-sonication duration. We assume that this technique in Y211 system reaches saturation after the particles reach submicron sizes under the conditions we used. Therefore, we conclude that 80 min of ultra-sonication is optimal where we can produce multitude of fine particles. For more comprehensive view, we analyzed high magnification images from FE-SEM. In addition to size reduction, we also observed uniformly sized particles that are irregular in shape.

The top-view photograph of Y123 20 mm in diameter samples with Y211 refined via ultrasonic time of 0, 20, 40, 60, and 80 min was displayed in Fig. 4 a–e, respectively. Fully fourfold growth was seen without any spontaneous nucleation from the seed crystal, and growing on four sectors to the edge of samples along ab-plane and the top to the bottom along c-axis represent that the samples are growing in form of a single grain. Single-grained samples were prepared by implementing the optimized temperature profile with TSMG process. In addition, this technique, in conjunction with batch processing, can aid in mass production of high quality YBCO bulk superconductors at low costs.

To examine the texturing information and phase purity of melt grown bulk Y123, we performed X-ray diffraction on flakes cleaved from Y0, Y40, and Y80 samples. Figure 5 shows all (00 l) peaks corresponding to the orthorhombic ab planes, which indicates a proper texturing and pure single grain nature of Y123 formed [21]. The small pieces with dimensions of about 1.5 × 1.5 × 0.5 mm3 were cut 2 mm under seed crystal along c-axis from Y0, Y40, and Y80 samples. The temperature dependence of normalized dc susceptibility was calculated using SQUID magnetometer in both zero-field-cooled (ZFC) and field-cooled (FC) under a field of 1 mT. All samples exhibited a sharp superconducting transition around 91–93 K (see in Table 1). The Y0 sample shows the highest Tc,on set at 92.8 K compare with samples Y40 and Y80. The Tc,on set values are close to standard critical temperature value of YBCO bulk superconductor [22]. The transition temperature width of Y40 and Y80 samples is wider than Y0 sample as the ultra-sonicated time increase and less than 1.5 K as presented in Fig. 6, which indicates that all samples were high quality. However, the YBCO bulk made from refined Y211 showed a slight drop in superconducting transition temperature which is better than that of what we observed in samples prepared from ball-milled Y-211powder [14, 23].

The critical current density (Jc) was calculated using the extended Bean’s critical state formula for a rectangular sample. The highest self-field JC value was observed in Y80 sample that was around 47 kA/cm2 and Jc at 1 T reached 10 kA/cm2 at 77 K, higher than that of what Y0 sample exhibited. The critical current density at self-field was showing an increment with increase in the ultra-sonication time, till 80 min (see in Table 1). In addition, at high fields, we can see a peak effect which is proportional to ultra-sonication time. Detailed Jc profile can be seen in Fig. 7. This could be because of very tiny particles close to the size of cavities or volume defects that are formed by means of ultra-sonication. This is possible because ultra-sonication can result in very fine particles when regular particles bombard each other or shear along surfaces. We also think that further prolonged ultra-sonication and increase power can improve the peak effect.

In general, trapped field measurements are related to flux pinning performance of the superconductor. Trapped field of the samples was measured at 77 K after field-cooling in magnetic field of 0.5 and 1 T. High trapped field of 0.42 T at 77 K was observed in sample Y80 at 0.3 mm distance from the top surface sample when field-cooled in presence of 1 T. More results of trapped field distribution of Y80 sample under a magnetic field of 0.5 T were presented in Fig. 8. The profile was showing a uniform single cone curve in the center, indicating that the sample has uniform single grain growth without cracks and underwent good oxygen treatment. Figure 9 represents the trapped field (0.3 mm away from the top surface) against ultra-sonication time, for all samples that are field-cooled with 1 T at 77 K. Effect of ultra-sonication time with trapped filed measurement relates with the Jc results and shows the highest value in Y211 with 80-min ultra-sonication.

The trapped field distribution at 77.3 K for the Y80 material presented in Fig. 4 (bottom, right). Note that the maximum trapped value recorded around 0.42 T when the Hall sensor is at the distance of 0.3 mm

To reveal the reason for these trends in Jc and trapped field, we studied the microstructure. The microstructure of samples prepared with different ultra-sonicated Y211 embedded in the Y123 matrix was analyzed by using FE-SEM and particle size analysis from image processing system; the results are shown in Fig. 10 a and b. Microstructure reveals that the Y211 secondary phase particles were finely dispersed inside the Y123 matrix of both ultra-sonicated and not ultra-sonicated samples. As observed, Y211 secondary phase particles in sample Y0 were formed as large and irregular as shown in Fig. 10a with the average size of 2 μm and 4 μm and dispersed inhomogeneously. Y80 sample shows that the Y211 were finer and uniform in as depicted homogeneously in Fig. 10b with the average size 0.5–1 μm. The effect of ultra-sonication increase among of small particles resulted in a significant decrease of the average of the Y211 secondary phase particle size in final samples. The superconducting performance improvement as well as trapped field and critical current density enhancement in the ultra-sonicated Y211 secondary phase based Y123 bulk.

4 Summary

Among various durations, 80 min of ultra-sonication seemed to be the optimum for refining Y211 powder based on the particle size and uniform shape of Y211 powder. We have successfully prepared YBCO bulk consisting of Y123 and Y211 mixed in a molar ratio of 10:5 with 0.5 wt% Pt by TSMG processing. XRD clearly shows that all the bulk Y123 samples have good texture and pure single grain nature. All samples exhibited superconductivity with Tc ~ 92.8 K and sharp superconducting transitions. The highest critical current density (Jc) was observed in 80-min ultra-sonicated bulk which was measured to be 47 kA/cm2 at self-field and 77 K. For the same bulk at 77 K, the trapped field measurements exhibited single uniform conical peak with the maximum value of 0.42 T at the center. SEM observations showed that the particle sizes of the most Y211 particles have been reduced to 1–2 μm and uniformly dispersed within the final Y123 matrix which led to the improvement in the superconducting properties of Y123 bulk superconductor. The ultra-sonication technique has great potential to refine Y211 particles for mass production of large high performance YBCO bulk superconductors for practical applications. In addition, this technique is cost-effective and brings nearly no contamination. All these features make it a best choice for mass production.

References

Murakami, M.: Appl. Supercond. 1, 1157–1173 (1993)

Jin, S., Tiefel, T.H., Sherwood, R.C., Davis, M.E., Dover, R.B.v., Kammlott, G.W., Fastnacht, R.A., Keith, H.D.: Appl. Phys. Lett. 52(24), 2074–2076 (1988)

Barna, D.: Phys. Rev. Accel. Beams. 20(4), 041002 (2017)

Coombs, T.A., Hong, Z., Zhu, X., Krabbes, G.: Supercond. Sci. Technol. 21(3), 034001 (2008)

Strasik, M., Hull, J.R., Mittleider, J.A., Gonder, J.F., Johnson, P.E., McCrary, K.E., McIver, C.R.: Supercond. Sci. Technol. 23(3), 034021 (2010)

Campbell, A.M., Cardwell, D.A.: Cryogenics. 37(10), 567–575 (1997)

Koblischka-Veneva, A., Mücklich, F., Koblischka, M.R., Hari Babu, N., Cardwell, D.A.: J. Am. Ceramic Soc. 90(8), 2582–2588 (2007)

Muralidhar, M., Sakai, N., Chikumoto, N., Jirsa, M., Machi, T., Nishiyama, M., Wu, Y., Murakami, M.: Phys. Rev. Lett. 89(23), 237001 (2002)

Muralidhar, M., Sakai, N., Nishiyama, M., Jirsa, M., Machi, T., Murakami, M.: Appl. Phys. Lett. 82(6), 943–945 (2003)

Muralidhar, M., Koblischka, M.R., Diko, P., Murakami, M.: Supercond. Sci. Technol. 9(2), 76–87 (1996)

Kim, C.-J., Kim, K.-B., Kuk, I.-H., Hong, G.-W.: Physica C: Supercond. 281(2), 244–252 (1997)

Hamada, T., Morimo, R., Takada, A., Yamashita, Y., Nakayama, K., Nagata, K., Yuji, T.: J. Mater. Proces.Technol. 100(1), 188–193 (2000)

Nariki, S., Sakai, N., Murakami, M., Hirabayashi, I.: Supercond. Sci. Technol. 17(2), S30–S35 (2004)

Muralidhar, M., Kenta, N., Zeng, X., Koblischka, M.R., Diko, P., Murakami, M.: Phys. Status Solidi (a). 213(2), 443–449 (2016)

Pavan Kumar Naik, S., Muralidhar, M., Koblischka, M.R., Koblischka-Veneva, A., Oka, T., Murakami, M.: Appl. Phys. Express. 12(6), 063002 (2019)

Franco, F., Pérez-Maqueda, L.A., Pérez-Rodríguez, J.L.: J. Colloid Interface Sci. 274(1), 107–117 (2004)

Chen, D.X., Goldfarb, R.B.: J. Appl. Phys. 66(6), 2489–2500 (1989)

Nariki, S., Sakai, N., Murakami, M., Hirabayashi, I.: IEEE Trans. Appl. Supercond. 15(2), 3110–3113 (2005)

Muralidhar, M., Sakai, N., Jirsa, M., Murakami, M., Koshizuka, N.: Physica C: Supercond. 412-414, 739–743 (2004)

Muralidhar, M., Sakai, N., Jirsa, M., Koshizuka, N., Murakami, M.: Appl. Phys. Lett. 83(24), 5005–5007 (2003)

Foerster, C.E., Serbena, F.C., Jurelo, A.R., Ferreira, T.R., Rodrigues, P., Chinelatto, A.L.: IEEE Trans. Appl. Supercond. 21(2), 52–59 (2011)

Mahmood, A., Chu, Y.S., Sung, T.H.: Supercond. Sci. Technol. 25(4), 045008 (2012)

Miryala, M., Sakai, N., Jirsa, M., Murakami, M., Koshizuka, N.: Supercond. Sci. Technol. 17, 1129 (2004)

Funding

This work was partly supported by Shibaura Institute of Technology (SIT) Research Center for Green Innovation and Grant-in-Aid FD research budget code 112282. Two of the authors (Sai Srikanth Arvapalli and Sunsanee Pinmangkorn) acknowledge the support from SIT for providing the financial support for the doctoral program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pinmangkorn, S., Miryala, M., Arvapalli, S.S. et al. Effect of Ultra-sonicated Y2BaCuO5 on Top-Seeded Melt Growth YBa2Cu3Oy Bulk Superconductor. J Supercond Nov Magn 33, 1667–1673 (2020). https://doi.org/10.1007/s10948-019-05405-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-019-05405-0